Page 1 of 2

AG SERIES

INSTALLATION AND OPERATING INSTRUCTIONS

FILE NO: 10. 822IN

DATE: Nov. 02, 2010

SUPERSEDES: New

DATE: Apr. 12, 2010

This installation guide gives basic instructions which are to be

observed during installation, operation and maintenance of the

circulator. It is therefore imperative that this manual be read by the

responsible person / operator prior to the installation and should

always be kept available at the site. It is not only the general safety

instructions under this main heading “Safety” that are to be observed

but also the specific information provided under the other main

headings.

Serial No.: See nameplate

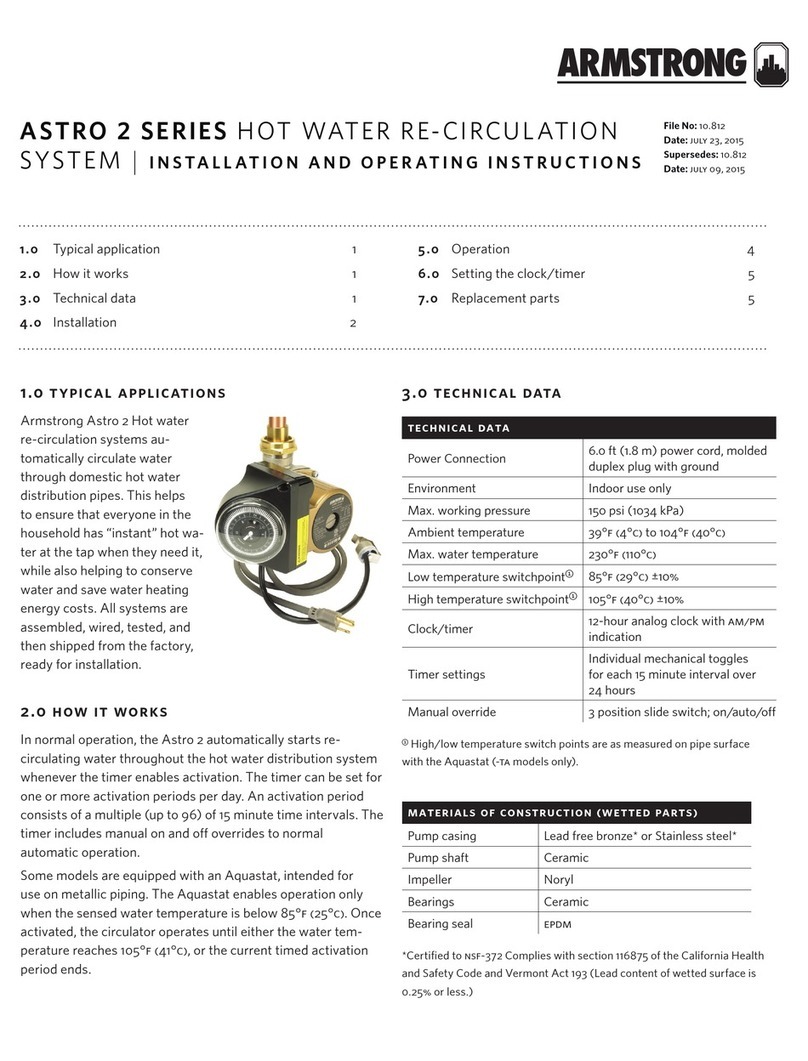

The “AG” CIRCULATORS are available in:

Dark blue model for heating and chilled water (20-50% Glycol

solution).

Yellow model for secondary hot water application.

CIRCULATOR MEDIUM

Clean, thin non-aggressive and non-explosive fluids without any solids

or fibres. Antifreeze without any mineral oil (special model upon

request)

Please note: If any liquid other than water is being circulated, we

recommend that you contact our their representatives as the circulator

characteristics may change.

SAFETY

- The surface temperature might be hot.

- When venting the circulator (fig. 5),

it could result in a slight escape of hot water or steam!

- Circulator should be wired in line with the existing

regulations.

- The electrical supply to the circulator is to be

switched off before adjusting the speed plug.

PERSONEL QUALIFICATION AND TRAINING

Personnel responsible for operation, maintenance, inspection and

installation of the circulator must be in possession of the necessary

qualifications for this kind of work.

Furthermore the owner should assure that the contents of the operation

manual is understood by his personnel.

Airborne Sound pressure level (distance 1 m)

max 55 dB (A)

TRANSPORT, HANDLING AND STORAGE

INSTRUCTIONS

a. Transport

i . AG circulators are despatched fully assembled.AG

circulators are packed for transport by road, sea and air carriers.

b. Handling

i. Crushing Hazard.

ii. When lifting an AG circulator above a weight of 25 kg,

use lifting equipment having a safe working load rating suitable

for the load specified. Use suitable slings for lifting any

circulator.

c. Storage

i. Short term Storage (six weeks). If the AG circulator is not to be

installed immediately after unpacking, then it is to be be stored

in a cool dry dust free location.

ii. Long term storage. If the AG circulator is not to be installed for

period of longer than six weeks after receipt on site, then it is to

be retained in its packing case. If the casing case is disposed

of, then the inlet and outlet connections are to be blanked off

with suitable clean covers to prevent ingress of damaging solids.

INSTALLATION

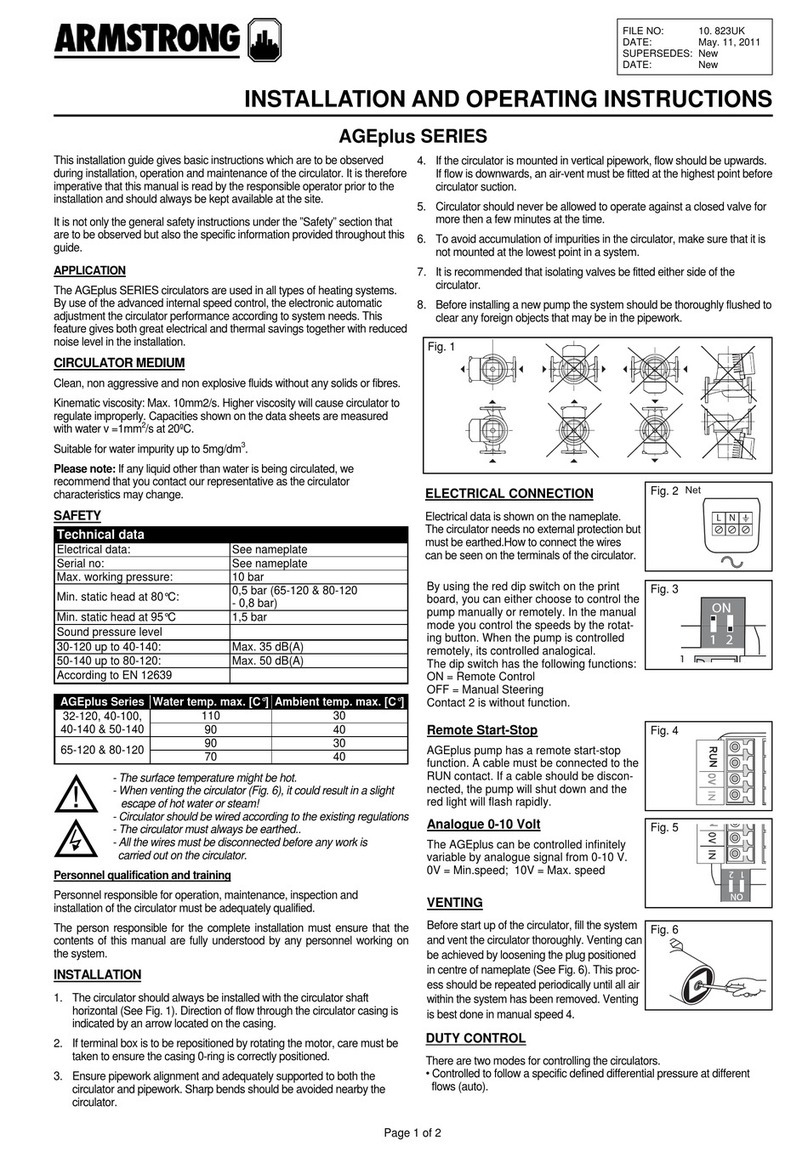

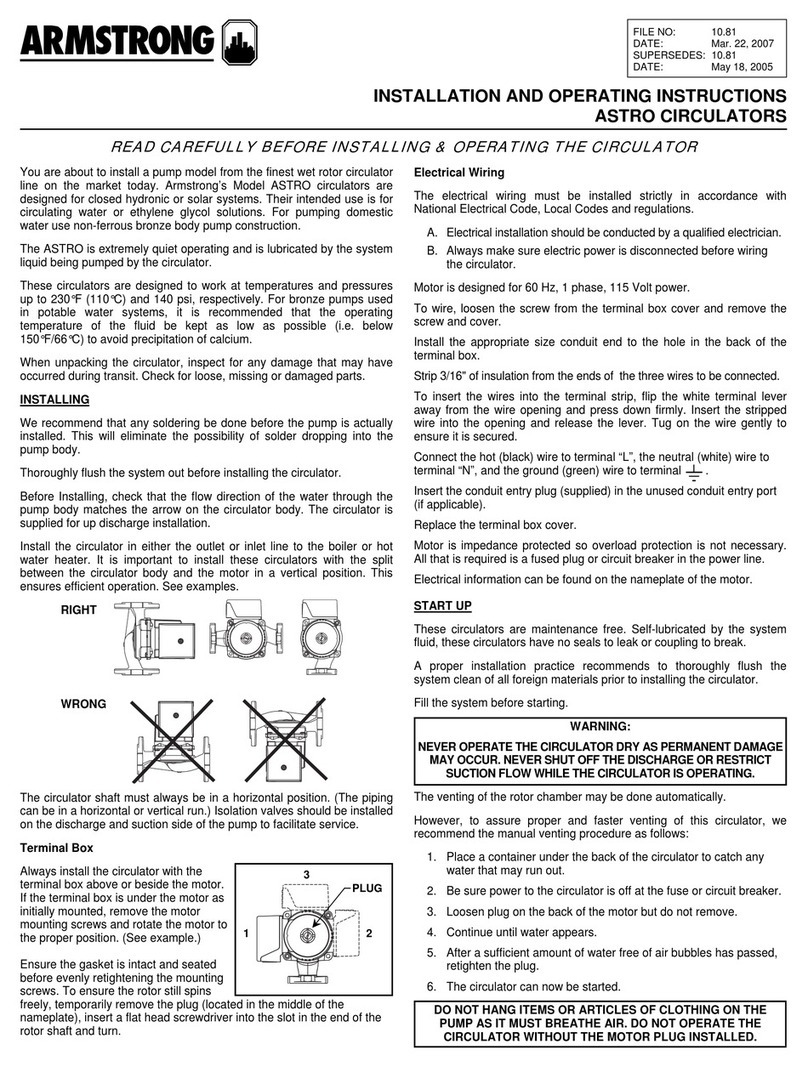

1. The circulator should always be installed with the circulator

shaft horizontal, see Fig. 1. Direction flow through the

circulator casing is indicated by an arrow.

2. Ensure pipework alignment is correct and the circulator and

pipework are adequately supported. Sharp bends should be

avoided adjacent to the circulator.

3. If circulator is mounted in vertical pipework, flow should be

upwards. If flow is downwards, an air-vent must be fitted at

the highest point before circulator suction. This applies

especially with yellow AGB circulators, which should be vented

regularly.

4. Circulators should never be allowed to operate for a long

period in a closed valve condition.

5. Circulators should never be installed with terminal box facing

downwards. If terminal box is repositioned by rotating head,

care must be taken to ensure the casing “0” ring is correctly

positioned.

6. To avoid accumulation of impurities in the circulator, ensure

that it is not mounted at the lowest point in a system.

7. It is recommended that isolating valves are fitted on either side

of the circulator.

8. System should be thoroughly flushed out to clear any solder,

steel wool, plaster or any other foreign matter that may be

lodged in the circulator.

Technical data

Electrical data: See nameplate

Max. working pressure: 10 bar

Min. static head at 82°C: 2-3m (dependent upon model)

Min. static head at 95°C 4-6m (dependent upon model)

- 15° C to + 120° C.

-15° C to + 65° C, (when used for

secondary hot water)

Temp. Model “C”

a

N

Fig.1

L

Thermal overload

protection

N

L

N

1-phase

L

b

1

NU

V

W

L

a

Thermal overload

protection

bN

LU1

V1

W1

W2

U2

V2

1X230/240V