Note: .

Please

test

fit

aI/ parts before beginning assembly. The glider'has a complete 3 view drawing separate to this manual.

Please refer to this drawing during assembly.

This.

drawingis the latestinformation abouUhe

glider

imd

shouldbe the

primary

source

forineasurem~nt

and

placementquestions.

.i

'.

,"

,

• . . • " j I . .

Finishing the Wood Surfaces

To

prevent the wood from pre-mature aging and moisture

damage, we recommend sealing the wood using lacquer

manufactured by DEFT (available from The Home Depot and

Lowe's stores). The best would

be

a "Satin" or "Semi gloss"

type

of

finish. (Prior to using lacquer, any white foam surface

should be sealed by applying a film like coat of epoxy). The

black poplar veneer wing skins (-OAmm thick) are sealed

under surface, then laminated with epoxy to the wing foam

cores. This

is

making a barrier preventing harsh lacquer thinner

penetration inside. We recommend

to

apply lacquer

in

a few

very light coats, this way lacquer thinner evaporates very fast

and does not have time to cause any harm to the wing foam

cores. The best finish results will

be

to brush

on

1 0 2 coats

of

Lacquer Sanding Sealer then sand the surface using 400 grit

sand paper, then spray

on

a very light 3-rd, 4-th and more coats

if desired.

Use as little as possible

to

keep the weight down.

Color

Option

:

After wing

is

completely finished with lacquer then you can

mask it and spray some color stripes especially to the bottom

side

of

the wing that will give the glider some accent and

provide you with better visibility during flight.

2

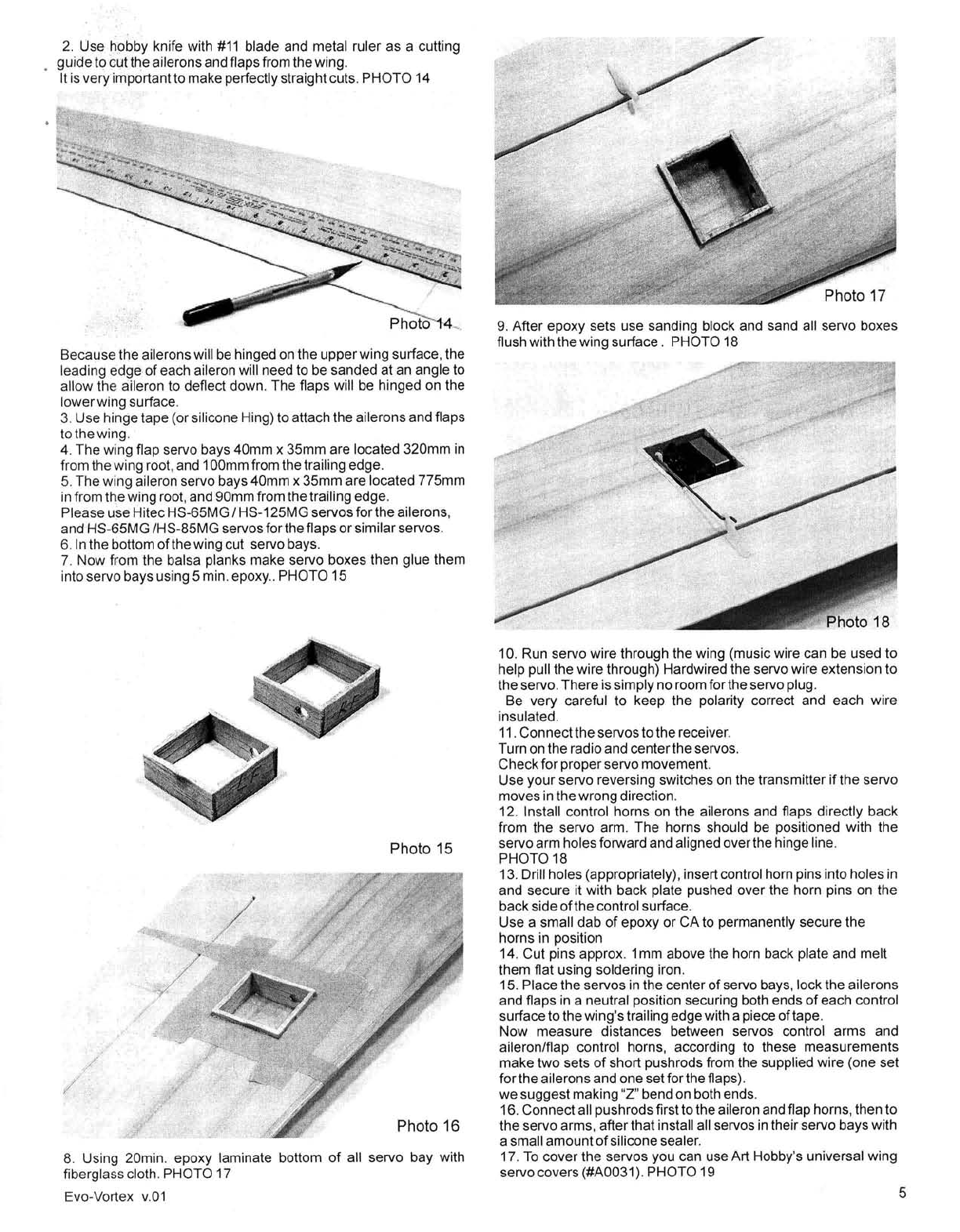

Recommended Building Steps

Attention:

The

ailerons

and flaps

should

remain

uncut

from

the

wing

as

long

as possible. Meaning after wing is finished

and painted it should be put aside for a few days to cure.

The paint curing process and reacting with the wood usually

takes 2-3 days even in a warm environment. During this time

the surface should remain uncut.

(many times modelers are impatient and cut the ailerons/flaps

as

soon

as

the wing

is

dry to the touch)

If the control surfaces are cut from wing shortly after it's painted

then more likely will be distorted during paint curing

It

is

best

to

start

building

the

glider

from

the

wing,

1.

finish both wing tips

2. glue together wing center panels and laminate the joint.

3. paint the wing (including personal touches) to its final stage

and put the wing aside to cure the paint (longer time is better)

4.

assemble and paint the glider tail

5.

assemble fuselage with tail, install pushrods, radio gear and

electric drive components

in

the fuselage.

(those steps usually take 2-3 evenings sometimes longer -this

is

also valuable time needed to cure painted wing)

6. cut wing servo bays and prepare them for servo installation.

7. now separate the ailerons from the wing, finish them and

hinge to the wing as soon

as

possible.

8. separate the flaps from the wing, finish them and hinge to the

wing as soon as possible.

(do not leave control surfaces unattached to the wing for a

longer period

of

time)

9. install aileron and flap control horns

10. Prepare wing servo wiring and install wing servos.

Notesaboutthefinishedsurfaces:

The fuselage is painted (in the mold). The white

paint

will be

damagedbythinners. The woodsurfaces

cC)n

be finishedwith a

proper

clear

varnish.

Remember

tha(the wing has a foam core

and

somepaints

may

attackthefoam internaily.

.;

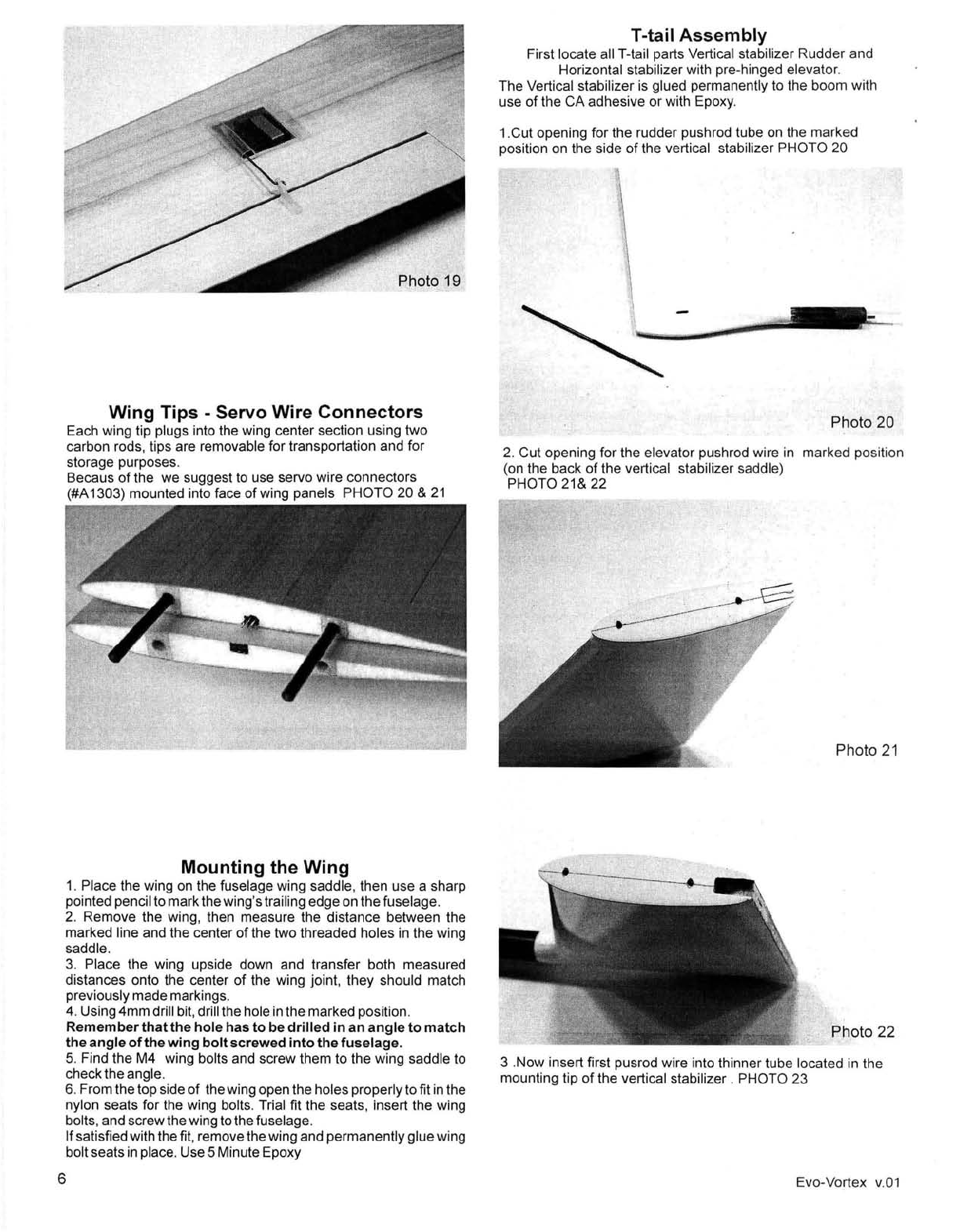

Wing Assembly

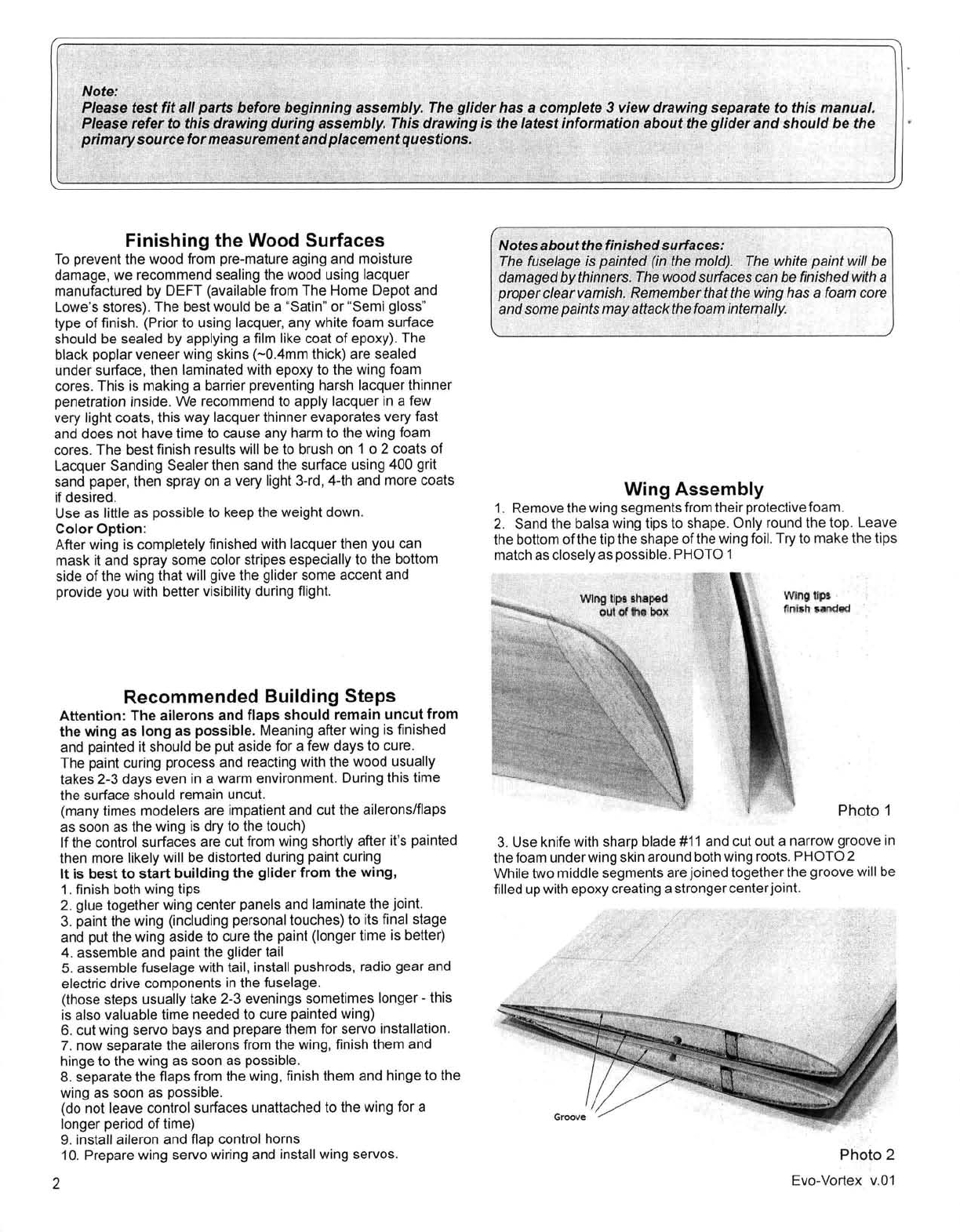

1. Remove the wing segmentsfrom their protectivefoam.

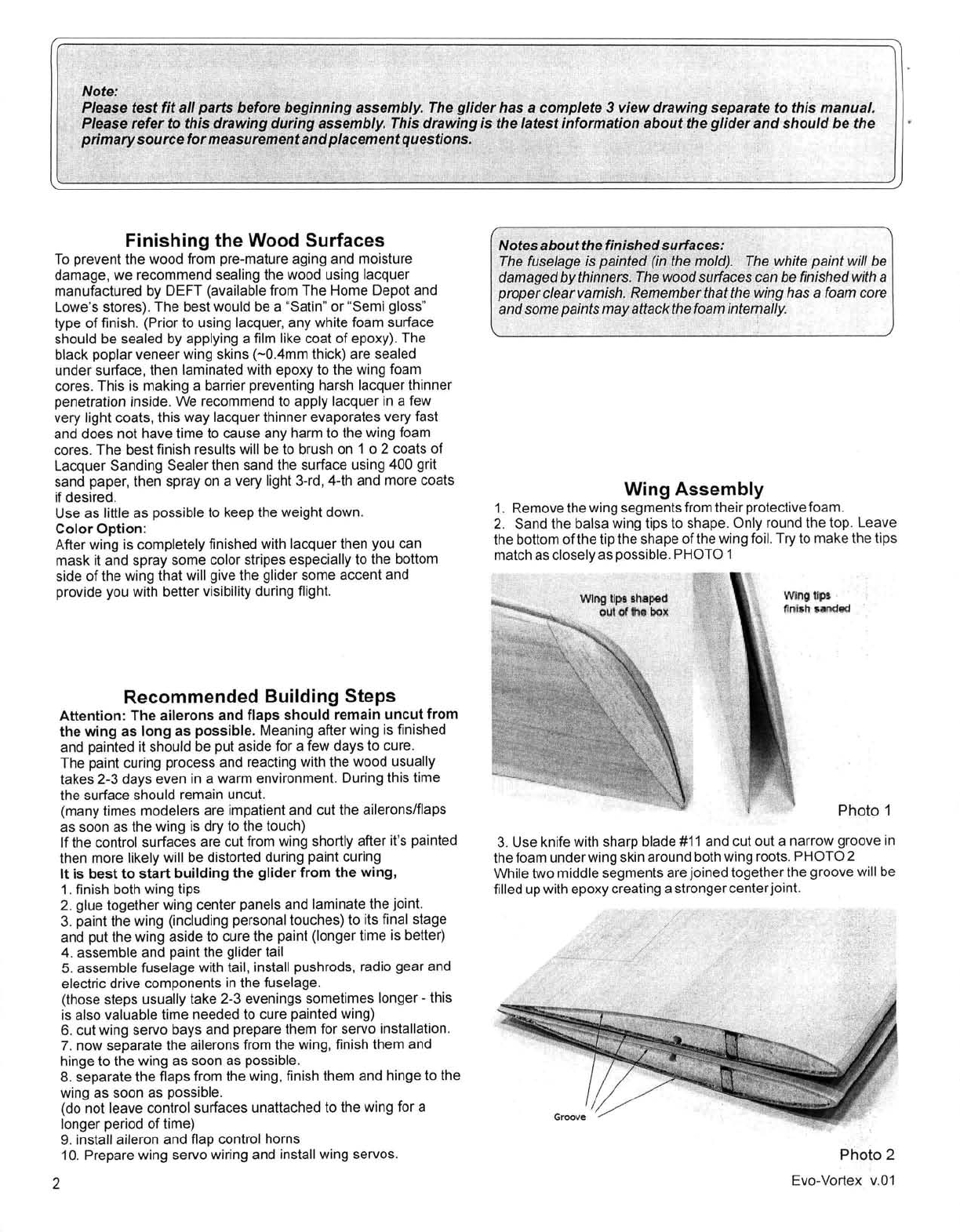

2. Sand the balsa wing tips to shape. Only round the top. Leave

the bottom

of

the tip the shape ofthe wing foil. Try to make the tips

match

as

closely as possible. PHOTO 1

Wing

uP' .

~

ml

h.

51!l11ded

Photo 1

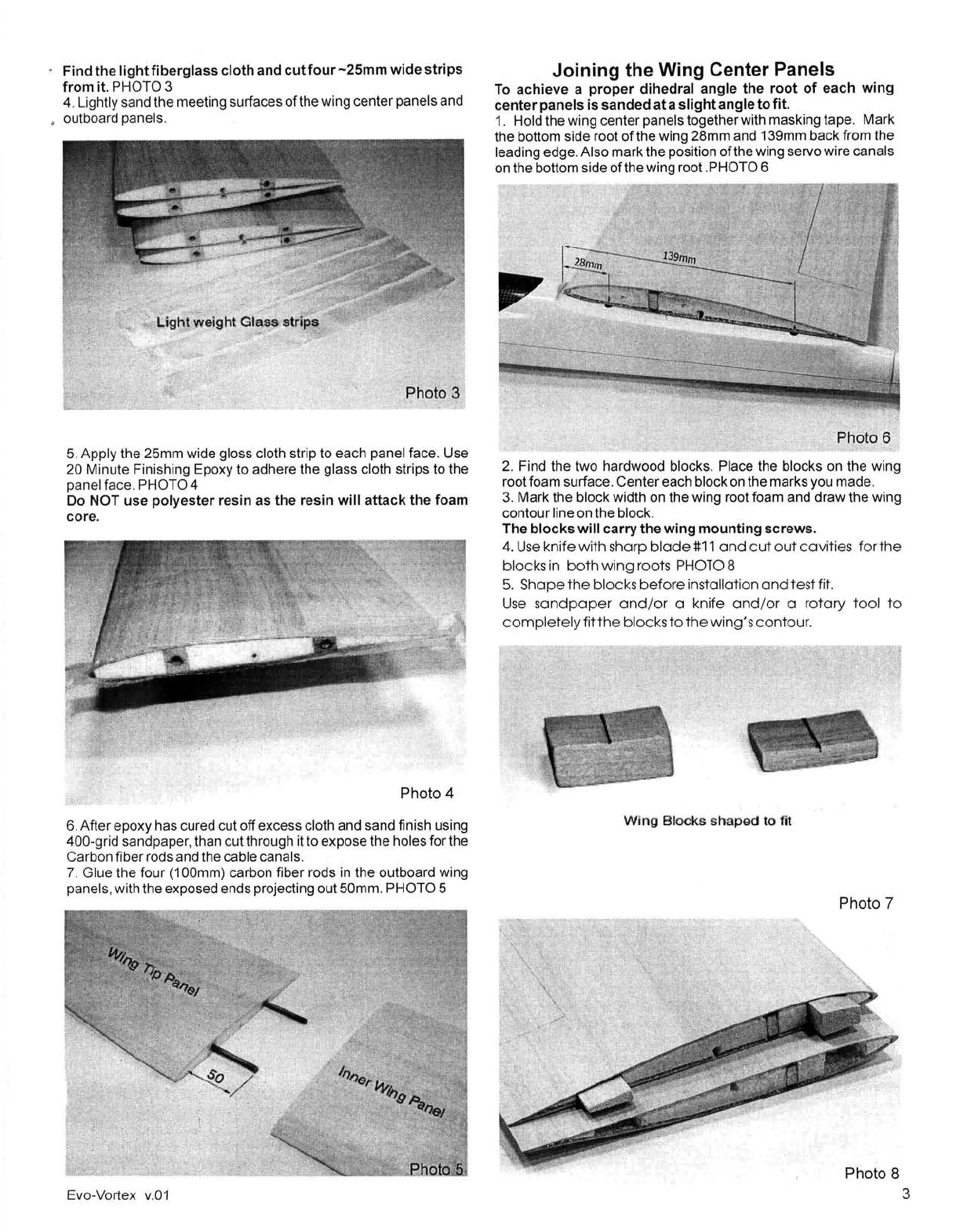

3. Use knife with sharp blade

#11

and cut out a narrow groove

in

the foam underwing skin around both wing roots.PHOTO 2

While two middle segments are joined together the groove will be

filled up with epoxy creating a strongercenterjOint.

Photo 2

Evo-Vortex v.

01