Instruction Manual

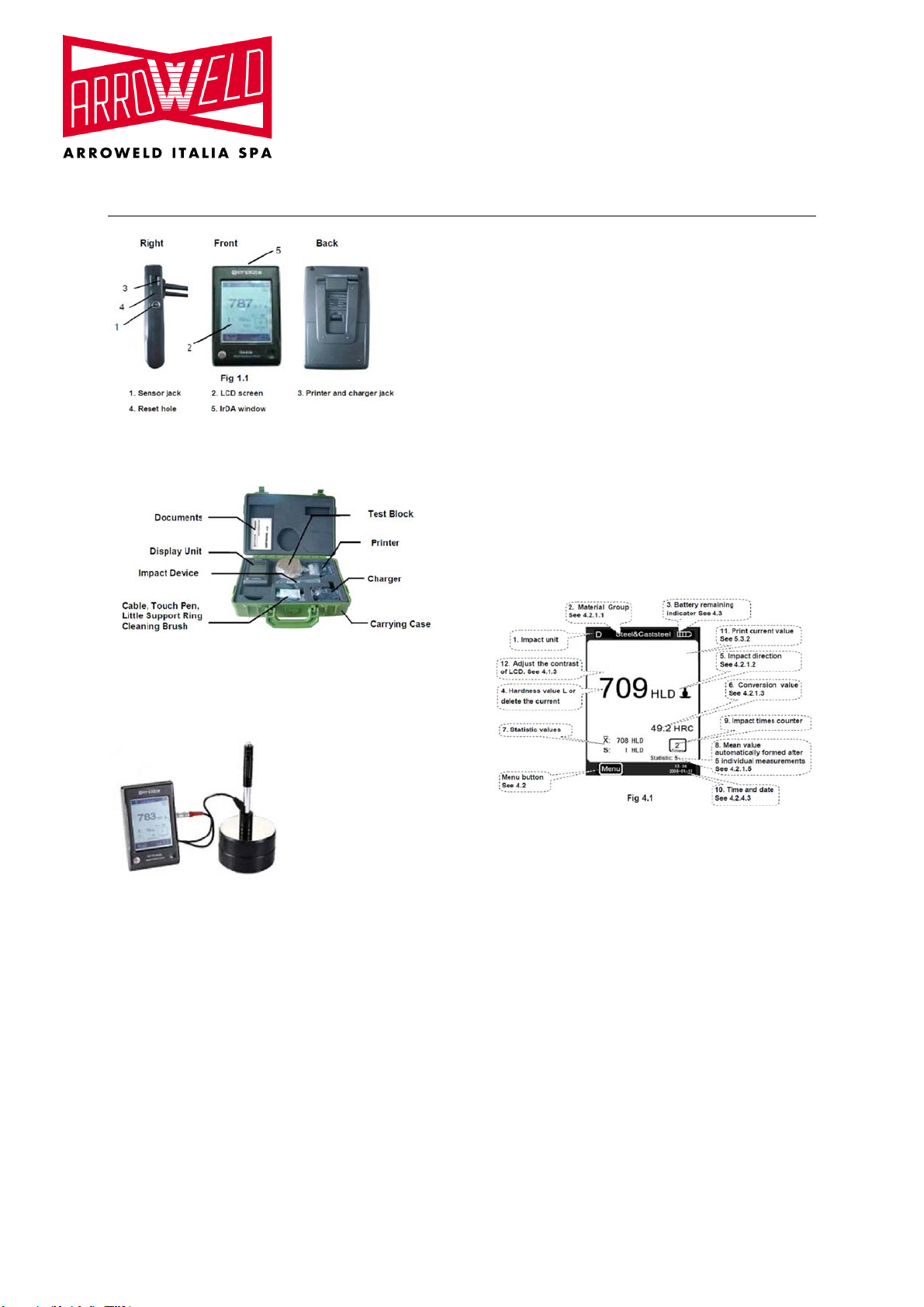

ARW-DPIT Touch

AS, 02.12.2010 DPIT GB Page 2 of 13

Via M. Pasubio, 137

36010 Zanè (VI)-(Italia)

Tel +39 0445 492313

Fax +39 0445 491365

E-mail:info@strumentieservizi.com

The measuring principle of DPIT Hardness Tester is

physically a rather simple dynamic hardness test:

An impact body with a hard metal test tip is propelled by

spring force against the surface of the test piece. Surface

deformation takes place when the impact body hits the test

surface, which results in a loss of kinetic energy. This

energy loss is calculated by velocity measurements when

the impact body is at a precise distance from the surface

for both, the impact phase and the rebound phase, of the

test. The permanent magnet in the impact body generates

an induction voltage in the single coil of the impact device.

The voltage of the signal is proportional to the velocity of

the impact body. A signal processing by the electronics

provides the hardness reading for display and storage.

Simply said, harder materials produce higher rebound

velocities than less harder ones (higher L- value).

DPIT Hardness Tester provides a direct hardness

measurement within any particular material group (i.e.

steel, aluminium etc.). It can be used as a final test result

without conversion. However, there are established

conversions to other hardness scales in this Hardness

Tester as a comfort for our customers. These conversions

to other scales (HRC, HRB, HB, HV, HSD etc.) are

programmed into the electronics and they can be shown

directly on the display as a test result. All data is stored in

the native L scale to prevent any possible errors with

multiple conversions.

1.2. The Hardness value “L”

This term was introduced 1978 into measuring technology

by Dr. Dietmar Leeb. It contains the quotient for the impact

body’s rebound and impact velocity, multiplied by 1000.

Harder materials produce higher rebound velocity than

less harder ones. With reference to a particular material

group (i.e. steel, aluminium etc.), the L value represents a

direct hardness measurement and is used as such.

Comparison curves with other standard statistic hardness

values have been established (Brinell, Vickers, Rockwell

C, B) for the most prevalent materials, enabling the

L values to be converted into the relevant values by these

procedures. With this hardness tester, such hardness

values can directly be displayed in the hardness scales

HRC, HRB, HB, HV, HSD and tensile strength (MPa).

1.3 Main features

- Highly accurate, ± 6 HL

- Automatic correction for impact direction

- Large, easy to read display with backlight

- User profiles for fast change of all settings

- Operation with Touch Screen

- Large memory with on- screen review of data

- Conversion to all common hardness scales

HRC, HRB, HB, HV, HSD and tensile strength

(MPa).

- Rechargeable Li- ion batteries

- Conforms to the standard ASTM A956-02

1.4 Application range

- Appropriate for all metals

- Ideal for production level testing

- Best suited for on- site testing of heavy, big or

already installed parts

- Handy for difficult to access or confined test

locations

- Automatic compensation for impact direction

- Excellent for material selection and acceptance

tests

- Easy to handle and accurate on curved test

surfaces (R> 10mm)

- Metal production & processing

- Automotive & transportation

- Aerospace & shipyard

- Testing services & laboratories

1.5 Technical information

1.5.1 Display unit

HL Display Range: 0 ~ 1000 HL

Accuracy: ± 6 HL

Display of the main body: large LCD with

adjustable contrast, backlight, Touch Screen

Unit Material: shock resistant ABS plastic

Internal Data Storage : ~ 800 measured values

• Resolution: 1 HL; 1 HV; 1 HB; 0,1 HRC;

0,1HRB; 1 HSD; 1 MPa

• Battery type: rechargeable Li- Ion

• Operating temperature: 0°C up to + 50°C

(32°F up to 122°F)

• Storage Temperature: -10°C up to + 60°C

(14°F up to 140°F)

• Humidity: 90 % max.

• Dimension: 135 x 83 x 24mm

(5.3 x 3.2 x 0.9 inches)

• Weight: 228 g

1.5.2 Impact unit D

Impact energy: 11 Nmm

Mass of the impact body: 5.5 g

Test tip diameter: 3 mm

Test tip material: tungsten carbide

Test tip hardness: ≥ 1600 HV

Impact length: 147 mm

Impact maximum diameter: 20 mm

Impact weight: 75 g