EN - 5

Handle fuel with care; it is highly flammable.

• Use an approved fuel container.

• NEVER add fuel to a running engine or

hot engine.

• Fill fuel tank outdoors with extreme care.

NEVER fill fuel tank indoors.

• NEVER fill containers inside a vehicle or

on a truck or trailer bed with a plastic

liner. ALWAYS place containers on the

ground, away from your vehicle, before

filling.

• When practical, remove gas-powered

equipment from the truck or trailer and

refuel it on the ground. If this is not

possible, then refuel such equipment on

a trailer with a portable container, rather

than from a gasoline dispenser nozzle.

• Keep the nozzle in contact with the rim of

the fuel tank or container opening at all

times, until refueling is complete. DO

NOT use a nozzle lock-open device.

• Replace gasoline cap securely and wipe

up spilled fuel.

• If fuel is spilled on clothing, change

clothing immediately.

NEVER attempt to make any adjustments

while the engine is running (except when

specifically recommended by manufacturer).

ALWAYS allow unit and engine to adjust to

outdoor temperature before operating.

Operation

Disengage all controls before starting

engine.

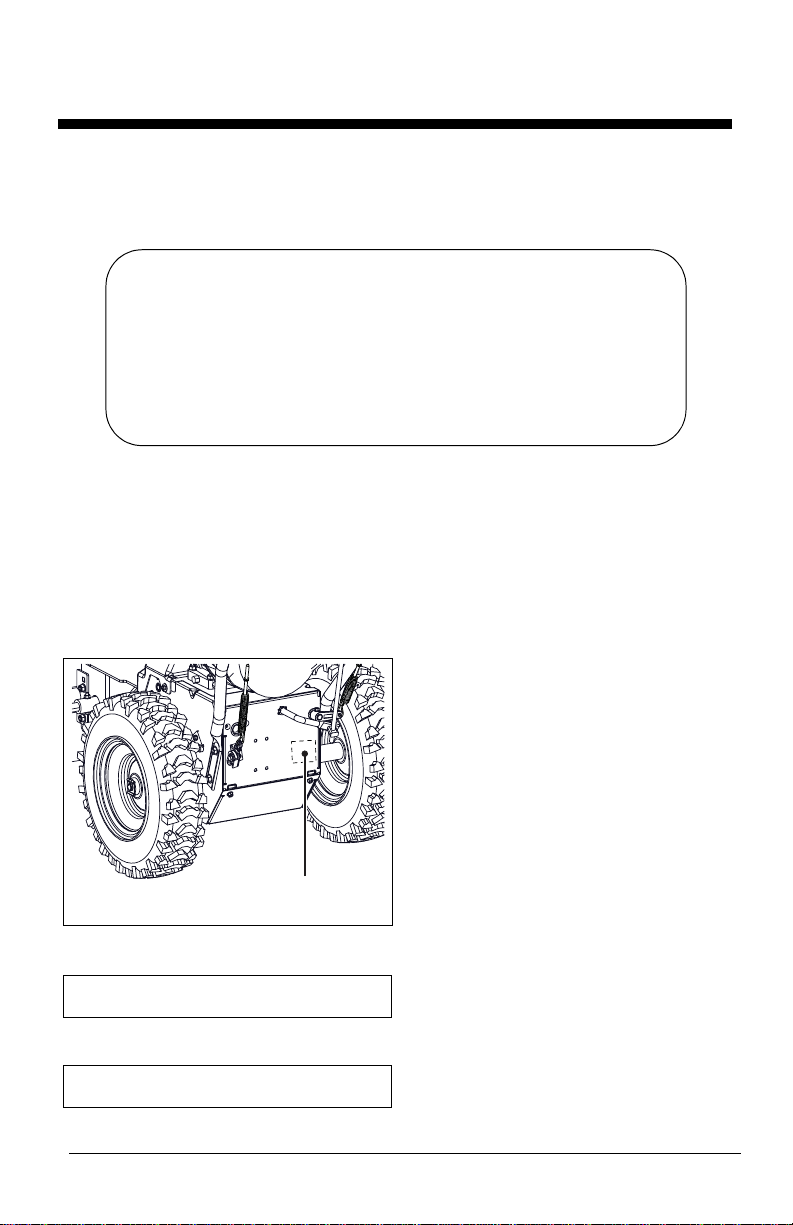

Adjust brush height before operating.

Engage traction drive clutch before

attachment clutch. If brush is set too low or if

terrain is irregular, brush can drive machine

rearward.

NEVER leave a running unit unattended.

ALWAYS stop engine and remove key

before leaving unit to prevent unauthorized

use.

DO NOT put hands or feet near or under

rotating parts. Keep clear of the discharge

area at all times.

Moving and/or rotating parts can cut off body

parts such as fingers or a hand. NEVER

place your hands, other body part or clothing

near any moving parts while unit is running.

ALWAYS keep hands away from all pinch

points.

DO NOT touch parts which might be hot

from operation. Allow parts to cool before

attempting to maintain, adjust or service.

Thrown objects can cause injury. Check for

weak spots on docks, ramps or floors. Avoid

uneven work areas and rough terrain and

stay alert for hidden hazards.

Exercise extreme caution when operating on

or crossing gravel drives, walks or roads.

Stay alert for hidden hazards or traffic.

After striking a foreign object, stop the

engine, remove the wire from the spark plug,

disconnect the cord on electric motors,

thoroughly inspect the unit for any damage,

and repair the damage before restarting and

operating the unit.

If the unit should start to vibrate abnormally,

stop the engine and check immediately for

the cause. Vibration is generally a warning

of trouble.

Stop the engine whenever you leave the

operating position and when making any

repairs, adjustments or inspections.

When cleaning, repairing or inspecting the

unit, stop the engine and make certain that

all moving parts have stopped. Disconnect

the spark plug wire and keep the wire away

from the plug to prevent someone from

accidentally starting the engine.

DO NOT run the engine indoors, except

when starting the engine and for

transporting the unit in or out of the building.

Open the outside doors; exhaust fumes are

dangerous.

NEVER operate the unit without proper

guards, and other safety protective devices

in place and working.

ALWAYS stand clear of the discharge area

when operating this unit.

NEVER direct the discharge toward people

or areas where injury or property damage

can occur from thrown objects. Keep

children and others away.

DO NOT overload the unit capacity by

attempting to operate at too fast a rate.

NEVER operate the unit at high transport

speeds on slippery surfaces. Look behind

and use care when operating in reverse.

DO NOT operate in reverse unless

absolutely necessary. ALWAYS back up

slowly and look down and behind before and

while backing.

DO NOT carry passengers.