6www.armstrongfluidtechnology.com

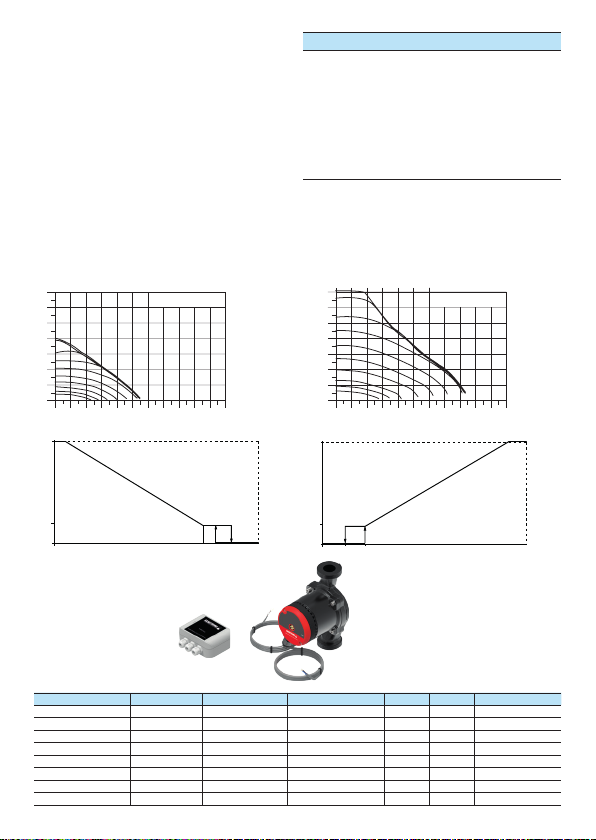

L4 L2

L3

L1

G

technical data

Rate of flow: up to 3.8 m3/h

Pressure head: 4 m/7 m

Control range: 4-25 W/4-70 W

Mediumtemperature:+2 °C to +110 °C

Installation length: 130 and 180 mm

Threaded connection:1“, 1½“ and 2“

Protection class: IP 42

Insulation class: F

Control: PWM1 (heating) and

PWM2 (solar, inverted)

flow medium

• heating water as per VDI 2035

• pure, thin, non-aggressive and non-explosive,

mineral oil-free medium without solid or long-

fibre components

• medium with a max. viscosity of 10 mm2/s

• operating data must be checked above 20% glycol

materials

component material material no.

Pump housing Grey-cast iron 0.6020

Impeller Polyamide (PA - GF 35)

Shaft Ceramic

Bearing Ceramic

Bearing plate Stainless steel 1.4301

Can Stainless steel 1.4301

product features

• compact design

• manual start-up

feature

• smooth running

• very low energy

consumption

• starting current limit

(softstart)

• air-vent screw

• pre-mounted cable

(1 m)*

• space-saving axially

integrated terminal box

• control input

switchable from

PWM1 to PWM2

* other cable lengths on request

temperature range

Ambient temperature: 0 °C to +40 °C

Temperature class: TF 110

Media temperature: +2 °C to +110 °C

To avoid condensation forming in the terminal box

and stator, the media temperature must always be

the same or higher than the ambient temperature.

ambient temp. media temp. min. media temp. max.

0 2 110

10 10 110

20 20 110

30 30 95

35 35 90

40 40 90

motor protection

The motor winding is designed to be blocking

current-proof. Therefore motor protection is not

required.

minimum inflow pressure

Please determine the minimum inflow pressure

for corresponding temperature from the following

table.

Media temperature < 75 °C > 90 °C

Minimum inflow pressure 0,05 bar 0,28 bar

casing pressure

10 bar

sound pressure level

The sound pressure level is < 45 dB (A).

dimensions

typ l1 l2 l3 l4

hep pwm 130/180 98 127 163

dimension illustration

ECM

Technology

technical data pump: