III

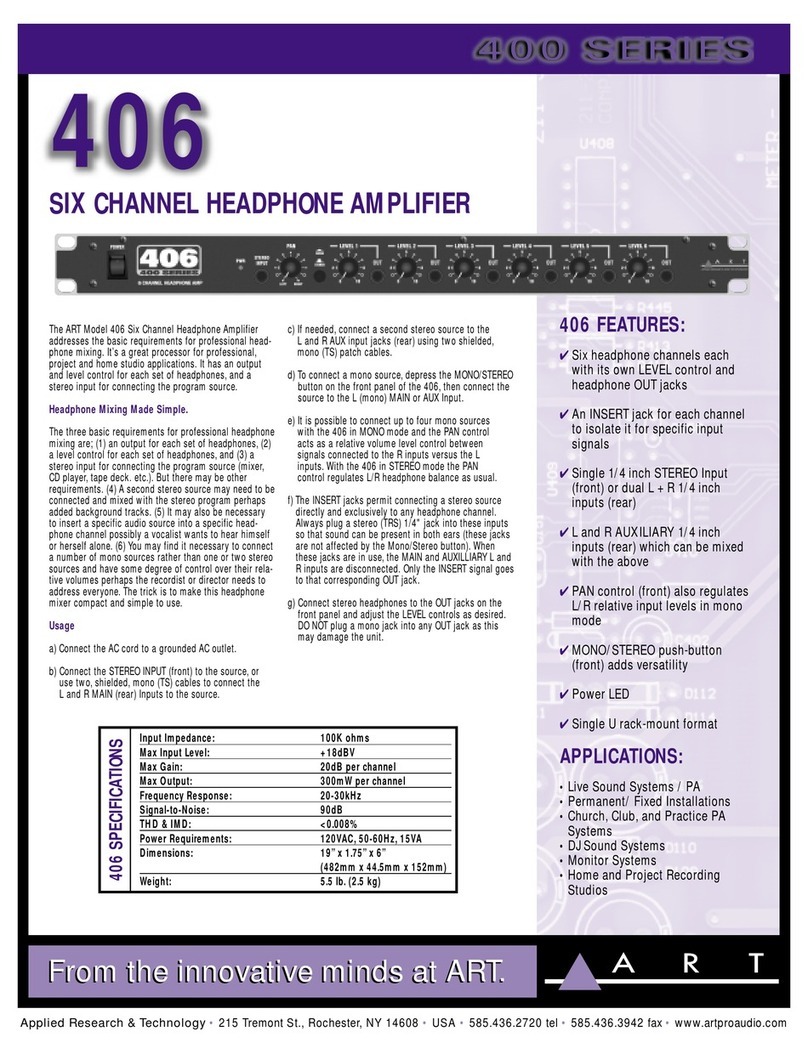

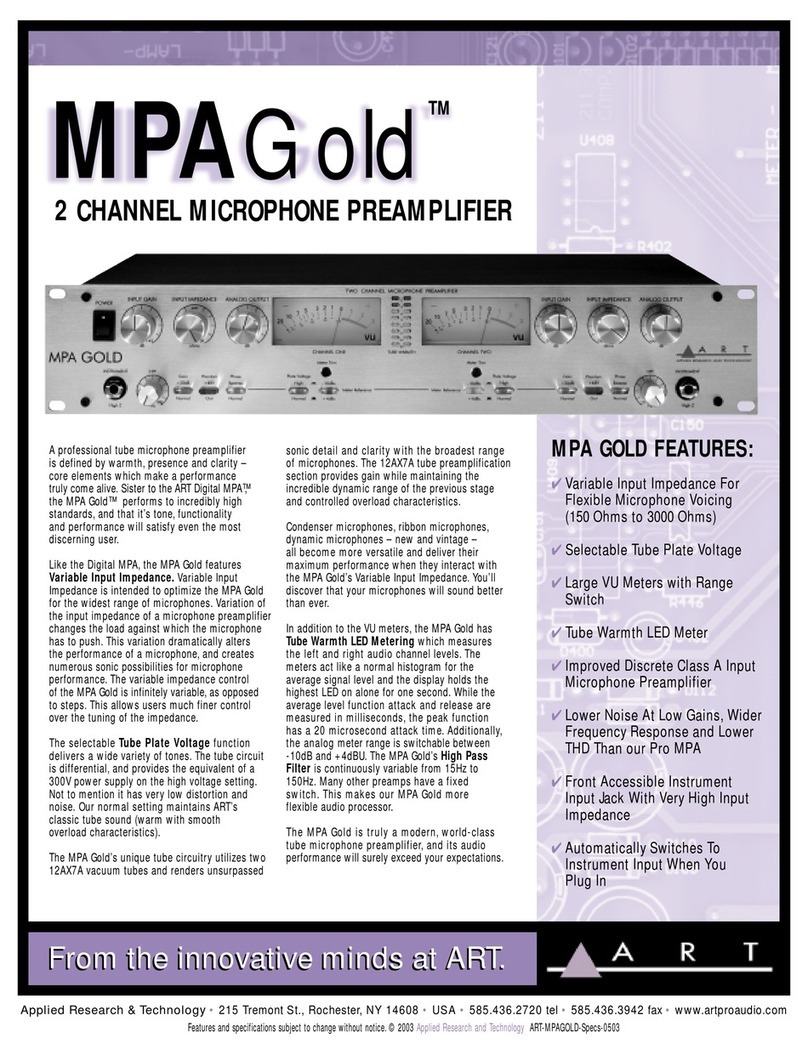

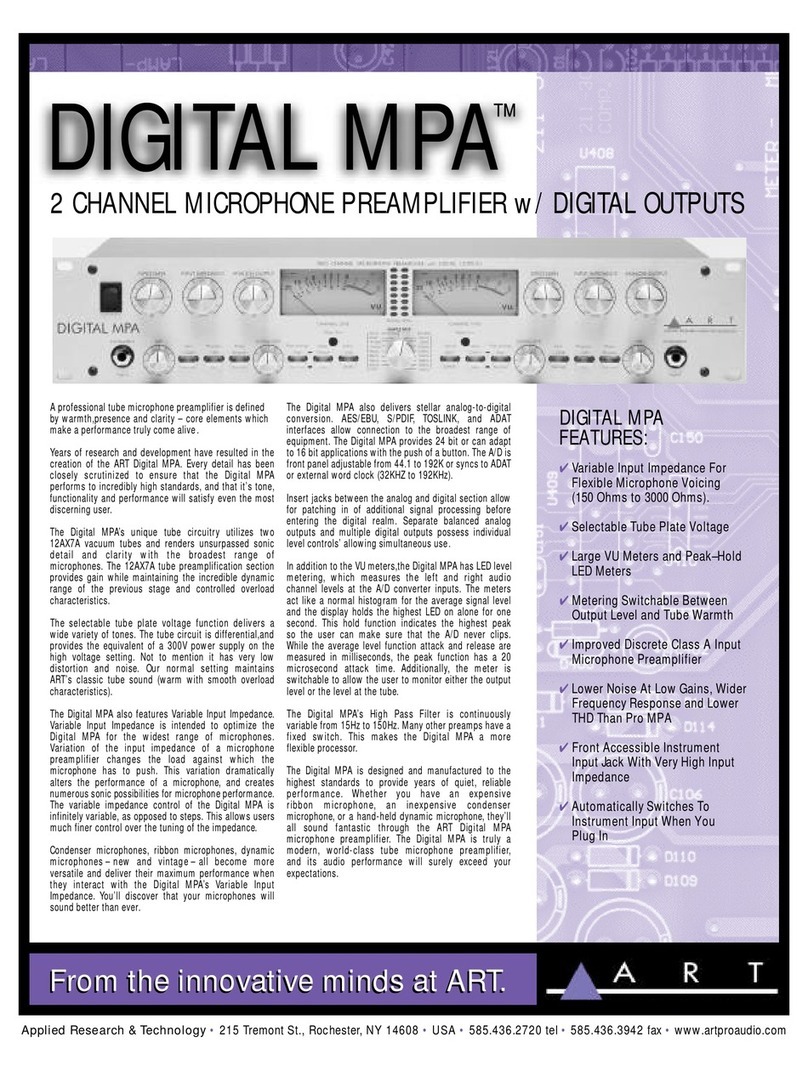

PRO CHANNEL II

TUBE PREAMP - OPTO COMPRESSOR - EQ

IMPORTANT SAFETY INSTRUCTIONS – READ FIRST......................................................................................................II

INTRODUCTION.....................................................................................................................................................................1

INSTALLATION......................................................................................................................................................................2

AC Power Hookup..................................................................................................................................................................................2

Analog Audio Connections.....................................................................................................................................................................2

FRONT PANEL CONTROLS and JACKS.............................................................................................................................3

Mic Preamp Controls..............................................................................................................................................................................3

Instrument Input .....................................................................................................................................................................................3

Gain Control...........................................................................................................................................................................................3

Impedance Control.................................................................................................................................................................................3

GAIN Switch...........................................................................................................................................................................................4

Phantom Power Switch ..........................................................................................................................................................................4

Invert Switch...........................................................................................................................................................................................4

Low Cut Control......................................................................................................................................................................................4

Preamp Output Control...........................................................................................................................................................................4

Tube Voltage Switch ..............................................................................................................................................................................5

Compressor Controls .............................................................................................................................................................................6

Threshold Control...................................................................................................................................................................................6

Ratio Control ..........................................................................................................................................................................................6

Attack Control.........................................................................................................................................................................................7

Release Control......................................................................................................................................................................................7

Compressor Output Control....................................................................................................................................................................7

Gain Reduction LED Meter.....................................................................................................................................................................8

Semi-Parametric EQ ..............................................................................................................................................................................8

EQ Bypass Switch..................................................................................................................................................................................9

CLIP LED ...............................................................................................................................................................................................9

Master Output Control............................................................................................................................................................................9

Output Meters.......................................................................................................................................................................................10

VU Meter Switches...............................................................................................................................................................................10

REAR PANEL CONNECTIONS...........................................................................................................................................11

INPUT Jack..........................................................................................................................................................................................11

PREAMP OUT Jack .............................................................................................................................................................................11

COMP IN Jack......................................................................................................................................................................................12

COMP OUT Jack..................................................................................................................................................................................12

EQ IN Jack...........................................................................................................................................................................................12

OUTPUT Jacks ....................................................................................................................................................................................12

OUTPUT LEVEL Switch.......................................................................................................................................................................12

APPLICATIONS....................................................................................................................................................................13

Bypassing Components Of The Pro Channel II....................................................................................................................................13

Optimizing The Preamp For Lowest Noise...........................................................................................................................................13

WARRANTY INFORMATION...............................................................................................................................................14

SERVICE...............................................................................................................................................................................27

SPECIFICATIONS................................................................................................................................................................28

LIST OF FIGURES

FIGURE 1 – Preamp section...................................................................................................................................................5

FIGURE 2 – Compressor Section...........................................................................................................................................6

FIGURE 3 – Equalizer Section................................................................................................................................................8

FIGURE 4 – Signal Flow Block Diagram ................................................................................................................................9

FIGURE 5 – Output Section..................................................................................................................................................10

FIGURE 6 – Rear Jacks........................................................................................................................................................11