installation &

operating instructions

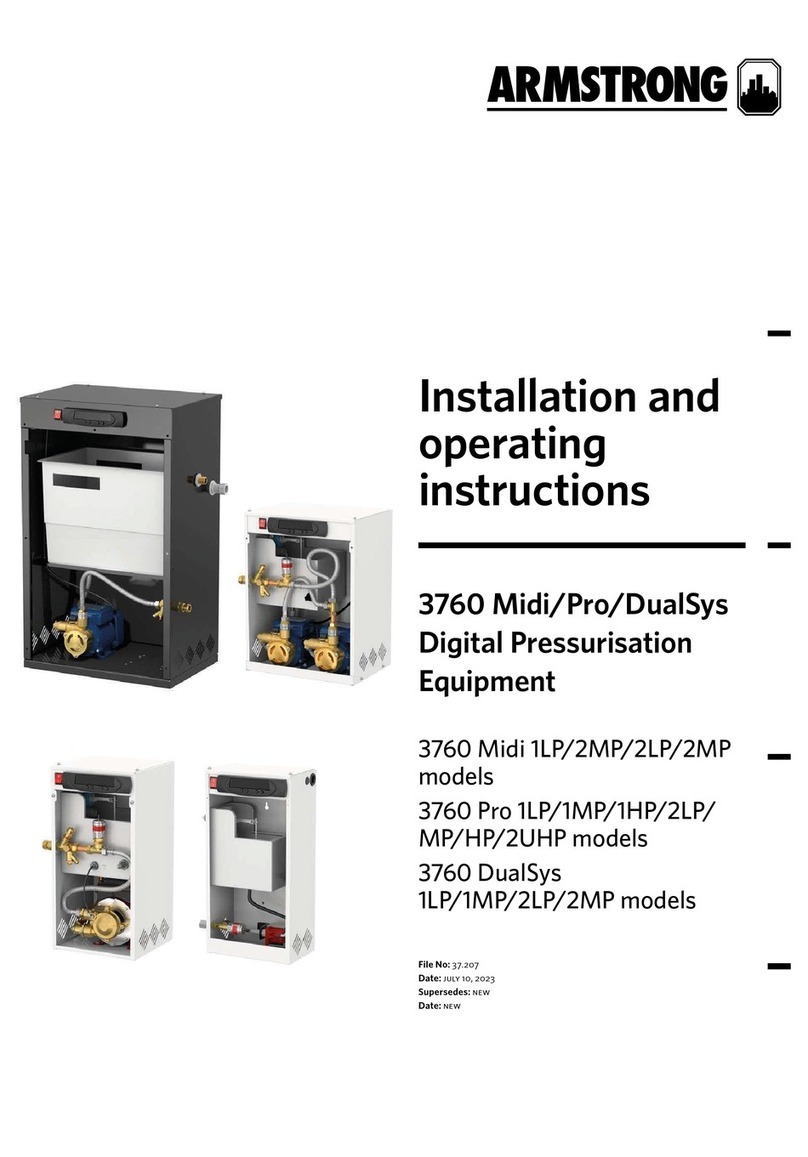

3760 Pro & Midi Range

Pressurisation Equipment

7

Installation

This pressurisation unit is not designed to be installed in an outdoor environment. The unit must be

installed in a frost free environment, away from precipitation and water sprays/jets. If there is a risk of

flooding, the unit must be installed on a raised plinth.

The unit is equipped with a Category 5 Weir overflow arrangement and must not be installed / sited

where damage to the local environs can occur on water egress

Please refer to the appropriate datasheet for the maximum working pressure and temperature of the

pressurisation unit. The conditions at the point of connection to the system must not exceed these

values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before connection to

the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape. If PTFE tape is

used, care must be taken to ensure that the tape does not obstruct the orifice of the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed between the

pressurisation unit and the heating/cooling system. These devices will prevent the pressure sensor

from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the same point,

to provide a neutral pressure reading. This point of connection should be in the system return, on the

suction side of the circulation pump.

© 2018 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 1.0 Aug-18 Page 11 / 48

Installation

This equipment is not designed to be installed in an outdoor environment. The unit must be

installed in a frost-free environment, away from precipitation and water sprays/jets. If there is a

risk of flooding, the unit must be installed on a raised plinth.

The unit is equipped with a Category 5 Weir overflow arrangement and must not be installed /

sited where damage to the local environs can occur on water egress

Please refer to the appropriate datasheet for the maximum working pressure and temperature of

the pressurisation unit. The conditions at the point of connection to the system must not exceed

these values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before

connection to the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape.

If PTFE tape is used, care must be taken to ensure that the tape does not obstruct the orifice of

the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed between the

pressurisation unit and the heating/cooling system. These devices will prevent the pressure

sensor from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the same

point, to provide a neutral pressure reading. This point of connection should be in the system

return, on the suction side of the circulation pump.

Connections to the return header of the system must be made in the horizontal plane, to prevent

system borne debris entering the equipment. Where 2 connections are required to the system

return header, they must join the header at 2 distinctly separate points at least 500 mm apart

© 2018 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 1.0 Aug-18 Page 11 / 48

Installation

This equipment is not designed to be installed in an outdoor environment. The unit must be

installed in a frost-free environment, away from precipitation and water sprays/jets. If there is a

risk of flooding, the unit must be installed on a raised plinth.

The unit is equipped with a Category 5 Weir overflow arrangement and must not be installed /

sited where damage to the local environs can occur on water egress

Please refer to the appropriate datasheet for the maximum working pressure and temperature of

the pressurisation unit. The conditions at the point of connection to the system must not exceed

these values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before

connection to the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape.

If PTFE tape is used, care must be taken to ensure that the tape does not obstruct the orifice of

the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed between the

pressurisation unit and the heating/cooling system. These devices will prevent the pressure

sensor from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the same

point, to provide a neutral pressure reading. This point of connection should be in the system

return, on the suction side of the circulation pump.

Connections to the return header of the system must be made in the horizontal plane, to prevent

system borne debris entering the equipment. Where 2 connections are required to the system

return header, they must join the header at 2 distinctly separate points at least 500 mm apart

© 2018 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 1.0 Aug-18 Page 11 / 48

Installation

This equipment is not designed to be installed in an outdoor environment. The unit must be

installed in a frost-free environment, away from precipitation and water sprays/jets. If there is a

risk of flooding, the unit must be installed on a raised plinth.

The unit is equipped with a Category 5 Weir overflow arrangement and must not be installed /

sited where damage to the local environs can occur on water egress

Please refer to the appropriate datasheet for the maximum working pressure and temperature of

the pressurisation unit. The conditions at the point of connection to the system must not exceed

these values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before

connection to the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape.

If PTFE tape is used, care must be taken to ensure that the tape does not obstruct the orifice of

the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed between the

pressurisation unit and the heating/cooling system. These devices will prevent the pressure

sensor from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the same

point, to provide a neutral pressure reading. This point of connection should be in the system

return, on the suction side of the circulation pump.

Connections to the return header of the system must be made in the horizontal plane, to prevent

system borne debris entering the equipment. Where 2 connections are required to the system

return header, they must join the header at 2 distinctly separate points at least 500 mm apart

© 2018 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 1.0 Aug-18 Page 11 / 48

Installation

This equipment is not designed to be installed in an outdoor environment. The unit must be

installed in a frost-free environment, away from precipitation and water sprays/jets. If there is a

risk of flooding, the unit must be installed on a raised plinth.

The unit is equipped with a Category 5 Weir overflow arrangement and must not be installed /

sited where damage to the local environs can occur on water egress

Please refer to the appropriate datasheet for the maximum working pressure and temperature of

the pressurisation unit. The conditions at the point of connection to the system must not exceed

these values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before

connection to the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape.

If PTFE tape is used, care must be taken to ensure that the tape does not obstruct the orifice of

the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed between the

pressurisation unit and the heating/cooling system. These devices will prevent the pressure

sensor from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the same

point, to provide a neutral pressure reading. This point of connection should be in the system

return, on the suction side of the circulation pump.

Connections to the return header of the system must be made in the horizontal plane, to prevent

system borne debris entering the equipment. Where 2 connections are required to the system

return header, they must join the header at 2 distinctly separate points at least 500 mm apart

© 2018 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 1.0 Aug-18 Page 11 / 48

Installation

This equipment is not designed to be installed in an outdoor environment. The unit must be

installed in a frost-free environment, away from precipitation and water sprays/jets. If there is a

risk of flooding, the unit must be installed on a raised plinth.

The unit is equipped with a Category 5 Weir overflow arrangement and must not be installed /

sited where damage to the local environs can occur on water egress

Please refer to the appropriate datasheet for the maximum working pressure and temperature of

the pressurisation unit. The conditions at the point of connection to the system must not exceed

these values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before

connection to the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape.

If PTFE tape is used, care must be taken to ensure that the tape does not obstruct the orifice of

the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed between the

pressurisation unit and the heating/cooling system. These devices will prevent the pressure

sensor from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the same

point, to provide a neutral pressure reading. This point of connection should be in the system

return, on the suction side of the circulation pump.

Connections to the return header of the system must be made in the horizontal plane, to prevent

system borne debris entering the equipment. Where 2 connections are required to the system

return header, they must join the header at 2 distinctly separate points at least 500 mm apart

© 2018 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 1.0 Aug-18 Page 11 / 48

Installation

This equipment is not designed to be installed in an outdoor environment. The unit must be

installed in a frost-free environment, away from precipitation and water sprays/jets. If there is a

risk of flooding, the unit must be installed on a raised plinth.

The unit is equipped with a Category 5 Weir overflow arrangement and must not be installed /

sited where damage to the local environs can occur on water egress

Please refer to the appropriate datasheet for the maximum working pressure and temperature of

the pressurisation unit. The conditions at the point of connection to the system must not exceed

these values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before

connection to the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape.

If PTFE tape is used, care must be taken to ensure that the tape does not obstruct the orifice of

the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed between the

pressurisation unit and the heating/cooling system. These devices will prevent the pressure

sensor from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the same

point, to provide a neutral pressure reading. This point of connection should be in the system

return, on the suction side of the circulation pump.

Connections to the return header of the system must be made in the horizontal plane, to prevent

system borne debris entering the equipment. Where 2 connections are required to the system

return header, they must join the header at 2 distinctly separate points at least 500 mm apart

© 2018 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 1.0 Aug-18 Page 11 / 48

Installation

This equipment is not designed to be installed in an outdoor environment. The unit must be

installed in a frost-free environment, away from precipitation and water sprays/jets. If there is a

risk of flooding, the unit must be installed on a raised plinth.

The unit is equipped with a Category 5 Weir overflow arrangement and must not be installed /

sited where damage to the local environs can occur on water egress

Please refer to the appropriate datasheet for the maximum working pressure and temperature of

the pressurisation unit. The conditions at the point of connection to the system must not exceed

these values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before

connection to the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape.

If PTFE tape is used, care must be taken to ensure that the tape does not obstruct the orifice of

the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed between the

pressurisation unit and the heating/cooling system. These devices will prevent the pressure

sensor from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the same

point, to provide a neutral pressure reading. This point of connection should be in the system

return, on the suction side of the circulation pump.

Connections to the return header of the system must be made in the horizontal plane, to prevent

system borne debris entering the equipment. Where 2 connections are required to the system

return header, they must join the header at 2 distinctly separate points at least 500 mm apart