1

Table of Contents

Introduction ..................................................................................................................... 3

What is the PT2X?.................................................................................................... 3

Initial Inspection and Handling ................................................................................ 3

Do’s and Don’ts ....................................................................................................... 4

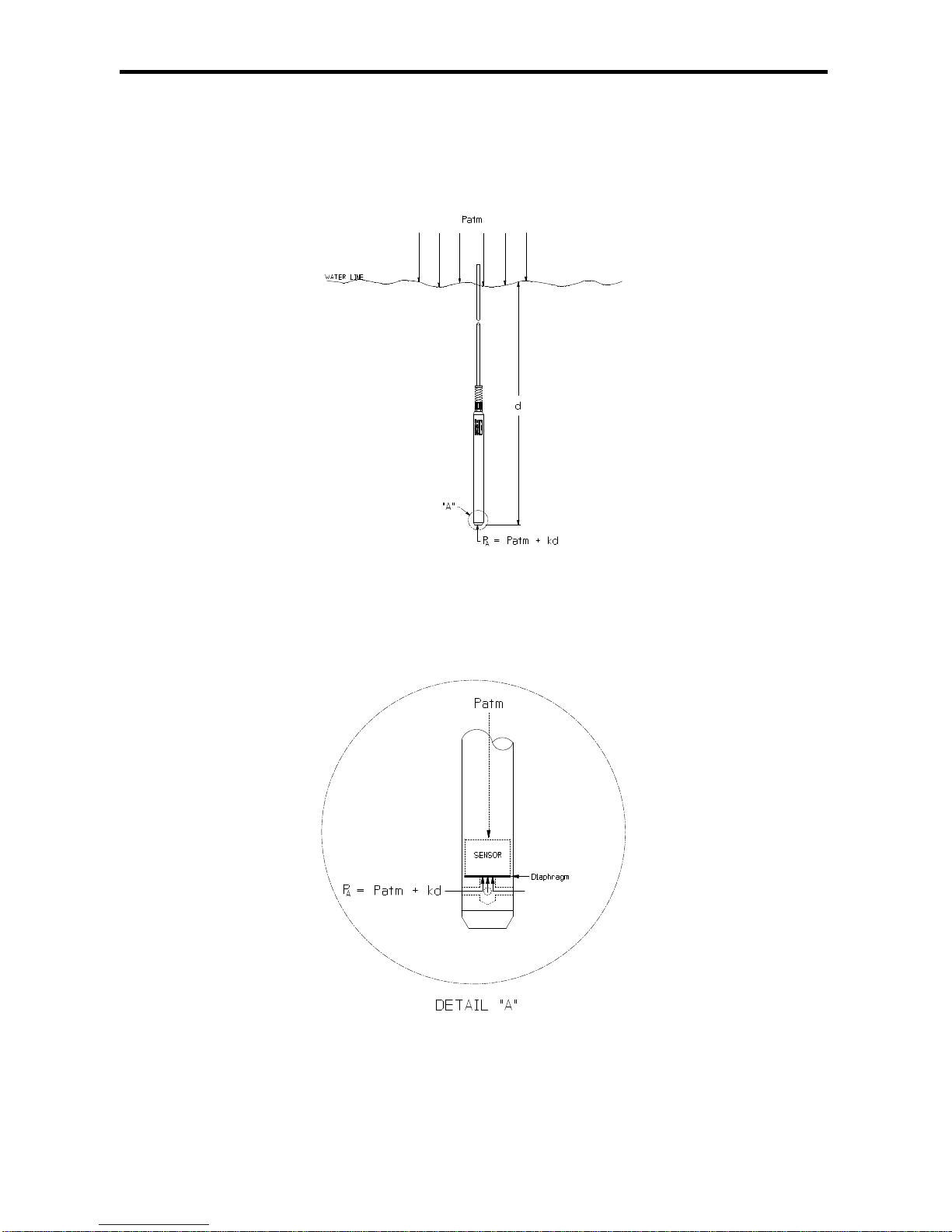

How Pressure Sensors Work ........................................................................................... 4

Installation and Operation ............................................................................................... 6

ConnectingExternalPower ....................................................................................... 6

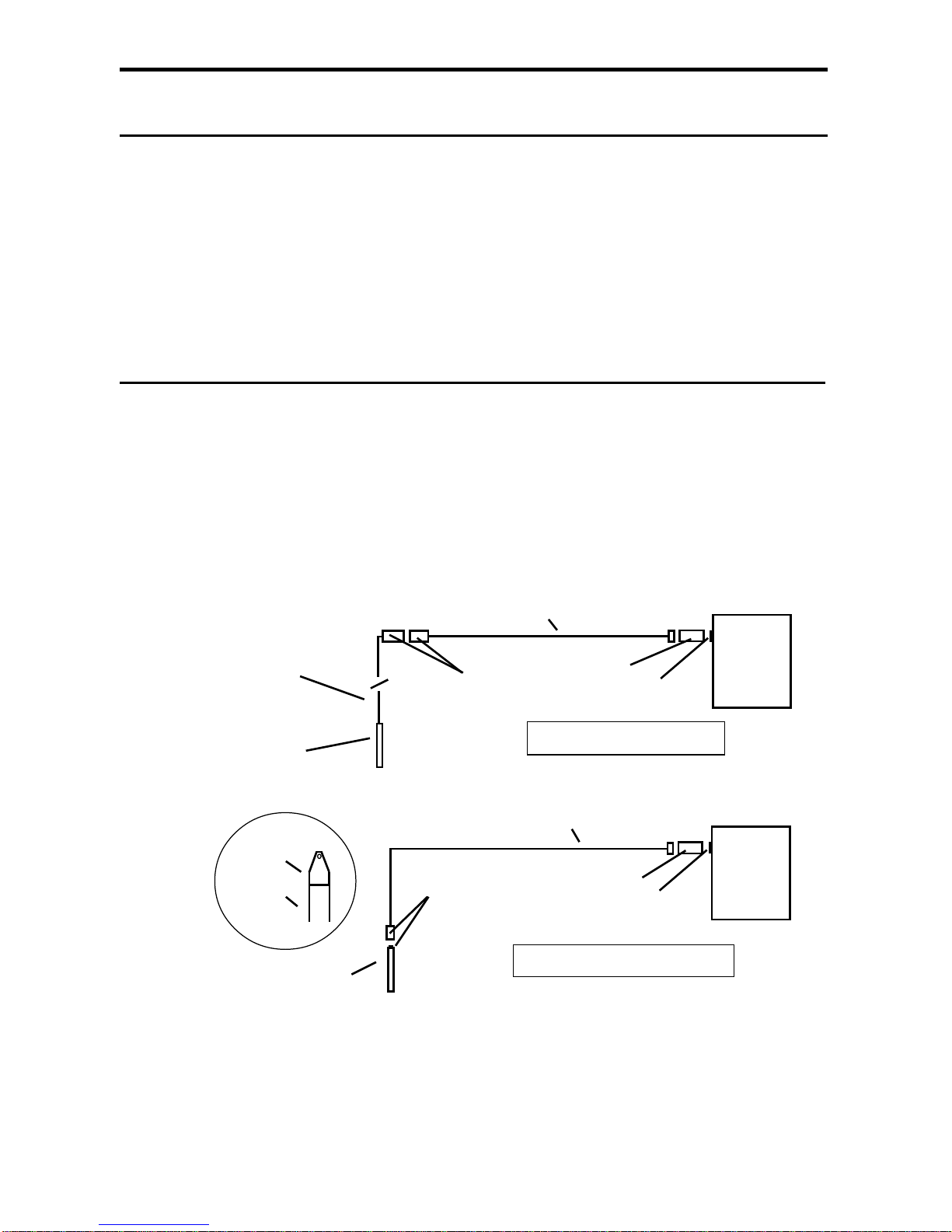

Connecting the PT2X to a Computer ........................................................................ 6

Installing theAqua4Plus Software............................................................................ 7

Installing the Sensor ................................................................................................. 7

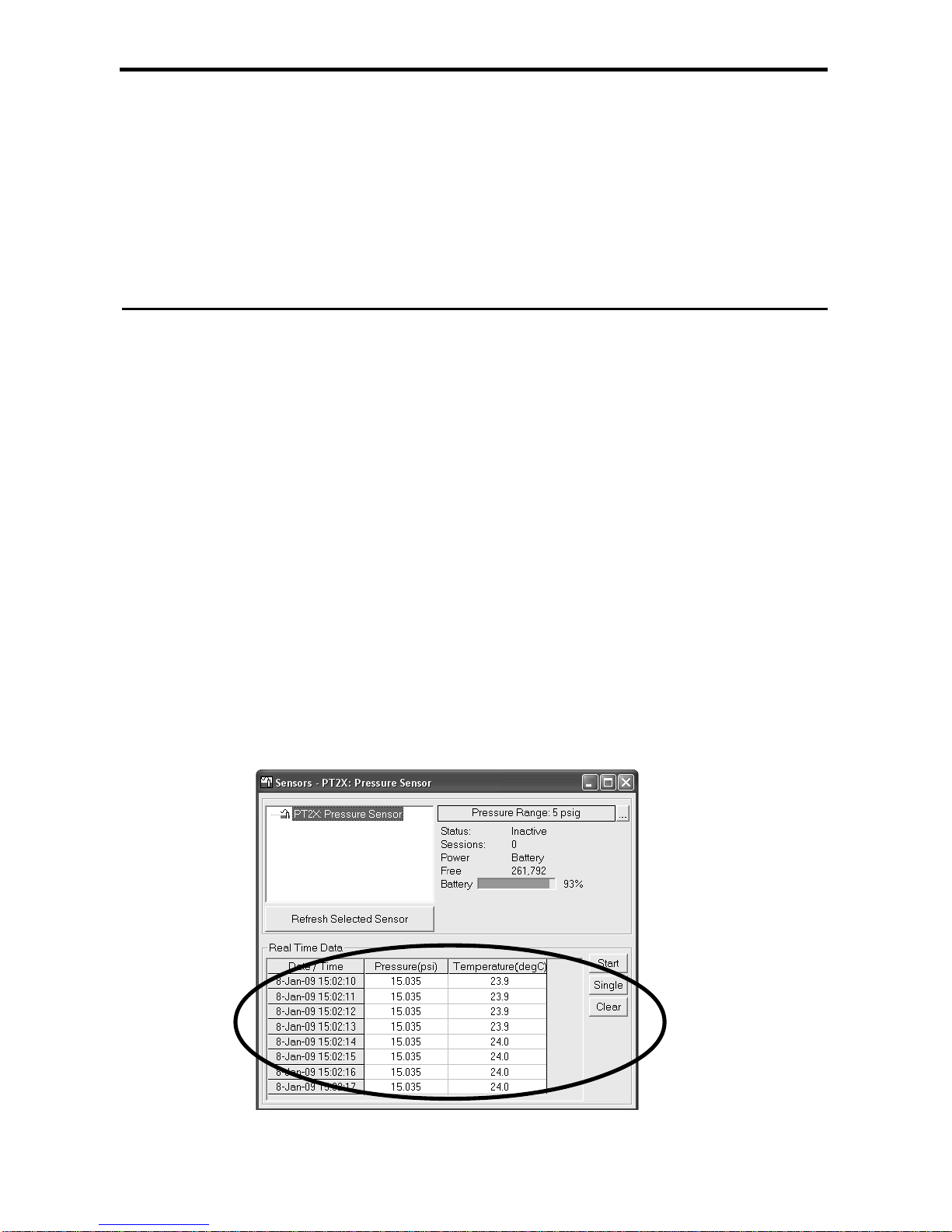

Collecting Data ......................................................................................................... 8

Maintenance ...................................................................................................................11

Changing Batteries ..................................................................................................11

RemovingDebrisfrom EndCone.............................................................................13

Desiccant Tubes ......................................................................................................14

Miscellaneous .........................................................................................................15

Trouble Shooting ............................................................................................................16

Erratic Readings .......................................................................................................16

OscillatingReadingsOver Time ..............................................................................16

Zero Readings When Pressurized ...........................................................................16

Grounding Issues ....................................................................................................16

AppendixA:Technical Specifications ............................................................................18

GeneralSpecification ...............................................................................................18

Wiring and Component Information ........................................................................18

Continuous Rate and Filter Settings ........................................................................21

BatteryLifeCalculation ...........................................................................................22

AppendixB:Field Calibration(Pressure) ........................................................................23

Appendix C: Measuring Elevation or Depth-to-Water ...................................................25

Depth-to-Water Calibration .....................................................................................25

GroundwaterElevationCalibration ..........................................................................26

Appendix D: Using a USB Port .......................................................................................27

Connecting with INW’s USB to RS485Adapter ......................................................27

Connecting with a USB to SerialAdapter ................................................................27

Appendix E: Reading the PT2X via Direct Read ............................................................29

Setting Units for Direct Read ...................................................................................29

ReadingVia Modbus®RTU .....................................................................................30

ReadingViaSDI-12 ..................................................................................................32

Reordering Information ...................................................................................................34

LimitedWarranty/Disclaimer-AquiStar®PT2X ...............................................................35