WACKER Group M 1000 User manual

www.wackergroup.com

Internal Vibrator

M 1000

M 2000

M 3000

OPERATOR’S MANUAL

0154561en 001

0403

0154561EN

Foreword

wc_tx000001gb.fm

Engine exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm.

1. Foreword

This manual provides information and procedures to safely operate

and maintain this Wacker model. For your own safety and protection

from injury, carefully read, understand and observe the safety

instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Corporation reserves the

right to change any portion of this information without notice.

All rights, especially copying and distribution rights are reserved.

Copyright 2002 by Wacker Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Corporation.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights and will be

prosecuted. We expressly reserve the right to make technical

modifications, even without due notice, which aim at improving our

machines or their safety standards.

WARNING

HMS

ii

MADE IN

USA

87577

hplbs kW

kg

Month / Year

dB(A)

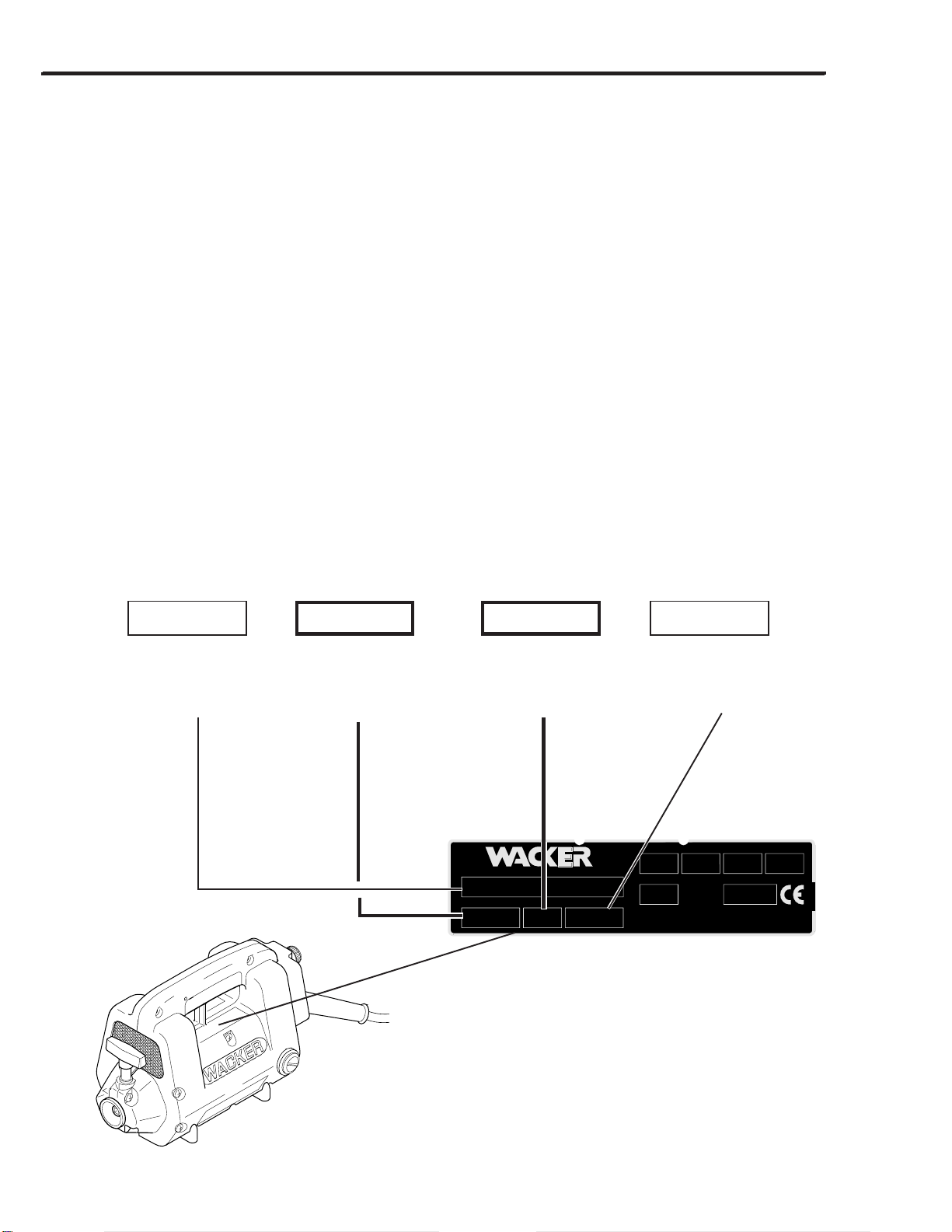

Item Number Rev. Serial Number

MENOMONEE FALLS, WI USA 53051

Model

Serial Number

Maschinen-Nummer

Número de Serie

Numéro de Série

My machine’s numbers are / Die Nummern meines Gerätes sind /

Los números de mi máquina son / Les numéros de ma machine sont :

Revision

Version

Nivel de revisión

Niveau de revision

Item Number

Artikel-Nummer

Número de referencia

Numéro de référence

Model number

Typ

Modelo

Modèle

M1000M1000

M1000M1000

M1000

00050410005041

00050410005041

0005041 101101

101101

101 50101015010101

50101015010101

5010101

Nameplate / Typenschild / Placa de Identificación / Plaque signalétique

A nameplate listing the Model Number, Item Number, Revision, and Serial Number is attached to each unit. Please

record the information found on this plate so it will be available should the nameplate become lost or damaged. When

ordering parts or requesting service information, you will always be asked to specify the model, item number,

revision number, and serial number of the unit.

Ein Typenschild mit Typ, Artikelnummer, Version und Maschinen-Nummer ist an jedem Gerät angebracht. Die Daten

von diesem Schild bitte notieren, damit sie auch bei Verlust oder Beschädigung des Schildes noch vorhanden sind.

DerTyp,dieArtikel-Nummer,dieVersions-NummerunddieMaschinen-NummersindbeiderErsatzteilbestellung

oder Nachfragen bezüglich Service-Informationen stets erforderlich.

Una placa de identificación con el modelo, número de referencia, nivel de revisión y número de serie ha sido añadida

en cada máquina. Favor de anotar los datos en la placa en caso de que la placa de identificación sea destruida o

perdida. En todos los pedidos para repuestos necesita siempre el modelo, el número de referencia, el nivel de

revisión y el número de serie de la máquina en cuestión.

Une plaque signalétique mentionnant le modèle, le numéro de référence, le niveau de revision et le numéro de série

est fixée sur chaque machine. Veuillez noter les informations relevées sur cette plaque de façon àce qu’elles soient

toujours disponibles si la plaque signalétique venait àêtre perdue ou endommagée. Lorsque vous commandez des

pièces détachées ou vous sollicitez des informations auprès-vente, on vous demandera toujours de préciser

le modèle, le numéro de référence, le niveau de revision et le numéro de série de la machine.

1007SD48

1

1A-1

HMS

Operating Information 1A

Contents

1.1 Safety Information ................................................................................ 1A-2

1.2 Safety................................................................................................... 1A-3

1.3 Technical Data ..................................................................................... 1A-4

1.4 Safety & Informational Labels .............................................................. 1A-5

1.5 Label Locations .................................................................................... 1A-5

1.6 Application ........................................................................................... 1A-6

1.7 Recommended HMS Combinations ..................................................... 1A-6

1.8 Extension Cords................................................................................... 1A-7

1.9 Connecting Motor to Power Supply ...................................................... 1A-7

1.10 Assembling Head, Motor and Shaft ...................................................... 1A-8

1.11 Operation ............................................................................................. 1A-8

1.12 Periodic Maintenance ........................................................................... 1A-9

1.13 Motor Brushes...................................................................................... 1A-9

1.14 Motor Housing...................................................................................... 1A-9

1.15 Lubricating Shaft ................................................................................ 1A-10

1.16 Lubricating Head ................................................................................ 1A-10

1.17 Checking Head for Wear .................................................................... 1A-11

1.18 Troubleshooting ................................................................................. 1A-11

1.19 Wiring Schematics ............................................................................. 1A-12

1A OPERATION HMS

1A-2

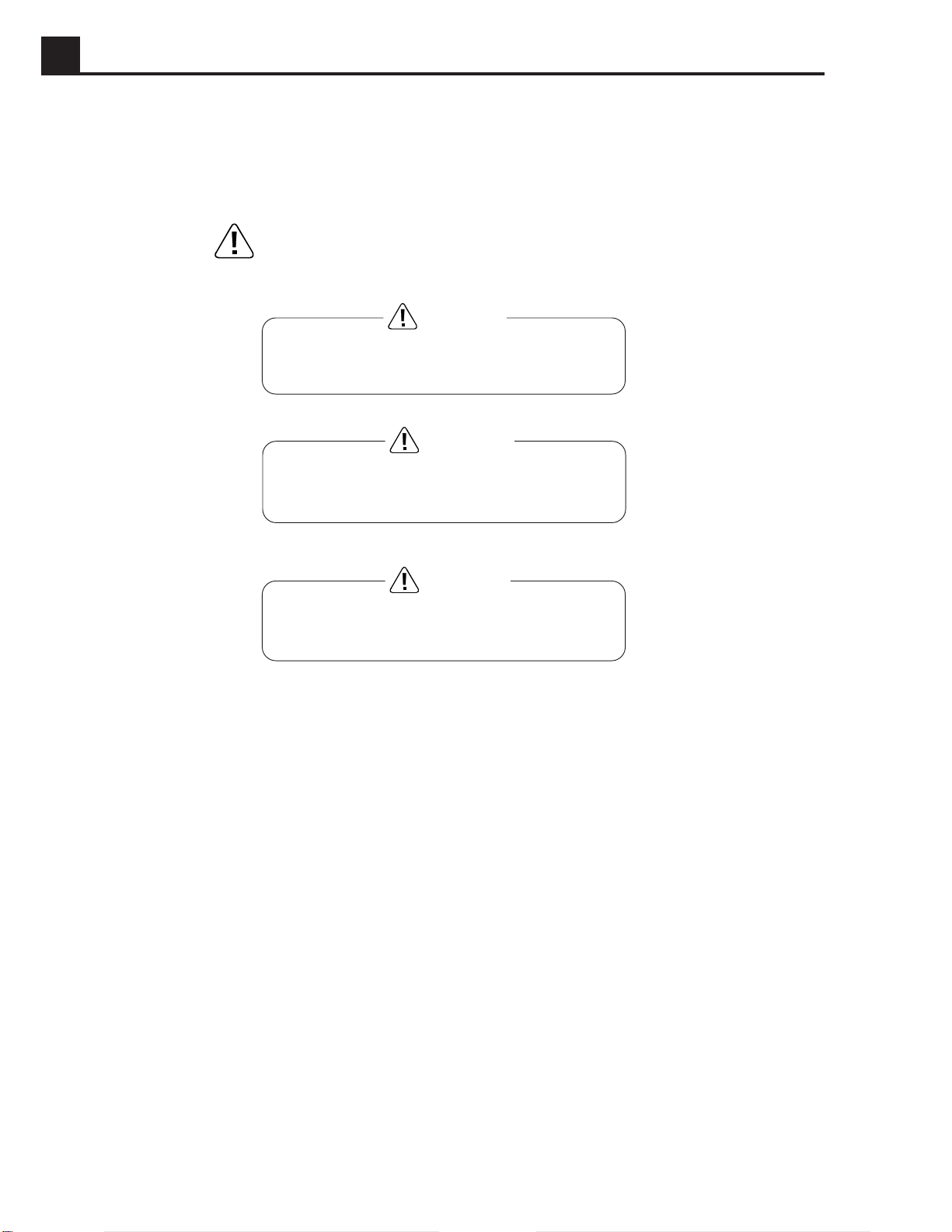

1.1 Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE callouts which must be followed to reduce the

possibility of personal injury, damage to the equipment, or improper service.

CAUTION: Used without the safety alert symbol,

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

Note:

Contains additional

information important to a procedure.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

DANGER

WARNING

CAUTION

HMS OPERATION 1A

1A-3

Familiarity and proper training are required for the safe operation of this equipment! Equipment operated or serviced

improperly or by untrained personnel can be dangerous! Read all operating instructions and the safety notes below.

Familiarize yourself with the proper use of this equipment before operating it.

WARNING

Keep work area clean and free of clutter.

Keep work area well lit.

Do not allow children or people other than the opera-

tor to handle power cables, extension cords or the

equipment.

Donot allownon-essential personnelor visitorsin the

work area.

Never operate motor in areas exposed to flammable

or explosive liquids or gases! The motor brushes

spark during operating and could ignite fumes.

Don't overreach! Keep proper footing and balance at

all times. Make sure any supporting structures are

strong enough and stable enough to support your

weight and the weight of any equipment on it.

Keep hands, feet, hair and loose clothing away from

moving parts. They can be caught in moving parts.

Wear protective clothing when operating equipment.

Goggles or safety glasses will protect against eye

damage caused by flying debris.

Never carry motor by cord or pull on it to disconnect

it from receptacle. Keep cord away from heat, oil and

sharp edges.

Keep handle, and other areas where motor and shaft

are gripped, dry, clean and free from oil and grease.

Avoidunintentional starting! Don't carrymotor around

jobsite while it is connected to power source. Don't

carry motor with finger on switch.

Stay alert! Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

Do not operate equipment if switch does not operate

properly.

Replace worn or damaged parts with replacement

parts designed and recommended for use by

WACKER Corporation.

Don't overload motor. An overloaded motor will over-

heat. Use only recommended head/motor/shaft com-

binations. See Table 1.

Neverallow untrainedpersonnel tooperate orservice

the equipment.

Never attach shaft to motor while it is running.

Alwayscheck thepower supplybefore runningmotor.

Using the wrong voltage supply will damage motor.

Always make sure motor switch is OFF before plug-

ging motor to power supply.

Any servicing, other than that covered in this instruc-

tion manual, should be performed by an authorized

WACKER Service Representative.

1.2 Safety

When using electric tools, basic safety precautions should always be followed to reduce the risk of fire, electric shock,

and personal injury! The guidelines following will help the user maintain operator safety.

When motor is used outdoors, use only extension

cords intended for and marked for outdoor use.

Always keep power cord away from heat, oil and

sharp edges which can damage it.

Make certain motor is in good working order and

properly grounded before starting.

Never operate motor with damaged or worn electrical

cords! When using an extension cord be sure to use

one heavy enough to carry the current load. See Table

2 for correct cable size to use.

Preventbody contactwith groundedsurfaces, suchas

pipes, metal railings, radiators and metal ductwork.

DANGER

1A OPERATION HMS

1A-4

M1000 (Green) M2000 (Yellow) M3000 (Red)

Voltage(AC/DC) V115 230 115 230 115 230

Current(Maximum) A9 4.5 15 6.5 20 10

Power Hp (kW) 1.3 (1.0) 1.3 (1.0) 2.3 (1.7) 2.0 (1.5) 3.1 (2.3) 3.1 (2.3)

Speed(No-load) rpm 15500 17500 16500

Weight lbs. (kg) 12(5.4) 13 (5.9) 18(8.1)

Motor type Universal electric motor

Frequency Hz 50/60

Phase 1

1.3 Technical Data

H25 H25S H35 H35S H45 H45S H55 H65

Diameter in. (mm) 1.0 (25) 1.0 (25) 1.4 (35) 1.4 (35) 1.8 (45) 1.8 (45) 2.3 (55) 2.5 (65)

Length in. (mm) 17.3 (440) 11.7 (295) 16.2 (410) 12.3 (310) 15.3 (385) 12.0 (305) 16.1 (410) 15.3 (385)

Weight lbs. (kg) 2.6 (1.2) 1.8 (0.9) 4.6 (2.1) 3.6 (1.6) 7.1 (3.2) 5.6 (2.5) 10.8 (4.9) 13.4 (6.0)

Compaction Dia. in. (cm) 16 (41) 14 (36) 24 (60) 22 (56) 30 (76) 28 (71) 40 (102) 48 (122)

Lubrication oz. (ml) 0.38 (10) 0.38 (10) 0.5 (15) 0.5 (15) 0.75 (22) 0.63 (19) 1.0 (30) 1.5 (44)

type SAE 80W140 synthetic oil (WACKER P/N 27238)

Sound and Vibration Measurements

The required sound specifications, per Appendix 1, Paragraph 1.7.4.f of the EC-Machine Regulations, are:

- the sound pressure level at operator’s location (LpA) = 84.7 dB(A)

-the guaranteed sound power level (LWA) = 96.4 dB(A)

Thesesound valueswere determinedaccording to ISO 3744 forthe soundpower level(LWA) andISO 6081for thesound

pressure level (LpA) at the operator’s location.

The weighted effective acceleration value, determined according to ISO 8662 Part 1, is 5.1 m/s2.

The sound and vibration measurements were obtained with the unit operating at nominal speed.

Vibrator Heads

Motors

Shafts

stfahS-EstfahS-S

E-1MSE-2MSE-4MSS-0MSS-1MSS-2MSS-3MSS-4MSS-5MSS-7MSS-9MS

htgneL)m(.tf)1(3)2(5,6)4(31)5,0(5,1)1(3)2(5,6)3(01)4(31)5(5,61)7(32)9(5,92

thgieW)gk(.sbl)4,1(3)3,2(5)3,4(01)3,2(5)3(7)5(11)7,6(51)5,8(91)5,01(32)41(13)7,71(93

noitacirbuL 08862N/P-ebuLtfahs-xelFREKCAW

HMS OPERATION 1A

1A-5

FOR SAFE OPERATION READ

OPERATOR’S MANUAL.

POUR UNE OPERATION SÛRE

LISEZ LA NOTICE D’EMPLOI.

SICHERHEITSANLEITUNGEN IN

BETRIEBSVORSCHRIFT LESEN.

PARA OPERACION SEGURA LEA

MANUAL DE OPERACION.

CAUTION

VORSICHT

PRECAUTION

PRECAUCION

1039SD19

78071-16

1.5 Label Locations

1.4 Safety & Informational Labels

This WACKER machine uses international pictorial labels where needed. These labels are described below:

Label Meaning

Read operator’s manual for machine information.

Wear eye, ear, and head protection when

operating machine.

1A OPERATION HMS

1A-6

1.6 Application

The HMS series of internal vibrators can be used over a

wide range of applications for the consolidation of con-

crete.

WACKER internal vibrators are typically used for on-site

vibration of concrete for foundations, walls, columns,

slab work, etc. Additional in-plant applications include

vibration of concrete during the production of pipes,

slabs, beams, double T columns, walls, etc.

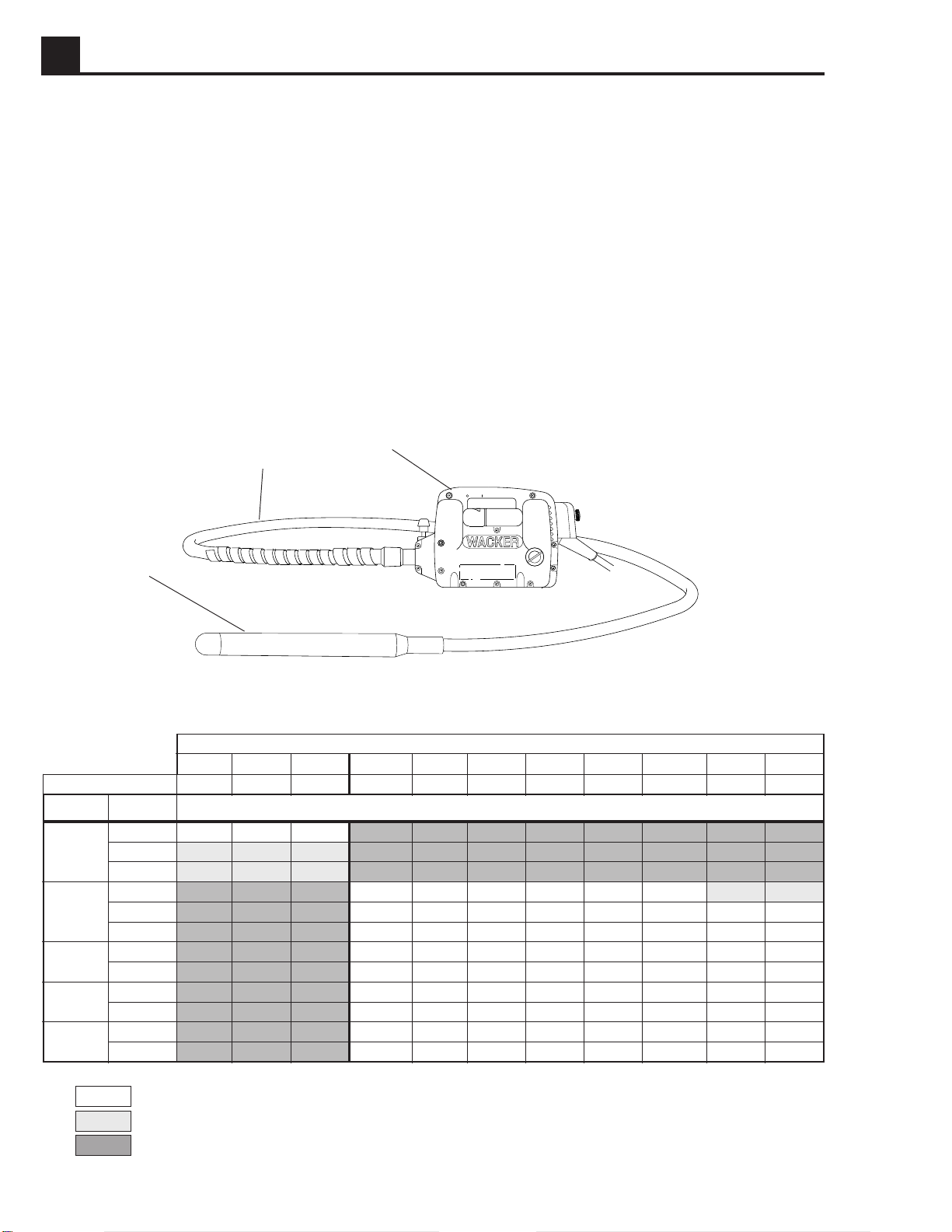

Acceptable Combinations

Not Recommended - On small diameter shafts, motor may overspeed shaft and head. On long shafts, motor may overload.

Not compatible

a

b

c

1007SD34

1.7 Recommended HMS Combinations

)b(stfahS

E-1MSE-2MSE-4MSS-0MSS-1MSS-2MSS-3MSS-4MSS-5MSS-7MSS-9MS

htgneL)m(.tf)1(3)2(5.6)4(31)5.0(5.1)1(3)2(5.6)3(01)4(31)5(5.61)7(32)9(5.92

)c(daeH)a(rotoM

52H

0001M x x x x x x x x

0002M • • • x x x x x x x x

0003M • • • x x x x x x x x

53H

0001M x x x • •

0002M x x x

0003M x x x

54H 0002M x x x

0003M x x x

55H 0002M x x x

0003M x x x

56H 0002M x x x

0003M x x x

The HMS Sytem has three basic parts:

(a) motor

(b) shaft

(c) head

These three pieces can be assembled in various combi-

nations to meet job requirements. Choosing the correct

combination is important to produce good results and

protect the parts from excessive wear and damage.

Selecting too large a head/shaft combination will over-

load the motor.

Refer to Table 1 below when selecting motor, shaft, and

head combinations.

Table 1 Recommended HMS Combinations

•

x

HMS OPERATION 1A

1A-7

1.8 Extension Cords

Extensioncords areoften requiredon jobsitesto connect

the motor. When choosing an extension cord make sure

it has adequate wire size for safety. An undersized cord

willcause a dropin linevoltage resultingin a lossof power

and overheating. Refer to Table 2 when selecting exten-

sion cords. It shows the correct wire size to use depend-

ing on cord length. If in doubt, use the next heavier cord

size.

On motors being used outdoors, use extension cords

rated for outdoor use.

WARNING

MAXIMUM CORD LENGTH - ft. (m)

25' 50' 100' 150' 175' 200'

(7.5m) (15 m) (30 m) (45 m) (55 m) (60 m)

M1000 16 (1.5) 16 (1.5) 14 (2.5) 14 (2.5) 12 (4) 12 (4)

M2000 16 (1.5) 16 (1.5) 14 (2.5) 12 (4) 10 (6) 10 (6)

M3000 16 (1.5) 14 (2.5) 12 (4) 10 (6) 8 (10) 8 (10)

M1000 16 (1.5) 16 (1.5) 16 (1.5) 16 (1.5) 14 (2.5) 14 (2.5)

M2000 16 (1.5) 16 (1.5) 16 (1.5) 14 (2.5) 14 (2.5) 14 (2.5)

M3000 16 (1.5) 16 (1.5) 14 (2.5) 14 (2.5) 12 (4) 12 (4)

115V

Table 2

Minimum wire size for extension cords -

AWG (mm2)

230V

Toreduce therisk ofelectric shock,motors equipped

with3-wire grounded plugsmust beproperly ground-

ed.On thesemotors use only3-wire groundedplugs,

receptacles, and extension cords.

1.9 Connecting Motor to Power Supply

WARNING

Improper use of extension cords can cause over-

heating or create serious fire or shock hazards.

Never use worn or damaged cords!

Note:

Not all countries require the use of a three-wire

grounded plug for this piece of equipment. In these

countries, motors are equipped with a two-wire plug

which can be plugged into a standard electrical outlet.

de

1007SD13

1. Check that switch on motor is off before connecting

motor to power source.

2. Make sure power supply matches voltage require-

ments listed on motor label. Running a motor at a low

voltage will cause it to run slow. This will reduce

perfomance and may cause motor to overheat.

3. On motors equipped with a three wire grounded plug

use three-wire grounded receptacles (d) when con-

necting the motor. If a 3-wire grounded receptacle is

not available, then a grounded adapter must be in-

stalled as shown in illustration (e) to ensure a proper

ground connection.

1A OPERATION HMS

1A-8

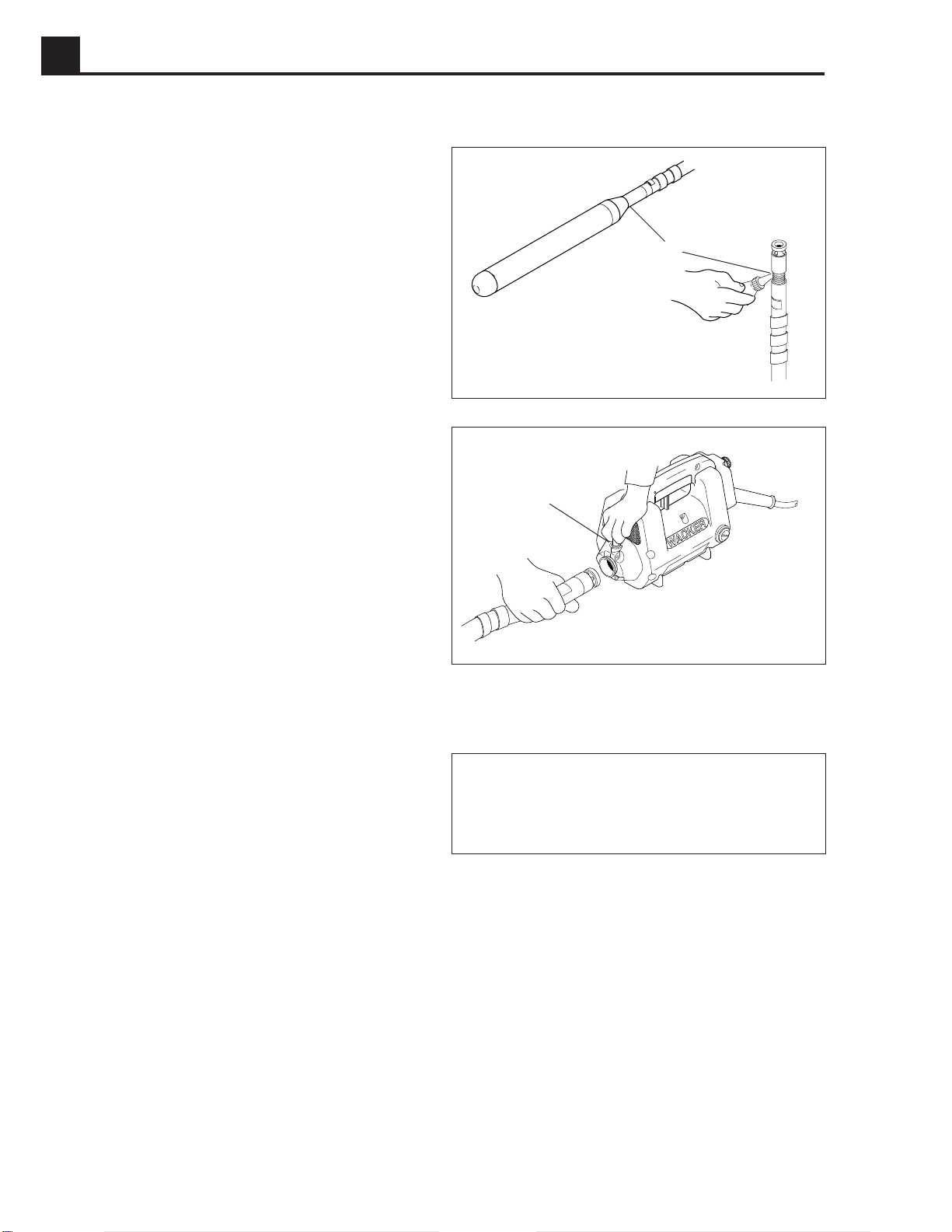

1.10 Assembling Head, Motor and Shaft

f

g

1007SD17

1007SD16

1.11 Operation

Hold head in air or place it on soft surface when starting

motor.This willprevent itfrom bouncingon hardsurfaces

which could damage bearings. During use, insert the

headquickly intothe mixand thenpull it out slowly. Rapid

removal is the main cause of poor concrete consolida-

tion. For best results submerge head completely and try

to establish a symmetrical pattern for inserting and

removing the head.

Avoidsharp bends in the shaft.This can create hot spots.

When moving around jobsite do not drag head and shaft

on ground.

Avoid touching forms and rebars when inserting head in

mix. This can transmit vibration to other areas of the mix

which may already be setting.

CAUTION: DO NOT run the motor with the head out of

the mix for long periods of time. This can cause the

bearings to overheat.

For more detailed information on the use, selec-

tion and application of WACKER equipment for

concreteconsolidation, orderWacker publication

WCW 982 “CONCRETE CONSOLIDATION”.

1. Apply pipe sealant to threads on head (c). Attach

head onto end of flexshaft (left hand thread) and

tighten using a wrench.

2. The shaft is attached to motor using a quick discon-

nect coupler. The coupler may vary depending on the

type of shaft being used. All new WACKER flexshafts

come equipped with a coupler and do not require any

additional coupling device. Refer to page 3-4 for

shafts equipped with couplers.

If you are using a shaft from another manufacturer, or

are attaching an older WACKER shaft, refer to page

3-7 to order the correct coupling to use. If a coupler

must be installed on the shaft, apply pipe sealant (f)

to threads before assembling.

3. Lubricate shaft core. See 1.15

Lubricating Shaft

.

4. To attach shaft to motor, pull adapter pin (g) on motor

up and slide coupler in place. Rotate coupler until pin

falls into coupler socket.

HMS OPERATION 1A

1A-9

1.12 Periodic Maintenance

Before Operating Inspect air filter and vent holes. Clean or replace dirty or clogged filters.

Inspect electrical cords for wear or damage. Do not use damaged cords.

Every 50 hours Inspect brushes in motor.

Every 100 hours Clean and lubricate core in shaft.

Every 300 hours Change oil in head.

1.14 Motor Housing

Clean motor housing immediately after use, using a

damp cloth to remove dust or concrete. Inspect rear air

filter, front screen, and vents on motor housing to make

sure they are open. Replace or clean clogged air filter

before operating motor to prevent overheating.

Toclean rearfilter: screw outknob andremove cover(d)

from motor. Remove filter (e) and wash in warm, soapy

water. Allow filter to dry completely before using.

1.13 Motor Brushes

To protect the motor, the brushes are designed to auto-

matically shut off the motor if they become too short. If the

motorstops during operation,the brushesmay needto be

replaced. To avoid having the brushes shut down the

motorunexpectedly, inspect brushesevery 50hours and

replace them when necessary. Always replace both

brushes at the same time.

To inspect or replace brushes:

1. Remove brush caps (a) from both sides of motor.

2. Pull brushes (b) out and measure length. Install new

brushes if length (c) is less than 3/8" (10 mm) long. If

brushes are still long enough, place them back in

motor. Make sure they are installed in the same

positions they were removed, to avoid arcing.

3. Break in new brushes by running motor for about 5

minutes with no shaft attached.

ca

b

1007SD06

d

e

1007SD05

1A OPERATION HMS

1A-10

f

g

1.15 Lubricating Shaft

Remove wire core (f) from shaft casing and wipe with a

clean cloth.

Apply a liberal amount of flex-shaft grease to the entire

lengthof the core by hand(g). Insertcore intocasing and

rotate it. Repeat this procedure several times.

CAUTION: DO NOT try to force the casing full of grease.

A tightly packed casing will put a heavy load on the motor

and could cause it to overheat.

CAUTION: DO NOT clean casing or core with solvents.

Excess solvent on casing or core may cause grease to

break down, resulting in damage to shaft.

h

1007SD15

1007SD14

1.16 Lubricating Head

The bearings in the head are lubricated with oil. To

extend bearing life, change oil in head every 300 hours

of operation.

To change oil:

Place head in a vise and remove tip from casing. If

necessary, add a couple of small spot welds (h) on tip to

provide a better grip for wrench. Drain old oil from casing

and add correct quantity of new oil. Refer to section 1.3

Technical Data

. Apply pipe sealant to threads on tip and

attach it tightly on casing.

Note:

In the interests of environmental protection, place

a plastic sheet and a container under the machine to

collect any liquid which drains off. Dispose of this liquid

in accordance with environmental protection legislation.

Use only SAE 80W140 synthetic oil or equivalent.

CAUTION:DO NOT overfill. Too muchoil in the head will

overload the motor.

HMS OPERATION 1A

1A-11

1.17 Checking Head for Wear

Periodically measure the outside diameter of the head

casing (a) in the area of most noticeable wear.

Replace head if measured diameter is less than the

minimum wear diameter.

NEW MINIMUM

DIAMETER WEAR DIAMETER

in. (mm) in. (mm)

H25 1.00 (25) 0.88 (22)

H35 1.38 (35) 1.25 (32)

H45 1.75 (44) 1.63 (41)

H55 2.25 (57) 2.13 (54)

H65 2.50 (64) 2.38 (60)

PROBLEM REASON

Motor does not start. 1. Open circuit breaker or blown fuse on power supply.

2. Brushes are worn too short. Replace.

3. Switch on motor bad or wire connections loose.

Motor runs at normal speed 1. Air filter, screen, or vents clogged, blocking air flow.

but overheats. 2. Too much grease in shaft.

3. Too much oil in head.

Motor runs at slow speed 1. Line voltage too low.

and overheats. 2. Extension cord too small.

3. Head/shaft combination too large.

4. Shaft not lubricated, core running dry.

5. Head bearings binding. Inspect and replace.

6. Rotor in motor rubbing.

7. Motor bearings failed. Inspect and replace.

Motor noisy 1. Worn brushes. Brushes installed incorrectly.

2. Worn motor bearings.

3. Rotor in motor rubbing.

1.18 Troubleshooting

a

1008SD06

1A OPERATION HMS

1A-12

W

B

L

L

B

Y

2

45

W

61

3

B

7

W

B

B

Y

2

45

W

61

3

B

W

B

7

1.19 Wiring Schematics

M1000 M2000 M3000

* NO GROUND WIRE

115V 5843 6305 5845

7159

7653

230V 5041 6551* 5800

230V 5494 5432

5495

M1000 M2000

230V 6590

M3000

1SWITCH

2STATOR

3ROTOR

4LH BRUSH

5RH BRUSH

6RFI CAPACITOR

7INDUCTION COIL

B- BLACK or BROWN

G- GREEN or GREEN W/

YELLOW STRIPE

Y- YELLOW

W- WHITE or BLUE

1SWITCH

2STATOR

3ROTOR

4LH BRUSH

5RH BRUSH

6RFI CAPACITOR

7INDUCTION COIL

B- BLACK or BROWN

G- GREEN or GREEN W/

YELLOW STRIPE

L- BLUE

Y- YELLOW

W- WHITE or BLUE

1039SD16

1039SD17

NOT USED ON 6551

1023SD06

W

B

B

2

45

W

1

3

G

W

1SWITCH

2STATOR

3ROTOR

4LH BRUSH

5RH BRUSH

B- BLACK or BROWN

G- GREEN or GREEN W/

YELLOW STRIPE

W- WHITE or BLUE

EC - CONFORMITY CERTIFICATE

EG-KONFORMITÄTS ERKLÄRUNG

CE-CERTIFICADO DE CONFORMIDAD

CERTIFICAT DE CONFORMITÉDE LA CEE

WACKER CORPORATION - MENOMONEE FALLS, WISCONSIN USA

hereby certify that the construction equipment specified hereunder

bescheinigt, daßdas Baugerät

certifica que la máquina de construcción

atteste que le matériel

1. Category - Art - Categoría - Catégorie

2. Make - Fabrikmarke - Marca - Marque

3. Type - Typ - Tipo - Type

4. Type serial number of equipment / Gerätenummer innerhalb Typenserie-Nummer

Número de serie de la máquina / Numéro dans la série du type de matériel

has been produced in accordance with the following standards

in Übereinstimmung mit folgenden Richtlinien hergestellt worden ist

ha sido fabricado en conformidad con las siguientes normas

est produit conforme aux dispositions des directives européennes ci-après

EMC 89/336/EEC

EN 60555

EN 55014

MSD 89/392/EEC

91/368/EEC

93/44/EEC

HD 400

IEC 745

File certificate carefully

Bescheinigung bitte sorgfältig aufbewahren

Conservar certificado cuidadosamente

Conserver certificat soigneusement

QM1-3000

WACKER CORPORATION

N92 W15000 Anthony Avenue Menomonee Falls, Wisconsin

53052-9007 USA (262) 255-0500 Fax (262) 255-0550

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Internal Vibrator

Innenvibrator

Vibrador Interno

Vibrateur Interne

WACKER

M1000/230V

M2000/115V

M2000/230V

M3000/230V

0005494, 0007653, 0005495,

0006590

WACKER CORPORATION

William Lahner Robert Motl

This manual suits for next models

2

Table of contents

Other WACKER Group Power Tools manuals