V-tail Assembly

The V-tail can be glued permanently to the boom with use of

the mounting plate or it can be made removable.

1. Find the V-tail stabilizer halves and the mounting plate set.

PHOTO 10

Mounting the Wing

1. Place the wing properly on the fuselage wing saddle, then use a

sharp pointed pencil to mark the wing’s trailing edge on the fuse-

lage.

2. Remove the wing, then measure the distance between the marked

line and the center of the two threaded holes in the wing saddle.

3. Place the wing upside down and transfer both measured dis-

tances onto the center of the wing joint.

4. Using 4mm drill bit, drill the hole in the marked position.

Remember that the hole has to be drilled in an angle to match

the angle of the wing bolt screwed into the fuselage.

5. Find the M4 stainless wing bolt.

6. From the top side of the wing open the holes properly to fit in the

nylon seats for the wing bolts. Trial fit the the seats, insert the wing

bolts, and screw the wing to the fuselage.

If satisfied with the fit, remove the wing and permanently glue wing

bolt seats in place. Use 5 Minute Epoxy

4.

Wing Servo and Control

Surface Installation

Refer to glider drawing and check the marking of the aileron and

flap location on each wing.

1. Cut the aileron and flap from the wing.

First cut both ends of each aileron and flap. We recommend using

a fine balsa saw to make those cuts. Use hobby knife with #11

blade and metal ruler as a cutting guide to cut the ailerons and

flaps from the wing. It is very important to make perfectly straight

cuts.

2. Because the ailerons will be hinged on the upper wing surface,

the leading edge of each aileron will need to be sanded at an

angle to allow the aileron to deflect down. The flaps will be hinged

on the lower wing surface.

3. Use hinge tape (or silicone hing) to attach the ailerons and flaps

to the wing.

4. The wing flap servo bays 40mm x 35mm are located 320mm in

from the wing root, and 100mm from the trailing edge.

5. The wing aileron servo bays 40mm x 35mm are located 775mm

in from the wing root, and 90mm from the trailing edge. Please use

Hitec HS-85 servos for the ailerons, and HS-85MG servos for the

flaps or similar wing servos. Make an exact cut in the bottom of the

wing for the servos. Align the servo so that the output arm is aligned

with the aileron or flap.

6. Run servo wire through the wing (music wire can be used to help

pull the wire through) Hardwire the servo wire extension to the

servo. There is simply no room for the servo plug. Be very careful to

keep the polarity correct and each wire insulated.

7. Connect the servos to the receiver. Turn on the radio and center

the servos. Check for proper servo movement. Use your servo re-

versing switches on the transmitter if the servo moves in the wrong

direction.

8. Install control horns on the ailerons and flaps directly back from

the servo arm. The horns should be positioned with the holes for-

ward and aligned over the hinge line. Use a small dab of epoxy or

CA to permanently secure the horns in position.

9. Place the servos in the center of servo bays, lock the ailerons

and flaps in a neutral position securing both ends of each control

surface to the wing’s trailing edge with a piece of tape. Now mea-

sure distances between servo control arms and aileron, and also

the flap control horns, according to these measurments make two

sets of short pushrods from the supplied wire (we suggest making

“Z” bend on both ends).

10. Connect the pushrods first to the aileron and flap horns, then to

the servo arms, after that install the servos in servo bays with a

small amount of silicone sealer.

11. To cover the servos you can use Art Hobby’s universal wing

servo covers (#A0031).

The plate and triangle are pre-cut to the correct angle of 105 de-

grees. All tail pieces: the mounting plate, two V-tail halves, and

triangle interlock together.

2. The mounting plate and triangle are a little bit longer, so both

pieces have to be cut to fit. At the back it should aligned with the

hinge line. The front should match the stabilizer.

3. After cutting the front and the back of the mounting plate and

triangle, they should be sanded to shape. PHOTO 11

PHOTO 10

PHOTO 11

Serenity v.11/2005

(change new piece of the towel if needed)

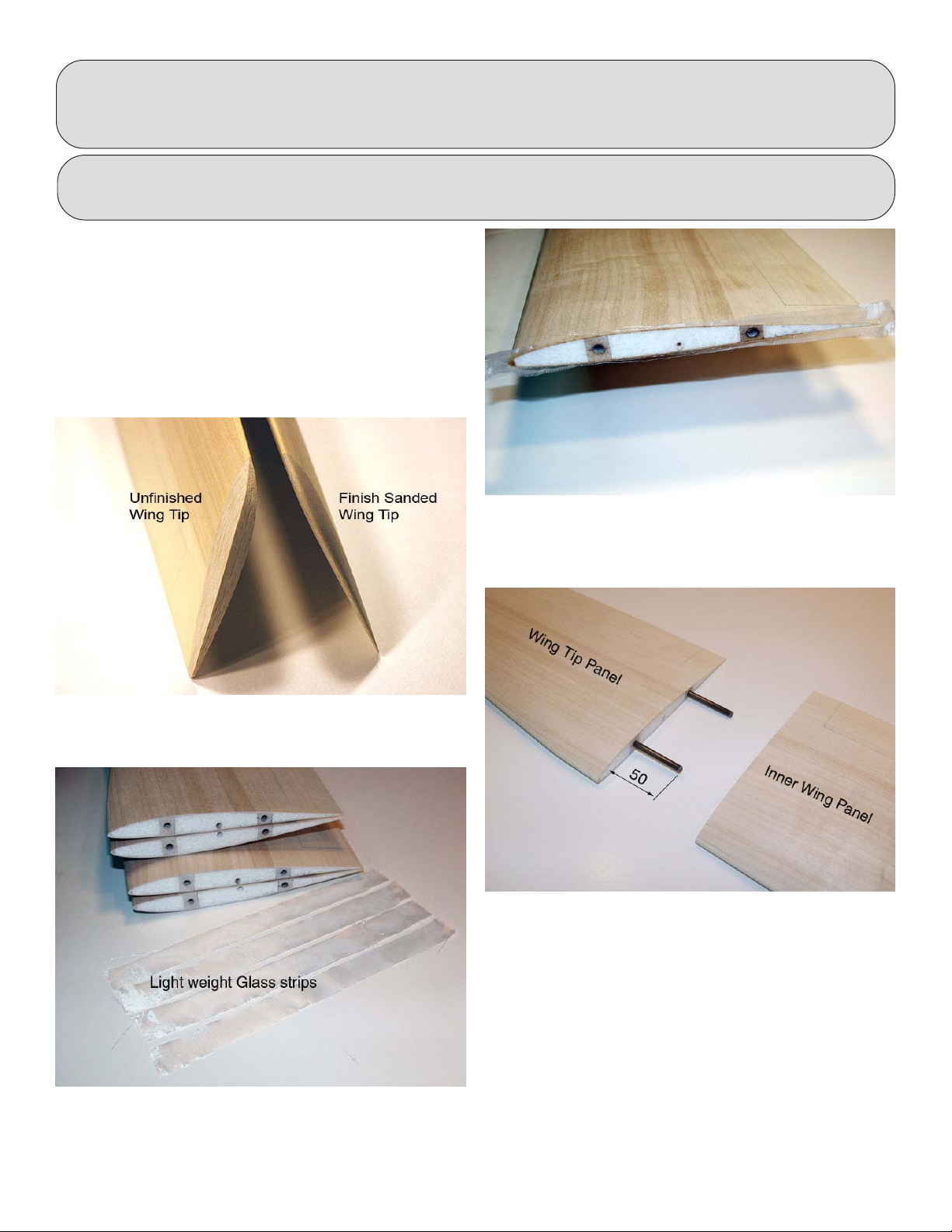

16. Repeat steps 11-15 and apply reinforcing cloth to the top of the

joint.

17. Once the epoxy has set, remove the masking tape. Apply fresh

masking tape 2mm past the end of epoxy.

18. Use 400 grid sand paper and sand the joint smooth if needed.

Do NOT sand away the wingsheeting where the glass ends.This

will weaken the wing and could cause failure.