aquilar AquiTron AT-G-ALERT Installation instructions

AquiTron AT-G-ALERT

Refrigerant Sensor

INSTALL ATION

& O P ERATION

INSTRUCTIONS

Please read these

instructions carefully

and keep them in a

safe place (preferably

close to the module)

for future reference.

These instructions

must be followed

carefully to ensure

proper operation.

AT-G-ALERT

Refrigerant Gas Sensor For

Occupied Spaces

A. GENERAL INFORMATION

The AquiTron AT-G-Alert continuously checks the ambient air of occupied spaces for refrigerant

leaks. The detector is for indoor applications. It is housed in an ABS enclosure that ts into

2-gang electrical back boxes (not included) with a minimum depth of 47mm.

Gas alarms and status messages are indicated visually by a 3-colored LED and audibly by a

buzzer. In case of an alarm and/or fault, relays switch (for example, to shut-o valves or to

activate alarm devices).

INTENDED USE

• Checks ambient air of occupied spaces for refrigerant leaks

• Intended for indoor applications

• ABS enclosure ts into most deep 2-gang electrical back boxes (not included)

• Can be operated as a stand-alone detector or connected to a BMS/BAS (Building

Management/Building Automation System)

• Designed to be installed in non-classied, non-hazardous, permanent locations.

DESIGN FEATURES

• Powered by 100 to 240 VAC, 50/60 Hz

• Gas alarms and status messages are indicated visually by a 3-colored LED and audibly by a

buzzer

• In case of an alarm and/or fault, relays can switch shut-o valves, alarm devices, or

indicators at a BMS/BAS

• Measured gas concentration, status signals and conguration information are accessible

via the Modbus RTU interface (see Section 8.9 on page 35)

• Can be calibrated and maintained non-intrusively using a magnetic wand

LEAK DETECTION SOLUTIONS

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk 1

INSTALLATION ITEMS

(NOT SUPPLIED)

• 47mm Back Box

TOOLS REQUIRED

• Drill or hole punch for electrical

conduit entries

• Phillips (cross-head) screwdriver

• Small at-head screwdriver

STORAGE

Keep the module in a dry place prior to

installation to avoid possible damage to

internal components.

Figure 1. AT-G-ALERT with examples of available fascia plates.

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

LEAK DETECTION SOLUTIONS

2

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

CONTENTS

1.0 Safety

1.1 Denition of Alert Icons

1.2 General Safety Statments

1.3 Safe Connection of Electrical Devices

2.0 Components Overview

3.0 Installation

3.1 General Information for Installation

3.2 Mechanical Installation

3.3 Conguration

3.4 Electrical Installation

4.0 Operation

4.1 Start-Up

4.2 Alarm Management Function and

conguration

4.2.1 Default Alarm Function

4.2.2 Alaram Delay - Switches 2 and 3

4.2.3 Failsafe - Switch 4

4.2.4 Alarm 2 Relay - Switch 5

4.2.5 Latching Alarm State - Switch 6

4.2.6 Buzzer Disable -Switch 7

4.3 Other Switch Congurations

4.3.1 Reset (Cycle Power) - Switch 1

4.3.2 Reset to Factory Default Values -

Switch 8

4.4 Operation of Magnetic Switches,

Buzzer and LED

5.0 Maintenance

5.1 Maintenance Intervals

5.2 Adjustments

5.2.1 Introduction

5.2.2 General Procedure

5.2.3 Zero Adjustment

5.2.4 Span Adjustment

5.2.5 Bump Test

5.3 Troubleshooting

5.3.1 Failed Span Adjustment

5.3.2 Hexadecimal Format

5.3.3 Fault Conditions

5.3.4 Fatal Faults

5.3.5 Critical Gas Fault

5.3.6 Negative Gas Faults

5.3.7 Non-Critical Faults

5.4 Replacing the Sensor Module

5.5 Cleaning the Detector

6.0 Sensor Principle

7.0 Disposing of the Detector

8.0 Technical Data

8.1 Approvals

8.2 Specications for Modbus RTU

Digital communication over RS-485

8.3 Power Supply and Relay

Specications

8.4 Wiring Specications

8.5 Physical Specications

8.6 Environmental Specictions

8.7 Sensor Specications

8.8 Default Alarm Levels

8.9 Modbus Registers

8.9.1 Read Device Identications

8.9.2 Analog Input Registers

8.9.3 Analog Output Registers

8.9.4 Input Status Flags

8.9.5 Output Status Flags

9.0 Ordering Information

9.1 AT-G-Alert Refrigerant Leak Detector

Congurations

9.2 Accessories

10.0 Back Boxes and Faceplates

10.1 Introductions

10.2 Hardware Overview

10.3 Using Optional Metal Tabs

10.4 Electrical Installation

10.5 Customizing Face Plates

10.6 Calbration

11.0 Declaration of Conformity

LEAK DETECTION SOLUTIONS

3

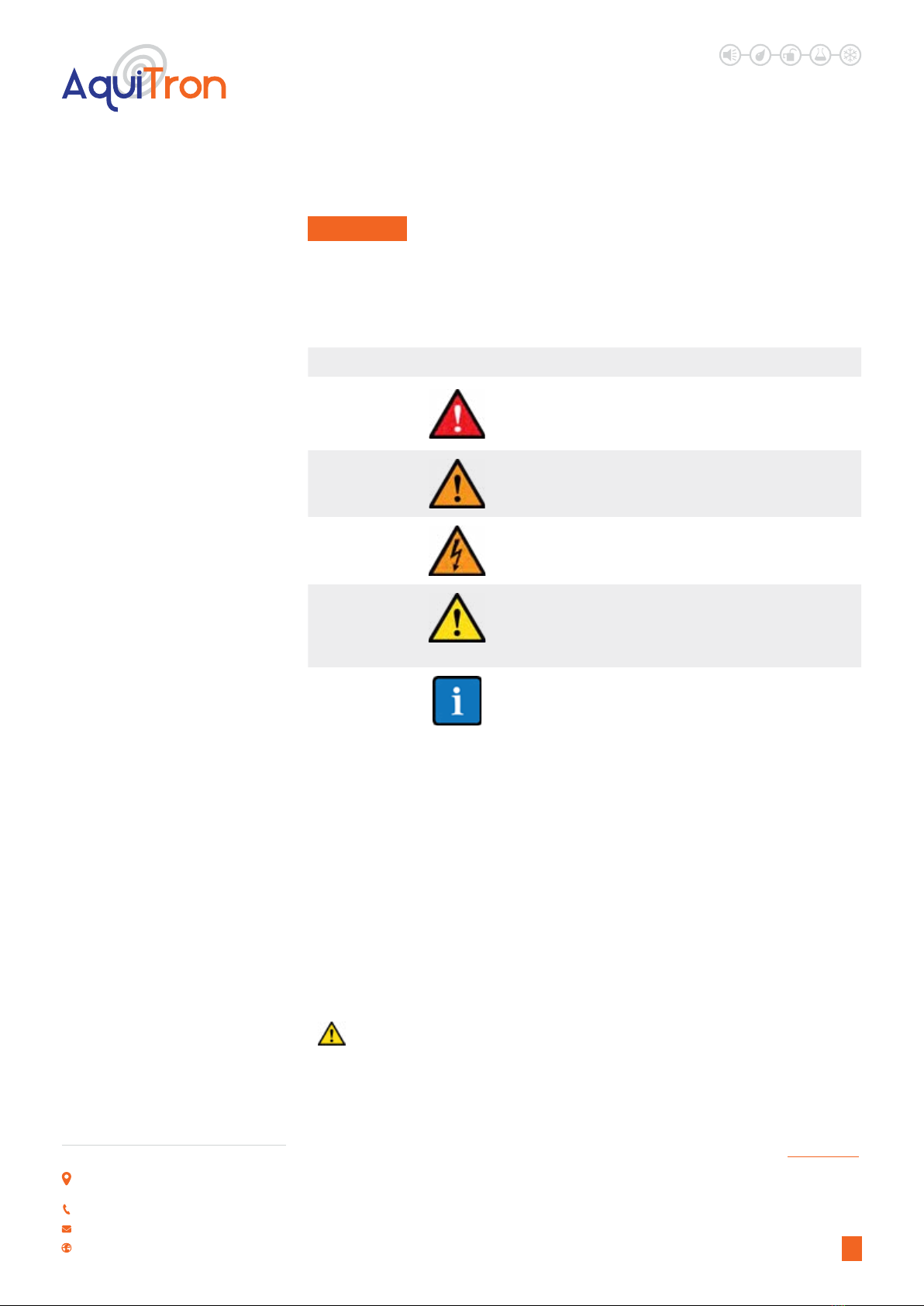

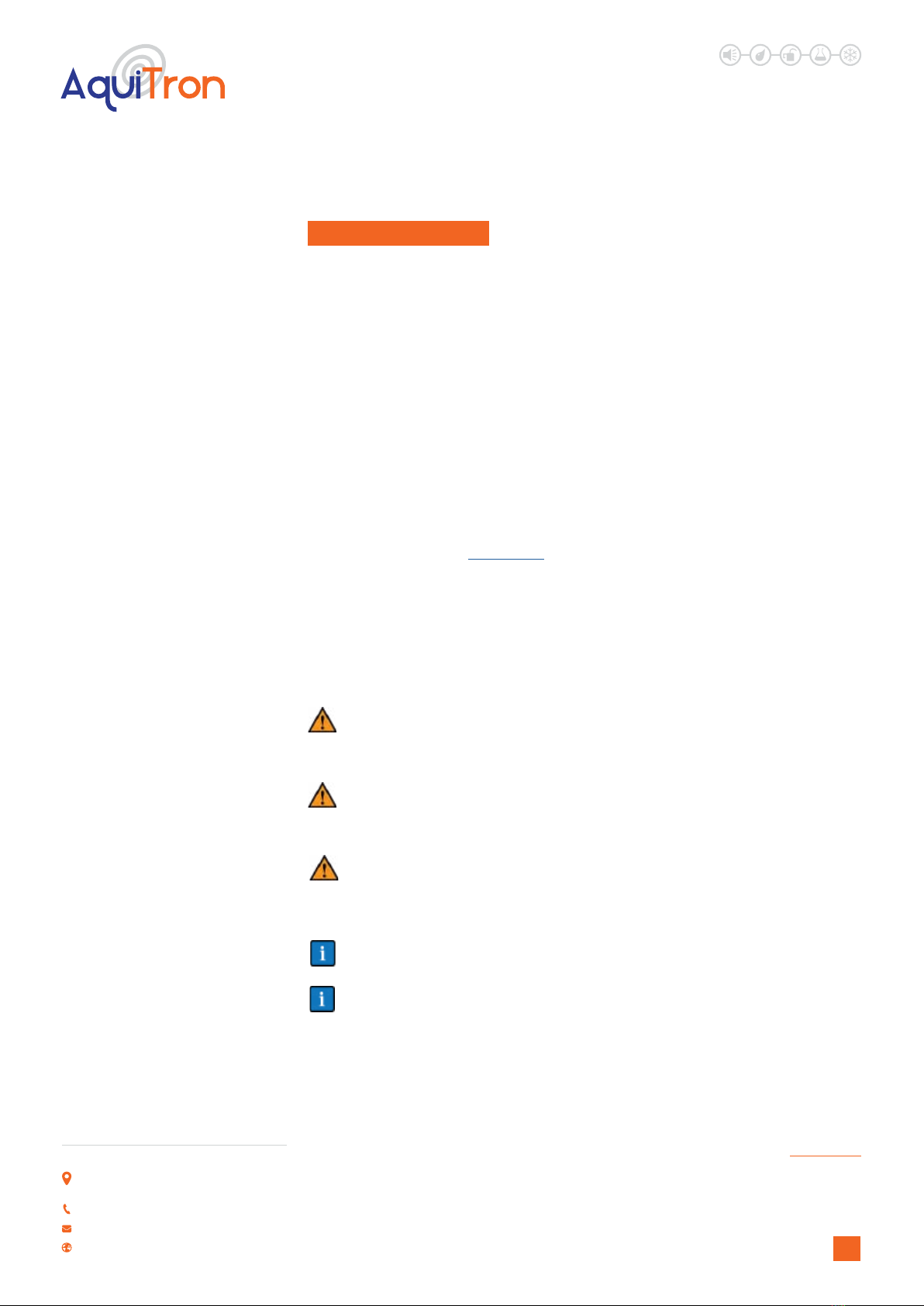

Alert Icon Description

DANGER

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

WARNING

Indicates a potential electrical shock hazard which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, could result in physical injury or damage to the

product or environment. It may also be used to alert against

unsafe practices.

NOTICE

Indicates additional information on how to use the product.

1. SAFETY

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

1.1 DEFINITION OF ALERT ICONS

The following alert icons are used in this document to highlight areas of the associated text that

require a greater awareness by the user.

1.2 GENERAL SAFETY STATEMENTS

• Before using this product, carefully read and strictly follow the instructions in the manual.

• Use the product only for the purposes specied in this document and under the conditions

listed.

• Ensure that product documentation is retained, made available, and appropriately used by

anyone operating the product.

• Comply with all local and national laws, rules, and regulations associated with this product.

• Only trained and competent personnel may use this product.

• Only trained and competent personnel may inspect, repair and maintain the product as

detailed in this manual. Maintenance that is not detailed in this manual must be completed

by Aquilar or personnel qualied by Aquilar.

• Use only genuine spare parts and accessories. Otherwise, operation may be impaired.

• Only operate the product within the framework of a risk-based alarm signaling concept.

REFRIGERANT SUFFOCATION RISK: Large refrigerant leaks into occupied spaces can

reach concentrations that pose a suocation risk to the occupants. While the AT-G-Alert

can be used to detect refrigerant leaks well below those concentrations, it is not designed

as a stand-alone safety device. Safety of the occupants must take a system design approach

including ventilation, detection, early warning, mitigation, and design redundancy among other

considerations.

↑ CONTENTS

LEAK DETECTION SOLUTIONS

4

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

1.3 SAFE CONNECTION OF ELECTRICAL DEVICES

Before connecting this detector to electrical devices not mentioned in this manual, consult the

manufacturer or a qualied professional.

The sensor must be connected by a marked, suitably located and easily reached switch or

circuit-breaker as means of disconnection.

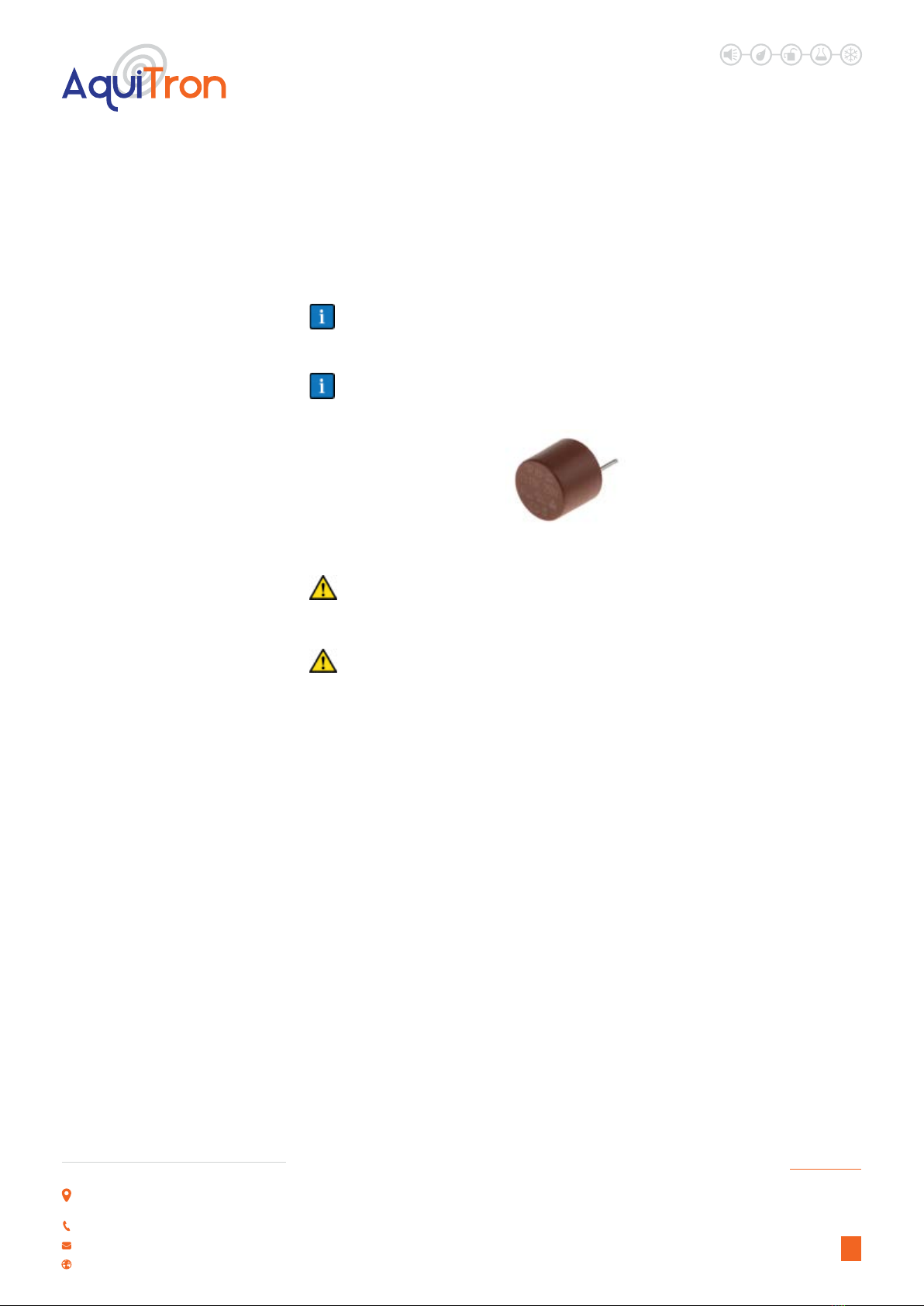

If replacement of either main power fuse is required, use only a TR5 Radial 3.15A 250V

slow fuse (Littlefuse 372 1315 0001 or equivalent).

Wiring must be in compliance with national and local wiring codes.

RS-485 signal cable must be insulated to the highest voltage level in the system. Protect

the RS-485 signal cable by using the supplied installation kit.

TR5 Radial 3.15A 250V

↑ CONTENTS

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

LEAK DETECTION SOLUTIONS

5

2. COMPONENTS OVERVIEW

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

1

1

2

3

4

55

6

7

8

9

Figure 2. AT-G-ALERT Components (Front)

1. Magnetic switch poistions

1 ( on top) and 2 ( on bottom)

2. Multi-color status LED

3. Sensor type/calibration and

ID/serial number labels

4. Mounting slots

5. Testing points - access holes x 2

6. Sensor alignment ribs

7. Replacement sensor module

8. Direction arrows x2 for proper mounting

9. Firmware version and part number/

calibration labels

↑ CONTENTS

LEAK DETECTION SOLUTIONS

6

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

10. Conguration DIP switches (1-8)

11. Relay 1 output connectors (low gas

alarm)

12. Relay 2 output connectors (high gas

alarm or fault)

13. Power connectors

14. Modbus serial communications

connectors

15. Wiring harness

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

12

13

14

15

10

11

↑ CONTENTS

LEAK DETECTION SOLUTIONS

7

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

3. INSTALLATION

3.1 GENERAL INFORMATION FOR INSTALLATION

Every detail of installation location is critical to ensure overall system performance and

eectiveness. Strict compliance and considerable thought must be given to every detail of the

installation process, including, but not limited to the following:

• Regulations as well as local, state, and national codes that govern the installation of gas

detection equipment

• Electrical codes that govern the routing and connection of electrical power and signal

cables to gas detection equipment

• The full range of environmental conditions to which the detectors will be exposed (refer

to section 6: Sensor Principle on page 28 for more information on ambient conditions and

cross-sensitivity)

• The physical characteristics of the gas or vapor to be detected

• The specics of the application (e.g., possible leaks, air movement/draft, etc.)

• The degree of accessibility required for maintenance purposes

• The types of optional equipment and accessories that will be used with the system

• Any limiting factors or regulations that would aect system performance or installations

• Wiring details, including the following:

• Wiring must be connected as indicated in this manual.

• The wiring for power and relays must be selected and fused according to the rated

voltages, currents, and environmental conditions.

• If stranded conductors are used, a ferrule should be used.

• A switch or circuit breaker must be included in the installation.

• The switch or circuit breaker must be suitably located and easily reached.

• The switch or circuit breaker must be marked as the disconnect device for the

equipment.

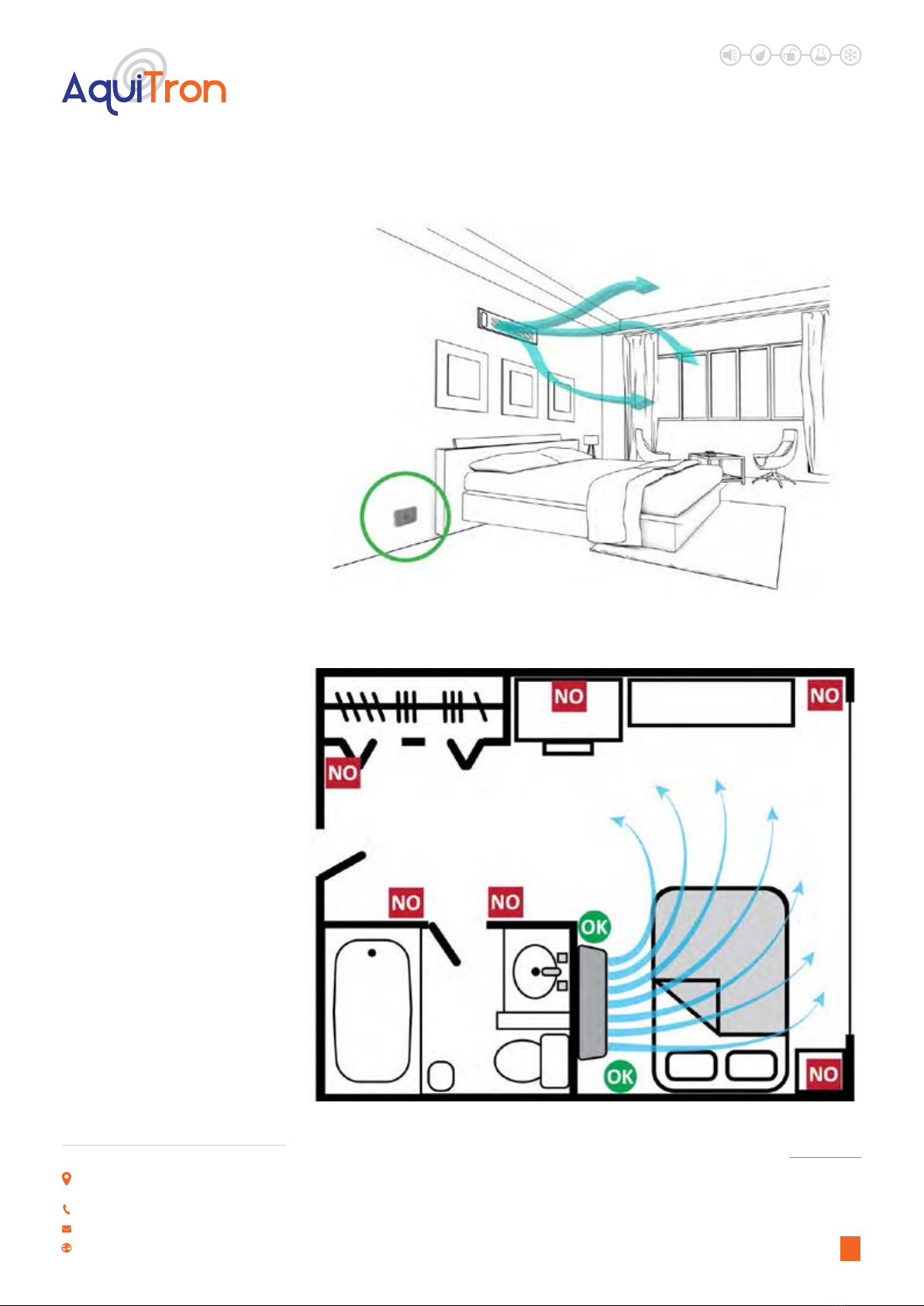

3.2 MECHANICAL INSTALLATION

• The detector ts in 47mm deep 2-gang electrical back boxes (not included)

• The detector must be accessible for maintenance (e.g., adjustment)

• The access pathway of the refrigerant gas to the sensor must not be obstructed

• The detector should be installed about 4 to 6 inches (100 to 150 mm) above the oor level

Figure 4. Typical AT-G-ALERT supported backboxes

↑ CONTENTS

LEAK DETECTION SOLUTIONS

8

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

Figure 6. Recommended Installation Locations

Figure 5. Typical AT-G-ALERT Installation in an Occupied Space Application

↑ CONTENTS

LEAK DETECTION SOLUTIONS

9

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

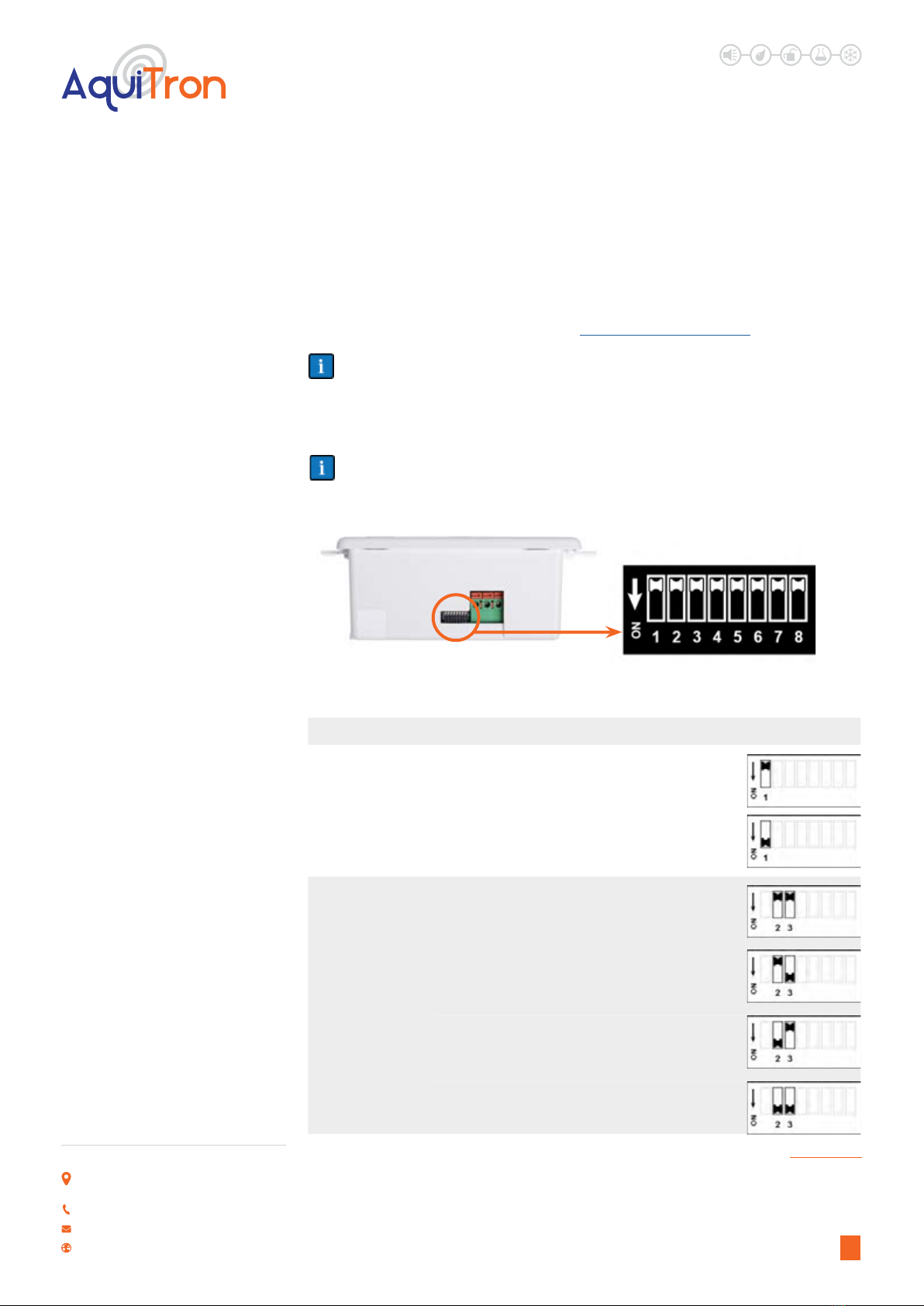

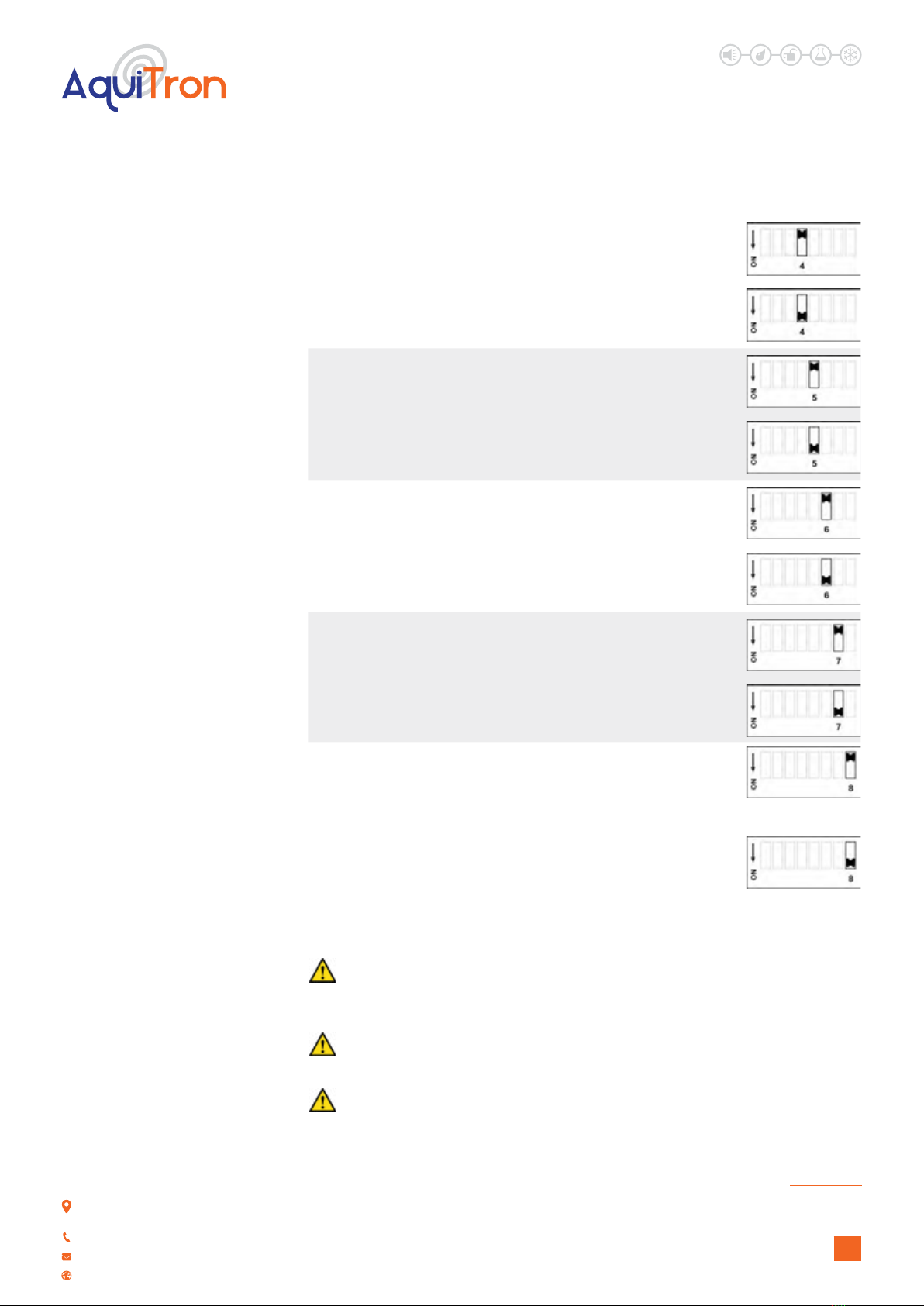

Figure 7. Switches for Conguring the AT-G-Alert

3.3 CONFIGURATION

Conguration is accomplished via switches or from a Remote Terminal Unit (RTU) on a Modbus

serial communications network. Review the default settings to determine if they are suitable for

your particular application. If default values are not suitable, change the conguration using the

DIP switches, or via the Modbus interface. A summary of switches is shown below. For details

on Modbus communications registers, refer to Section 8.9: Modbus Register.

By default, switch congurations supersede Modbus congurations. Use Modbus register

2007 (Modbus Precedence over DIP Switch Settings) to change this precedence.

Changes of congurations will not take eect until the detector is restarted (i.e., toggling switch

1 or cycling power).

For a proper reset, switch 1 must be toggled (ON then OFF). If it is left ON, the detector is

held in reset mode and will not function correctly until the switch is returned to the OFF

position.

Switch Function Options and Description Positions

1Restart

O = Normal Operation (default)

On = Restart AT-G-ALERT (must return switch to OFF

position)

2, 3 Alarm ON

Delay

O, O = No delay (default)

O, On = 5 minute delay

On, O = 10 minute delay

On, On = 15 minute delay

↑ CONTENTS

LEAK DETECTION SOLUTIONS

10

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

4

Failsafe

Relay

Selection

O = Normal Relay Operation (default)

On = Failsafe Relay Operation

5

Relay

2 Fault

Indication

O = High Alarm or Fault (default)

On = High Alarm Only

6Alarm

Latching

O = Alarms automatically reset (default)

On = Alarms latch and require manual reset

7Buzzer

Disable

O = Buzzer enabled (default)

On = Buzzer disabled

8

Reset

Detector

Settings

to Factory

Default

Values

O = Normal operation

On = Used in reset procedure for resetting Modbus

registers to their factory default values (see section

4.3.2 on page 21 for reset information and section

8.9 on page 36 for Modbus registers and default

values).

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

3.4 ELECTRICAL INSTALLATION

Caution: A switch or circuit breaker must be included in the installation. The switch or

circuit breaker must be suitably located and easily reached, and it must be marked as the

disconnect device for the equipment.

Caution: Ensure all wiring connections are made before applying power.

Caution: This product uses semiconductors which can be damaged by electrostatic

discharge (ESD). When handling the printed circuit boards (PCBs), observe proper ESD

precautions so that the electronics are not damaged.

↑ CONTENTS

LEAK DETECTION SOLUTIONS

11

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

Caution: RS-485 signal cable must be insulated to the highest voltage level in the system.

Protect the RS-485 signal cable by using the supplied installation kit.

Caution: Wiring must be in compliance with national and local wiring codes.

Notice: When inserting wire into the terminal, release the spring clamp by pushing the

release latch back.

Description of ELECTRICAL Installation

1. Remove fascia by loosening the set screw.

2. Observing proper polarity, connect wires for power to the appropriate terminals.

Power:

100Vac-240Vac

Earth / Ground

Label:

L - Vac Line

N - Vac Neutral

G - Vac earth ground

Figure 8. Wiring Power

4. Observing proper polarity, connect normally closed (NC) common (COM), and normally open

(NO) wires for relays to the appropriate terminals.

Figure 9. Wiring Relay 1 (Low Gas Alarm) and Relay 2 (High Gas Alarm or Fault)

↑ CONTENTS

LEAK DETECTION SOLUTIONS

12

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

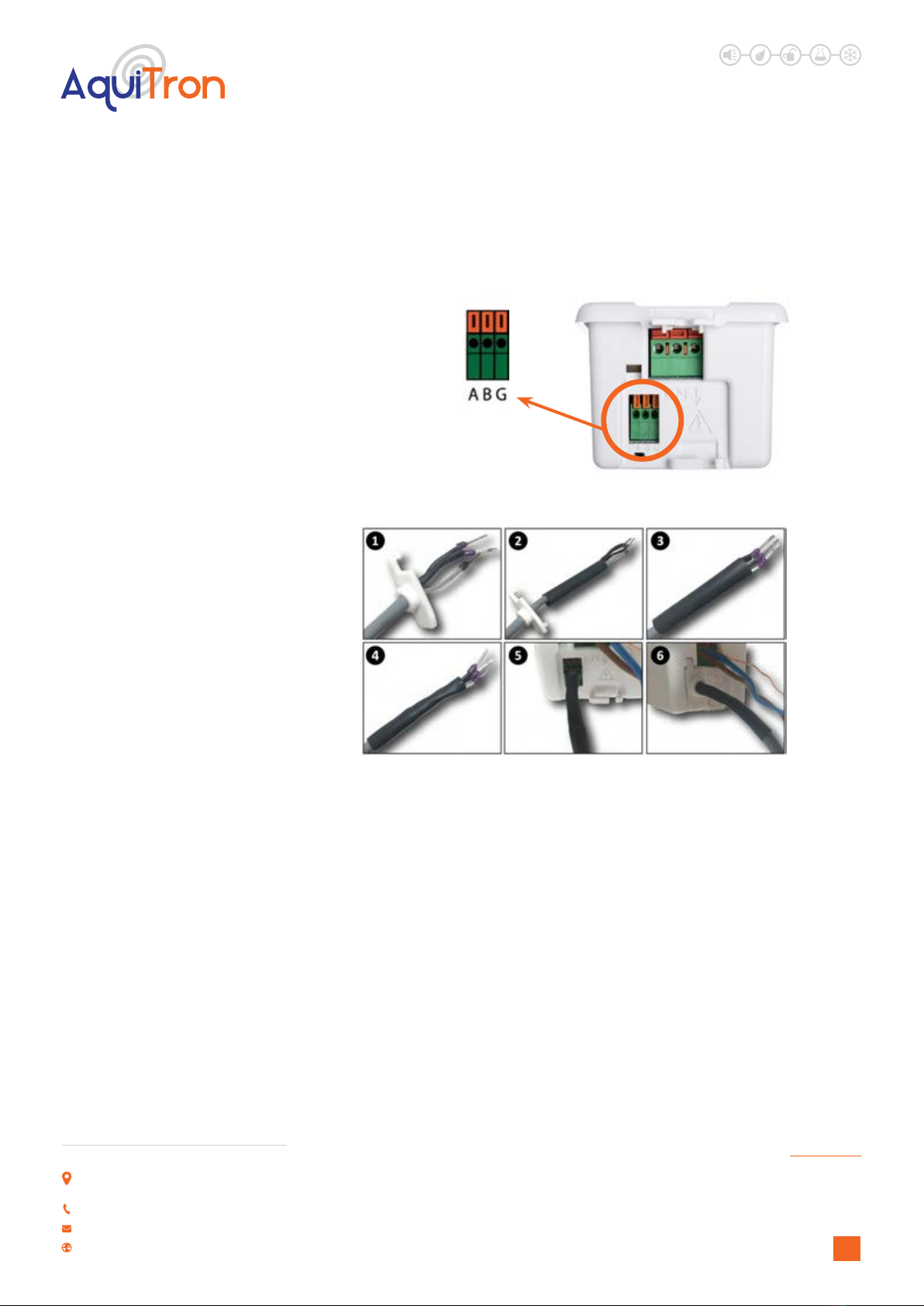

5. Observing proper polarity, make the Modbus connections as follows, using the gures below

for reference.

Label:

A - RS-485 “A” (non-

inverted)

B - RS-485 “B” (inverted)

G - RS-485 shield

Figure 10. Modbus Wiring Terminals

1. Prepare signal cable and put boot over the signal cable (1).

2. Add ferules if required (2).

3. Apply 10 cm piece of shrink wrap as close to the wire ends/ferules

as possible while leaving some free wire to allow connection to the

detector (3).

4. Heat the shrink wrap (4).

5. Connect signal wires/ferules to the detector (5).

6. Slide rubber boot along the wire and shrink wrap assembly and

connect it to the detector (6).

Figure 11. Details for Connecting Modbus Communications Wiring

6. Conrm conguration of switches. Refer to Section 3.3 on page 9.

↑ CONTENTS

7. Place detector into electrical back box (not included).

8. Put cover plate on and secure through mounting screws.

LEAK DETECTION SOLUTIONS

13

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

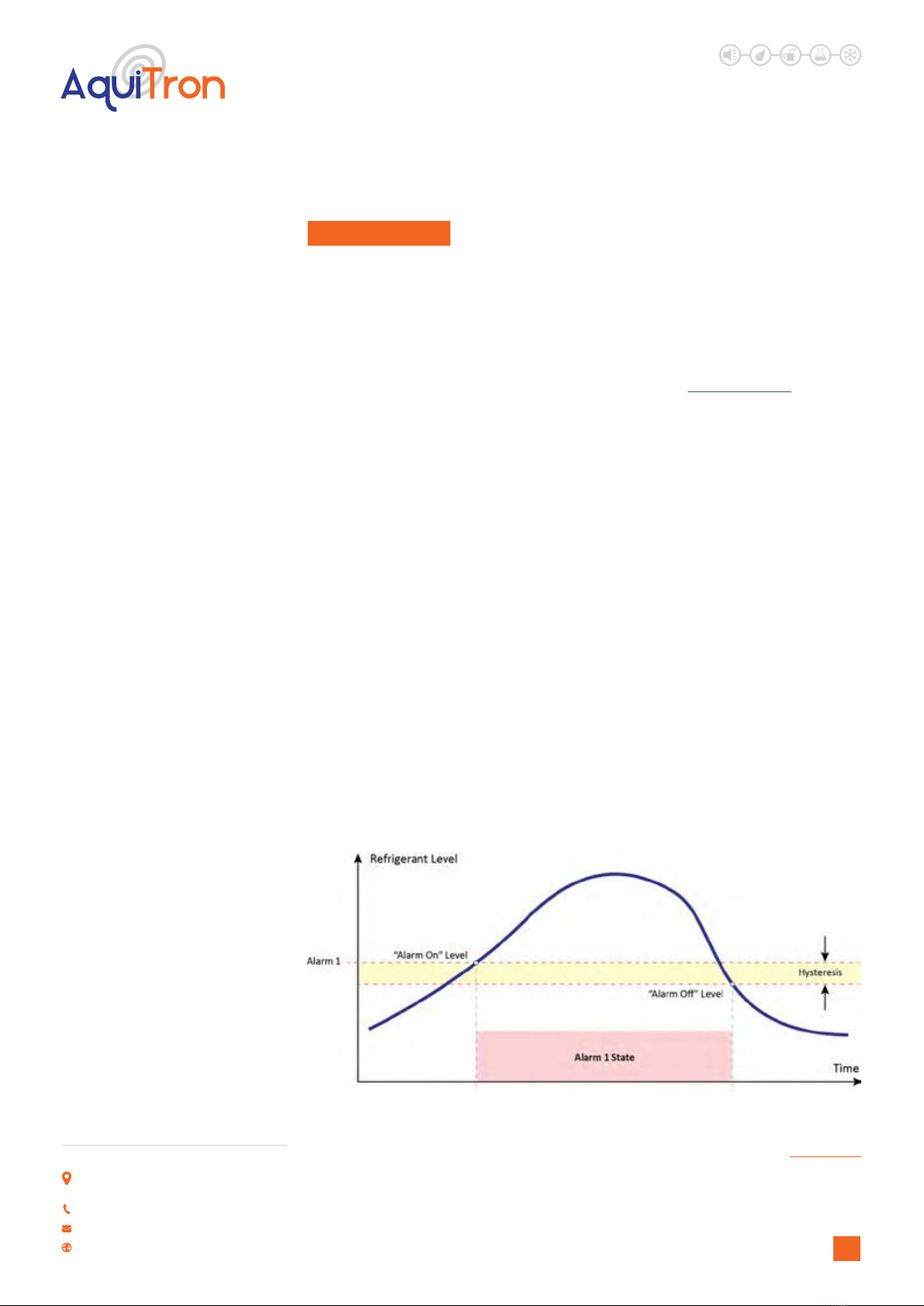

4.2 ALARM MANAGEMENT FUNCTION AND CONFIGURATION

The AT-G-Alert oers several dierent ways how the detector behaves in case of a refrigerant

alarm. The alarm manager can either be congured through the switches or the Modbus

interface.

Figure 15. Default Alarm Generation

4.1 STARTUP

1. Switch power on.

2. Observe start-up sequence and warm-up

phase.

• Green LED will blink at 0.5 Hz for about 5

minutes

• Modbus ag for warm-up is set

• Buzzer is o

• Relay state is “no alarm”

4. OPERATION

3. Observe normal operation

• Green LED is steady on

• Buzzer is o

• Relay state is “no alarm”

4. A bump test is required following

installation to verify instrument

functionality. (See section 5.2.5)

4.2.1 Default Alarm Function

If the refrigerant concentration raises above

the alarm 1 set-point:

• The LED ashes red with 0.5 Hz

• The buzzer beeps at 0.5 Hz

• The alarm 1 relay changes state

• The Modbus alarm 1 ag is set.

Once the alarm 1 condition is no longer

present and below the hysteresis value

(imposed to avoid relay chatter), the detector

returns to normal operation.

If the refrigerant concentration raises above

the alarm 2 set-point:

• The LED ashes red with 2 Hz.

• The buzzer beeps at 2 Hz

• The alarm 2 relay changes state

• The Modbus alarm 2 ag is set.

Once the alarm 2 condition is no longer

present and below the hysteresis value

(avoiding relay chatter), the detector returns

to alarm 1 state.

↑ CONTENTS

LEAK DETECTION SOLUTIONS

14

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

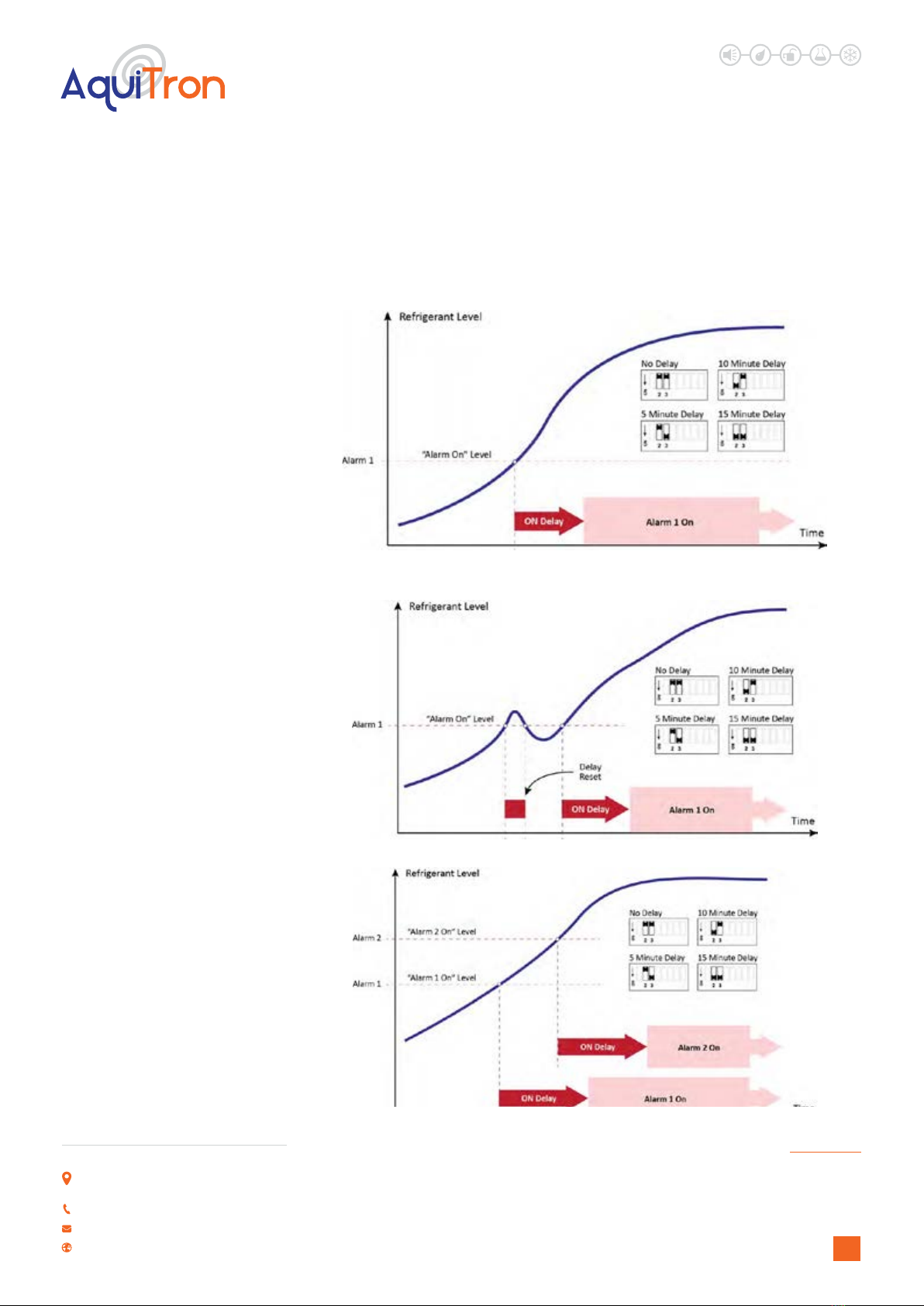

4.2.2 Alarm Delay – Switches 2 and 3

To avoid premature alarms, ensuring the presence of refrigerant for a certain amount of time,

the triggering of the alarm can be delayed for a short period of time. Unless the alarm condition

is present for at least the delay time, the alarm will not be triggered.

Figure 16. Alarm ON Delay (Alarm Condition Must Be Present for at Least the Programmed Time)

Figure 17. Alarm ON Delay (A Shorter Delay Time Is Disregarded)

Figure 18. Alarm ON Delay for Multiple Alarm Levels

↑ CONTENTS

LEAK DETECTION SOLUTIONS

15

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

4.2.3 Failsafe – Switch 4

If ON, the relays will change state whenever either of the following occurs.

• Power loss

• Alarm condition.

4.2.4 Alarm 2 Relay – Switch 5

If ON, the relay will only change state as a result of an alarm condition. In the default

conguration, Relay 2 will also indicate critical faults.

4.2.5 Latching Alarm State – Switch 6

If ON, the relay and Modbus ag will not change state until the concentration is below the alarm

level and it is acknowledged. The acknowledgement can either happen by tapping and holding

the magnetic wand for 5 seconds to the switch indicated as ( • • ) or by changing the respective

Modbus ag to 0.

In the default conguration the alarms will automatically reset when the gas level is below the

alarm thresholds.

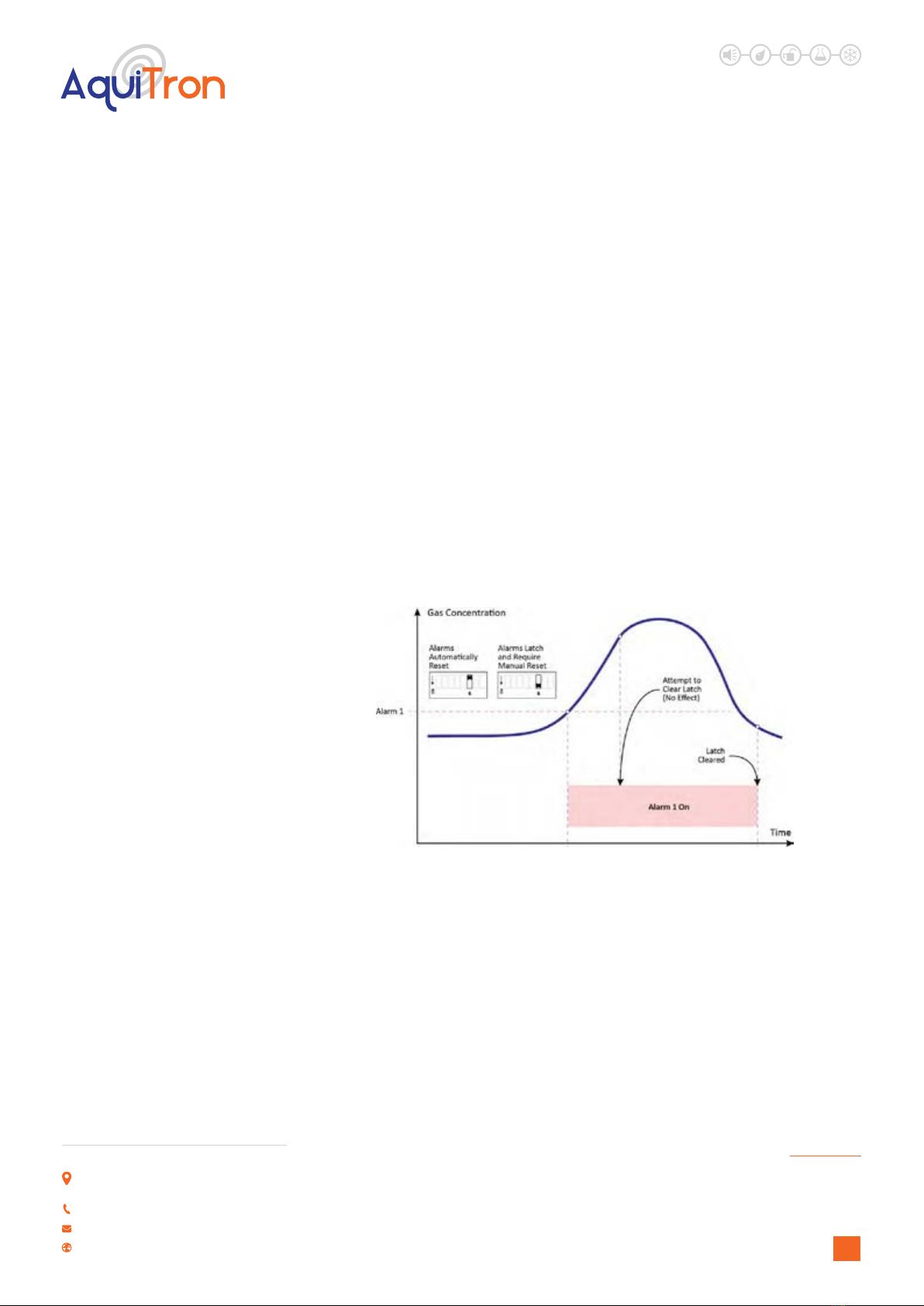

Figure 19. Latched Alarm Requiring Acknowledgement and Gas Concentration below Alarm Level

4.2.6 Buzzer Disable – Switch 7

If ON, the buzzer is disabled and will not sound.

4.3 OTHER SWITCH CONFIGURATIONS

4.3.1 Reset (Cycle Power) - Switch 1

Use the following procedure to cycle power to the AT-G-Alert.

1. Move switch 1 to the ON position.

2. Move switch 1 to the OFF position.

3. Power is cycled to the AT-G-Alert.

↑ CONTENTS

LEAK DETECTION SOLUTIONS

16

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

4.3.2 Reset to Factory Default Values - Switch 8

Use the following procedure to reset all congurable Modbus registers to their factory default

values.

1. Ensure that the detector is o. If the detector is on, turn o power.

2. Set switch 8 to ON.

3. Turn on the detector. The buzzer will be ON and the LED will be OFF.

4. Set switch 8 to OFF. The buzzer will be OFF and the LED will be OFF.

5. Using the magnetic wand, hold magnetic switch 1 ( •) for 60 seconds. LED is GREEN during

this period.

6. Wait for the LED to changes to ORANGE.

7. Reset the detector by cycling power (by toggling switch 1).

8. Detector will start-up as normal and re-read all switch settings.

4.4 OPERATION OF MAGNETIC SWITCHES, BUZZER AND LED

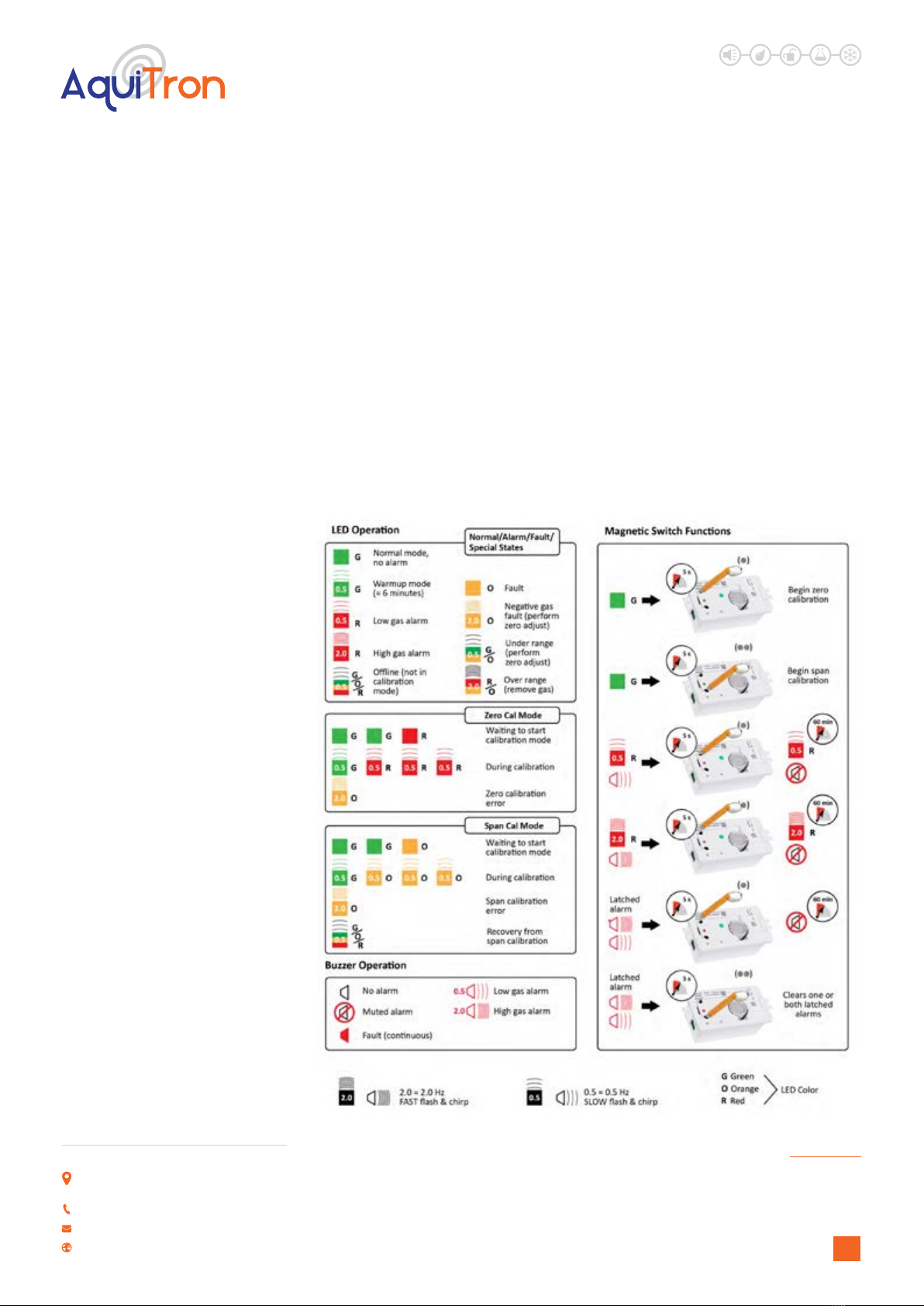

Figure 20. Operation of Magnetic Switches, Buzzer, and LED

↑ CONTENTS

LEAK DETECTION SOLUTIONS

17

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

5.0 MAINTENANCE

5.1 MAINTENANCE INTERVALS

During Commissioning:

• Check calibration.

• Check LEDs for proper operation.*

• Check for proper buzzer and relay operation.*

• Check signal transmission to the BMS/BAS (central controller) if connected.*

During Commissioning:

• Inspection by trained service personnel.

• Check LEDs for proper operation.*

• Check for proper buzzer and relay operation.*

• Calibrate the sensor or contact Aquilar for sensor exchange with factory-calibrated sensor.

As Required:

• Replace sensor module(s) (see page 27).

*These can be activated via Modbus commands.

5.2 ADJUSTMENTS

5.2.1 Introduction

Warning: Breathing Hazard: Calibration gas must not be inhaled See appropriate Safety

Data Sheets. Calibration gas should be vented into a fume hood or to the outside of the

building.

Warning: Zero First, Then Span: For proper operation, never adjust the span before

completing a zero adjustment. Performing these operations out of order will cause faulty

calibration.

Warning: Aquilar recommends calibrating detectors within the application-specic

conditions and with target gas. This method of zeroing the detector in the application

environment and performing a target gas calibration is more accurate. A surrogate gas

calibration may only be performed as an

Notice: The sensor should be fully warmed-up (at least 2 hours, 24 hours recommended).

Notice: When entering the functions for zero or span adjustment, the detector will

automatically enter OFFLINE mode, and will remain OFFLINE until either the OFFLINE

mode is canceled by tapping the respective magnetic switch, or the OFFLINE mode times out

within 6 minutes (typical) after the adjustment has ended.

↑ CONTENTS

LEAK DETECTION SOLUTIONS

18

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

5.2.2 General Procedure

1. Verify that the detector is NOT in alarm and does not have a fault condition (i.e., it must not

have a continuous orange LED).

2. Verify that the calibration gas is in a balance of air, not Nitrogen (N2).

3. Fit testing hood to the fascia plate (7) or base plate (6) (see below).

4. Check switch 8 to OFF. The buzzer is OFF and the LED is OFF.

5. Connect the tubing to the barbed ttings of the pressure regulator and testing hood.

6. Verify that gas ow is approximately 0.3 to 1.0 L/min.

7. If operation is intended to be at higher altitudes, the factory calibration will result in a reading

lower than the reading at sea level (reduced partial pressure). A new span adjustment is

recommended if the altitude or the ambient pressure is changed. The factory calibration is

set to sea level.

8. Always perform a zero adjustment before a span adjustment.

Warning: Ambient air can be used to zero the sensor instead of synthetic air

only if the area is known to be free of the target gas or any gas to which the

sensor may be cross- sensitive. In this case, no cylinder or testing hood is needed for

the zero adjustment.

Figure 21. Calibration Assembly

1. Testing hood

2. Flow meter

3. Pressure regulator

4. Calibration gas

5. Tubing

6. Calibration from base plate (with test point access)

7. Calibration from fascia plate

1

2

4

5

3

7

6

↑ CONTENTS

LEAK DETECTION SOLUTIONS

19

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-ALERT

Refrigerant Gas Sensor

for occupied spaces

5.2.3 Zero Adjustment ( ... continued for General Procedure)

9. Tap and hold ( • ) for more than 5 seconds. The LED will blink green-green-red to indicate

the detector is ready. Verify that the calibration gas is in a balance of air, not Nitrogen (N2).

10. Apply synthetic air (or use ambient air per the warning above).Set switch 8 to OFF. The

buzzer will be OFF and the LED will be OFF.

11. Tap ( • ) within 30 seconds to conrm start of calibration. Otherwise the detector will time-

out and return to normal operation.

12. As the process progresses, the LED will blink green-red, green-red-red, green-red-red-red,

etc.

• To abort calibration, tap and hold ( • ) for >5 seconds, turn o gas ow and remove the

testing hood. The detector will return to normal operation.

• If calibration is successful (green LED), skip to step 15.

• If calibration is unsuccessful (orange LED blinks @ 2 Hz), then tap ( •) to discard the

calibration attempt, and see Section 5.3 on page 26 for troubleshooting.

13. Turn o gas ow from synthetic air

14. Replace synthetic air tank with calibration gas tank in preparation for span adjustment.

5.2.4 Span Adjustment

15. Tap and hold ( ••) for >5 seconds. The LED will blink green-green-orange when the detector

is ready.

16. Apply span gas in the concentration listed on the cal gas concentration label (beneath the

detector’s cover plate). This may require the temporary removal of the bezel and cover plate

to see the label.

17. Tap ( • • ) within 30 seconds to conrm initiation of the calibration. Otherwise the detector

will time-out and return to normal operation.Turn o gas ow from synthetic air

18. As the calibration process progresses, the LED will blink green-orange, green-orange-

orange, green-orange-orange-orange, etc.

• To abort calibration, tap and hold ( • • ) for >5 seconds, turn o gas ow and remove the

testing hood. The detector will return to normal operation.

• If calibration is successful, the LED will blink green-orange-red indicating ‘oine’. Turn o

gas ow and remove the testing hood. After 6 minutes the detector will return to normal

operation.

• If calibration is unsuccessful (orange LED blinks @ 2 Hz), then tap ( • • ) to discard the

calibration attempt, and see Section 5.3 on page 21 for troubleshooting. Turn o gas

ow and remove the testing hood. After 6 minutes the detector will return to normal

operation.

5.2.5 Bump Test

A bump test is a live test of a system to verify that the detector responds to gas and all

connected alarm devices, BMS, etc. are operating accordingly. In this case it is necessary that

all involved persons are informed about the test and certain alarms might have to be inhibited

(e.g., shutdown valves, notication of authorities, etc.).

1. Inform building personnel of test so that certain alarms may be inhibited (e.g.,

shutdown valves, notication of authorities, etc.).

↑ CONTENTS

Other manuals for AquiTron AT-G-ALERT

1

Other aquilar Accessories manuals