Page 1 of 2

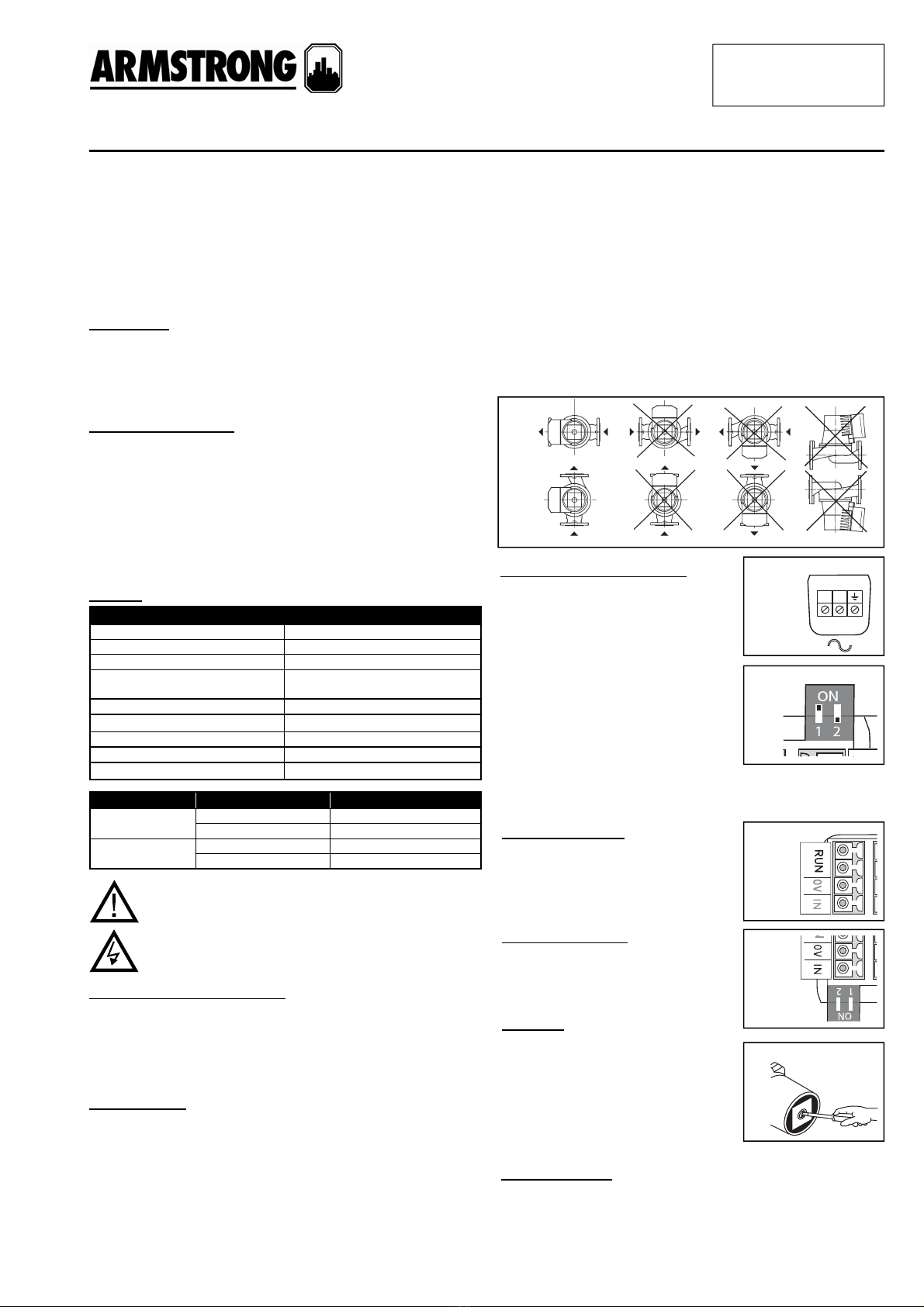

By using the red dip switch on the print

board, you can either choose to control the

pump manually or remotely. In the manual

mode you control the speeds by the rotat-

ing button. When the pump is controlled

remotely, its controlled analogical.

The dip switch has the following functions:

ON = Remote Control

OFF = Manual Steering

Contact 2 is without function.

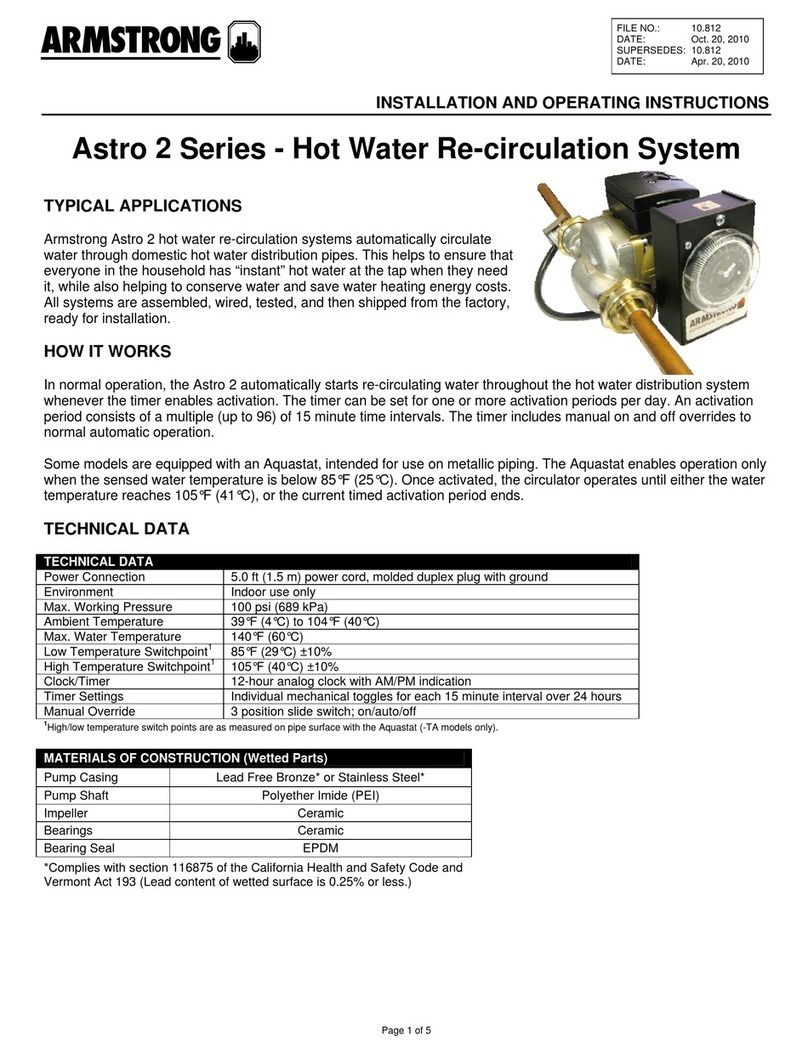

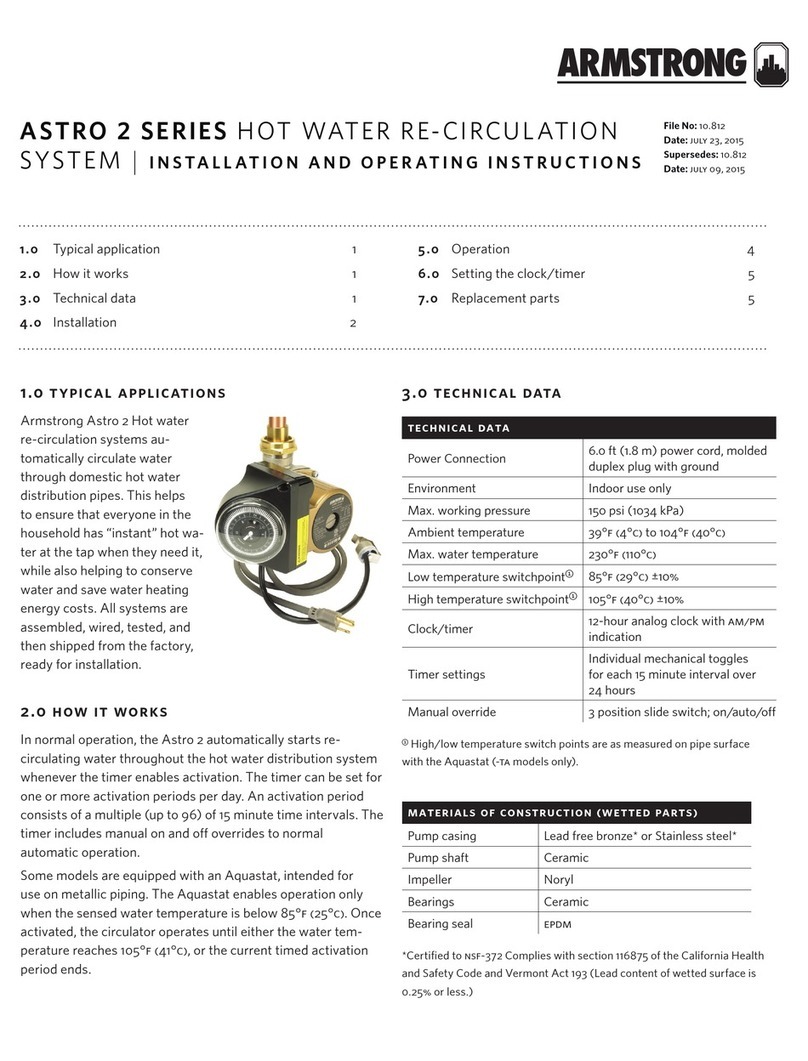

This installation guide gives basic instructions which are to be observed

during installation, operation and maintenance of the circulator. It is therefore

imperative that this manual is read by the responsible operator prior to the

installation and should always be kept available at the site.

It is not only the general safety instructions under the ”Safety” section that

are to be observed but also the specific information provided throughout this

guide.

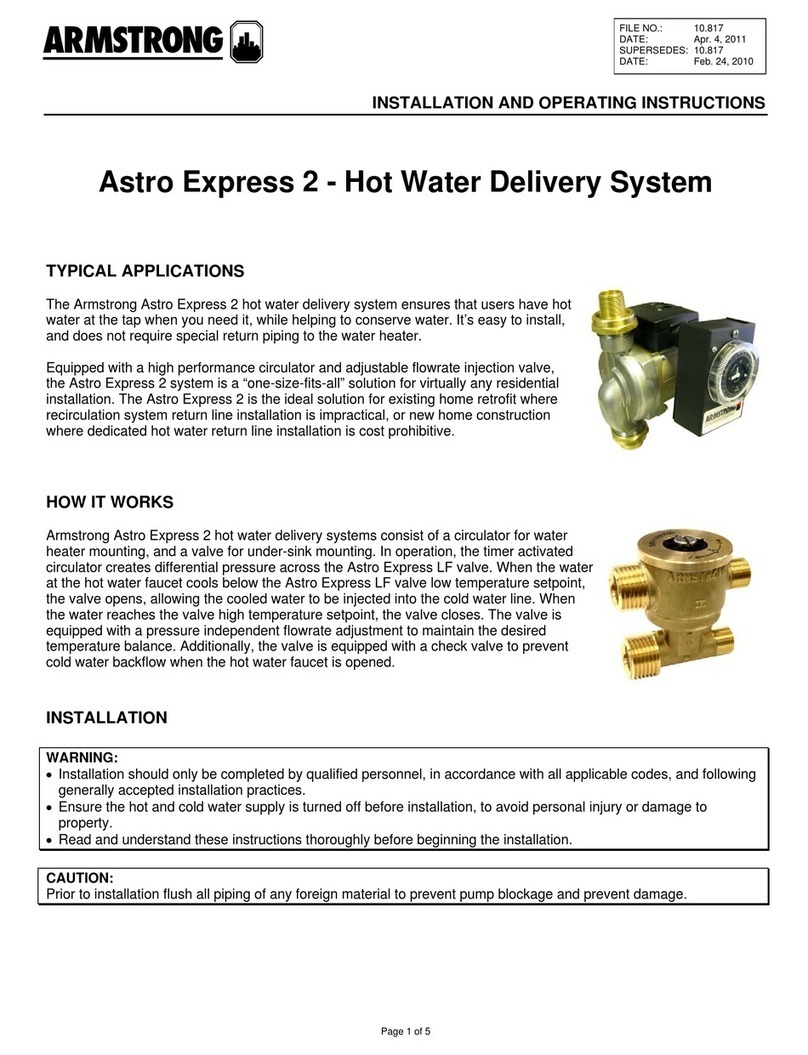

APPLICATION

The AGEplus SERIES circulators are used in all types of heating systems.

By use of the advanced internal speed control, the electronic automatic

adjustment the circulator performance according to system needs. This

feature gives both great electrical and thermal savings together with reduced

noise level in the installation.

CIRCULATOR MEDIUM

Clean, non aggressive and non explosive fluids without any solids or fibres.

Kinematic viscosity: Max. 10mm2/s. Higher viscosity will cause circulator to

regulate improperly. Capacities shown on the data sheets are measured

with water v =1mm2/s at 20ºC.

Suitable for water impurity up to 5mg/dm3.

Please note: If any liquid other than water is being circulated, we

recommend that you contact our representative as the circulator

characteristics may change.

SAFETY

- The surface temperature might be hot.

- When venting the circulator (Fig. 6), it could result in a slight

escape of hot water or steam!

- Circulator should be wired according to the existing regulations

- The circulator must always be earthed..

- All the wires must be disconnected before any work is

carried out on the circulator.

Personnel qualification and training

Personnel responsible for operation, maintenance, inspection and

installation of the circulator must be adequatelyqualified.

The person responsible for the complete installation must ensure that the

contents of this manual are fully understood by any personnel working on

the system.

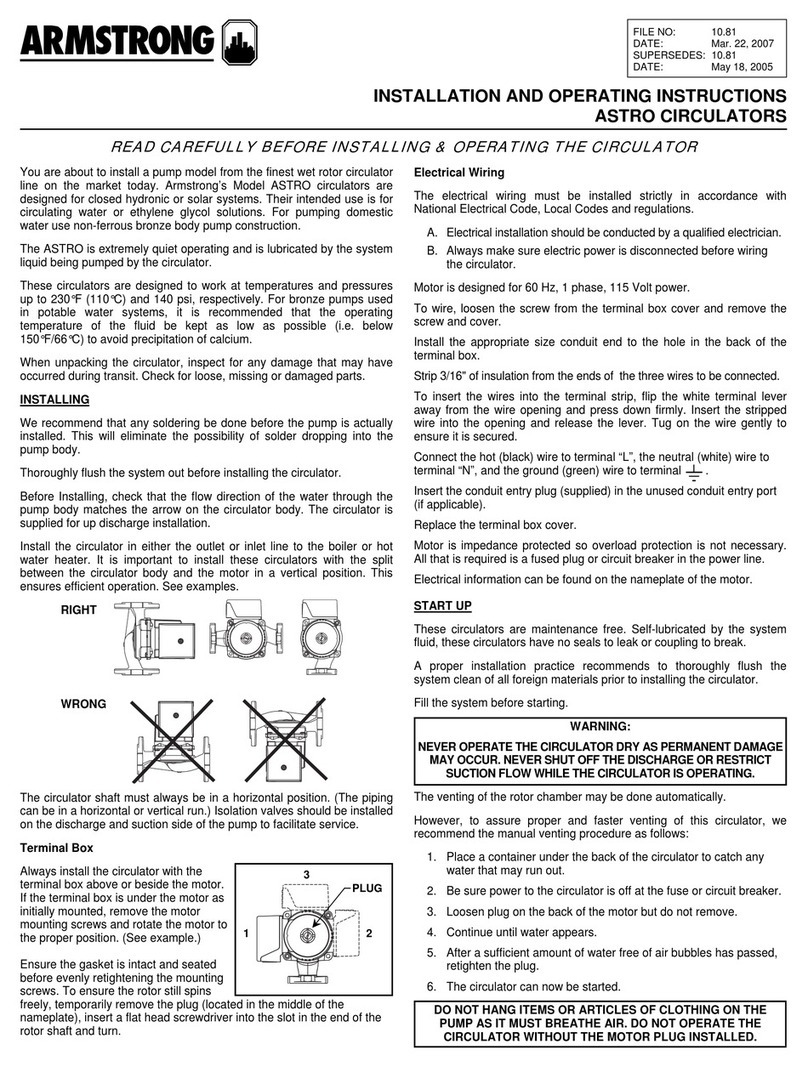

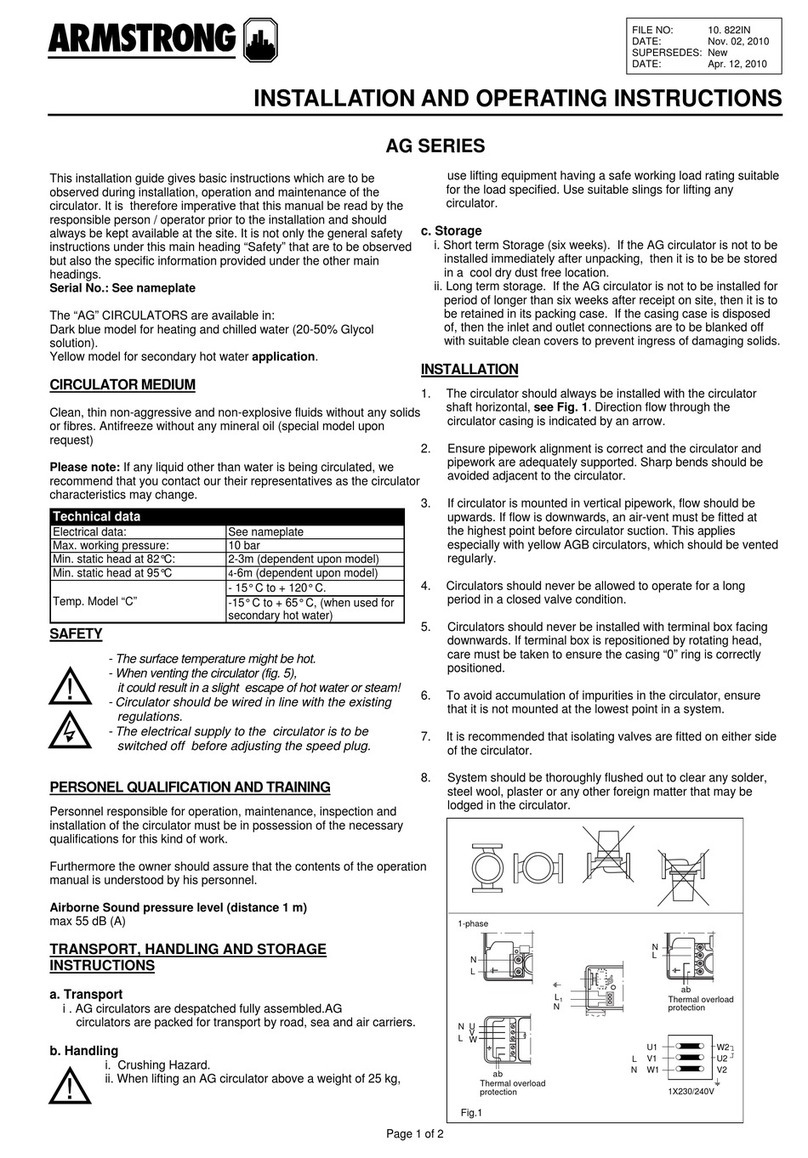

INSTALLATION

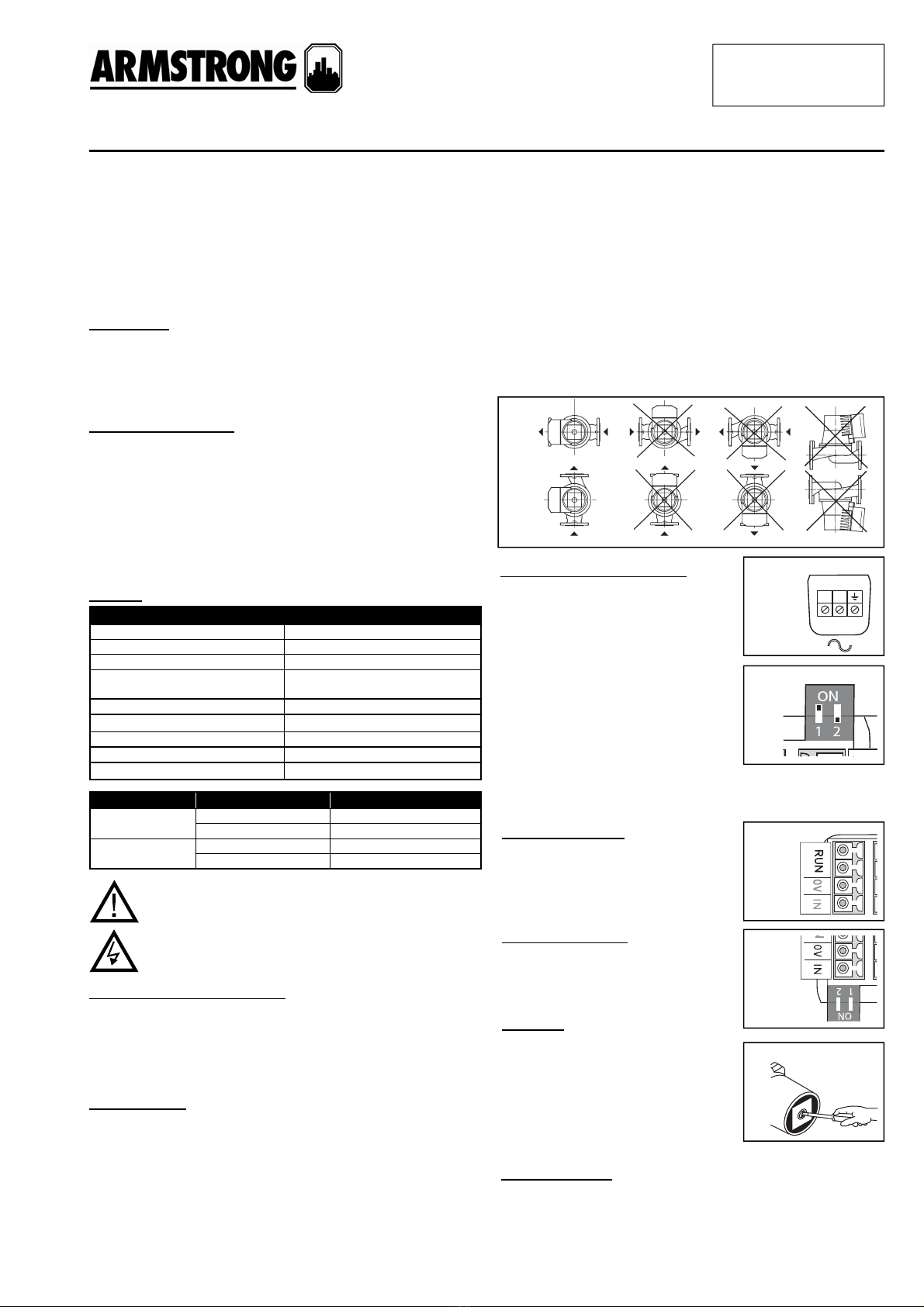

1. The circulator should always be installed with the circulator shaft

horizontal (See Fig. 1). Direction of flow through the circulator casing is

indicated by an arrow located on the casing.

2. If terminal box is to be repositioned by rotating the motor, care must be

taken to ensure the casing 0-ring is correctly positioned.

3. Ensure pipework alignment and adequately supported to both the

circulator and pipework. Sharp bends should be avoided nearby the

circulator.

4. If the circulator is mounted in vertical pipework, flow should be upwards.

If flow is downwards, an air-vent must be fitted at the highest point before

circulator suction.

5. Circulator should never be allowed to operate against a closed valve for

more then a few minutes at the time.

6. To avoid accumulation of impurities in the circulator, make sure that it is

not mounted at the lowest point in a system.

7. It is recommended that isolating valves be fitted eitherside of the

circulator.

8. Before installing a new pump the system should be thoroughly flushed to

clear any foreign objects that may be in the pipework.

AGEplus Series Water temp. max. [C°] Ambient temp. max. [C°]

32-120, 40-100,

40-140 & 50-140 110 30

90 40

90 30

70 40

65-120 & 80-120

Fig. 1

VENTING

Before start up of the circulator, fill the system

and vent the circulator thoroughly. Venting can

be achieved by loosening the plug positioned

in centre of nameplate (See Fig. 6). This proc-

ess should be repeated periodicallyuntil all air

within the system has been removed. Venting

is best done in manual speed 4.

ELECTRICAL CONNECTION

Electrical data is shown on the nameplate.

The circulator needs no external protection but

must be earthed.How to connect the wires

can be seen on the terminals of the circulator.

Technical data

Electrical data: See nameplate

Serial no: See nameplate

Max. working pressure: 10 bar

Min. static head at 80°C: 0,5 bar (65-120 & 80-120

- 0,8 bar)

Min. static head at 95°C 1,5 bar

Sound pressure level

30-120 up to 40-140: Max. 35 dB(A)

50-140 up to 80-120: Max. 50 dB(A)

According to EN 12639

INSTALLATION AND OPERATING INSTRUCTIONS

FILE NO: 10. 823UK

DATE: May. 11, 2011

SUPERSEDES: New

DATE: New

AGEplus SERIES

Analogue 0-10 Volt

The AGEplus can be controlled infinitely

variable by analogue signal from 0-10 V.

0V = Min.speed; 10V = Max. speed

Remote Start-Stop

AGEplus pump has a remote start-stop

function. A cable must be connected to the

RUN contact. If a cable should be discon-

nected, the pump will shut down and the

red light will flash rapidly.

DUTY CONTROL

There are two modes for controlling the circulators.

• Controlled to follow a specific defined differential pressure at different

flows (auto).

Fig. 2

L N

Net

Fig. 3

Fig. 4

Fig. 5

Fig. 6