Model: 2852-FCS User Manual Rev: 1.0

3

1.0 INSTRUMENT OVERVIEW

The Arjay Model 2852-FCS Foam Control Switch provides two independent alarm relays for

monitoring and control of foam in tanks, sumps and vessels.

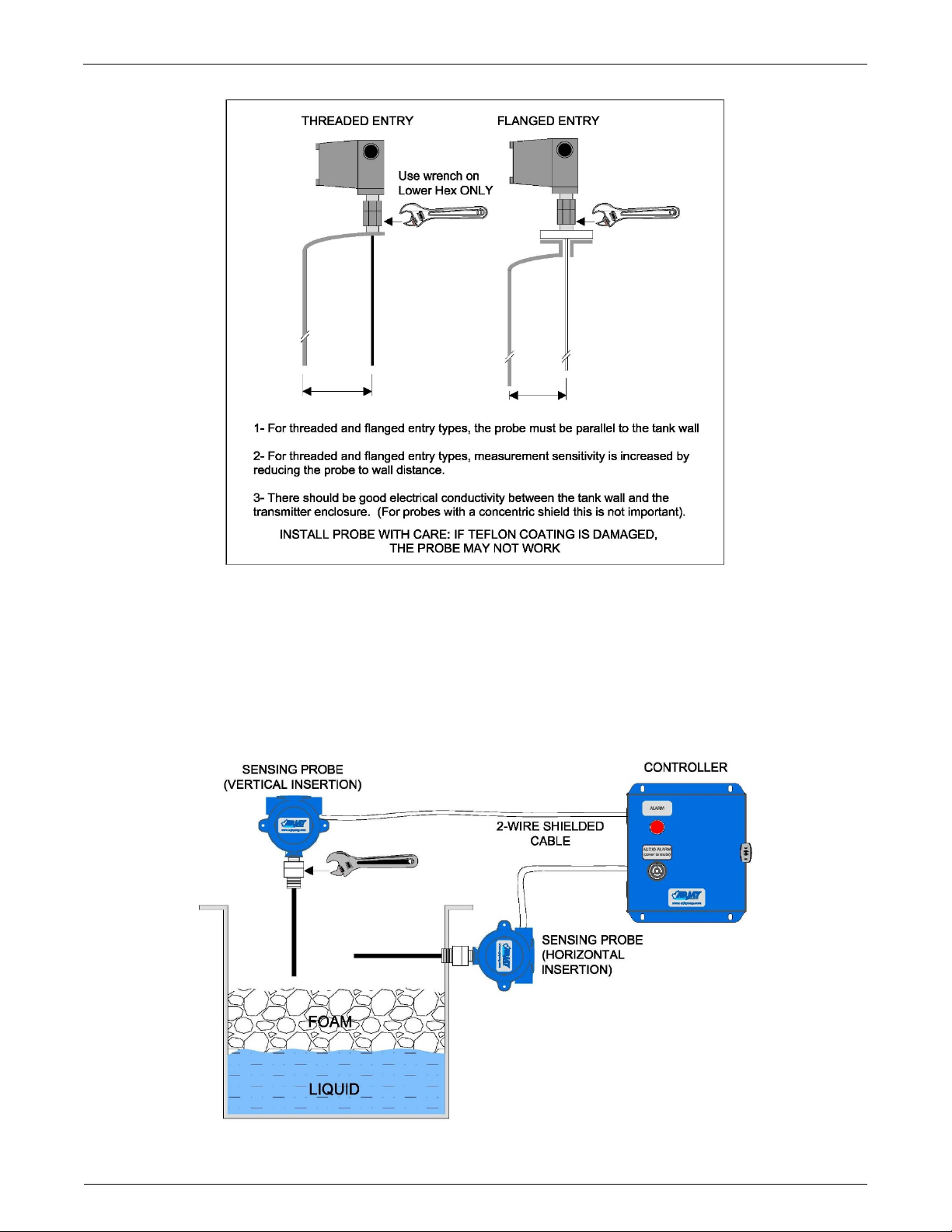

The Arjay system has an active capacitance probe that is inserted into the vessel. As the foam

level approaches or changes around the probe, the capacitance reading of the probe increases or

decreases. The controller relays are calibrated to alarm at user determined levels of product on

the probe.

The remote mounted Arjay 2852 controller monitors the capacitance change of the probe and

activates the relay contacts for use with alarms, pumps, valves, etc.

The complete 2852-FCS system consists of the probe, the PMC card, and the 2852 controller.

The standard probe is constructed of a Teflon coated SS rod. The PMC card is mounted in a

junction box mounted on top of the probe. The PMC card translates the capacitance signal from

the probe into a frequency pulse, which is then transmitted up to one kilometer to the 2852

controller via 2-wire shielded cable.

Probes can be inserted vertically, horizontally, or angled into the tank. The sensor does not

differentiate between liquid and foam. This system is designed to alarm for foam presence in a

normal air condition.

On vertical and angled probes, the two relays can be set at the same or different levels. Each relay

also has a differential setpoint to allow the relay to activate at one level and de-activate at a

different level. This is similar to a latching format which can cycle a valve or control action between

two points through the use of only one relay. For example, the defoamer spray can be activated at

a high point and held on until the foam reaches a desired lower point.

On a horizontal insertion, both relays are calibrated to the same setpoint.

For single point high foam level applications, it is typical for both relays to be calibrated without

bringing the foam level up to a specific alarm point. For example, in a high alarm application, the

controller can be calibrated to air. An alarm will occur when the foam approaches and begins to

cover the probe.

This model is intended for use in General Purpose non-hazardous areas. For hazardous

location use refer to Arjay Engineering Ltd. for the appropriate model.

1.1 Features

Microprocessor based capacitance Controller

Relay and 4/20mA alarm output

Modbus protocol via RS-485 for access by Arjay handheld, Central Access Panel or

compatible system

Local Auto calibration or remote calibration via network

User specified custom features may be added by contacting Arjay Engineering Ltd.

1.2 Model Number vs. Voltage Input

2852-FCS-1 100-240 VAC power input

2852-FCS-3 12 VDC power input

2852-FCS-4 24 VDC power input