12

4

6

8

9

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

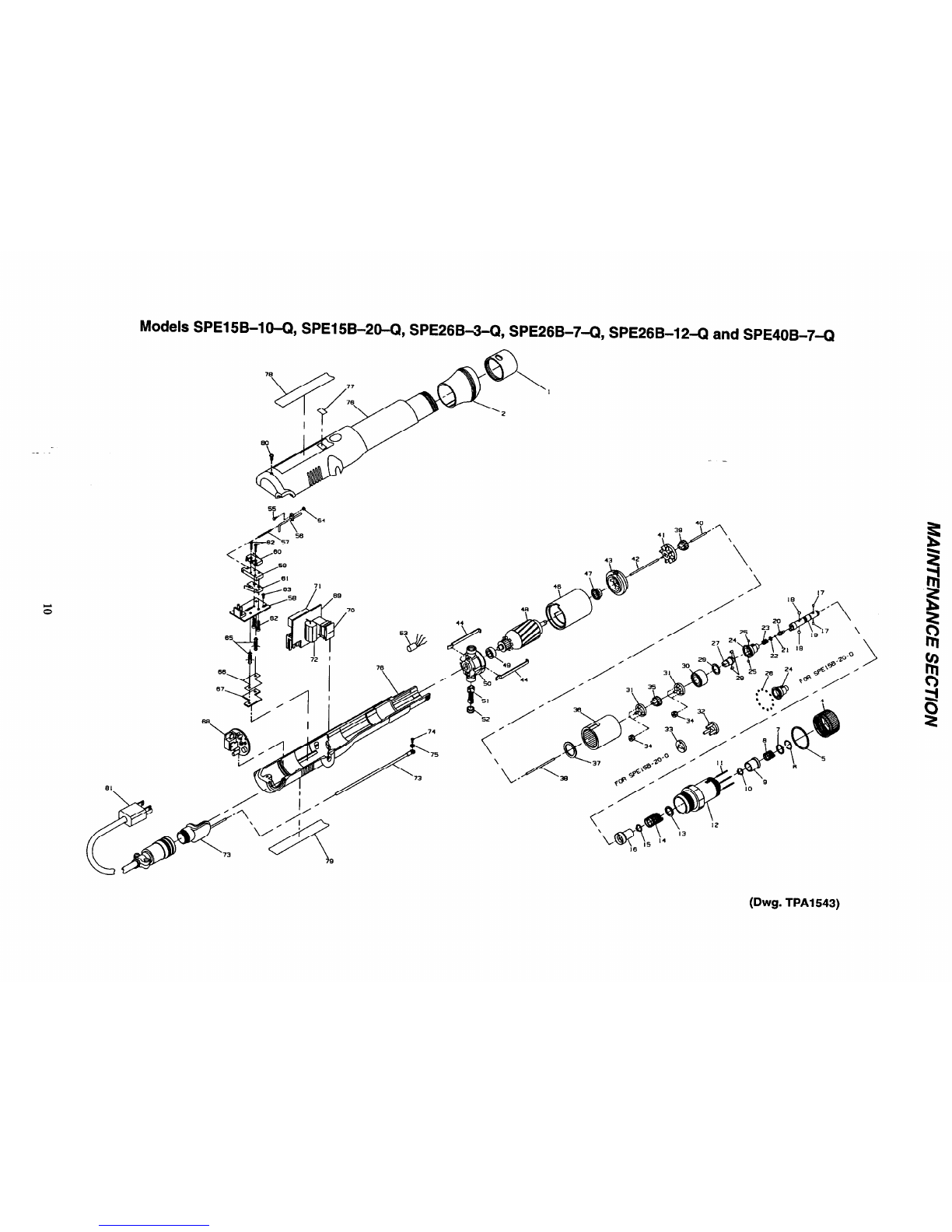

Models SLE15B-10-Q SLE15B-20-Q SLE26B3-Q, SLE26B-7-Q SLE26B-12-Q

and STE40B-7-Q Electric Screwdrivers

PART NUMBER FOR ORDERING

Retainer Coupling ................................

StraightFlange(Standardon STE4ON-7-Q) ...........

SlantedFlange(Standardon all others) ................

Clutch Adjusting Ring .............................

Indicator Ring ...................................

Bit RetainerRetaining Ring (Front) ..................

Bit RetainerCollar ...............................

Bit RetainerSpring ...............................

Bit RetainerSleeve ...............................

Bit RetainerRetaining Ring .........................

Clutch Adjusting Pin (3) ...........................

Clutch Housing Assembly ..........................

FrontShim ......................................

Rear Shim.......................................

Clutch SpringPlate ...............................

Clutch Spring

for SLElSB-l0-Q ..........................

for SLElSB-20-Q ..........................

for SLE26B-3-Q, SLE26B-74 and

SLE26B-12-Q .............................

for STE40B-7-Q ...........................

TaperRing Retaining Ring .........................

TaperRing Assembly

for SLE15B-20-Q ..........................

for SLElSB-10-Q, SLE26B-3-Q

SLE26B-7-Q andSLE26B-12-Q .............

for STE40B-7-Q ...........................

Bit Retaining Ball (.094dia.) (2) ....................

Pilot CamBall (.156dia.) (4) .......................

Bit Holder Assembly ..............................

Pilot ...........................................

Pilot Ball (.062dia.) ...............................

CamGuide

for SLE15B-20-Q ..........................

for all others ...............................

Cam Guide Ball (.156dia.) .........................

CamGuide Bearing Ball (23) (078”dia.)

(forSLE15B-20-Q) ..............................

SLE15B-125

EP4007N-123

EP4007N-124

EP4007N-582

EP4007N-682

EP4007N-683

EP4007N-585

EP4007N-931

EP4007N-930

EP4007N-584

EP4007N-416

EP4007N-580

EL4007N-623

EL4007N624

EP4007N-623

EP1510N-583

EP1520N-583

EP2607N-583

EP4007N-583

EP4007N-584

EP152ON-588

EP2607N-588

EP4007N-588

ROOOB-263

2U-696

EP4007N-586

EP4007NA08

EP4007N-422

EP1520N-681

EP4007NA-681

2U-696

EL1520N-510

27

28

29

30

31

33

34

35

36

38

PART NUMBER FOR ORDERING

Cam for SLE26B-3-Q andSTE40B-7-Q ............

for all others ...............................

CamRoller (2) ...................................

SpindleWasher

for SLE15B-20-Q ..........................

for all others ...............................

SpindleBearing ..................................

Spindle/GearHead(2)

for SLElSB-l0-Q, SLE26B-3-Q and

SLE26B-7-Q ..............................

for SLE26B-12-Q ..........................

for STE40B-7-Q ...........................

GearHead(for SLEl5B-20-Q) .....................

GearHeadSpacer(for SLE15B-20-Q) ...............

PlanetGear

for SLE15B-10-Q ..........................

for SLE15B-20-Q ..........................

for SLE26B-3-Q ...........................

for SLE26B-7-Q ...........................

for SLE26B-12-Q ..........................

for STE40B-7-Q ...........................

GearHeadPinion Gear

for SLEl5B-10-Q andSLEl5B-20-Q ..........

for SLE26B-3-Q ...........................

for SLE26B-7-Q ...........................

for SLE26B-12-Q ..........................

for STE40B-7-Q ...........................

GearCase

for SLElSB-l0-Q ..........................

for SLE15B-20-Q, SLE26B-3Q, SLE26B-12-Q

andSTE40B-74 ..........................

for SLE26B-7-Q ...........................

GearCaseShield .................................

Clutch Pilot Rod “I” (2.26” long) ....................

EP4007N-581

EP1510N-581

EP4007N-587

EL152ON-509

EP4007N-509

EP4007N-510

EP2607N-216

EP2612N-216

EP4007N-216

EP1520N-216

EP1520N-108

EPlSl0N-10

EP1520N-10

EP2603N-10

EP2607N-10

EP2612N-10

EP4007N-10

EP1510N-17

EP2603N-17

EP2607N-17

EP2612N-17

EP4007N-17

EP1510-37

EP4007N-37

EP2607N-17

EP4007N-207

EP4007N-435

*

Not illustrated.