5 / 12

t

Grinding a Tip Flat

Electrodes with tip ats deliver improved arc characteristics, longer tip life, improved

arc starting, and reduced tungsten contamination

FIGURE-4

The grinder is equipped with four holes: 040” (10mm), 1/16”

(16mm), 3/32” (24mm) and 1/8” (32mm) in the top housing to

produce a tip at on the end of the tungsten electrode

To Produce a Tip Flat:

Insert the tungsten into the correct size hole in the top of the

housing (

SEEFIGURE-4

)

Gently press the tungsten into the diamond wheel and rotate

for one 360º rotation while exerting pressure so the tungsten

touches the wheel Remove electrode and check for desired tip

at Repeat as needed

t

Cutting the Tungsten

Gently press electrode until it contacts the grinding wheel

rotating it to form a groove completely around the tungsten

While you can cut the electrode in half from one side it will cause excessive wheel wear and

shorten wheel life Instead, cut a groove around the electrode approximately half the thickness

of the material Turn unit o, insert electode into the appropriate size collet and gently snap the

tungsten in two Done properly, this procedure won’t splinter or damage the integrity of the

electrode material

Note: Take care when cutting electrodes so as not to bind the tungsten by wedging it

between the wheel and the machine housing

FIGURE-5

The grinder is equipped with a slot for cutting tungsten to length

or for cutting o contaminated portions

Note: To ensure the highest-quality welds, cut contaminated

portions of the electrode prior to sharpening so as not to

contaminate the diamond wheel

Place electrode in the angle slot so the desired portion of the

tungsten to be cut lines up with the edge of the diamond wheel

(

SEEFIGURE-5

)

Note: Reset grind angle after adjusting the contact point to an

unused surface of the grinding wheel

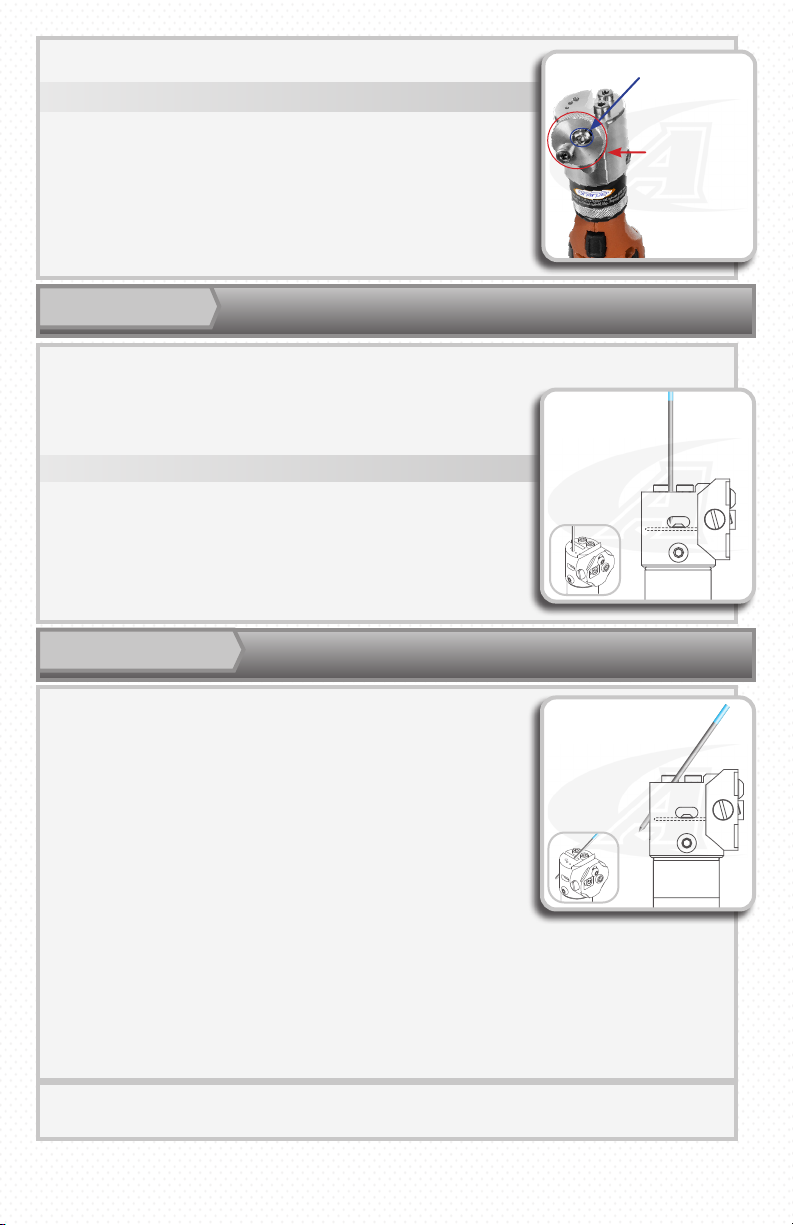

For A Long Taper

Loosen the collet disc screw and lower the collet disc so the point

of entry of the tungsten is closer to the diamond wheel

(

SEEFIGURE-3

)

Note that the lower the disc, the longer the point Conversely,

the higher the disc, the shorter the angle

Note: For a longer angle taper, the tungsten must contact the

outer most diameter of the wheel because a longer taper requires

more contact with the grinding surface

FIGURE-3

2-Lower and

rotate the

collet disc

to change

the contact

point on the

grinding wheel.

1-Loosen set

screw to rotate

the collet disc