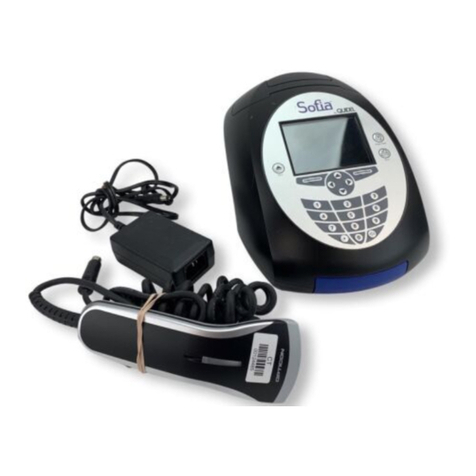

ArgoxScan AR-3000 User manual

0

NOTICE:

This equipment has been tested and it complies with

the limits for a Class a digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to

provide a reasonable protection against harmful

interference when the equipment is operated under a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the

instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in

a residential area is likely to cause harmful

interference in which case the user will be required to

correct the interference at his own expenses.

Note: All brands and trademarks shall belong to their

respective owner.

Note: Specification is subject to changes without

notice.

This device complies with Part 15 of the FCC Rules.

Operation shall be subject to the following two

conditions:

(1) This device may not cause harmful interface, and

(2) This device must accept any interface received,

including interface that may cause undesirable

operation.

1

Using the ArgoxScan AR-3000

The ArgoxScan can automatically scan barcode at a distance.

Simply aim and pull the trigger. Code scanning is performed

along the center of the light bar emitted from the reading

window. This bar must cover the entire code.

Recommended Steps

When the required settings have been configured, all settings

are stored in non- volatile memory of the scanner after

reading EXIT Label. Recommended steps are as follows.

1) Set the right host interface for your scanner.

(The scanner is in factory default shown as bold label)

2) Set interface to optimize protocol of the scanner with

your host in interface section.

3) Set system control of the scanner, such as specific

adjustments double confirm, indicator and scanning

mode which you prefer using in the system control

section.

4) Set code options of the scanner for your usage in the

code option section. You must make sure to enable the

symbology first, then Min./Max. code length, code ID

checksum and truncate digits are also converted.

5) Set string format of the scanner, such as preamble,

postamble Prefix, suffix, code ID and code name

transmission for your application in the string format

section.

Note: If it stil does not work properly. Please contact your

dealer for further information.

2

CONTENTS

Chapter 1 Introduction

Introduction

Default Setting ……………………………………….

4

ArgoxScanAR-3000 specification ………………..

6

Programming the ArgoxScan……………………..

9

Chapter 2 Parameter Setting

Interface

Interface Selection …………………………………..

11

USB HID Keyboard……………………………….…

12

RS-232 …………………………………………….….

15

Pin Assignments …………………………………….

18

System Control

Scan mode...………………………………………….

19

Indication …………………………..…………………

25

Code Option

UPCA ……………………………………..………….

27

UPCE …………………………………………………

32

EAN-13 ……………………………………………….

36

EAN-8 …………………………………………………

40

Code 39 ………………………………………………

44

Interleaved 2 of 5 ……………………………………

49

Industrial 2 of 5 ………………………………………

50

Matrix 2 of 5 Eur ……………………………………

52

Codabar ………………………………………………

54

Code-128/GS1-128 …………………………………

57

Code-93 ………………………………………………

61

Code-11 ………………………………………….……

64

MSI/Plessey ………………………………………….

66

UK/Plessey …………………………………………..

69

3

Telepen ……………………………………………….

71

Standard 2 of 5 ………………………………………

73

China Post ……………………………………………

75

Italian pharmacode ………………………….………

77

GS1 Data Omniidirectiona (RSS-14)……..……….

79

GS1 Databar Limited (RSS- Limited )………..……

81

GS1 Databar Expanded (RSS-Expanded) ………..

83

String Format

String Setting / Transmission

(Prefix/Suffix)…………………………………………

85

String Setting / Transmission

(Preamble/Postamble)………………………………

87

String Setting / Transmission

(Insert Group Characters)…………………………..

89

String Setting / Transmission

(Others)…….…………………………………………

93

Datamagic…………………………………………….

95

Appendix

Test Chart …………………………………………….

101

ASCII Code Table ……………………………………

104

Parameter setting List ……………………………….

105

4

Introduction

Installation RS-232

1) Disconnect power to the terminal/computer.

2) Connect the appropriate interface cable and external

power supply (DC adapter) to the scanner.

3) Plug the serial connector into the serial port on the back

of your computer/terminal. Tighten the two screws to

secure the connector to the port.

4) Plug the power pack into a power source.

5) Once the scanner has been fully connected, turn the

terminal/computer power back on.

USB HID (Simulate with keyboard wedge)

1) Connect the USB cable between scanner and PC.

2) Windows will automatically detect the USB device.

USB Com

1) Connect the USB cable between scanner and PC.

2) Windows will automatically detect the USB device.

Note: If any of the above operations is incorrect, turn off the

power immediately and check any improper

connections. Go through all above steps again.

5

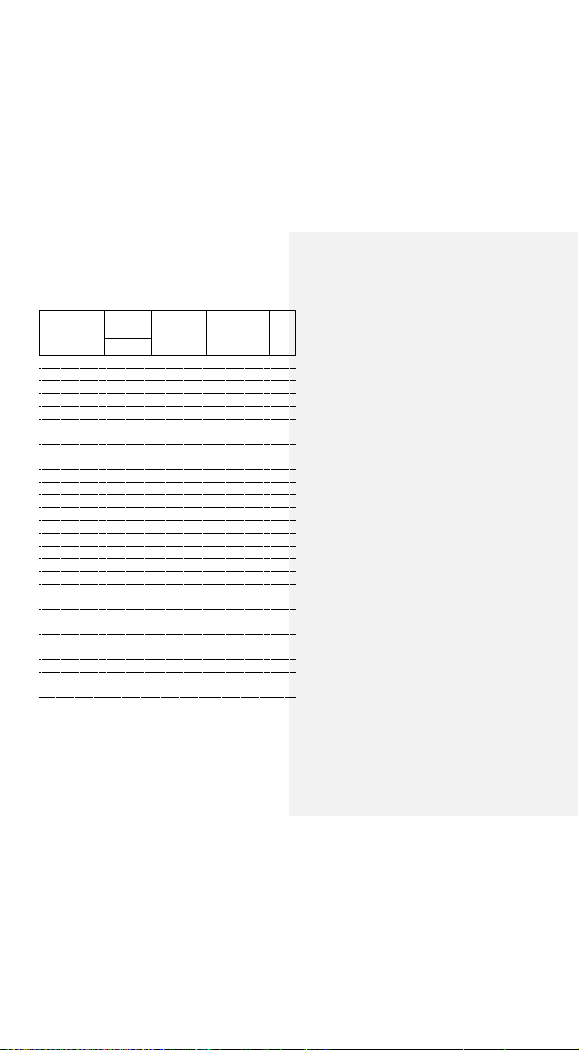

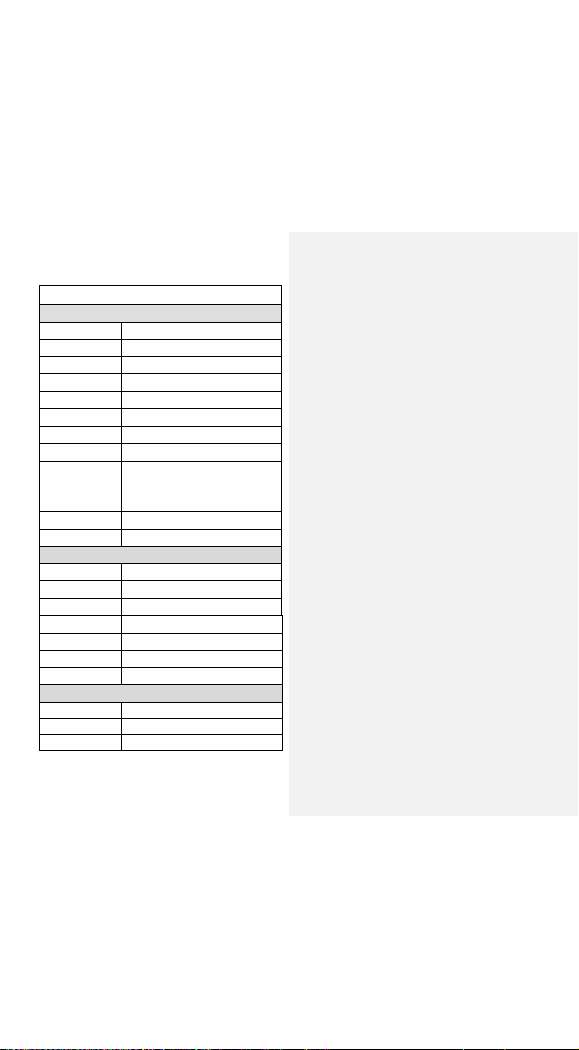

Default setting

For each barcode shown as below:

Code Type

Read

Enable

Checksum

Verification

Enable

Checksum

Transmission

Enable

Code

ID

3000

UPC-A

V

V

V

A

UPC-E

V

V

V

E

EAN-13

V

V

V

F

EAN-8

V

V

V

FF

Code-39

V

*

Interleaved

2 of 5

V

i

Industrial

2 of 5

-

-

i

Matrix 2 of 5

B

Codabar

%

Code-128

V

V

#

Code-93

V two digits

&

Code-11

VOne digit

O

MSI/Plessey

V

@

UK/Plessey

V

@

Telepen

S

Standard 2 of 5

-

-

i

GS1databar

Omnidirectiona

-

-

R4

GS1databar

Limited

-

-

RL

GS1databar

Expanded

-

-

RX

China Post

t

Italian

Pharmacode.

p

6

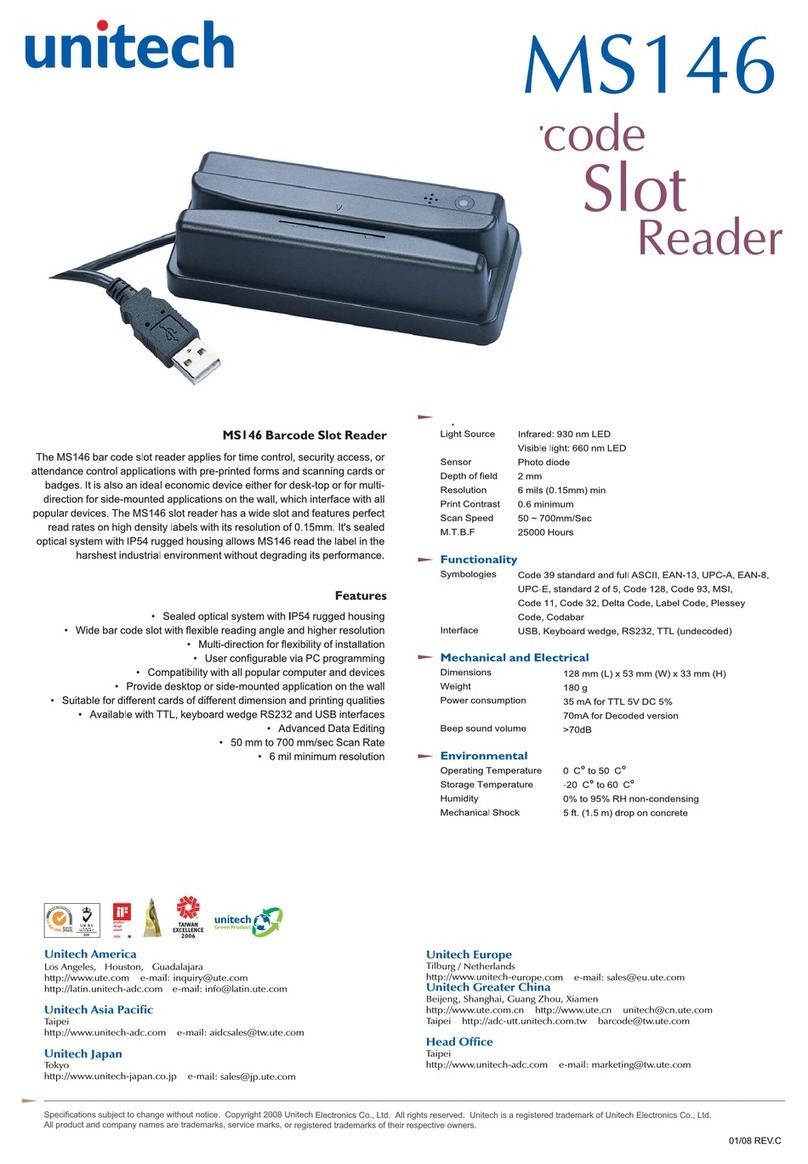

Weight

85 g (cable not included)

Interface

USB COM/ USB HID /RS-232

Case material

ABS

Cushion material

TPR

Electrical

Input Voltage

5 VDC ± 0.25V

Power - Operating

850mW

Power - Standby

250 mW

AR-3000

Operational

Light Source

623 nm Visible Red LED

Optical System

2500 pixel CCD (Charge-coupled device)

Depth of Scan Field

0-85 mm (code 39, PCS=90%, 20mils)

Scanning Width

50 mm at 10mm

Scan Speed

300 scans/sec

Resolution

3mil Code39,PCS=90%

Print Contrast

30% or more

Scanning Angle

Pitch: ±60° Yaw: ±30°

Decode Capability

Auto-discriminates all standard

barcodes; Other symbologies can be

ordered optionally

Beeper Operation

7 tones or no beep

Indicator

Blue LED

Mechanical

Length

163mm

Width-head

75 mm

Depth-head

50 mm

7

Current - Operating

200 mA@5 VDC

Current - Standby

60 mA@5 VDC

Physical and Environment

Operating

Temperature

0℃to 50℃(32℉to 122℉)

Storage

Temperature

-20℃to 60℃

(-4℉to 140℉)

Humidity

5% to 90% relative humidity,

non-condensing

Light Level

Up to 20000 Lux.

Impact resistance

1.5m drop to concrete

EMC regulation

FCC Class A,CE, BSMI

8

Programming

Programming

method

Scan Utility

Manual (Reading special barcode)

DOS command through RS-232,

Windows configuration program

Program upgrade

Enabled built-in flash memory

Programmable

characteristics

Code type selection, check digit

selection, Decoding option Transmitted

character delay, Message suffix, Good

read beep tone and volume, Scanner

trigger selection, interface type ,Data

Editing

9

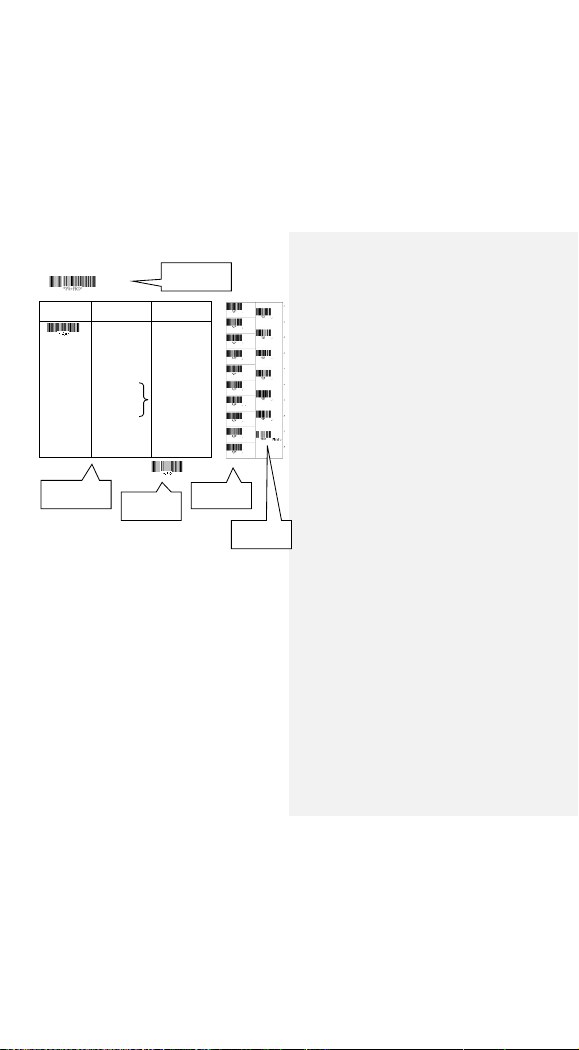

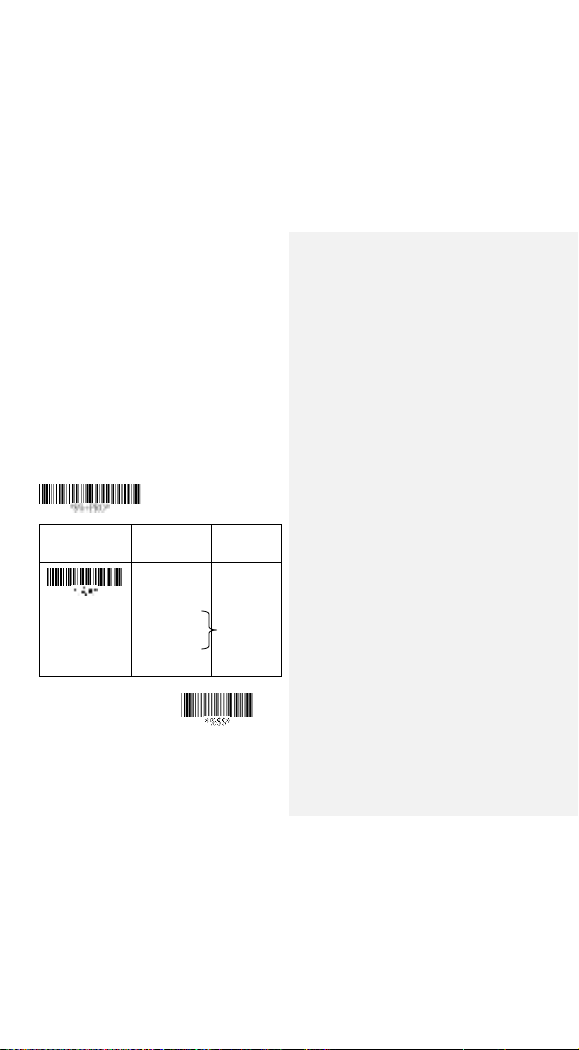

Programming the AR-3000

To program the AR-3000, you must scan a series of

programming barcode in the correct order. On the last page

of this manual, you will see a table of alphanumeric barcodes,

which are used to program the various options presented.

To program each option, you must:

1. Scan the Program barcode on the parameter setting part.

2. Enter the option mode by scanning the Option Bar Code

(also on the Parameter setting part).

3. To the right of the option barcode, the necessary

alphanumeric inputs are listed. Scan these alphanumeric

entries from the last page . To confirm above steps, you

must scan the Finish barcode on the last page.

4. Once you have finished programming. Scan the Exit

barcode, listed on the lower right hand corner of each

parameter setting part.

10

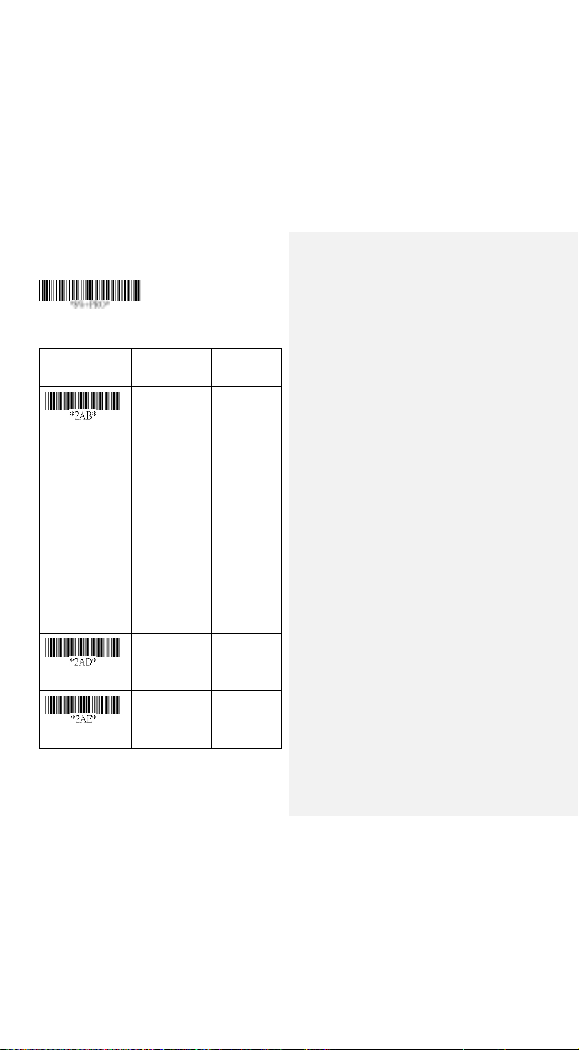

Option Bar Code

Option

Alphanumeric Entry

Interface

selection

Keyboard Wedge

RS-232

Wand emulation

USB

/RS-232

Auto detection

Reserved

00

01

02

03

04*

05

Program

Exit

Program Barcode

Option Barcode

Exit Barcode

On the last page

Finish barcode

11

Exit

Interface Selection

This decoder built-in scanner comes in one model and

supports interfaces such as keyboard wedge, RS232 serial

and the latest USB interface. In most of the cases, simply

selecting an appropriate cable with a device code will work

for a specific interface.

Interface selection: You can change factory interface

default for another type interface. By plugging different

cables, setting right interface, the scanner will change to

another interface. However, you must make sure which cable

you need.

RS232/ USB HID Auto detection: By setting this function, it

will automatically select the RS-232 or /USB HID interface for

the user.

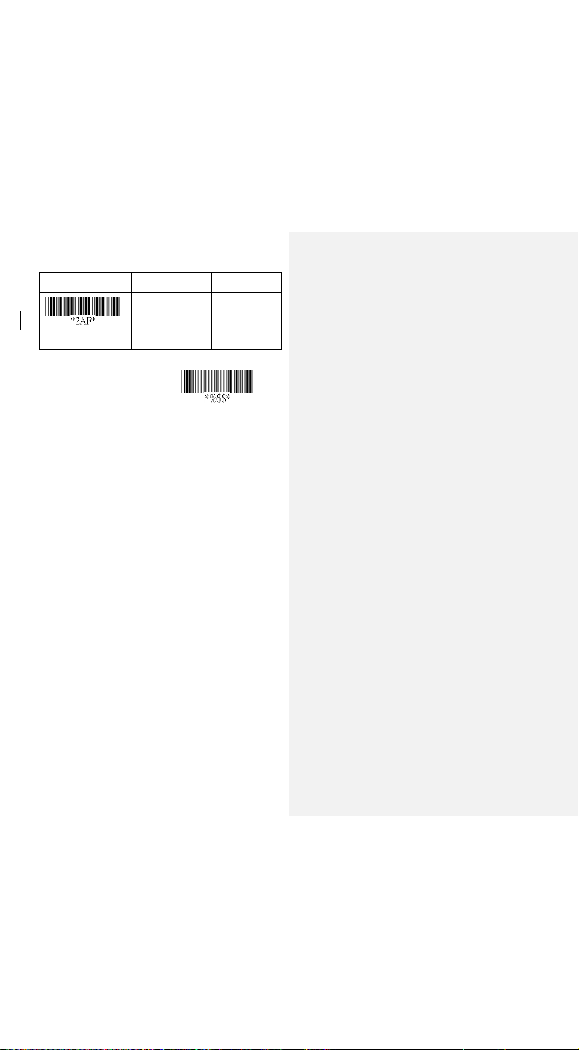

Option Bar Code

Option

Alphanumeric

Entry

Interface selection

RS-232

USB HID

RS232/

USB HID

Auto detection

USB COM

01

03

04*

05

Program

Note:*-Default

12

USB HID Keyboard

USB HID Keyboard Layout: The selecting of keyboard

layout supports languages other than USA keyboard layout.

First you need to confirm country language that you desire. In

DOS, using command “keyb”to select the desirable

keyboard layout or in WINDOWS entry “Control”then pops

“Keyboard”to select country from the “language”item. For

details, please refer to your DOS or WINDOWS user’s

manual.

Function Key: Set Enable, scanner can output code as

pressing function-key in your application program while the

barcode datas contain ASCIIvalues between 0116 to 1F16.

Refer to ASCII table.

Numeric Key: The Keypad has to be selected if your

application program is only keypad numeric code acceptable.

The scanner will output code as you press the numeric

keypad when it reads a numeric digit. (The keypad is on the

right side of keyboard, and Num Lock control key is also on.)

If Alt+Keypad is selected, the data characters will be

transmitted as “Alt”+ numbers. For example, when sending

character “A”, the actual sending will be “Alt”+65. It is also

useful when using non-English OS and keyboard layout.

Caps Lock: By selecting Caps lock”ON”or Caps lock”OFF”,

scanner can get Caps Lock status.

13

Option Bar Code

Option

Alphanumeric

Entry

Keyboard layout

USA

Belgium

Danish

France

Germany

Italian

Portuguese

Spanish

Swedish

Switzerland

UK

Latin American

Japanese

00*

01

02

03

04

05

06

07

08

09

10

11

12

Function key

Disable

Enable

00

01*

Numeric key

Alphabetic key

Numeric keypad

(Num lock state

00*

01

Program

14

Exit

only)Alt+Keypad

02

Caps lock

Caps lock”ON”

Caps lock”OFF”

Caps lock for Mac

00

01*

02

15

RS-232

CTS: Clear To Send (Hardware Signal)

RTS: Request To Send (Hardware Signal)

Xon: Transmit On (ASCII Code 1116)

Xoff: Transmit Off (ASCII Code13 16)

Flow control:

None-The communication only uses TxD and RxD signals

without regard for any hardware or software handshaking

protocol.

RTS/CTS-If the scanner wants to send the barcode data to

host computer, it will issue the RTS signal first, wait for the

CTS signal from the host computer, and then perform the

normal data communication. If there is no replied CTS signal

from the host computer after the timeout (Response Delay)

duration, the scanner will issue a 5 warning beeps.

Xon/Xoff- When the host computer is unable to accept data,

it sends a Xoff code to inform the scanner to suspend data

transmission, and Xon to continue.

ACK/NAK- When the ACK/NAK protocol is used, the

scanner waits for an ACK (acknowledge) or (not

acknowledge) from the host computer after data transmission,

and will resend in response to a NAK.

Inter-character delay: This is the delay time between data

character’s data output. It is also same as Inter-char. delay of

keyboard wedge.

Block transmission delay: This is the delay time between

barcode data output. It is also the same as Block

transmission delay of keyboard wedge.

Response delay: This delay is used for serial

16

Exit

communication of the scanner to wait for handshaking

acknowledgment from the host computer.

Option Bar Code

Option

Alphanumeric

Entry

Flow control

None

RTS/CTS

Xon/Xoff

ACK/NAK

00*

01

02

03

Inter-character delay

00-99 (msec)

00-99

00*

Block transmission

delay

00-99 (10 msec)

00-99

00*

Response delay

00-99 (100 msec)

00-99

20*

Program

17

Exit

Option Bar Code

Option

Alphanumeric

Entry

Baud rate

600 BPS

1200 BPS

2400 BPS

4800 BPS

9600 BPS

19200 BPS

38400 BPS

57600BPS

115200BPS

01

02

03

04

05*

06

07

08

09

Parity

None

Odd

Even

00*

01

02

Data bit

8 bits

7 bits

00*

01

Stop bit

One bit

Two bits

00*

01

Program

18

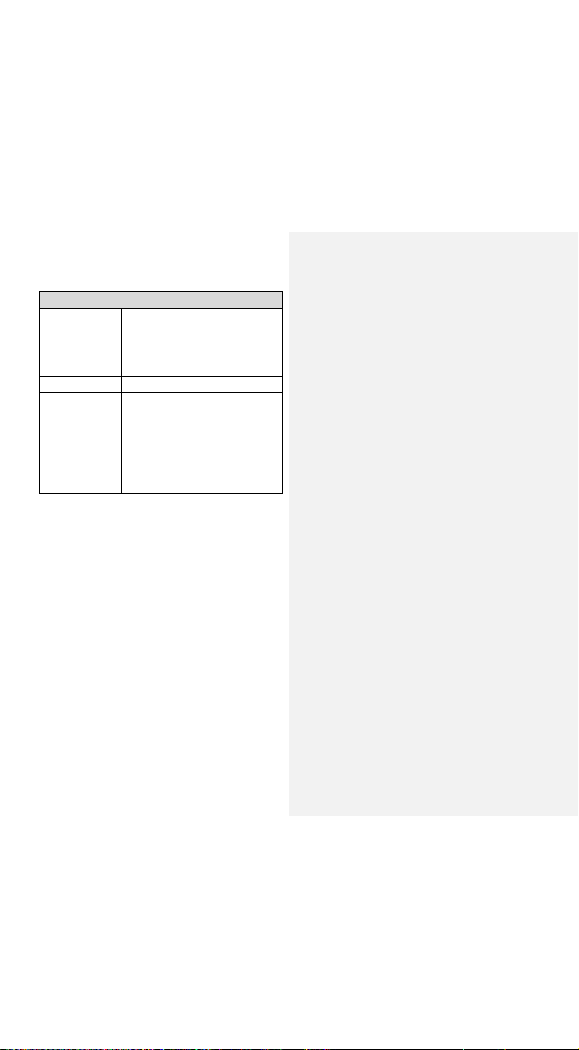

Pin Assignments

RS-232 DB-9F Connector (To Host Side):

Pin

Definition

1

NC

2

TXD

3

RXD

4

NC

5

GND

6

NC

7

CTS

8

RTS

9

VCC (+5V)

4

2

3

1

8

6

9

7

5

19

Scan

Scanning mode:

Good-read off-The trigger button must be pressed to

activate scanning. The light source of the scanner stops

scanning when there is a successful reading or no code is

decoded after the Stand-by duration elapsed.

Momentary-The trigger button acts as a switch. Press button

to activate scanning and release button to stop scanning.

Alternate-The trigger button acts as a toggle switch. Press

button to activate or stop scanning.

Timeout off-The trigger button must be pressed to activate

scanning, and the scanner stops scanning when no code is

decoded after the Stand-by durationhas elapsed.

Continue-Scanner always keeps reading, and it does not

matter when the trigger button is pressed or duration has

elapsed.

Test only-For test of scan performance only. This should not

be used to be utilized to check the accuracy of transmitted

data.

Double read timeout: It determines the duration of Double

confirm. For example, if you set 5 times in Double confirm

and set 10 milliseconds in Double read timeout, the

decoder will decode a bar code 5 times in 10 milliseconds.

You need to turn on Double confirm to use this feature.

Double confirm: It determines how many times the decoder

needs to confirm a bar code.

Supplement Check Counter: It will be more reliable to read

the barcode an extension (supplement) like UPCE/A or

EAN-8/13, but it slows down the decoding speed when this

counter is set more.

Table of contents

Other ArgoxScan Barcode Reader manuals