3

ContEnts

• Legend symbols...............................................................................................................2

• Manual foreword and use................................................................................................4

• Manual use modes...........................................................................................................4

• Limitations........................................................................................................................4

• Responsibility ..................................................................................................................4

1 Risks and protections before assembly ........................................................................4

2 Bravo DSB ........................................................................................................................4

3 Intended use.....................................................................................................................5

4 PrecauTIonS .....................................................................................................................5

5 Package content...............................................................................................................5

6 Position on farming machine..........................................................................................6

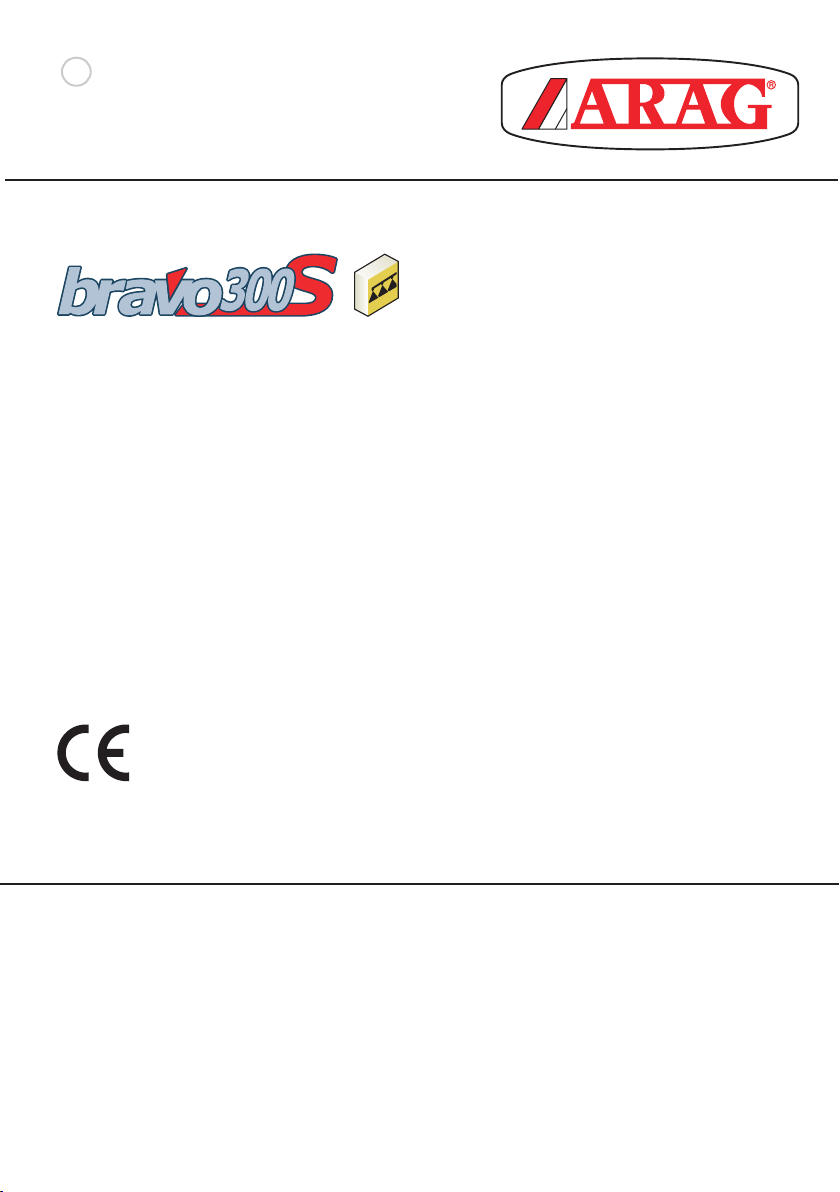

6.1 System recommended composition.........................................................................6

6.2 Monitor and control unit positioning .........................................................................7

6.3 Bracket fixing ...........................................................................................................8

6.4 Remote control unit (RCU) fixing .............................................................................8

6.5 Control unit position .................................................................................................9

6.6 Hydraulic unit positioning.........................................................................................9

7 Computer connection to the farming machine .............................................................9

7.1 General precautions for a correct harness position .................................................9

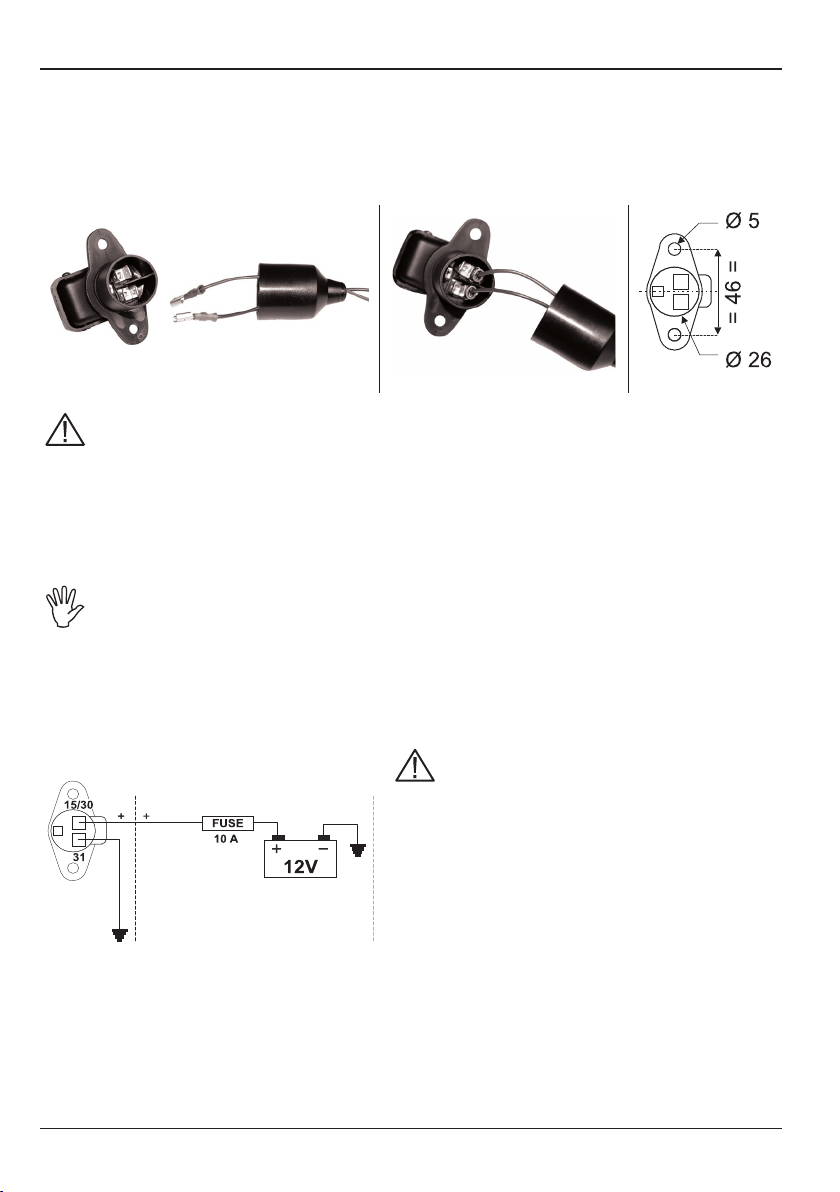

7.2 Power supply connection ....................................................................................... 10

8 Connecting the harness to control unit, hydraulic unit and available functions 11

8.1 Remote Control Unit (RCU) connection................................................................. 11

8.2 Connecting the control unit valves ......................................................................... 11

8.3 Hydraulic valves connection ..................................................................................13

8.4 Connection of sensors and other available functions ............................................ 14

8.5 SD memory card.................................................................................................... 15

9 Maintenance / Diagnostics / Repairs............................................................................ 16

9.1 Troubleshooting .....................................................................................................16

9.2 Computer technical data........................................................................................16

10 Disposal at the end of service ...................................................................................... 16

11 Guarantee terms.............................................................................................................18