2

Recommended Building Steps

Attention: The ailerons should remain uncut from the wing

as long as possible. Meaning after wing is finished and

painted it should be put aside to cure. The paint curing process

and reacting with the wood usually takes 2-3 days even in a

warm environment. During this time all surfaces should remain

uncut. (many times modelers are impatient and cut the

ailerons/flaps as soon as the wing is dry to the touch)

If the control surfaces are cut from wing shortly after it’s painted

then more likely will be distorted while paint curing.

We recommend to start building the glider from the wing:

1. finish both wing tips

2. cut and box wing servo bays preparing for servo installation.

3. glue together wing center panels and laminate the joint.

4. paint the wing (including personal touches) to its final stage

and put the wing aside to cure the paint (longer time is better)

5. prepare wing servo wiring and.

6. assemble the glider tail

7. assemble fuselage with tail, install push-rods and servos in

the pod. (those steps usually take 1-2 evenings - this is also

valuable time needed to cure painted wing)

8. separate ailerons from the wing.

9. install aileron servos and control horns and finis wiring.

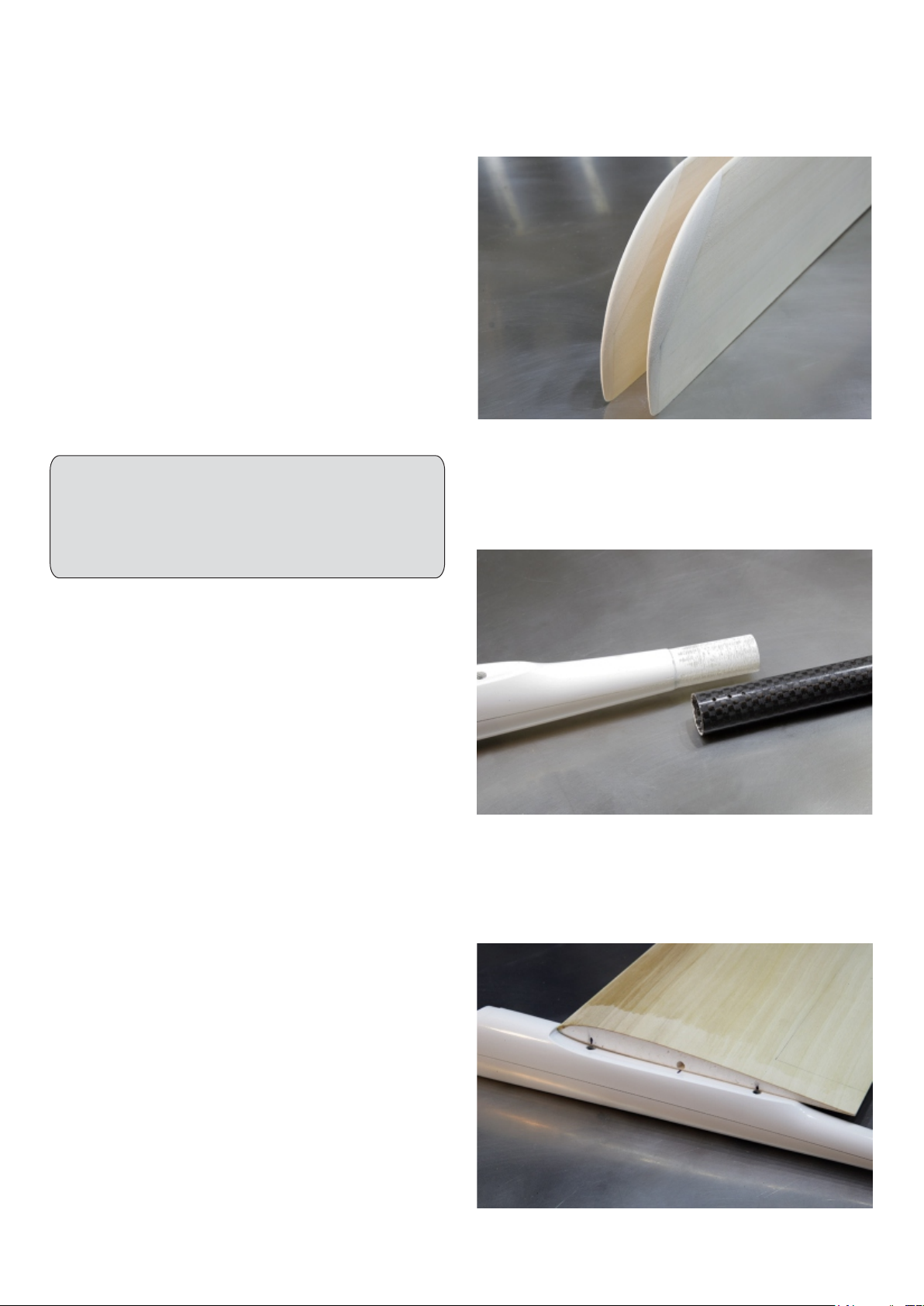

Wing Tips

1. Remove the wing segments from their protective foam.

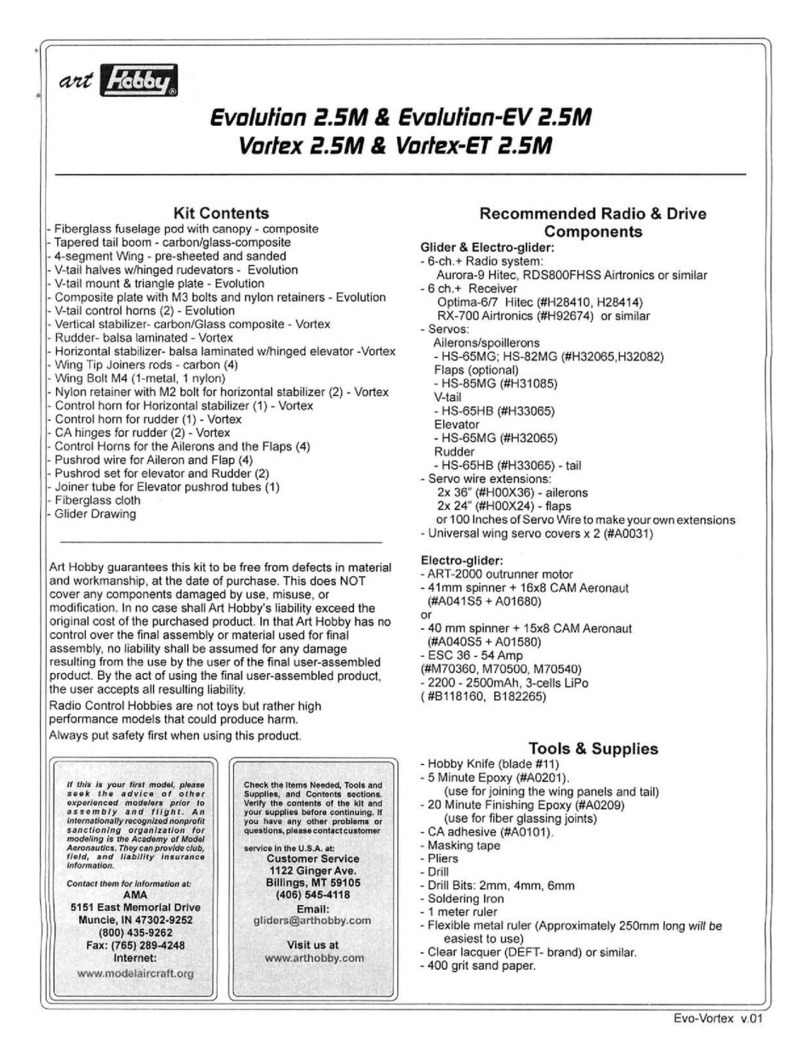

2. Sand the balsa wing tips to shape. Only round the top. Leave

the bottom of the tip the shape of the wing foil. Try to make the tips

match as closely as possible. Photo 1

Finishing wing Wood Surfaces

To prevent the wood from pre-mature aging and moisture

damage, we recommend sealing all wood surfaces using

lacquer manufactured by DEFT (available from ACE Hardware

stores or Lowe’s).

(Prior to using lacquer, any white foam surface should be

sealed with epoxy). The black poplar veneer wing skins

(~0.4mm thick) are sealed under surface, then laminated with

epoxy to the wing foam cores. This process is making a barrier

preventing harsh lacquer thinner penetration inside.

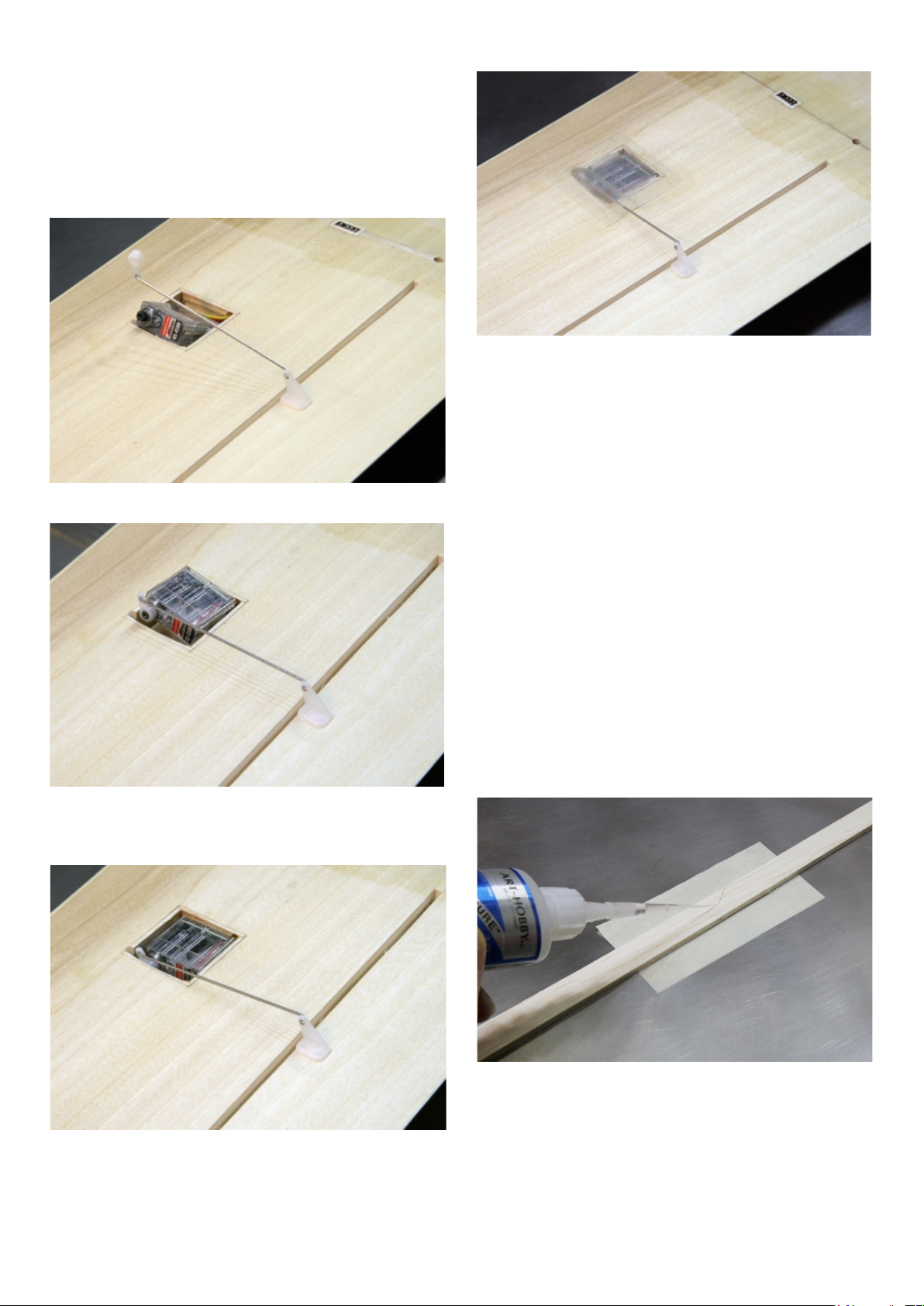

We recommend to apply lacquer in very light coats, this way

lacquer thinner evaporates very fast and does not have time to

cause any harm to the wing. The best finish result is achieved

by brushing 2 light coats of Lacquer Sanding Sealer then sand

surface after second coat using 400 grit sandpaper, then spray

on a very light finishing coat if desired - use as little as possible

to keep the weight down.

Color Option: After wing is completely finished with lacquer

you can mask it and spray some color stripes, especially to the

bottom side of the wing. This will give the glider some accent

and provide you with better visibility during flight, especially

high altitude thermal gliding. P. 1

Joining Wing Panels

To achieve a proper dihedral angle the root of each wing

halve is sanded at a slight angle to fit.

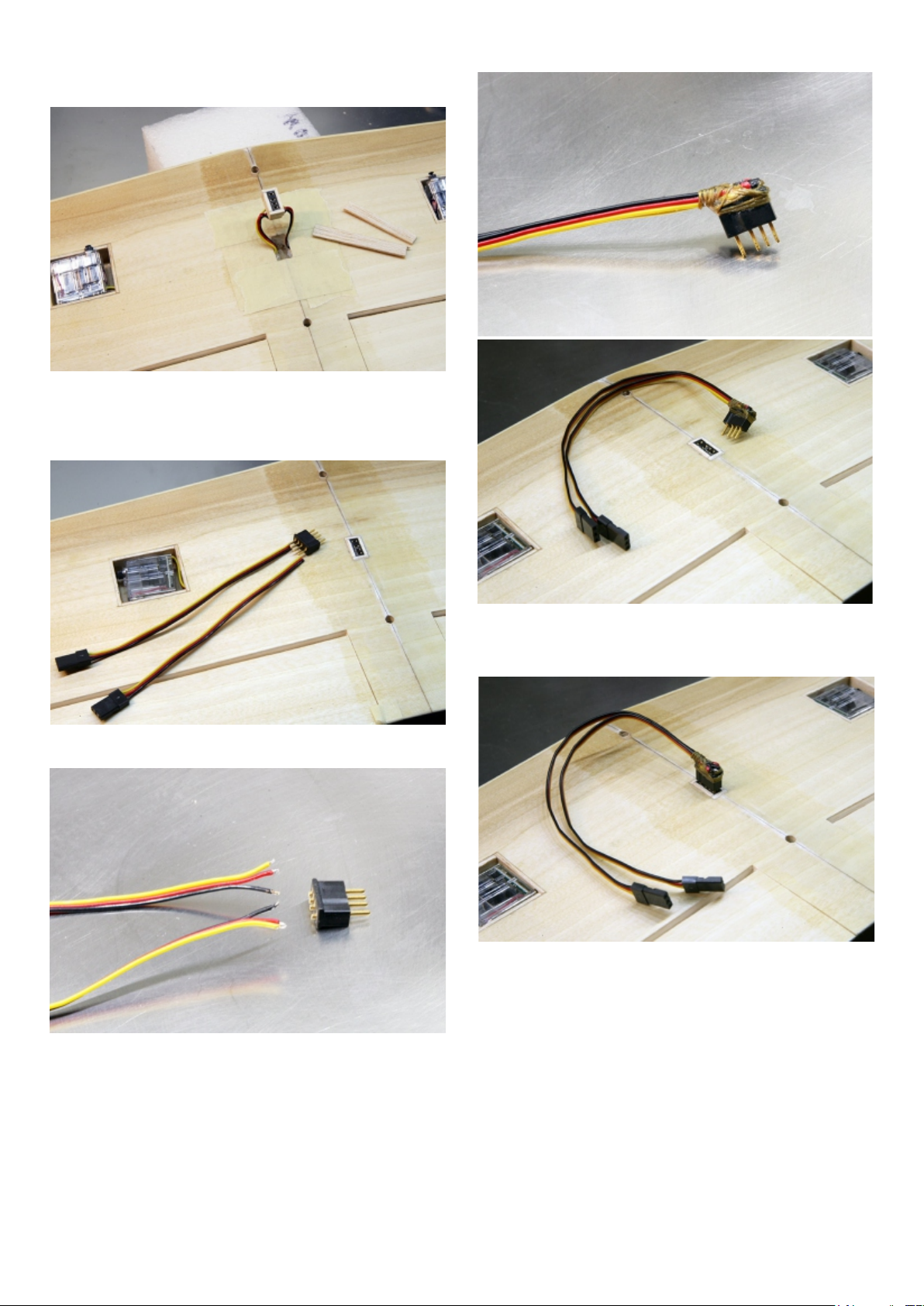

1. Place one of the wing halves root on the pod saddle. Mark the

bottom side root of the wing 40mm and 120mm back from the

leading edge. Also mark the position of the wing servo wire

canals on the bottom side of the wing panels roots . Photo 3

P. 3

Pod and Boom Preparation

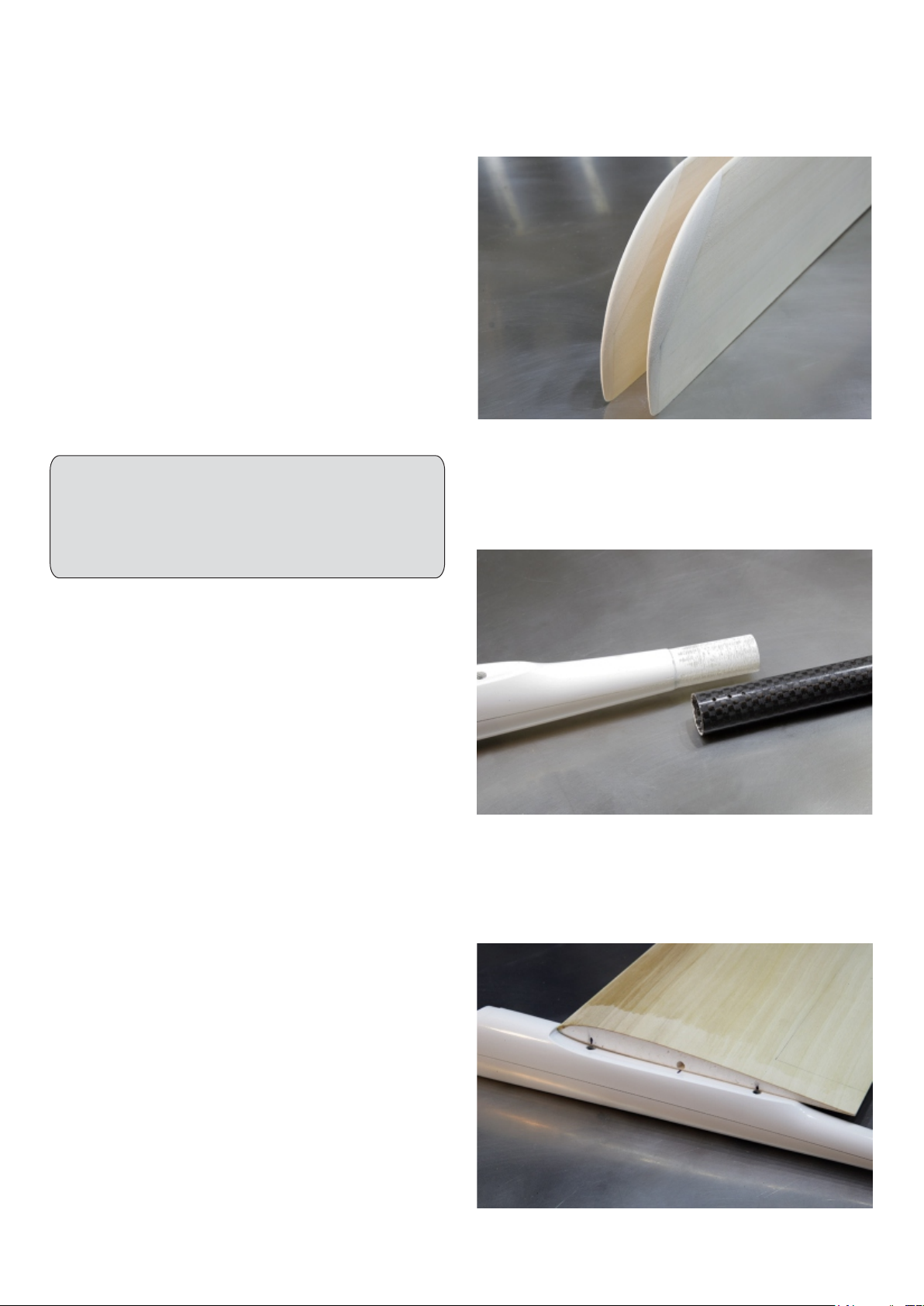

1. Use coares sand paper and rough up paint surface on the

fuselage pod joiner tip joiner tip. Trial fit the boom with the pod

and check the alignment.

2. Drill three 2mm holes in the boom, they will be used later for

gluing pod and boom together. Photo 2

Note: Do NOT glue together pod to boom in this stage.

P. 2

Momentum-DL v.1

Notes about the finished surfaces:

The fuselage is painted (in the mold). The white paint will be

damaged by thinners. The wood surfaces can be finished with

a proper clear finish. Remember that the wing has a foam

core and some paints may attack the foam internally.