Wing Installation

The wing is bolted to the fuselage with three 5mm nylon bolts

and blind nuts. The bolts are inserted through the hardwood

blocks in the wing. It is important that the wing bolts are posi-

tioned through the middle of the blocks. It is also important to

properly glue the plywood plates securely inside the fuselage.

Please thoroughly read through this section before beginning

assembly.

1. Find the wing, fuselage, nylon wing bolts, and plywood plates.

2. Mark the bolt hole positions on the top of the wing. The holes

should be positioned 15mm from the wing root, and should be

centered over the block. To check your work, measure the distance

between the holes (from front to back).The holes should be 150mm

apart.

3. Through the WING ONLY, use the marks you made as a guide to

drill 5mm diameter holes for the wing bolts. The holes should be

drilled perpendicular to the top of the wing.

4. Test fit the wing on the fuselage. It should be leve on the fuselage

and perpendicular (90 degrees) to the fuselage centerline.

5. Mark the hole position on the fuselage wing saddle for the wing

bolts. By marking the holes to match the holes you just drilled, you

are assured a perfect match.

6. Open an acess hole on the top of the wing saddle. The hole

should be 40mm wide and 90mm long. Center the hole between

the screw positions. We suggest using a rotary tool and a sanding

drum to make the hole.

7. Double check the hole positions on the fuselage.

Open the holes with a 5mm drill bit.

8. Insert the wing bolts into the wing and place the wing on the

fuselage. Check that the wing is now properly centered on the

fuselage.

9. Locate the two plywood plates. These plates will support the

blind nuts in the fuselage.

10. Trim the edge of the plate to fit under the wing saddle.Test fit the

plates in the fuselage.

11. Glue the plates in position with 5 minute epoxy.

12. Once the glue dries, use a 7mm drill bit to open the holes for the

blind nuts.

13. Insert the blind nuts. Install the wing bolts (with the wing in

position).

14. To set the blind nuts in position, glue them in place with epoxy.

4.

Tow Hook Installation

1. If you have decided to install the towhook, you will need a 4mm

blind nut and 1/4 inch 5 ply plywood, 3/4 inch wide by 3 inches

long.

2. The Towhook is located 63mm behind the wing’s leading edge.

3. Shape the 1/4 inch plywood strip to match the fuselage curves.

4. Install the plywood over the towhook position (inside the fuse-

lage) with a generous portion of 5 minute epoxy.

5. Once the glue has set, drill a 4mm hole for the towhook.

6. Open the hole in the plywood for the blind nut.

7. Install the blind nut and the towhook.

Wing Servo and Control

Surface Installation

Refer to glider drawing and check the marking of the aileron and

flap location on each wing.

1. Cut the aileron and flap from the wing.

First cut both ends of each aileron and flap. We recommend using

a fine balsa saw to make those cuts. Use hobby knife with #11

blade and metal ruler as a cutting guide to cut the ailerons and

flaps from the wing.

It is very important to make perfectly straight cuts.

2. Because the ailerons will be hinged on the upper wing surface,

the leading edge of each aileron will need to be sanded at an

angle to allow the aileron to deflect down.

The flaps will be hinged on the lower wing surface.

3. Use hinge tape (or silicone hing) to attach the ailerons and flaps

to the wing.

4. The wing flap servo bays 40mm x 35mm are located 320mm in

from the wing root, and 100mm from the trailing edge.

5. The wing aileron servo bays 40mm x 35mm are located 775mm

in from the wing root, and 90mm from the trailing edge. Please use

Hitec HS-85 servos for the ailerons, and HS-85MG servos for the

flaps or similar wing servos. Make an exact cut in the bottom of the

wing for the servos. Align the servo so that the output arm is aligned

with the aileron or flap.

6. Run servo wire through the wing (music wire can be used to help

pull the wire through) Hardwire the servo wire extension to the

servo. There is simply no room for the servo plug. Be very careful to

keep the polarity correct and each wire insulated.

7. Connect the servos to the receiver. Turn on the radio and center

the servos. Check for proper servo movement - use servo reversing

switches on the transmitter if the servo turn in the wrong direction.

8. Install control horns on the ailerons and flaps directly back from

the servo arm. The horns should be positioned with the holes for-

ward and aligned over the hinge line. Use a small dab of epoxy or

CA to permanently secure the horns in position.

9. Place the servos in the center of servo bays, lock the ailerons

and flaps in a neutral position securing both ends of each control

surface to the wing’s trailing edge with a piece of tape.

PHOTO 9

SierraS v.03

Now measure distances between servo control arms and aileron,

and also the flap control horns, according to these measurments

make two sets of short pushrods from the supplied wire (we sug-

gest making “Z” bend on both ends).

10. Connect the pushrods first to the aileron and flap horns, then to

the servo arms, after that install the servos in servo bays with a

small amount of silicone sealer.

11. To cover the servos you can use Art Hobby’s universal wing

servo covers (#A0031) PHOTO 9

(change new the towel if needed)

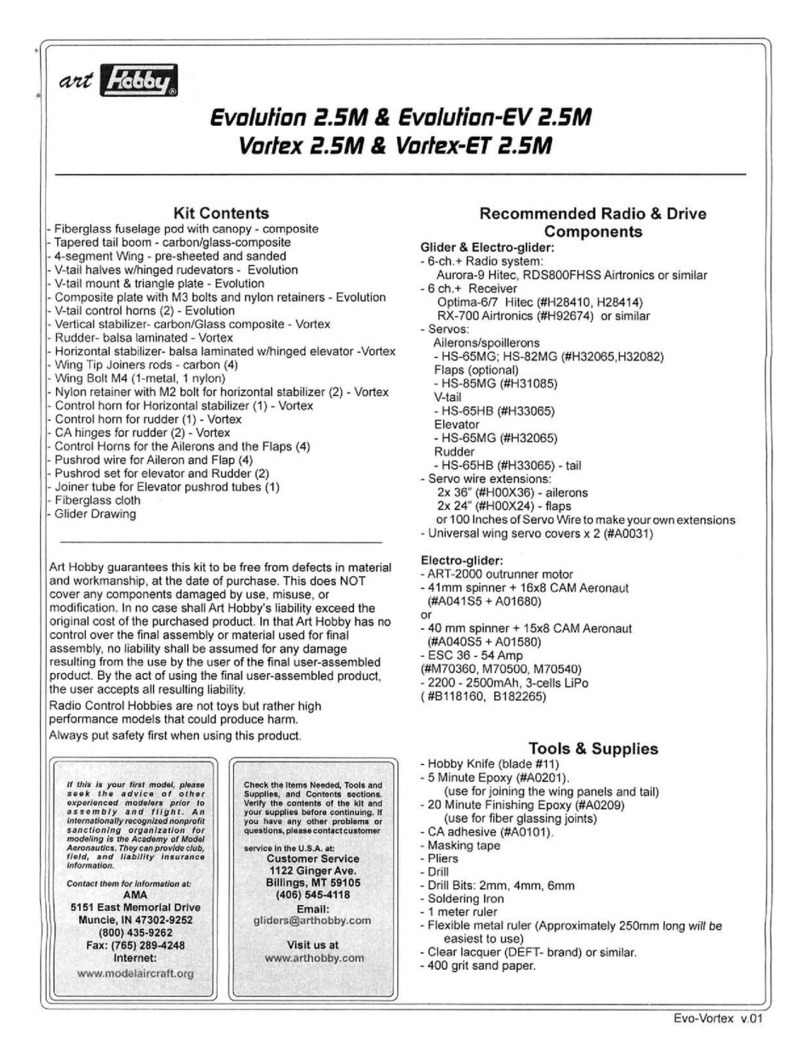

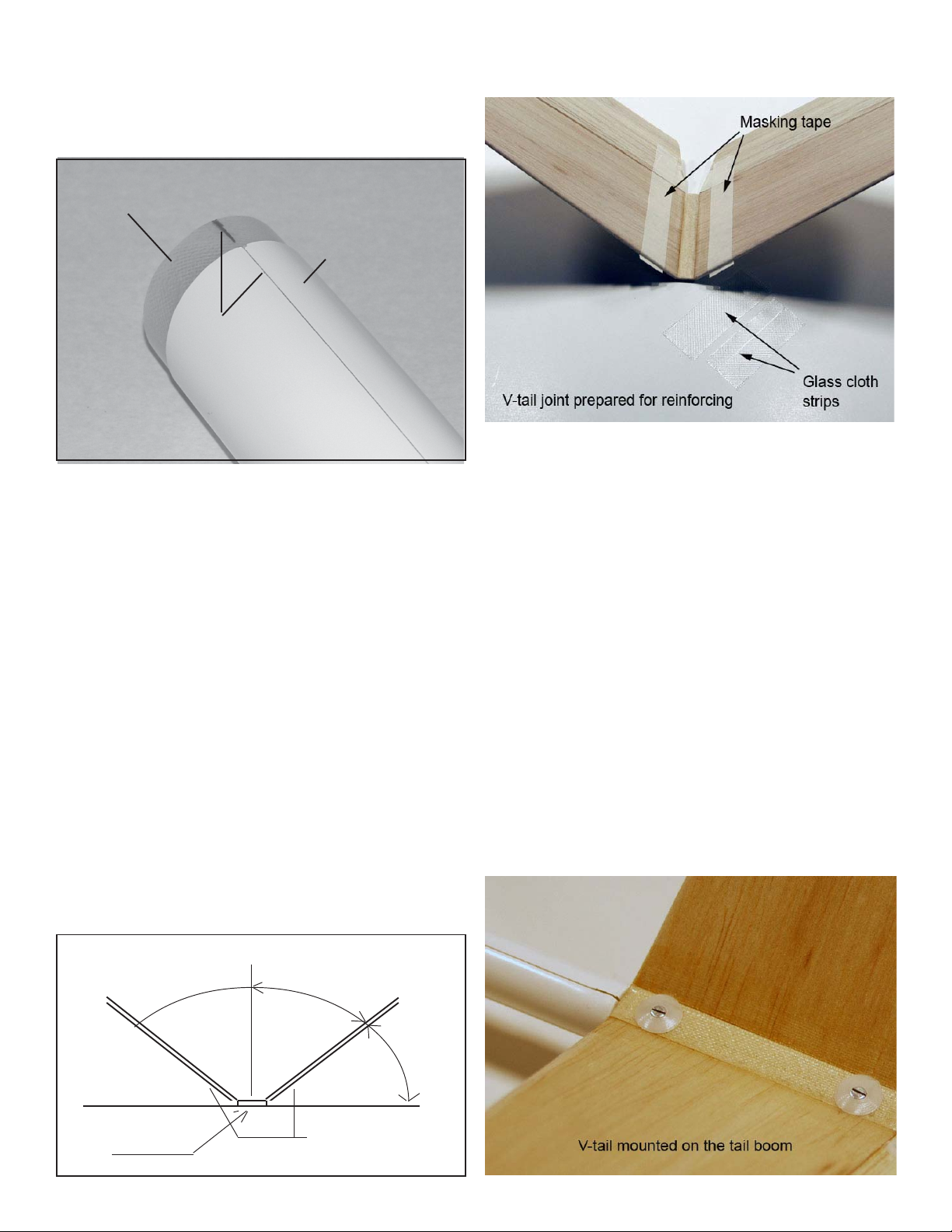

16. Repeat steps 11-14 and apply reinforcing cloth to the top of the

joint.

17. Once the epoxy has set, remove the masking tape.

Apply fresh masking tape 2mm past the end of epoxy.

18. Use 400 grid sand paper and sand the joint smooth if needed.

Do NOT sand away the wingsheeting where the glass ends.

This will weaken the wing and could cause failure.