Turning the screw clockwise will lower the console. Turning the screw counter-clockwise will raise

the console.

GRINDING THE TUNGSTEN ELECTRODE

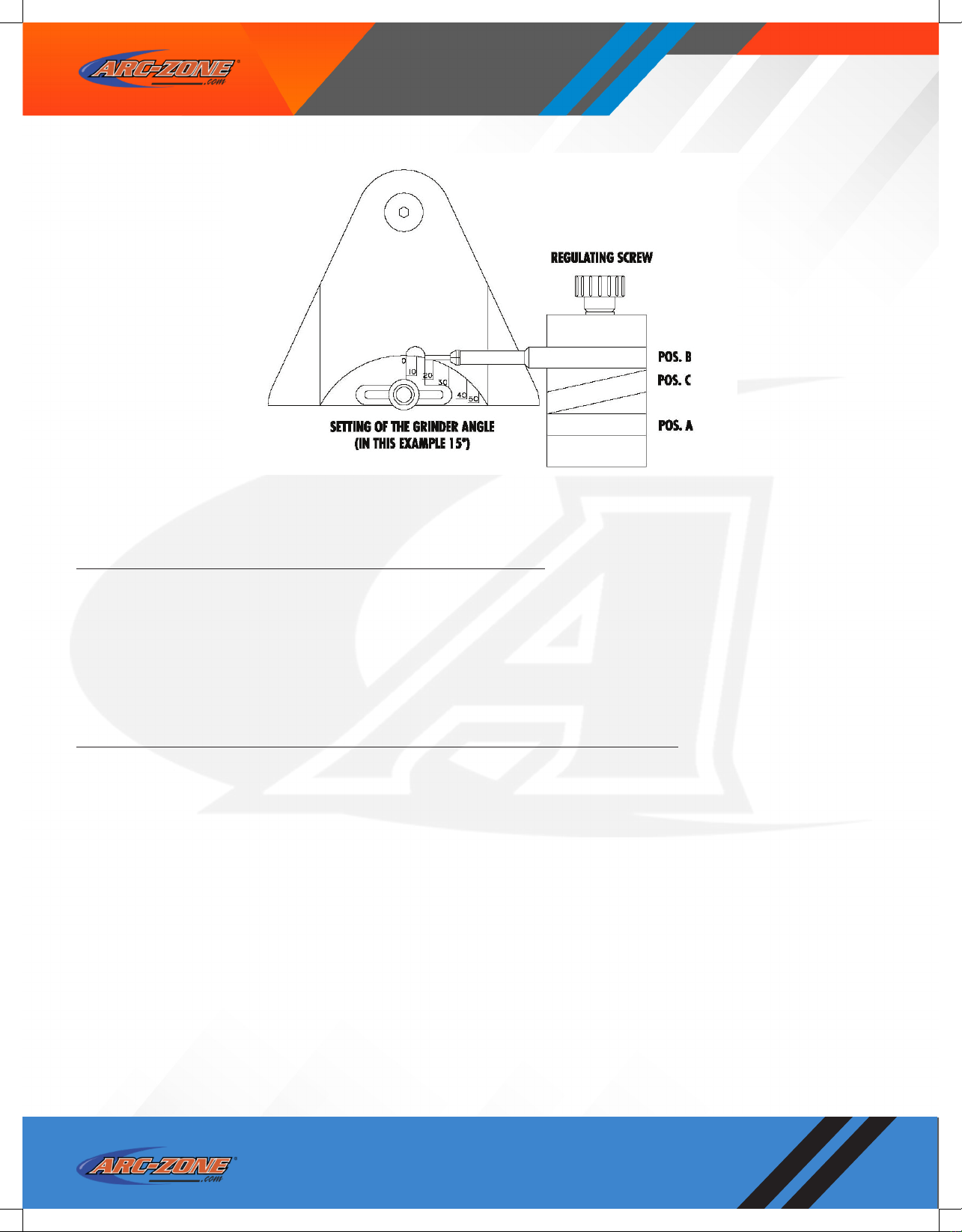

With the power switch is in the OFF position plug in the grinder. Move the power switch to the

ON position. Remove the electrode holder assembly, with the electrode tightened in place from

position “B” and insert it into position “A” (see Fig. 3).

While rotating the holder, use light pressure to feed the electrode into the grinding chamber so

that it contacts the grinding wheel. Continue to rotate the holder using light pressure against the

grinding wheel until the grinding operation is complete. This is indicated by the shoulder on the

electrode holder (or spacer piece) contacting the console.

When the grinding operation is complete, remove the holder and electrode from the machine with

a slight rotating motion. This will remove any excess grinding uid from the electrode.

Maintenance

MAINTAINING THE GRINDING FLUID

The Neutra LTG should always be lled with sufcient grinding uid. This ensures optimum dust

collection and adequate cooling of the diamond wheel. The correct level is between the MIN and

MAX indicators on the inspection cover frame #9. Check the uid level regularly and top up as

necessary. Only the original type grinding uid will ensure maximum grind quality and wheel life.

Periodically, the grinding uid should be drained off into a suitable, sealed container, through hose

#26 (Fig. 1) (it may be necessary to rotate the grinder onto its side to remove all of the uid). If

your grinder is equipped with the optional reservoir, remove and clean reservoir after draining uid

from main chamber. Rell reservoir with new grinding uid and install. Rell the grind chamber to

the MAX indicator line.

CAUTION: When performing this procedure tag the grinder so that it will

not be operated without uid!

Contaminated uid should be placed in a suitable container and disposed of according to the

standards set by your local authorities.

CLEANING THE GRINDING CHAMBER

After approximately 6 to 10 hours of operation the grinding chamber should be cleaned. Personnel

performing this operation should wear the necessary protective equipment.

Drain all grinding uid through hose #26 (Fig. 1) into a suitable container and dispose of properly

(it will be necessary to rotate the grinder onto its side to remove all of the uid). Remove screws

#38 (Fig. 1) , inspection cover frame #9 (Fig. 2) and plastic inspection cover #7 (Fig. 2). Clean

out the grinding chamber and rinse with clean grinding uid. If your grinder is equipped with the

optional reservoir, remove and clean the reservoir bottle. Rell with grinding uid and install.

Retain all grinding residue and uid in a suitable container and dispose of according to the standards

set by your local authorities.

Replace the inspection cover assembly and ll the grinding chamber to the proper level with uid.

Arc-Zone.com, Inc. • 1331 Specialty Dr • Vista, CA 92081 • Tel. 1.760.931.1500