Installing these on any other dispensers will void warranty and may pose

potential risk fire or electric shock. DO NOT INSTALL if the dispenser is not one

of the dispensers listed on the lighted valance sign label.

IMPORTANT SAFEGUARDS - READ AND FOLLOW ALL

SAFETY INSTRUCTIONS

•Failure to follow these instructions can result in injury or death.

When using electrical equipment, basic safety precautions should

always be followed including the following:

•Product must be installed in accordance with NFPA 30A, NFPA 70

NEC, and your local electrical code by a qualified electrician trained

for performing installation or service on petroleum dispensers and

related equipment.

•To avoid the possibility of electrical shock, turn off power supply

before installation or servicing. Multiple disconnects may be

required. Physically lock, restrict access to, or tag the circuit

breakers you turn off when servicing the dispenser.

•Replace and secure all electrical enclosure covers before restoring

power.

•Remove all metal shavings created during installation process.

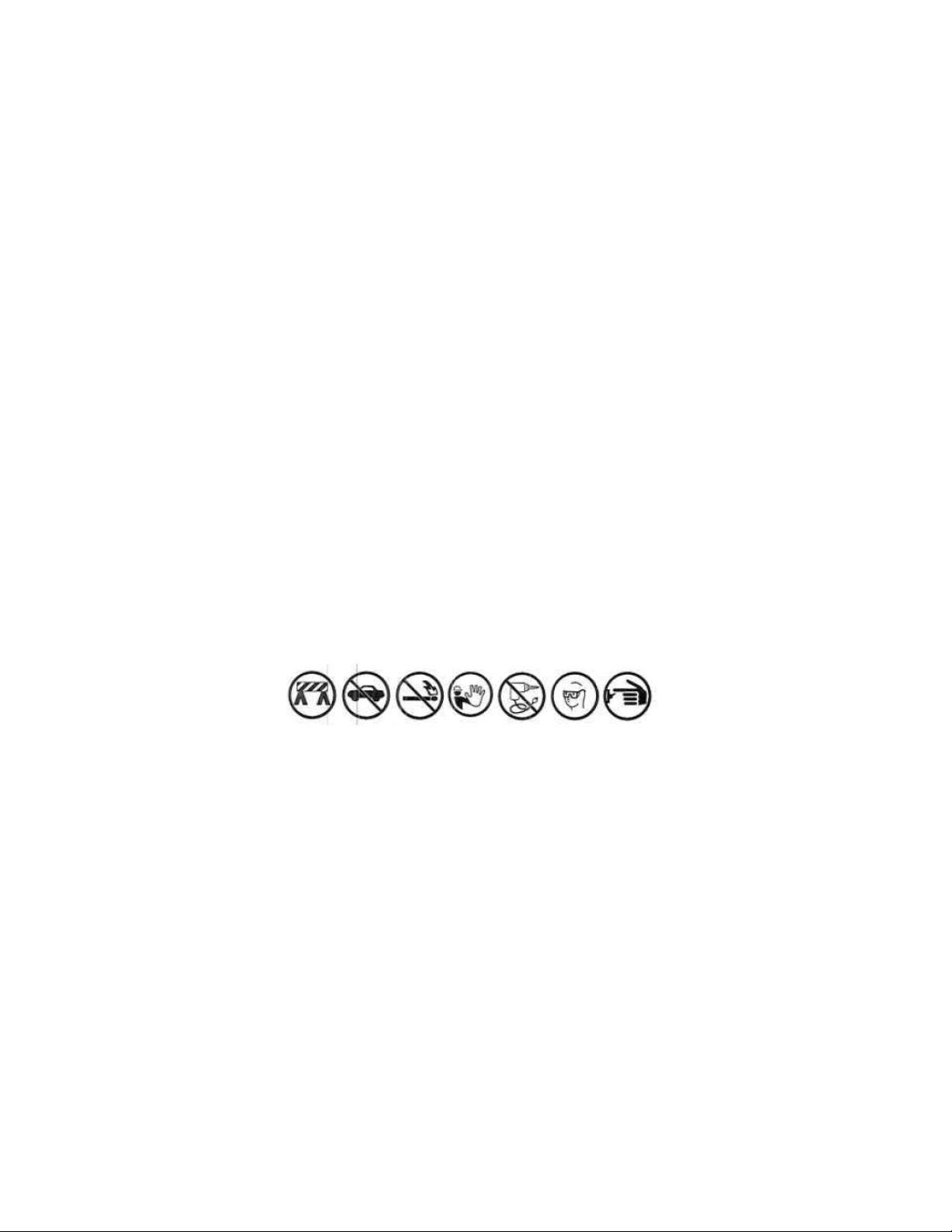

•Barricade work area and do not allow vehicles or unauthorized

people in the work area.

•Do not smoke, or have open flames.

•Do not use power tools in work area.

•Wear eye protection during the installation.

•Two people are required for installation of this product.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE