506860-01Issue 1404Page 6 of 35

Placement

Be aware that some localities are adopting sound ordinances

based on how noisy the unit is at the neighbor’s home, not

at the original installation. Install the unit as far as possible

from the property line. When possible, do not install the unit

directly outside a bedroom window. Glass has a very high

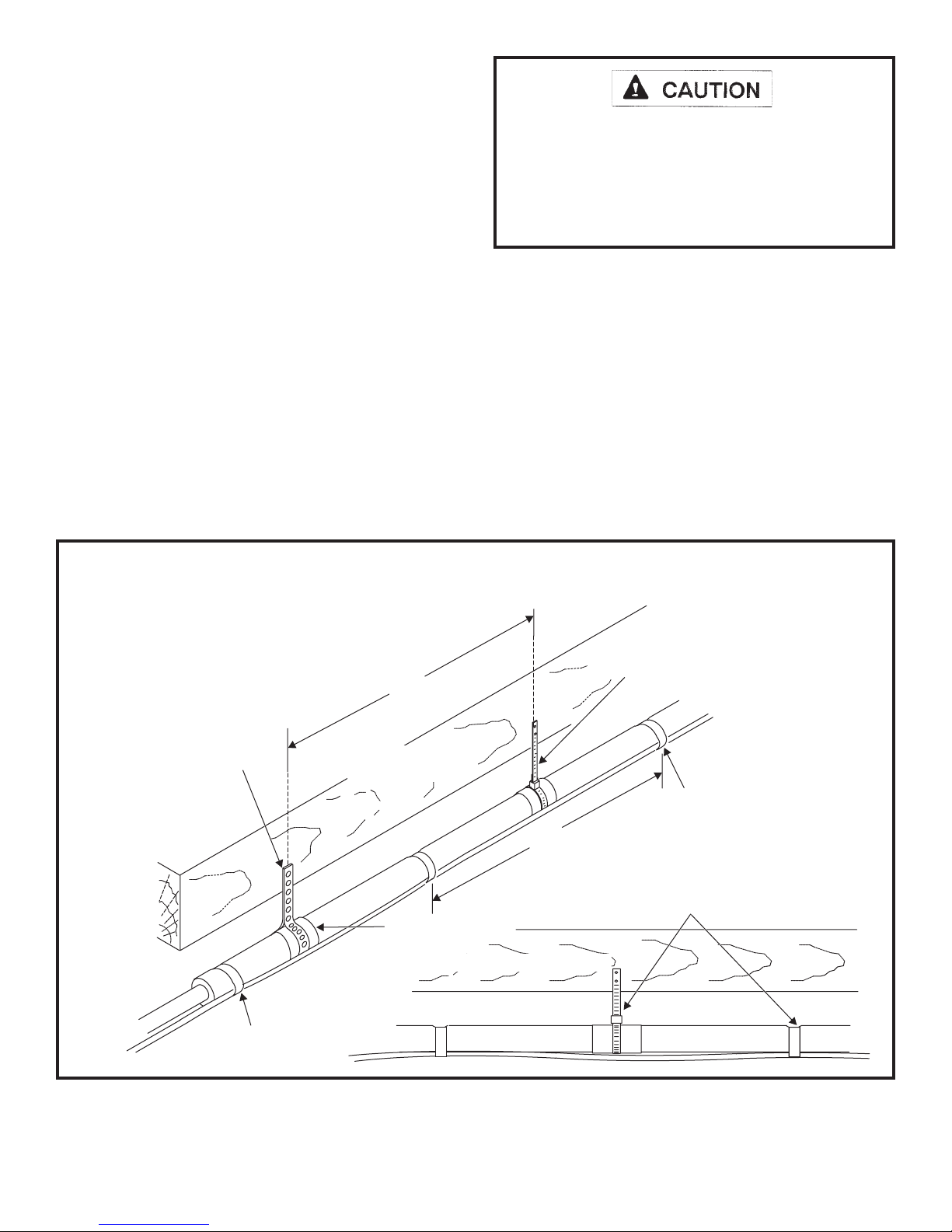

level of sound transmission. Figure 7 shows how to place

the outdoor unit and line set to reduce line set vibration.

Line Set Isolation

Illustrations on pages 7 and 8 demonstrate procedures which

ensure proper refrigerant line set isolation. Figure 8 shows

how to install line sets on horizontal runs. Figure 9 shows

how to make a transition from horizontal to vertical. Figure

10 shows how to install line sets on vertical runs.

4. Remove the Schrader core assemblies before brazing

to protect them from damage due to extreme heat.

Replace the cores when brazing is complete.

5. Remove light maroon washers from service valves

and shield light maroon stickers to protect them during

brazing. Wrap a wet cloth around the valve body and

copper tube stub to protect it from heat damage.

6. Braze the line set to the service valve. Quench the

joints with water or a wet cloth to prevent heat damage

to the valve core and opening port. The tube end must

stay bottomed in the tting during nal assembly

to ensure proper seating, sealing, and rigidity.

7. Install the thermal expansion valve which is sold

separately and which is approved for use with R410A

refrigerant in the liquid line at the indoor coil (see

Refrigerant Metering Device on page 10).

Brazing Connection Procedure

1. Cut ends of refrigerant lines square (free from nicks or

dents). Debur the ends. The pipe must remain round;

do not pinch end of line.

2. Before making line set connections, use dry nitrogen to

purge the refrigerant piping. This will help to prevent

oxidation and the introduction of moisture into the

system.

3. Use silver alloy brazing rods (5% or 6% silver alloy for

copper-to-copper brazing or 45% silver alloy for copper-

to-brass or copper-to-steel brazing) which are rated for

use with R410A refrigerant.

Refrigerant Piping

If the 4SHP16/18LS unit is being installed with a new indoor

coil and line set, the refrigerant connections should be made

as outlined in this section. If an existing line set and/or

indoor coil will be used to complete the system, refer to this

section as well as the section that follows entitled- Flushing

Existing Line Set and Indoor Coil.

If this unit is being matched with an approved line set

or indoor coil which was previously charged with R-22

refrigerant, the line set and coil must be ushed prior to

installation. If the unit is being used with and existing indoor

coil which was equipped with a liquid line which served as

a metering device (RFCI), the liquid line must be replaced

prior to the installation of the 4SHP16/18LS unit.

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (sweat connections) to the indoor

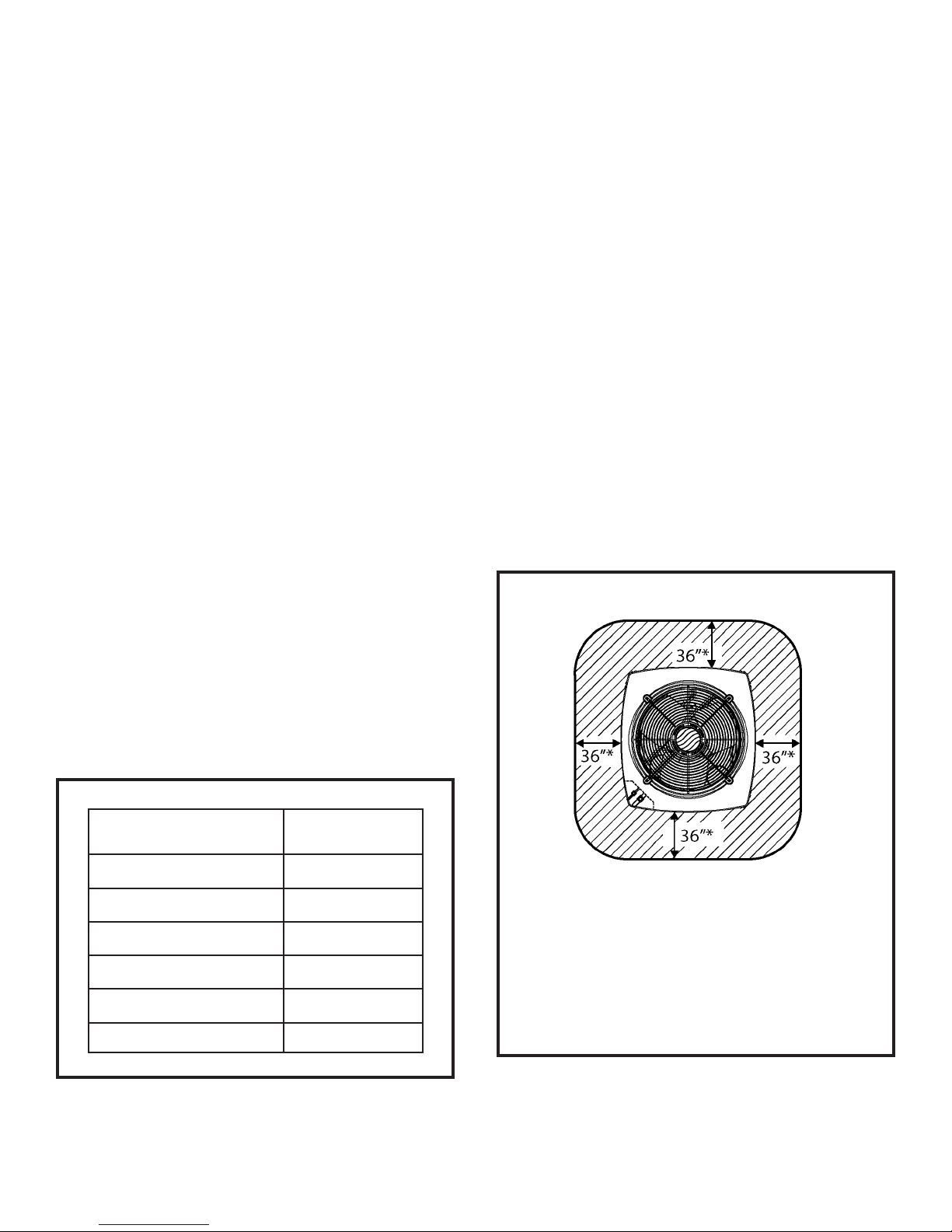

Figure 7

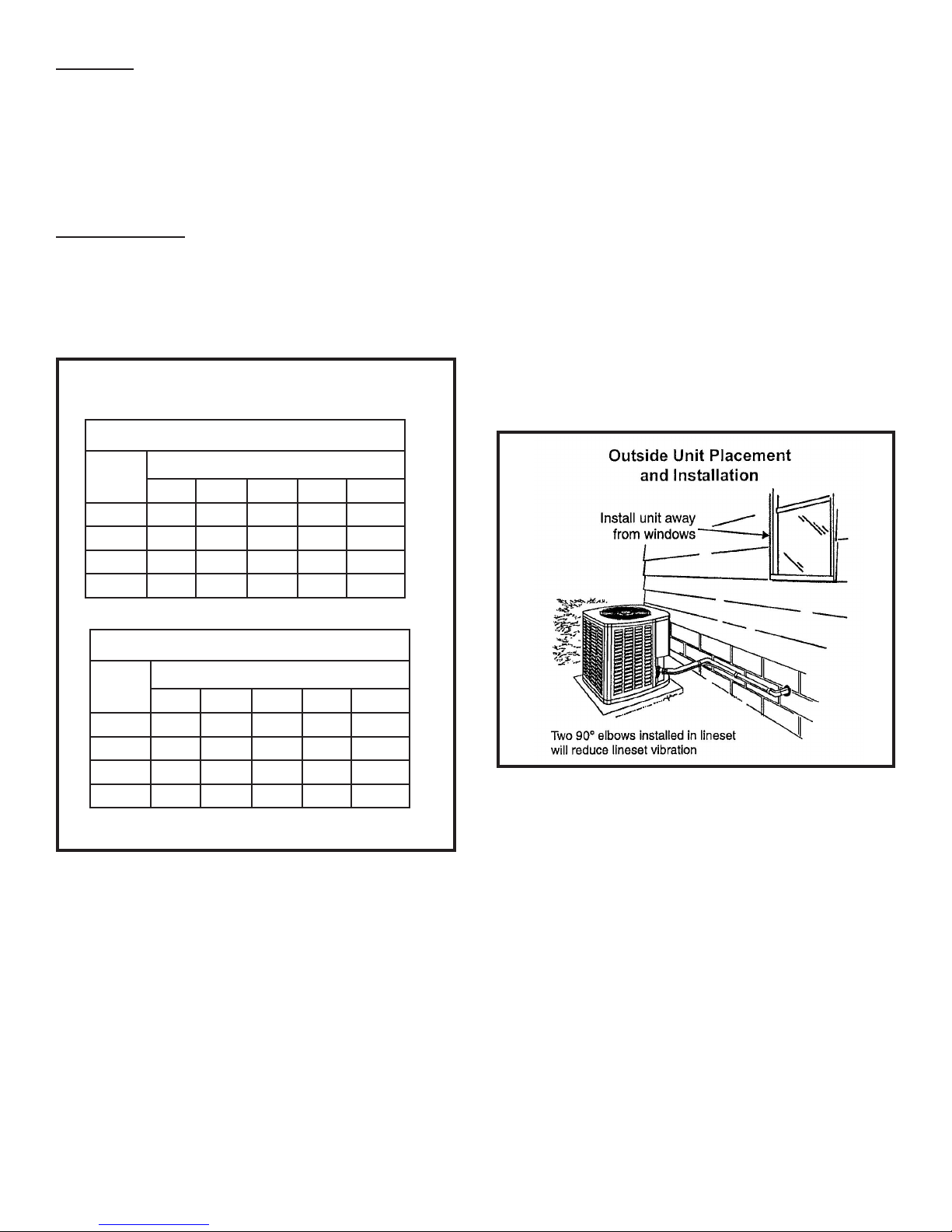

Table 2

Refrigerant Line Set Diameters (in.)

For installations exceeding 50’, contact Technical Services.

Liquid Line

BTUH Line Set Length and Size

12 ft. 25 ft. 50 ft. 75 ft. 100 ft.

24,000 3/8 3/8 3/8 3/8 3/8

36,000 3/8 3/8 3/8 3/8 1/2

48,000 3/8 3/8 3/8 1/2 1/2

60,000 3/8 3/8 3/8 1/2 1/2

Suction Line

BTUH Line Set Length and Size

12 ft. 25 ft. 50 ft. 75 ft. 100 ft.

24,000 3/4 7/8 3/4 7/8 7/8

36,000 7/8 7/8 7/8 7/8 1-1/8

48,000 1-1/8 1-1/8 1-1/8 1-1/8 1-1/8

60,000 1-1/8 1-1/8 1-1/8 1-1/8 1-1/8