Arch Pulsar 3 series User manual

Operator's Manual

Model #PS 5000

9.3.14

Arch Chemicals, Inc.

1200 Lower River Road

Charleston, TN 37310-0800

1-800-4-PULSAR

Lonza is committed to maintaining and improving our leadership in the

stewardship of our products. One of our initiatives is to make health, safety, and

environmental protection an integral part of a product’s life cycle – from

manufacture, marketing, and distribution to use, recycling, and disposal.

Everyone involved with the product has responsibilities to address society’s

interest in a healthy environment and in products that can be used safely. We are

each responsible for providing a safe workplace. All who use and handle products

must follow safe and environmentally sound practices.

For more information about the stewardship of our products, contact your Lonza

Representative.

Product Stewardship

“Making the World a Better Place"

is now a part of

www.lonza.com

ey Work

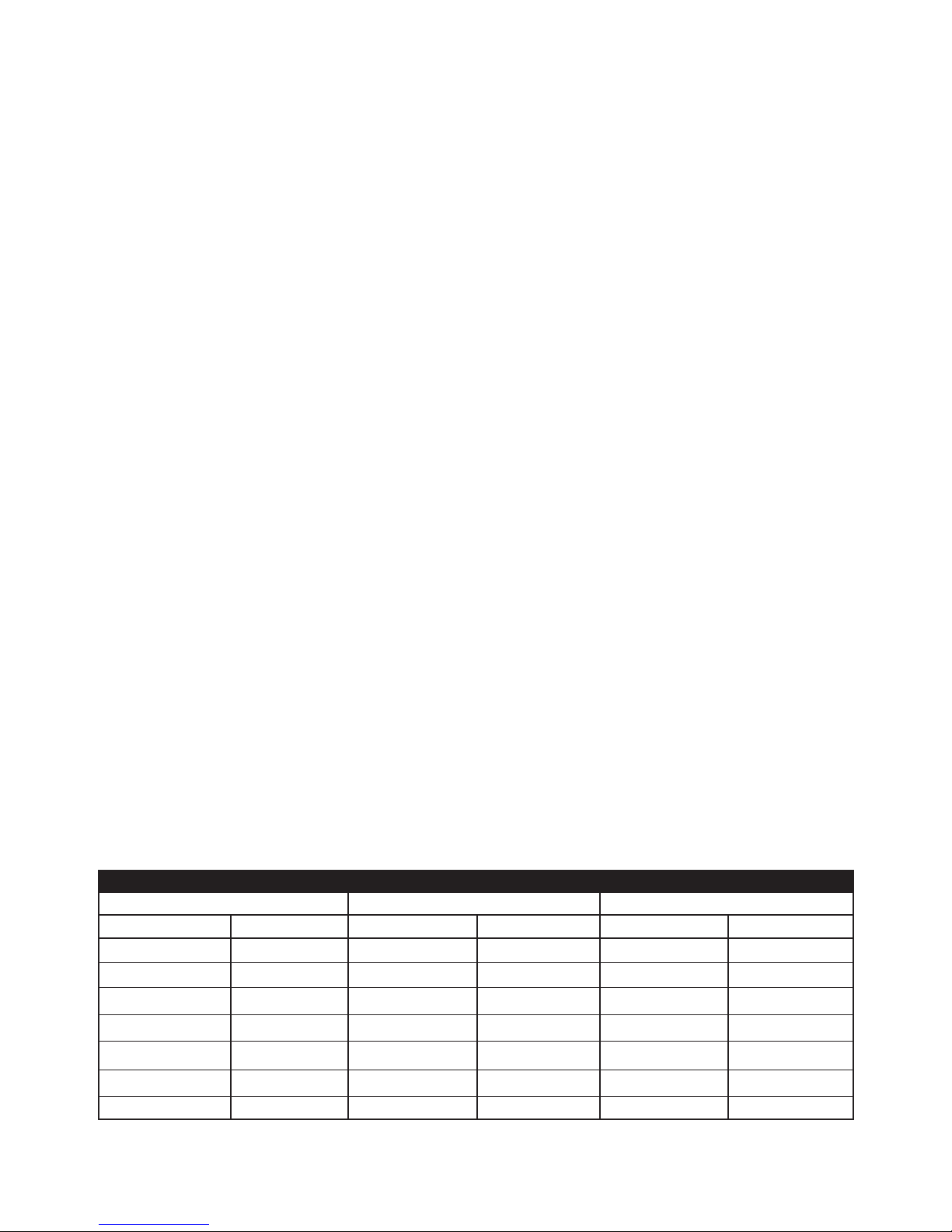

All Figures in Chart (below right) represent Chlorinator Output in Pounds of Available Chlorine Per Day.

– 1 –

General Principles of Operation

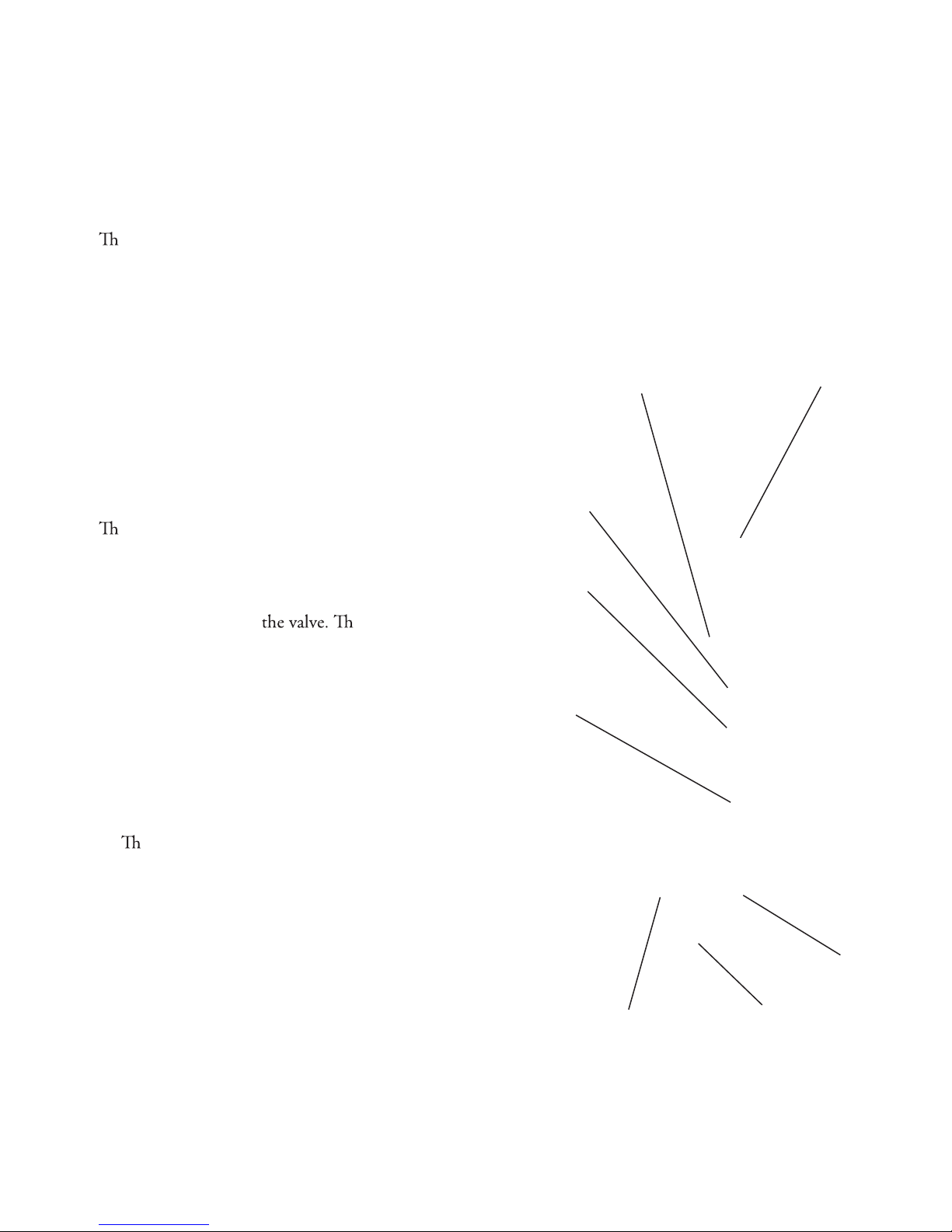

e three main components of the Pulsar® 3 Chlorinator

are (from top to bottom) the briquette tank, the manifold

e water from the

pool enters the Pulsar® 3 Chlorinator via the emergency

shuto e water then splits to feed the spray

e spray

manifold then distributes the water onto the briquette bed

e chlorinated solution

falls into the discharge tank and is discharged into the

e amount of chlorine

discharged is determined by the ORP controller or the

Timer/Solenoid Assembly. Inlet water pressure of 17 to 45

psi is required to provide sucient flow into the Pulsar® 3.

ese pressures will result in an inlet flow of 1.6

gallons/minute. e Pulsar® 3 feed rate settings referred to

in the Pulsar System Owners manual are calibrated for this

flow rate. Flow out of the Pulsar® 3 Chlorinator requires

vacuum to properly evacuate the discharge tank. A minimum

outlet flow-rate of 1.7 gallons/minute ensures that the flow

out of the Pulsar® 3 exceeds the flow in. Once the Pulsar® 3

has been installed the outlet flow can be measured by

watching the level in the bottom tank. If the level is

rising as the feeder is running, there is insucient

flow out.

Pounds of Available Chlorine Per Day

Upper Timer

Knob Setting

“Normal” Bottom

Knob Setting

“Low” Bottom

Knob Setting

“High” Bottom

Knob Setting

A B C D E F G

55 14 3.2 1.7 1.3 1.1 1.0

90 24 6.5 3.6 2.5 2.0 1.8

120 30 7.4 4.1 3.0 2.4 2.2

Inlet:

Emergency

Shut-Off Valve3

Briquette

Hopper

Outlet:

Discharge

Valve

Discharge

Tank

SPECIFICATIONS − Model PS 5000

Operational Requirements:

Inlet pressure (Range) 17-45 psi

isp03laedI

Outlet Vacuum 5-29" hg

Operating Temperature 40-130˚F

Operational Characteristics:

Inlet flow 1.6 gpm

Outlet flow (Min.) 1.7 gpm

Note: To maintain NSF approval a flow

indicator must be installed.

Dimensions:

Tubing 1/2" O.D.

enelyhteyloP

Chlorinator diameter 19"

Chlorinator height 33"

Chlorinator weight (full) 125 lbs

Chlorinator weight (empty) 27 lbs

Capacity

62 lbs Pulsar Plus Dry Chlorinator

Briquettes (equivalent 40 lbs. available

chlorine per day)

Feed Rate:

Pulsar Plus Briquettes 1.0 - 120 lbs of

Available Chlorine per day

Recommend Pool Size1

10,000−4000,000 gallon unstabilized

10,000−1,500,000 gallon stabilized

1Subject to local health codes.

Pre Start-Up Checklist

Following the procedure outlined below will ensure a smooth start-up of the Pulsar 3 Chlorinator. For

seasonal operation, perform this procedure each spring.

IMPORTANT!!

Do NOT put Pulsar Plus Briquettes in the chlorinator during the start-up operation

Inlet Water Flow

e inlet water flow system is designed to provide a steady side-stream of clean filtered pool water to the

chlorinator.

1. Switch on the pool recirculation system and open all valves to the chlorinator.

2. Check the flow indicator (if present) of the Pulsar system to see that water is flowing into the

chlorinator

3. Check to see that the three nozzles are

spraying water onto the Briquette-Tank grid

and water is flowing from Solids Removal

Manifold.

4. Check all lines leading to the Chlorinator

for leaks. hand tighten all fittings if any leaks

are found.

Outlet Water Flow

e float on the Discharge Valve rises with

the water level and allows the pump suction

to draw the chlorinated water into the pool's

recirculation system as the Discharge Tank fills

with water. When the water level drops, the

float falls, shutting o e Discharge

Valve also contains a check valve to prevent

pool water from backing up into the Discharge

Tank. Use the following procedure to ensure

that the outlet water flow system is operating

properly.

1. With the briquette hopper and deflection

plate of the chlorinator temporarily out

of the way, fill the Discharge Tank with

sucient water to open the Discharge Valve

- use a hose or pail.

2. e float should rise, opening the Discharge

Valve, allowing water to be drawn out by

the Pulsar evacuation system (or venturi on

2" or less piping).

3. Check the system for leaks. If small air

bubbles are visibly moving, there may be

an air leak. Tighten the connections and

make sure the tubing is properly installed in

the fittings. (NOTE: Air bubbles near the

Pulsar 3 Chlorinator body that do not move

are normal and do not indicate leaks.)

4. Check to see that water is flowing through

both nozzles of the solids removal system.

5. Check for air leaks after the Discharge

Valve closes.

– 2 –

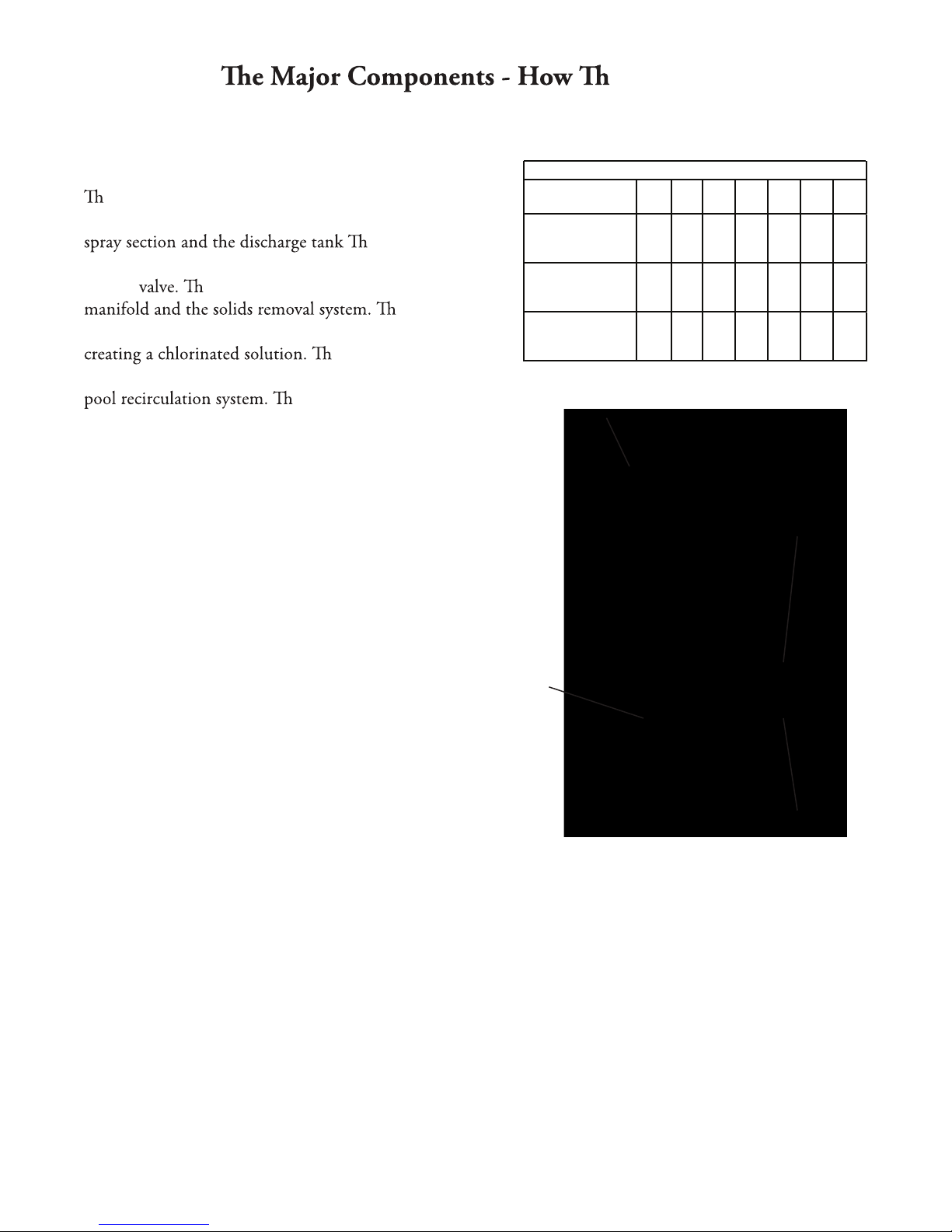

Briquette

Tank

Briquette

Grid

Spray

Manifold

Deflection

Plate

Emergency

Shut-Off

Float

Inlet flow

Outlet Flow

to Venturi

Discharge

Valve

Solids Removal

Manifold

Discharge

Float

After completing the PRE-START-UP CHECKLIST, and establishing that all components of the chlorinator are

operating properly, your PULSAR® 3 Chlorinator is ready for start-up. Routine maintenance of the PULSAR®

3 Chlorinator is minimized when proper pool water balance is maintained. Maintain pool water chemistry as

follows:

Total Alkalinity 60-80ppm

Calcium Hardness 200-1800ppm

pH 7.2-7.6

Adherence to these recommendations at all times will ensure the most effective and economical performance from

the PULSAR® 3 Chlorinator.

NOTE: e use of CO2 to lower pH will raise Total Alkalinity. High total alkalinity (over 80 ppm) will increase

scale and solids buildup in chlorinator.

WARNING: Use ONLY Pulsar® Plus Briquettes in the Chlorinator. e use of any other treatment chemicals

will void the warranty. DANGER: Under no circumstances mix calcium hypochlorite with other forms of

concentrated chlorine or other chemicals. Fire and/or explosion may result. Caution must be used when refilling

dispenser.

KEEP OUT OF REACH OF CHILDREN

1. Fill the Briquette Tank with Pulsar® Plus Briquettes. e Briquette Tank holds 62 pounds of briquettes.

2. Check the chart below to determine an approximate start-up timer setting for your pool (or be certain that

the ORP Controller is calibrated and the set-points are correct). Set the Upper and Lower Timer Knobs at the

recommended setting.

NOTE: For best chlorinator performance, use the “normal” bottom timer setting. is will assist in maintaining desired

Free Available Chlorine level in pool and help maintain chlorinator maintenance.

3. Open all valves to the pool and to the chlorinator.

4. Monitor the water flow to the chlorinator daily to ensure that a proper flow is being maintained.

5. During the first few days of operation, check chlorine level in the pool frequently to establish the best Timer

setting (or ORP Controller setting) for your pool. Adjust the chlorine output either up or down according to

the table or, adjust the ORP setpoint.

– 3 –

Recommended Start-Up Settings

Pool Size in thousands of gallons (000)

High Bottom Timer Setting Low Bottom Timer Setting Normal Bottom Timer Setting

Unstabilized Stabilized* Unstabilized Stabilized* Unstabilized Stabilized*

492

86

30

18

12

—

—

1,800

440

116

60

43

37

30

370

67

24

12

—

—

—

1,353

350

98

43

37

30

25

220

37

12

—

—

—

—

836

197

50

25

20

17

12

*Do not exceed 25 ppm stabilizer

Start-Up Procedures

– 4 –

Pulsar®3 Chlorinator Inspection & Maintenance

Calcium Hypochlorite by the nature of its manufacture, contains a small amount of calcium carbonate. Proper

water balance will minimize the buildup of calcium carbonate solids in the Pulsar® 3 Chlorinator, however,

periodic cleaning of chlorinator components is normal and recommended. e following is a list of the parts to be

cleaned and the proper procedures to do so.

SECTION A

Cleaning PULSAR® 3 Chlorinator with PULSAR® Plus Acid Cleaner 50

Inspection: e solids build-up and cleaning frequency required for the unit will depend on the amount of

Briquettes used and the pool water chemistry. Described below is the easiest way to remove solids and minor scale

buildup using the PULSAR® Plus Acid Cleaner 50.

WARNING

Do NOT use Muriatic Acid to perform the following procedures.

Chlorine gas may evolve causing serious injury or possible death.

Maintenance Procedure Steps:

1. Close the inlet and outlet shutoff valves to the chlorinator.

2. Lift the Briquette Tank off of the Spray Manifold Section and Discharge Tank and pour the contents into a clean

dry bucket. Be sure to remove all pieces of briquettes or tablets. If necessary, rinse any heavy solids buildup from

the tank before proceeding.

3. Remove briquette grid and place in black tub (provided with system). Fill with 1 gallon of water. Slowly pour ½

quart PULSAR® Plus Acid Cleaner 50 into tub and ½ quart PULSAR® Plus Acid Cleaner 50 into discharge tank.

Frequent agitation may be required to dissolve solids and scale. Allow acid to dissolve solids and scale, evident

by the foaming action. After 5 to 10 minutes, check for presence of scale on grid. If necessary, add additional

PULSAR® Plus Acid Cleaner 50 to dissolve any remaining scale or scrape with putty knife.

4. Pour the solution from tub into the discharge tank. Dispose of scale with backwash from filter.

5. Place the Briquette grid back into bottom of hopper.

Rinse the Briquette grid thoroughly with water and

open the inlet-shutoff valve to allow the spray to

rinse the grid from the bottom. e solution from the

Discharge tank will clean the discharge valve, tubing

and venturi when system is restarted.

6. Pour Pulsar® Plus Briquettes from bucket back into

Briquette Tank. Resume operation.

7. Open inlet and outlet shut off valves to the chlorinator.

NOTE: To increase the period between Grid cleanings,

allow Briquette Tank to completely empty once a week.

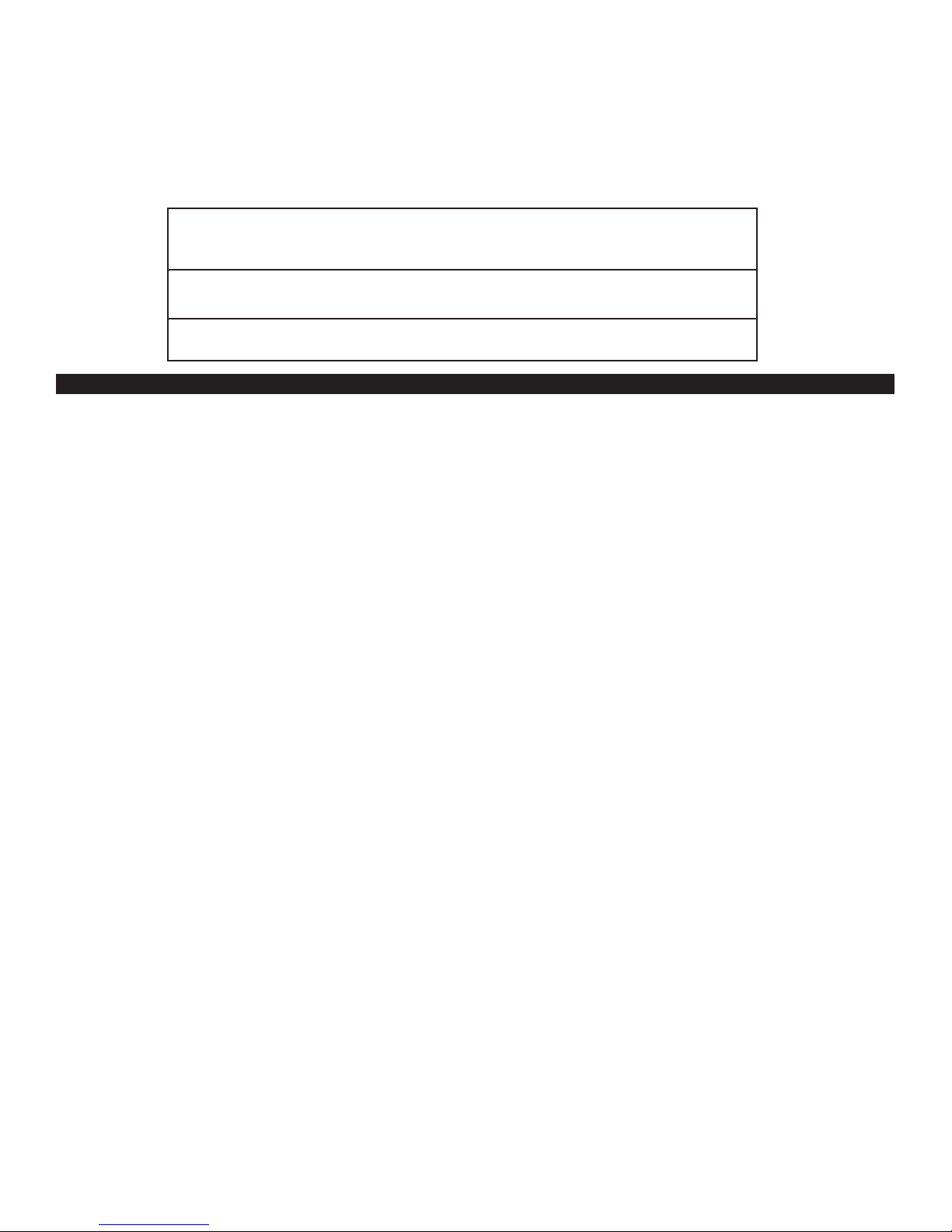

Table of Contents

Suggested

Inspection

Frequency

As Needed

As Needed

Section

Section A

Section B

Contents

Use of Pulsar Plus Acid Cleaner 50 to remove solids

and scale from the Pulsar 3 Chlorinator

Troubleshooting Guide

– 5 –

SECTION B

Troubleshooter's Guide

Problem Cause Solution

Insufficient water

flow to chlorinator

Excess chlorine in pool

Air leaks

Chlorinator overflow

Check water flow through spray nozzles Clean spray nozzles with compressed air.

Do not use mechanical cleaning method.

Inlet Shutoff Valve closed Open Inlet Shutoff Valve

Emergency Shut Off Valve in closed position If ESV Valve is stuck, lower gently to reset

Solenoid Valve not operating

Check with Dealer

Feed rate/output too low Increase feed rate/output on timer or ORP

Chlorinator empty Refill Briquette Tank with Pulsar® Plus

Briquettes

No inlet water flow See insufficient water flow section

Outlet/Shutoff Valve closed Open Outlet Shutoff Valve

Clogged Discharge Tubing Refer to Section A or Replace

discharge tubing

Briquettes stuck together Tap side of Briquette Tank to loosen

Clogged Briquette Tank Grid Refer to Section A

Clogged Venturi System Remove venturi – soak in tub with 50/50

mixture of water and Pulsar Plus Acid

Cleaner solution.

Closed valves in venturi system Open venturi system valves

Automatic Controller Problem Refer to automatic controller manual

Feed rate/output too high Decrease feed rate/output on timer

Discharge Tubing not properly installed in fittings Reinstall Discharge Tubing

Discharge Valve seat failure Replace Discharge Valve Arm

Scale prevents Discharge Valve from Remove Discharge Valve Assembly and soak

properly seating in dilute acid to remove scale

Pinched O-rings in Tubing Connectors Inspect O-rings on discharge side of feeder

Discharge Tubing clogged Refer to Section A or Replace Discharge

tubing

Clogged venturi system See clogged venturi system solution

Insufficient outlet suction Check with Dealer

Emergency shutoff valve failure Check with Dealer

Insufficient chlorine

in pool

WARRANTY POLICY

Pulsar® 3 Commercial Pool Chlorinator

Arch Chemicals, Inc. (“Arch”) warrants equipment of its manufacture and bearing its identification to be free of defects in workmanship and material.

Arch’s liability under this warranty extends for a period of two (2) years (excluding electrical components which carry a 1 year warranty) from the date

of installation as performed by an Authorized Commercial Dealer Representative and registered with Arch Water Chemicals via the Arch Commercial

Chlorinator Warranty Registration Card. Systems for which there is no Warranty Registration Card on file carry no warranty of any kind, expressed or

implied.

In addition, each system is covered by a sixty (60) day, 100% buy-back guarantee. If the original purchaser (“owner”) is dissatisfied with the Pulsar® 3

Commercial Pool Chlorinator performance for any reason, they can return it to the Authorized Commercial Pool Dealer for a full refund. e equipment

must have received normal use and care, and Arch must be notified in writing before the sixty (60) days have expired. ere is no reimbursement for

chemicals used during the sixty (60) days. Arch disclaims all liability for damage during transportation, for consequential damage of whatever nature,

for damage due to handling, installation or improper operation, and for determined suitability for the use intended by purchaser (“owner”). Arch makes

no warranties, either expressed or implied, other than those stated above. No Arch Representative or Authorized Commercial Dealer Representative has

authority to change or modify this warranty in any respect. Pulsar® 3 Parts

Arch warrants equipment parts of its manufacture and bearing its identification to be free of defects in workmanship and material. Arch’s liability under

this warranty extends for a period of ninety (90) days from the date of installation as performed by an Authorized Commercial Dealer Representative.

is warranty is restricted to Pulsar® 3 Chlorinator Parts purchased on a replacement basis.

Arch Water Chemicals, Inc.

1-800-4 PULSAR

– 6 –

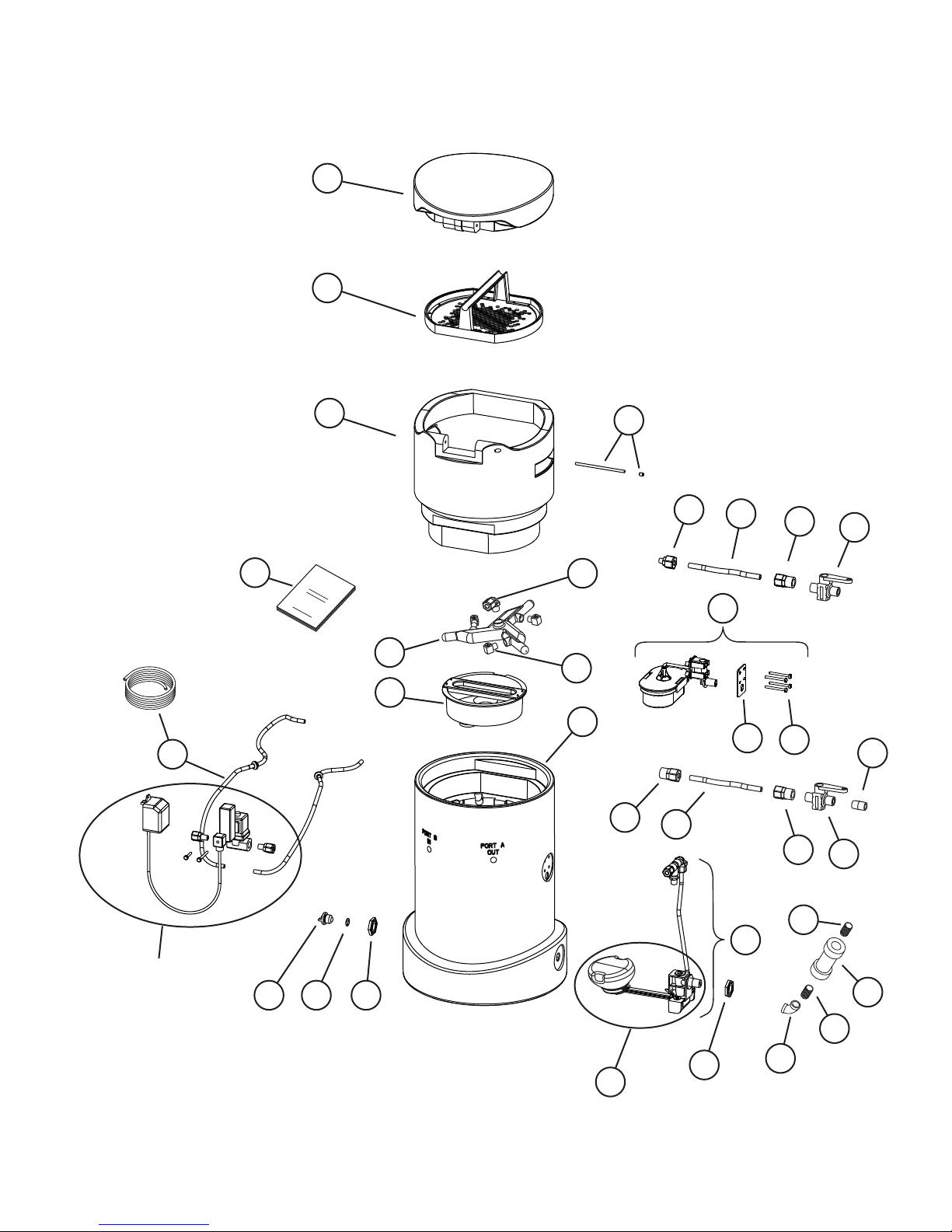

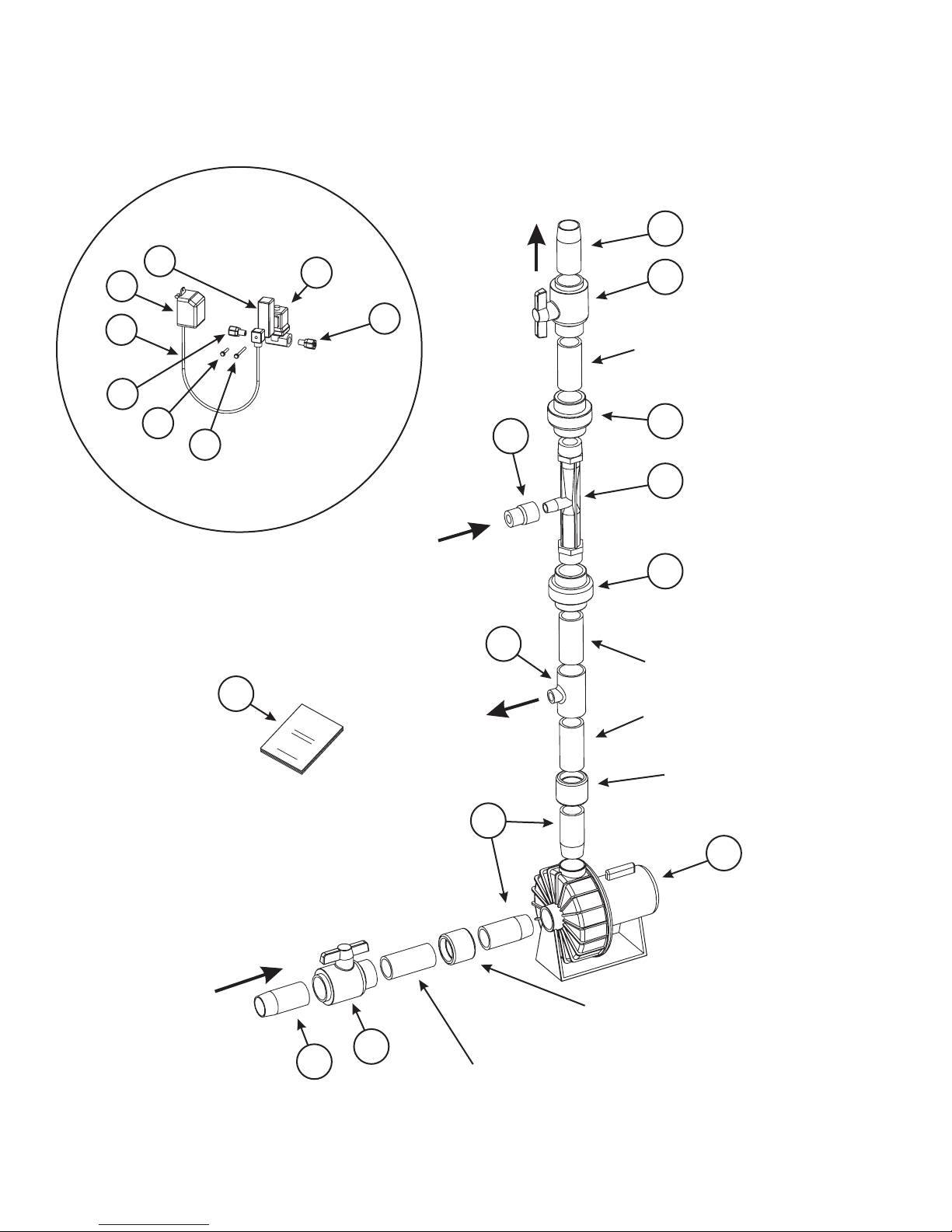

Pulsar®3 Feeder Detailed View

17

2

3

7

8

13

37

Pulsar 3

Operator’s Manual

1

4

36 5

6

9

24 26 28 25

18 46

47

47

48

30

28 26

28 27

29

50

20 19 18

21

solenoid assembly

(included with

installation

kit only)

17

50

37

– 7 –

22

23

49

10

32

45

33

31

44 39

42

40

43

12

11

42 39

41

38

16

30

(not included)

(not included)

14

15

– 8 –

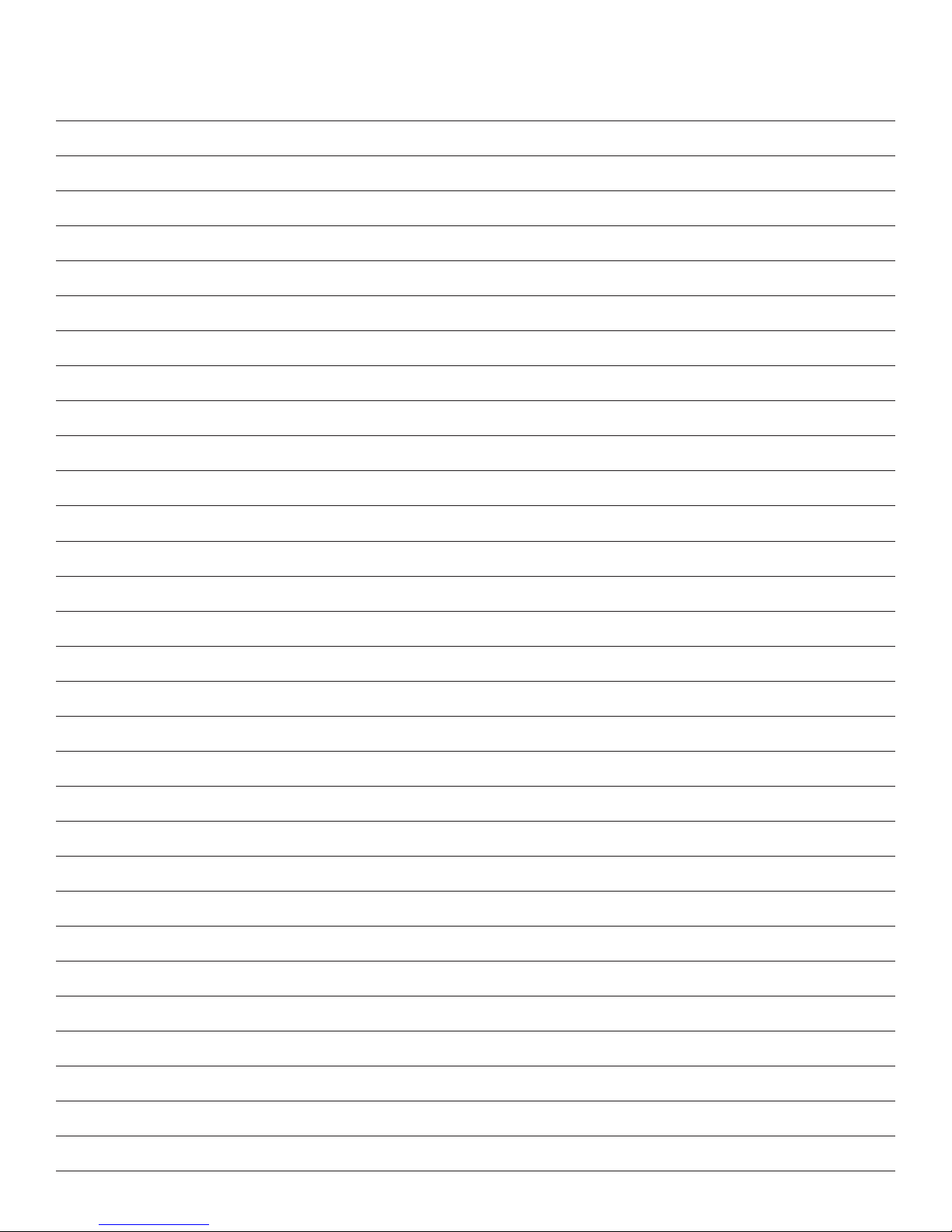

Pulsar®3 Installation Kit

4

flow

to pool

solenoid assembly

6

1½ coupling slip x slip

(installer provides)

6

7

4

cut 1½ “ PVC pipe

(installer provides)

cut 1½ “ PVC pipe

(installer provides)

cut 1½ “ PVC pipe

(installer provides)

3

2

3

1

wolf

loopmorf

wolf

redeefmorf

wolf

redeefot

6

5

P raslu 3

Instalaltion

launaM

12

1½ coupling slip x slip

(installer provides)

15

13

9

10

13

11

14 8

Pulsar®3

– 9 –

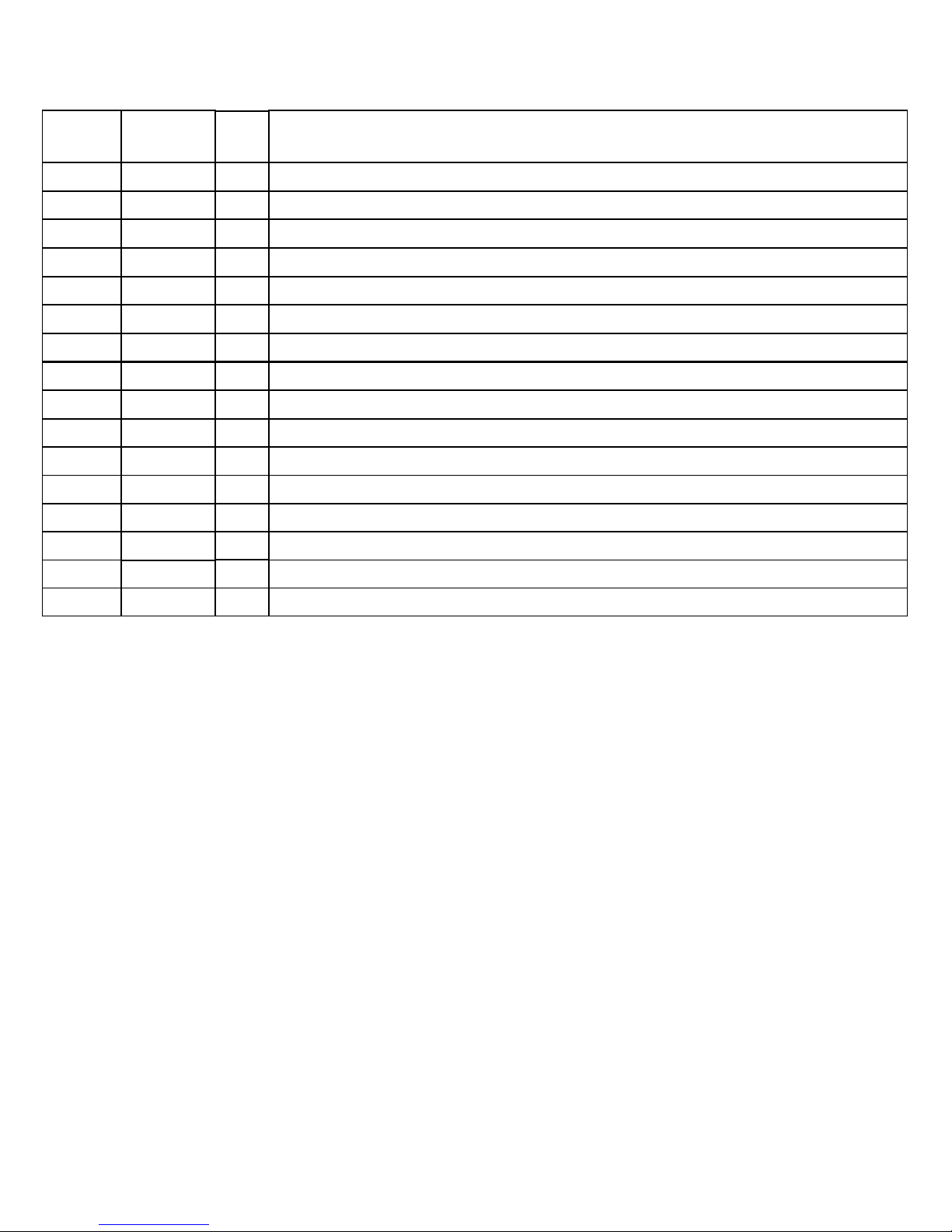

Diagram

Number

Part

NumberDescription

Qty

071528 Pulsar 3 System, PS 5000-Includes Installation Kit

1

171608 Hinge Rod W/Set ScrewforP3 Hopper

1

271607 Lid for P3

1

371609 Briquette Screen Assembly for P3

1

471606 Hopper without Lidfor P3

1

571619 Elbow (P6ME6) 3/8" ForFeeders 30991 & P3

2

671617 Spray Nozzle forP3

3

779047 Manifold forP3

1

871620 Deflection Plate Assembly

1

971610 Base without assembled parts for P3

1

10 79806 Discharge Valve Body

1

11 71536 Emergency Shut O Mounting Plate

1

12 71535 Emergency Shut O Valve with Arm Only

1

13 71537 Emergency Shut O Mounting PVC Screws(1/4x20x2 1/4)

4

14 71539 Emergency Shut O Float Plate

1

15 71538 Emergency Shut O Float Plate PVC Nut

1

16 71540 Emergency Shut O Overflow Float

1

17 71496 Emergency Shut O Valve Assembly - Part 71910 Not Included

0

18 71583 Discharge Valve Locknut

2

19 71613 (4026) O-Ring #115 - Used in Plug

1

20 71612 Plug for FeederBody for P3

1

21 71558 3/8" O.D. Polyethylene Tubing - 20'

1

22 79805 Discharge Valve Arm

1

23 Discharge Valve Float

1

24 71614 Tube Connector (P8MC4)for P3

1

25 71621 1/2" Ball Valve MM (Inlet)

1

26 71626 20' 1/2" O.D. PE Tubing(P4 only need 3 inch piece)

1

27 71627 1/2" Ball Valve MF (Outlet)

1

28 71588 (5008) 1/2" X 1/2" Female Connector (P8FC8)

3

29 71611 1/2" X close PVC Nipple

1

30 71910 Rubber Gasket for Emergency Shut O Valve1

31 72863 Discharge Valve Enhancement Adaptor

1

32 75860 10-32X5/8" PVC Screws (Packaged 4)2

33 72865 Custom Washer for Discharge Valve Adapter

2

71373 Cleaning pan for Briquette Grid (Pulsar 3) - not shown in diagram

1

79808/79810

Pulsar®3

Diagram

Number

Part

Number

DescriptionQty

71598 (8001) Scoops (Pulsar Accessory)- not shown in diagram1

36 71622 Operators Manual for P3 System1

37 72864 P3 Enchancement Kit0

38 71900 Parker tting W6ME41

39 71968 1/4" Threaded PVC Tee with Nipple2

40 72862 Spray Nozzle (Lechler 632.364.5E.BC)1

41 71572 (3045) Reducing Bushing (3/8"x1/4") For Feeder 30025 (PPI)&P3 Enhancement K1

42 71582 (4014) Parker Fitting P6MC42

43 72861 Spray Nozzle (Lechler 632.564.5E.BC)1

44 71563 (3002) PVC Elbow For Feeders 30025, 30991and P3 Enhancement Kit1

45 71574 (3103) 3/8" P.E. Tubing E-64-0500 (13.5")1

46 79222 1 45ºPVC Threaded Elbow

47 71916 2 1/2” NPT PVC Closed Nipple

48 79218 1 Check Valve (True Union)

49 71576 1 Discharge Valve Body Gasket

50 79804 0 Discharge Valve Assembly

– 10 –

Pulsar®3 Installation Kit

Diagram

Number

Part

Number

DescriptionQty

0 71531 Installation Kit for Pulsar 3 System1

1 Horsepower Pump for Pulsar System Installation1 79214 1

2 71811 Venturi for Pulsar Systems1

3 71907 Unions(Quick disconnects) Venturi (Slip X Thread)2

4 71913 1 1/2" Slip PVC sch40 ball valves2

5 71547 1 1/2" X 1/2" Schedule 80 PVC T SXF1

671548 1 1/2" X 12" PVC Nipple2

7 71917 3/4" FNPT X 1/2" FNPT PVC Reducer1

8 71894 Solenoid (24 VAC) Pulsar Line1

9 71525 Screw (Long) M3X55, Timer/Solenoid Assembly1

10 71526 Screw (Short) M3X32 Solenoid Assembly Only1

11 72329 15 ft Pre-Molded Cable (24V AC Transformer to Solenoid)1

12 71658 Installation Manual for Pulsar 3 System1

13 71590 (5023) 1/2" X 3/8" Male Connector (W6MC8)-Parker2

14 71923 24V AC Transformer/Plug US1

15 71689 Timer - 24V AC1

P3 Notes:

Lonza Emergency Action Network (LEAN)

The Lonza Emergency Action Network (“LEAN”) is Lonza’s emergency action system. Call the

LEAN system at 1-800-654-6911) in North America, and at (Country Code for the United States)

423-780-2970 elsewhere in the world. The LEAN system is available 24 hours a day, 7 days a week

for assistance with spills, injuries and emergencies of any kind. It uses computers and other systems

to make Lonza’s environmental, technical transportation, toxicological and other expertise about its

products readily available to anyone needing assistance. The LEAN system also includes emergency

response teams capable of providing on-site support throughout North America.

(800) 654-6911

(From outside North America, call after the country code for the US, 423-780-2970)

Additionally, in the event of an emergency, CHEMTREC (ChemicalTransportation Emergency Center)

should be contacted. CHEMTREC is a national center established by the Chemical Manufacturers

Association (CMA) in Washington, DC, to relay pertinent emergency information concerning specific

chemicals on request.

CHEMTREC has a 24-hour toll-free telephone number (800) 424-9300, intended primarily for use

by those who respond to chemical transportation emergencies. CHEMTREC may also be accessed

through the CMA website at www.cmahq.com.

Material Safety Data Sheets (MSDS) can be obtained by contacting (800)-511-MSDS.

Pulsar®is a registered trademark of Arch Chemicals, Inc. which is now part of Lonza. The configuration of the briquette-shaped chemical tablet is a

registered trademark of Arch Chemicals, Inc. 9/14

This manual suits for next models

1

Table of contents