4

53012-53013

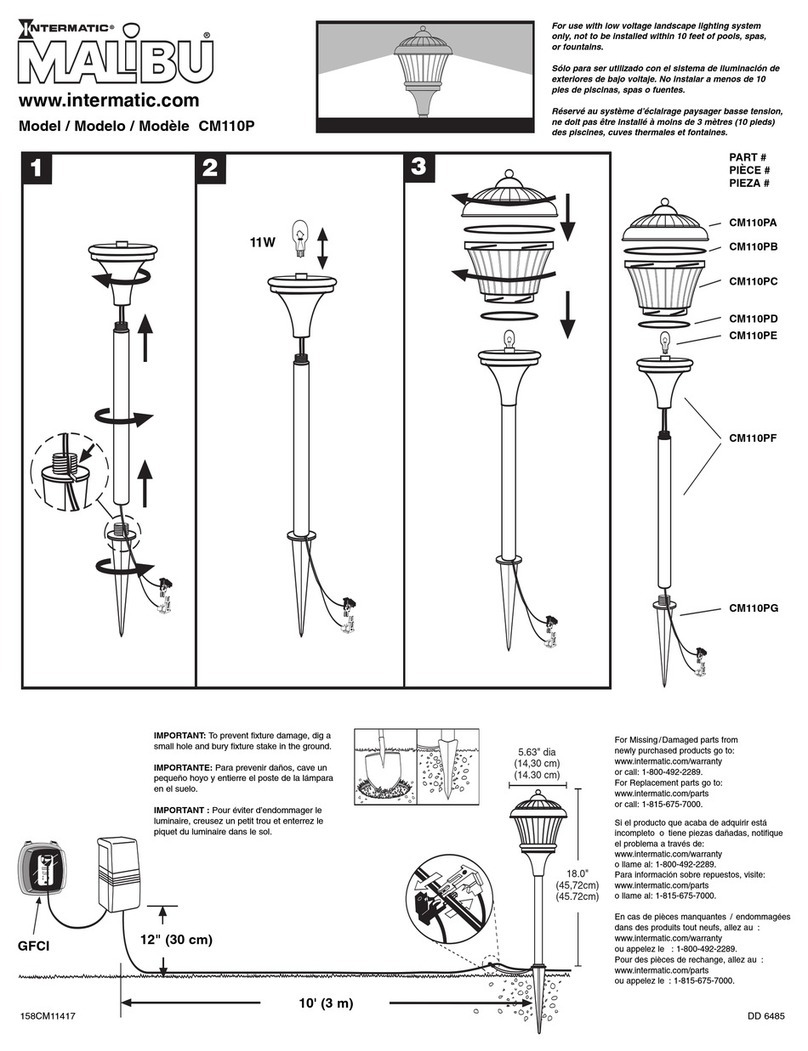

Bulk Grease Loading Via Filler Valve:

WARNING: Do not attempt to bulk fill a grease gun with the cartridge sleeve still in the barrel. Remove

cartridge before proceeding with bulk fill.

1. Make sure the filler valve adapter on the barrel pump is

compatible with the bulk loading adapter on the grease gun

head unit. (Fig 6)

2. Connect the bulk loading adapter to the filler valve on the head

of the gun pushing in and making sure the connection is secure.

3. Operate the pump handle while holding the gun firmly making

sure the bulk loading connect does not release. As grease

pumps into the grease gun barrel the plunger will begin to

extend. Bulk loading is complete once the plunger rod is fully

extended.

4. Twist the grease gun and the bulk loading connection from

the pump adapter. Press plunger lock release and push the plunger rod back into the gun.

5. Finally, pump the handle a few times and press the air release valve to release trapped air.

Continue pumping until grease comes out of the coupler. The grease gun is now fully primed.

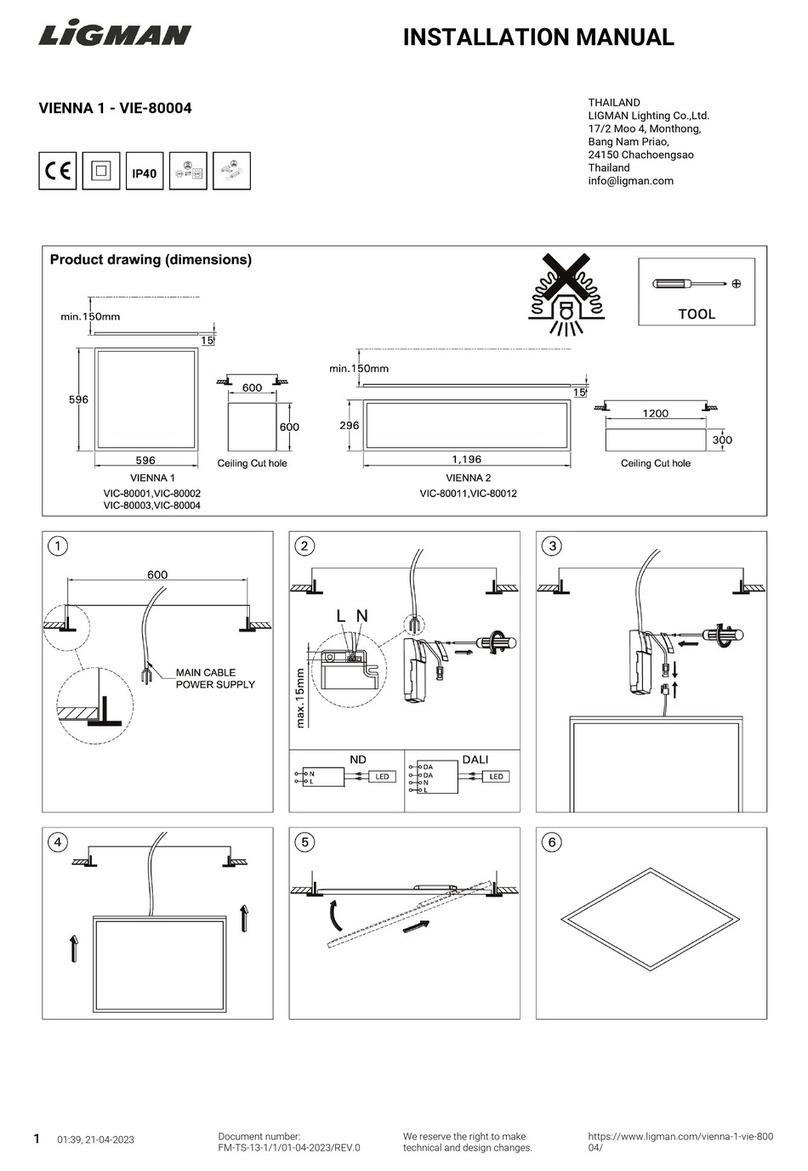

Suction Loading:

WARNING: Do not attempt to suction load a grease gun with the cartridge sleeve still in the barrel.

Remove cartridge before proceeding with bulk fill.

1. Remove the grease gun head unit from the barrel completely.

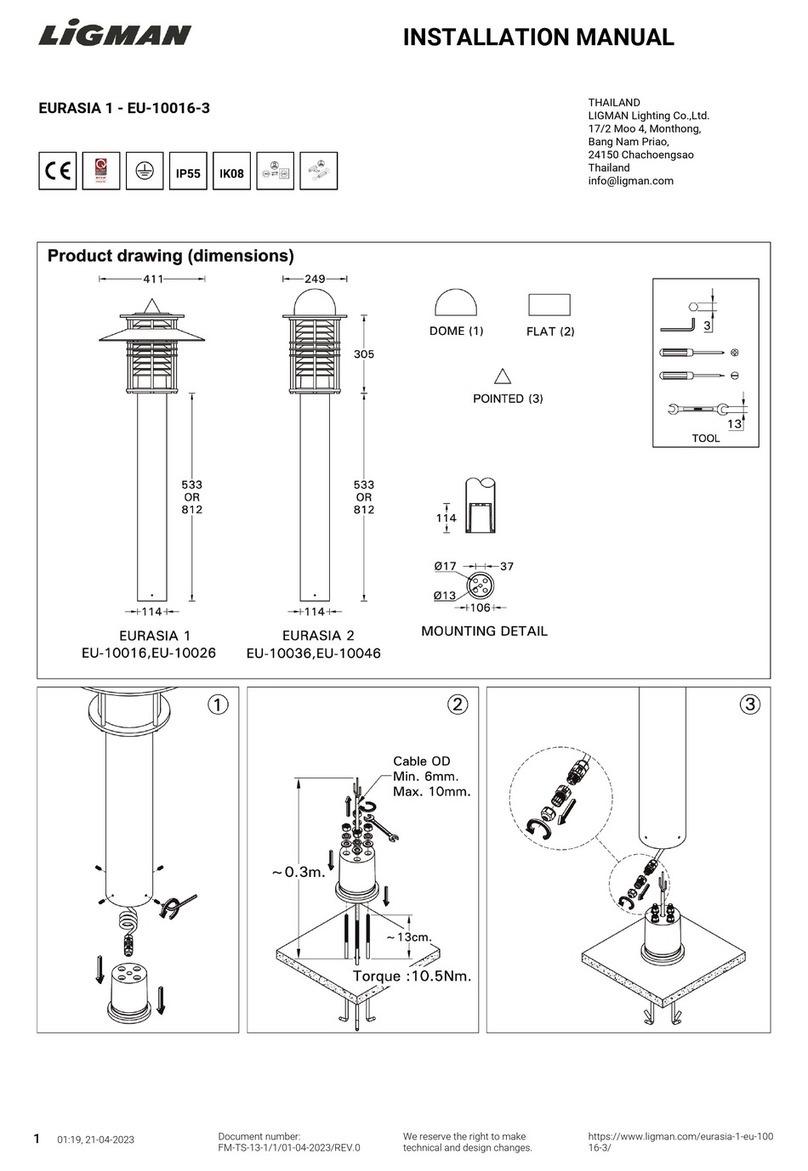

2. Making sure the plunger handle is depressed completely place the

open end of the barrel into grease container and submerge. Hold

the barrel firm and pull back slowly on the plunger handle. Be sure

the mouth of the barrel continues to be submerged under the

surface of the grease so that air is not sucked into the barrel. (Fig. 7)

3. Suction loading is completed when plunger rod is pulled to the full

extent, and no air has been transferred into the chamber.

4. Reinstall the grease gun head unit to the barrel. Release the

plunger lock and push the plunger rod back into the grease gun.

WARNING: Grease guns can lose their prime due to air pockets in the grease. If this occurs, remove

the trapped air by bleeding the head unit by pumping and pressing the air release valve on the head.

Repeat this until grease begins to flow again.

6. Finally, pump the handle a few times and press the air release valve to release trapped air. Continue

pumping until grease comes out of the coupler. The grease gun is now fully primed.

Bulk load

filler valve

Fig. 6

Fig. 7