69

13.1 Output adjustment

Bravo 400S can control chemical output with an automatic adjustment function (par. 13.2, DEFAULT:ON).

Bravo 400S keeps the set spray rate constant regardless from the changes in speed

and boom section status.

Rate manual regulation shall be carried out with the suitable

switch (par. 12.2).

In this case the spray rate can be set with the function F1 Spray rate (par. 16.1),

or by uploading a prescription map (par. 13.3) from one of the external memories

(SD card or pendrive).

If necessary, during spraying, it is possible to intervene on the dedicated switch

(par. 12.2) to adjust output to crop conditions, increasing

or decreasing momentarily the application rate up to ±50%.

F2 Enables / disables automatic output adjustment (DEFAULT:ON).

1

2

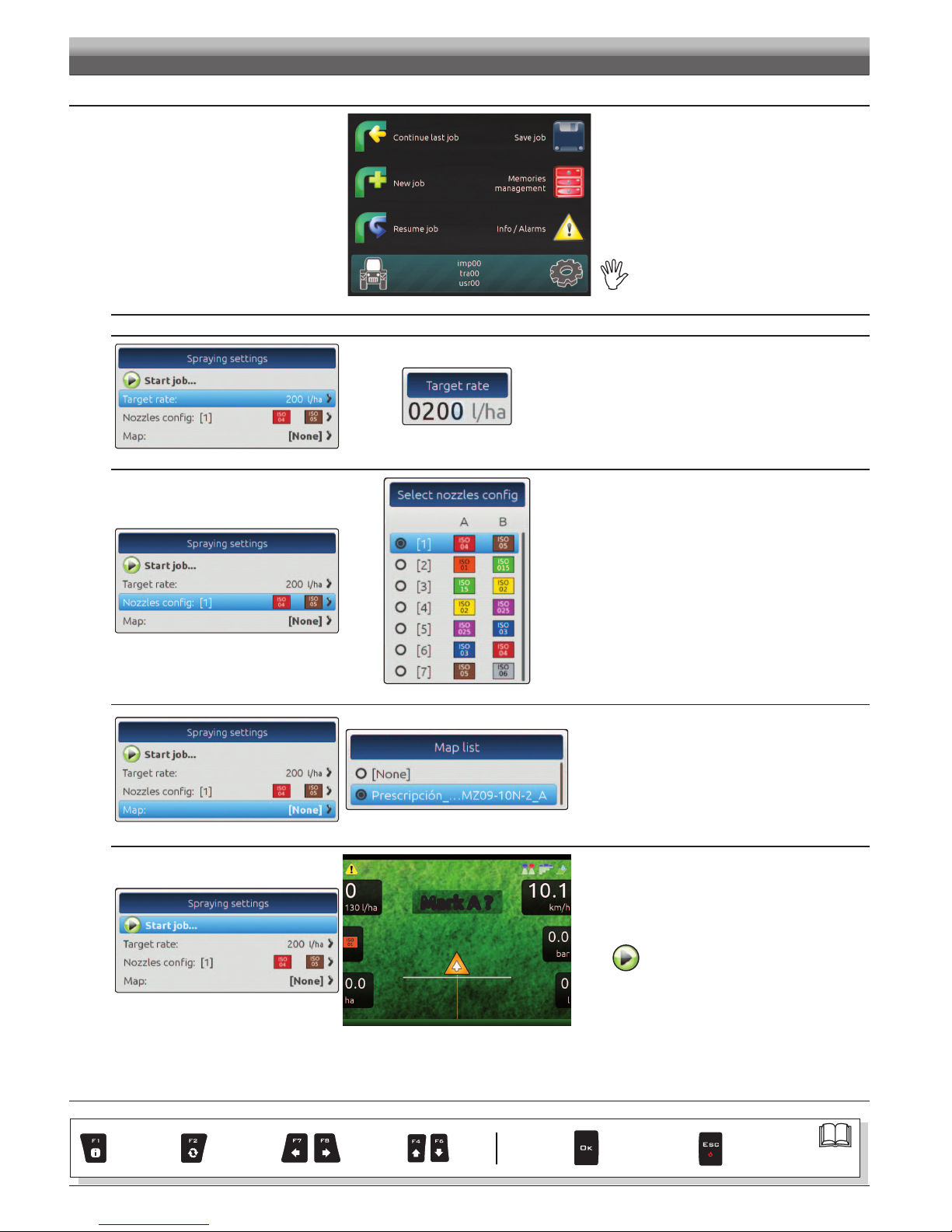

Fig.246

1In the guidance screen, press Auto.

2Press F2 (Fig. 246) to enable or disable automatic adjustment.

Automatic

adjustment ON

Automatic

adjustment OFF

13.3 Importing and using a prescription map

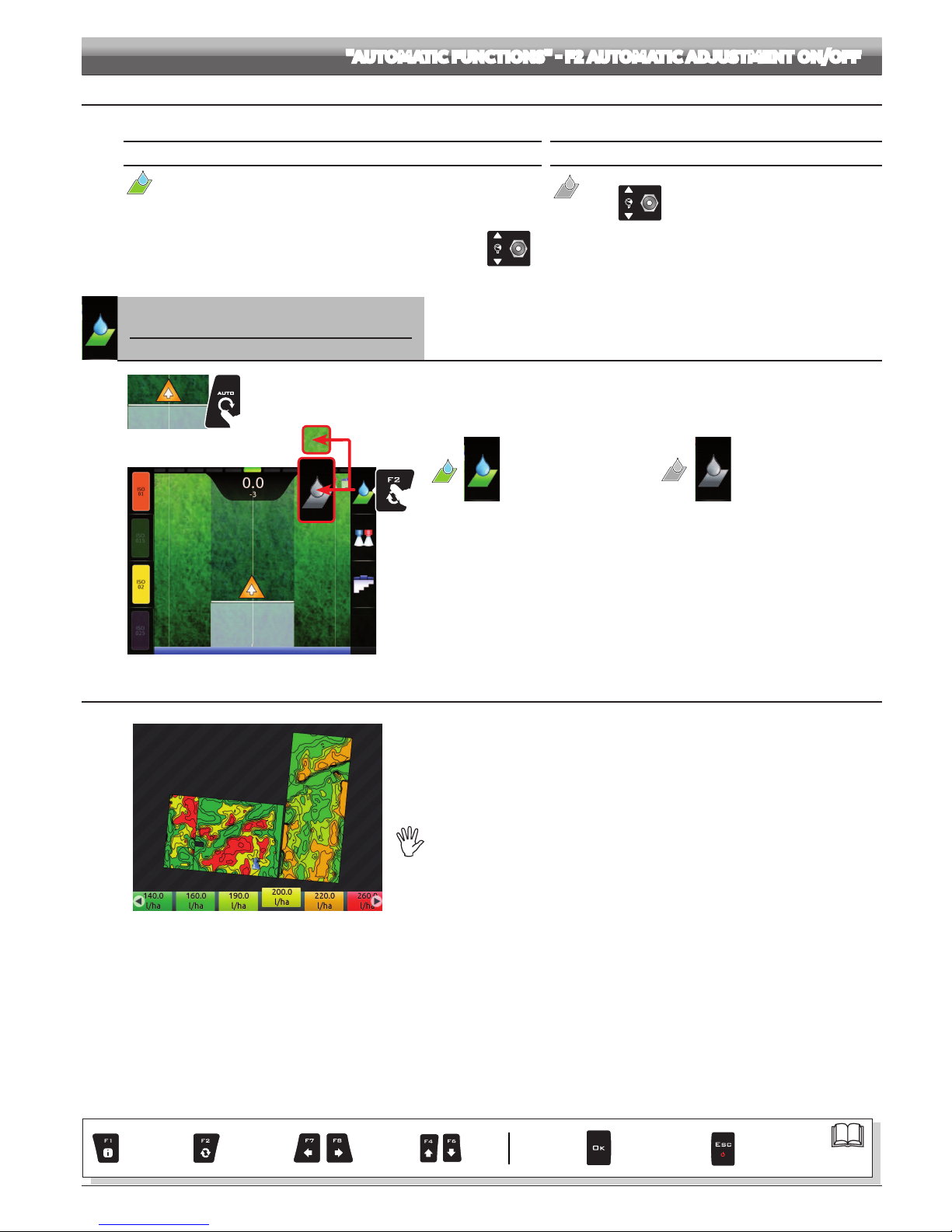

Fig.247

Bravo 400S can vary output by using the data contained in a "prescription map", which indicates

the exact quantity of uid that must be sprayed at every point in the eld.

The map is created thanks to a special analysis and simulation software. The correct spray rate

is established for every point on the map, in order to obtain the optimal yield from a eld with the

minimum expenditure in terms of materials and time.

To enable Bravo 400S to read and use the collected information, the following is required:

- The prescription map must be in " Shapele ESRI® " format.

- The database eld containing the indication of the spray rate that must be applied

to the different areas must be named "Rate".

- The database may include other elds, provided that these contain exclusively numerical

values (the presence of any alphabetic characters will prevent the database from being

imported correctly).

ESRI®isaregisteredtrademarkofESRI,California,USA

At this point you must transfer the prescription map from one of the external memories (SD card or pendrive) onto Bravo 400S:

• Save the map on one of the external memories.

• Copy the map onto the internal memory, through the menu Maps > Copy to internal memory (from SD card par. 14.4.2, or pendrive par. 14.4.3).

• Select one of the functions in the "Home" menu: F1 Continue last job (par. 14.1), F3 New job (par. 14.3) or F5 Resume job (par. 14.5).

• In the job start screen select the desired prescription map.

• Proceed with the job. According to the position detected by the GPS receiver, Bravo 400S will use the appropriate spray rate for the area that is

being sprayed (Fig. 247).

If the tractor is on a "black" area on the map, i.e., without a spray rate indication, Bravo 400S stops spraying.

Par.

7. 4

Exit function

or data change

Conrm access

or data change

Scroll

(LEFT /

RIGHT)

Delete

selected

character

Value

Increase /

decrease

Scroll

(UP /

DOWN)

Enter

selected

character