Cleveland Alliances

01361883418

3

CONTINUES

COnTEnTS

• Legend symbols ............................................................................................................................ 2

• Foreword and use of this guide................................................................................................. 5

• Using the manual .......................................................................................................................... 5

• Limitations....................................................................................................................................... 5

• Liability............................................................................................................................................. 5

1 Product description ...................................................................................................................... 6

2 Bravo DSB ....................................................................................................................................... 6

3 Risks and precautions before assembly ................................................................................ 6

4 Intended use ................................................................................................................................... 6

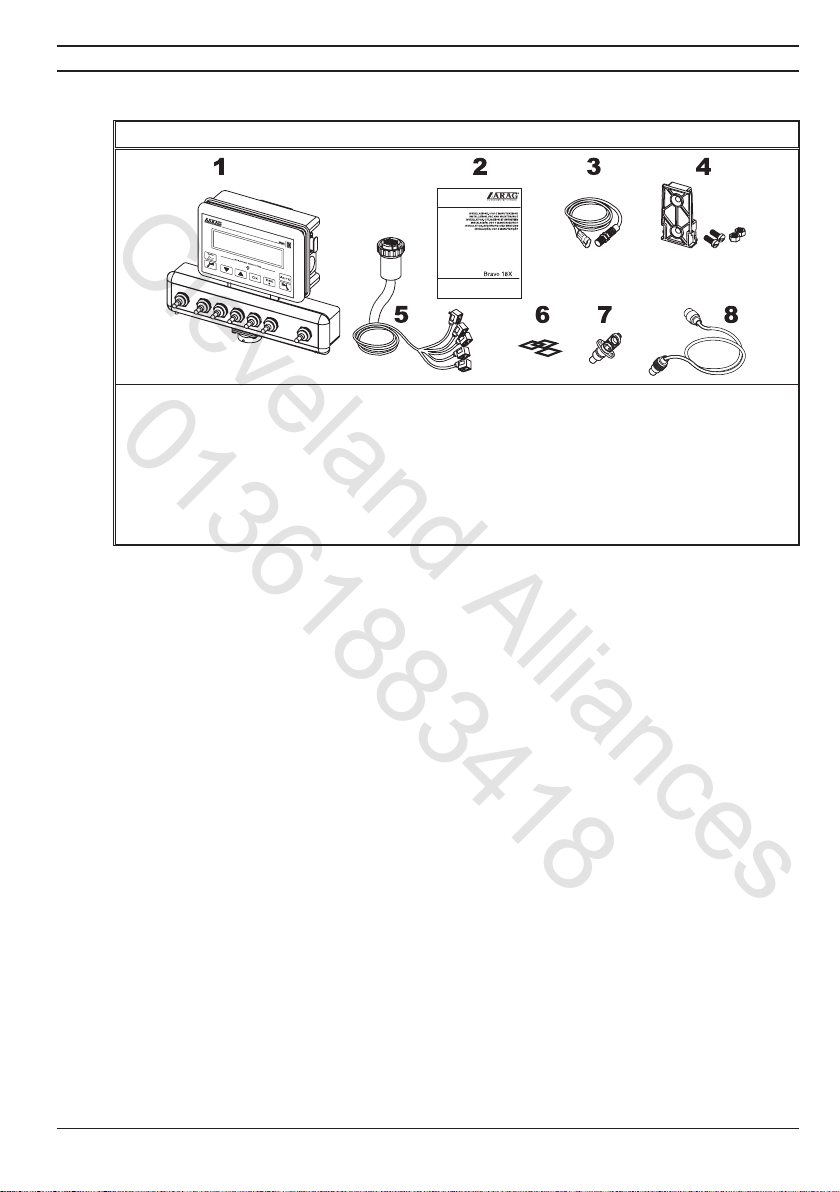

5 Contents of the package ............................................................................................................. 7

6 Location on the machine............................................................................................................. 8

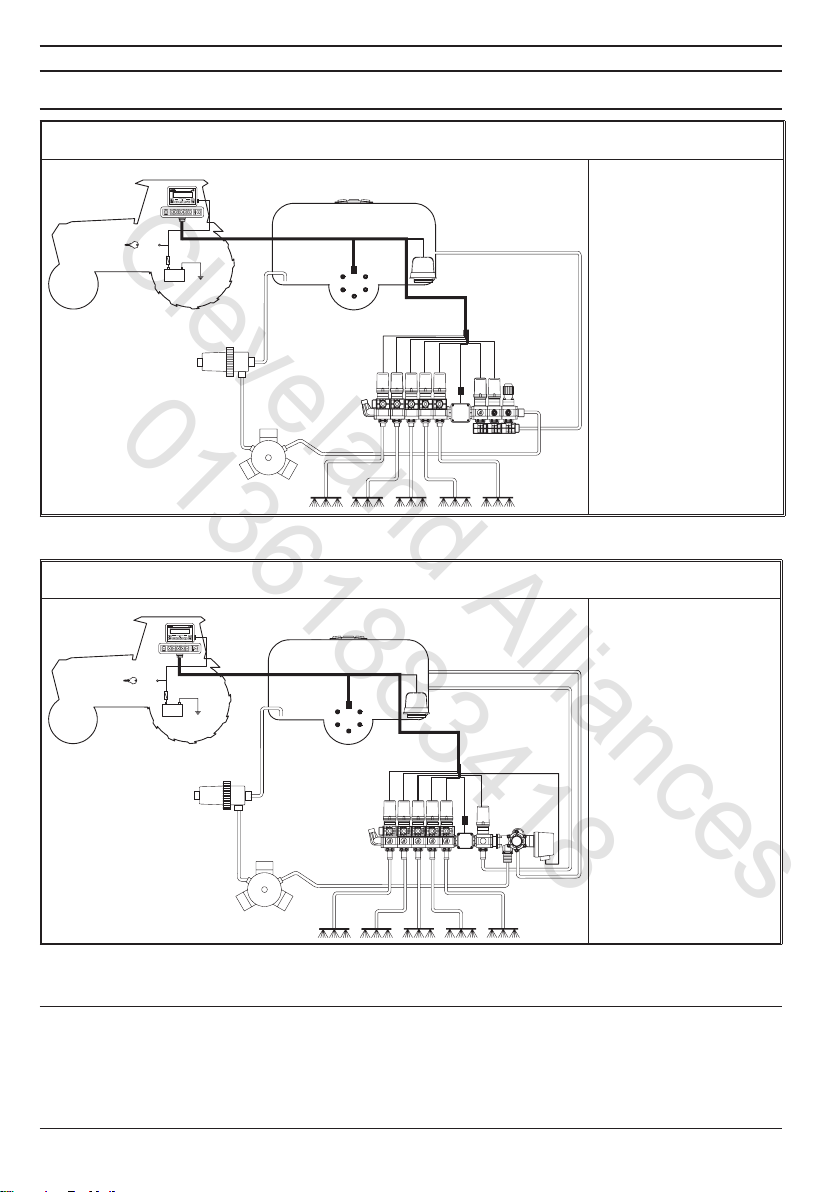

6.1 Recommended system configuration ............................................................................... 8

6.2 Locating the computer......................................................................................................... 9

6.3 Mounting the bracket ......................................................................................................... 10

6.4 Location of the control unit ............................................................................................... 10

7 Connecting the computer to the machine............................................................................ 10

7.1 General precautions for cable runs................................................................................. 10

7.2 Power connection................................................................................................................11

8 Connecting the cable to the control unit and services .................................................... 12

8.1 Connecting the multi-pin connector ................................................................................ 12

8.2 Connecting the valves ....................................................................................................... 12

8.3 Connecting the sensors and other services.................................................................. 13

9 Accessory connections............................................................................................................. 14

9.1 Foam marker....................................................................................................................... 14

10 Computer controls and display............................................................................................... 15

10.1 Control panel....................................................................................................................... 15

10.2 Using the control keys ....................................................................................................... 15

10.3 Using the switches ............................................................................................................. 16

10.4 Display (delivery)................................................................................................................ 16

11 Preliminary programming ......................................................................................................... 17

11.1 Pre-programming tests and checks................................................................................. 17

11.2 Switching on the computer ............................................................................................... 17

11.3 Switching on the computer for advanced programming .............................................. 18

11.4 Advanced menu.................................................................................................................. 18

11.5 Language............................................................................................................................. 19

11.6 Unit of measure .................................................................................................................. 19

11.7 Nr of sections...................................................................................................................... 19

11.8 Total boom width ................................................................................................................ 19

11.9 Section ................................................................................................................................ 20

11.10 Section valve....................................................................................................................... 20

11.11 Flowmeter............................................................................................................................ 20

11.12 Tank volume ........................................................................................................................ 21

11.13 Tank reserve........................................................................................................................ 21

11.14 Spraying menu.................................................................................................................... 21