3

English

CONTINUES

CONTENTS

• Legend of symbols ..........................................................................................................2

• Preface and scope of the manual...................................................................................5

• Using the manual.............................................................................................................5

• Limits ................................................................................................................................5

• Liability .............................................................................................................................5

1 Risks and precautions before assembly .......................................................................6

2 Bravo DSB ........................................................................................................................6

3 Intended use.....................................................................................................................6

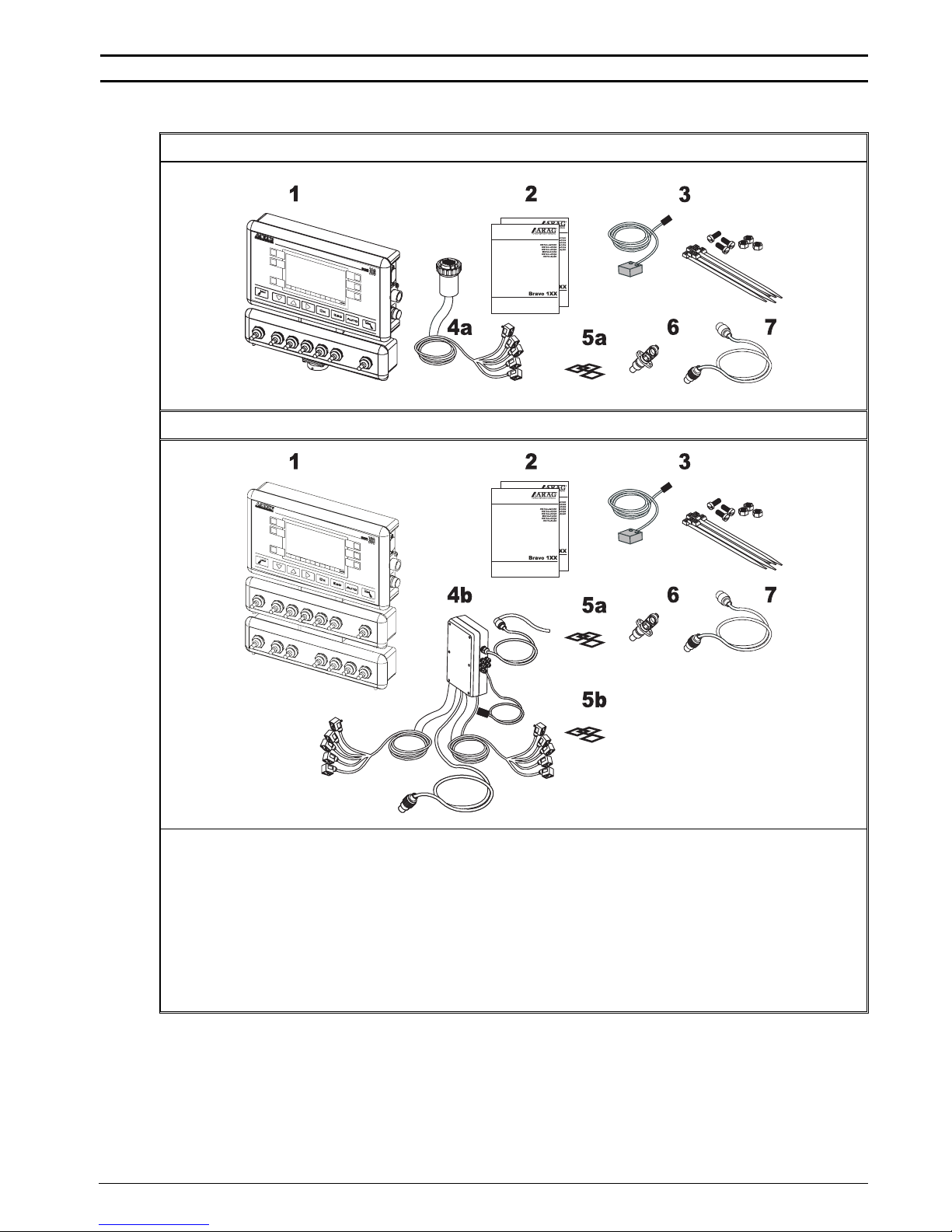

4 Contents of the package .................................................................................................7

5 Location on the machine ................................................................................................8

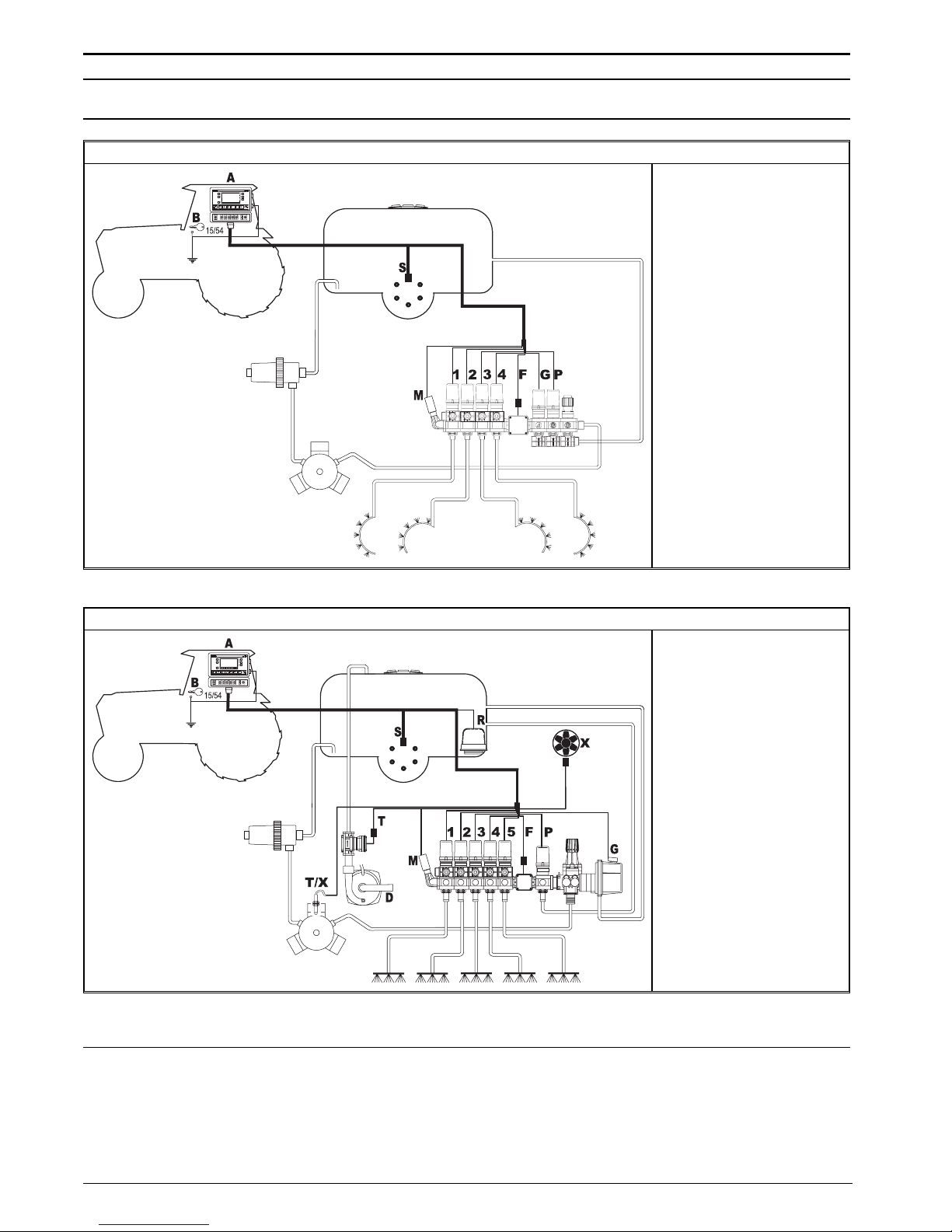

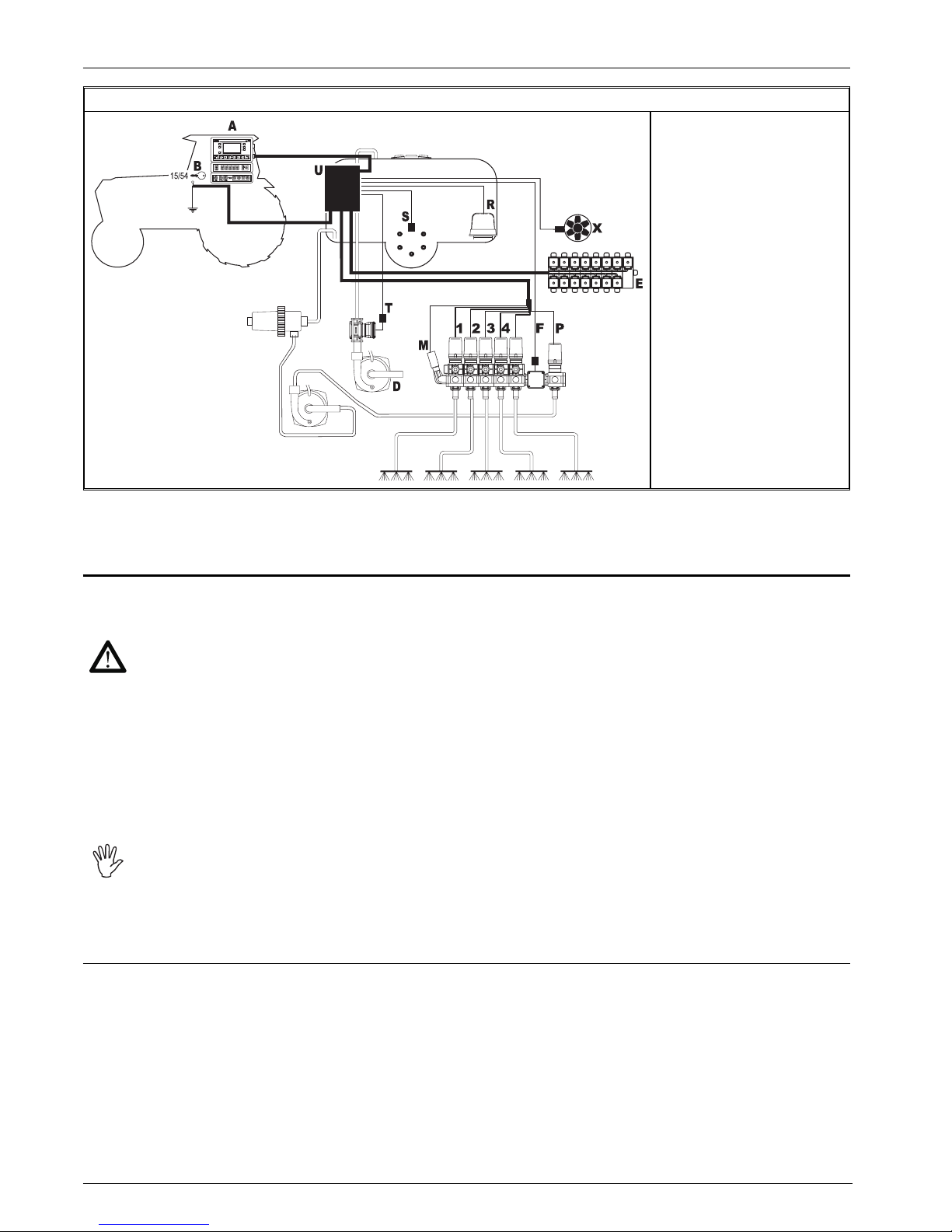

5.1 System configuration ...............................................................................................8

5.2 Locating the computer ...........................................................................................10

5.3 Mounting the bracket .............................................................................................12

5.4 Installing the remote unit .......................................................................................12

5.5 Location of the control unit ....................................................................................12

6 Connecting the computer to the machine...................................................................13

6.1 General precautions for cable runs .......................................................................13

6.2 Power connection ..................................................................................................14

7 Connecting the cable to the control unit and services ..............................................15

7.1 Connecting the multi-pin connector .......................................................................15

7.2 Connecting the valves ...........................................................................................15

7.3 Connecting the sensors and other services ..........................................................16

8 Accessory connections ................................................................................................17

8.1 Pump Protector......................................................................................................17

8.2 Foam marker .........................................................................................................17

8.3 Printer ....................................................................................................................18

8.4 Transferring the counter data to a PC ...................................................................18

9 Programming .................................................................................................................19

9.1 Pre-programming tests and checks.......................................................................19

9.2 Advanced menu.....................................................................................................19

9.3 Control panel .........................................................................................................21

9.4 Using the keys and switches .................................................................................21

9.5 Display (delivery / programming)...........................................................................24

9.6 Display (programming) ..........................................................................................25

9.7 Launch protection - BRAVO 32X serie ..................................................................26

9.8 Setting the display brightness................................................................................26

9.9 Access to advanced programming ........................................................................26

9.10 Units of measurement (Menu 30.0) .......................................................................27

9.11 Number of sections (Menu 40.0) ...........................................................................27

9.12 Boom width (Menu 43.0) .......................................................................................28

9.12.1 Technical headings.................................................................................................... 29

9.13 Nozzle spacing (Menu 46.0)..................................................................................30

9.14 Type of section valve (Menu 50.0) ........................................................................30

9.15 Operating mode.....................................................................................................31