6

STANDARD ASSEMBLY NUMBERS / OPTIONS

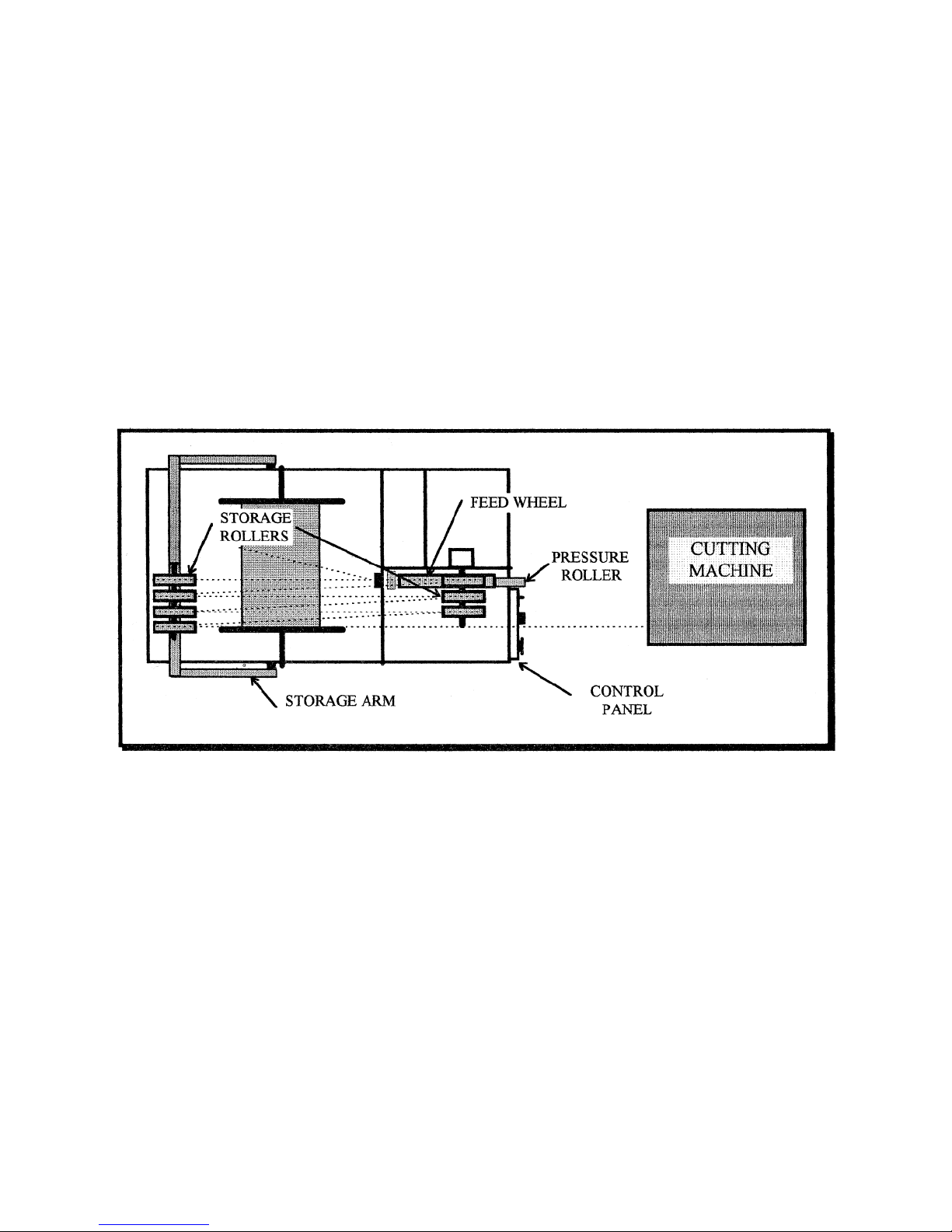

MAINASSEMBLY

2‐134900‐500MainBaseAssembly(Standard)–onthedrawingitlistsvoltageoptions,e‐stopoption,

andbarreladaptorkit.Forthesizingbelowifyoudonotuseaconetocenterspoolontheshaft,the

maximumreelwidthis15.5(394mm).Thesizeoftheshaftis0.625(16mm)diameter.

PULLEYS

2‐134900‐510Aluminumlargewire3pulleyoption.Maximumwirediameteris0.50inches(12.7mm).

2‐134900‐520Plastic3pulleyoption(Standard).Maximumwirediameteris0.38inches(9.6mm).

2‐134900‐530Aluminumlargewire7pulleyoption,forlongwires.Maximumwirediameteris0.50

inches(12.7mm).7pulleysgivesyouaddedwireaccumulation.Thisisusefulwhenyouareprocessing

wiresgreaterthan10feed(3meters)inlength.

2‐134900‐540Plastic9pulleyoption,forlongwires.Maximumwirediameteris0.38inches(9.6mm).9

pulleysgivesyouaddedwireaccumulation.Thisisusefulwhenyouareprocessingwiresgreaterthan10

feed(3meters)inlength.

ROLLERS

2‐134900‐550Reelsupportrollers.Thisoptionswillallowyousetthespoolintothepre‐feeder,rather

thanputtingashaftthroughthecoreofthespoolandhangingthespoolinthepre‐feeder.Thisoption

requiresthespoolflangestoberoundandundamaged.

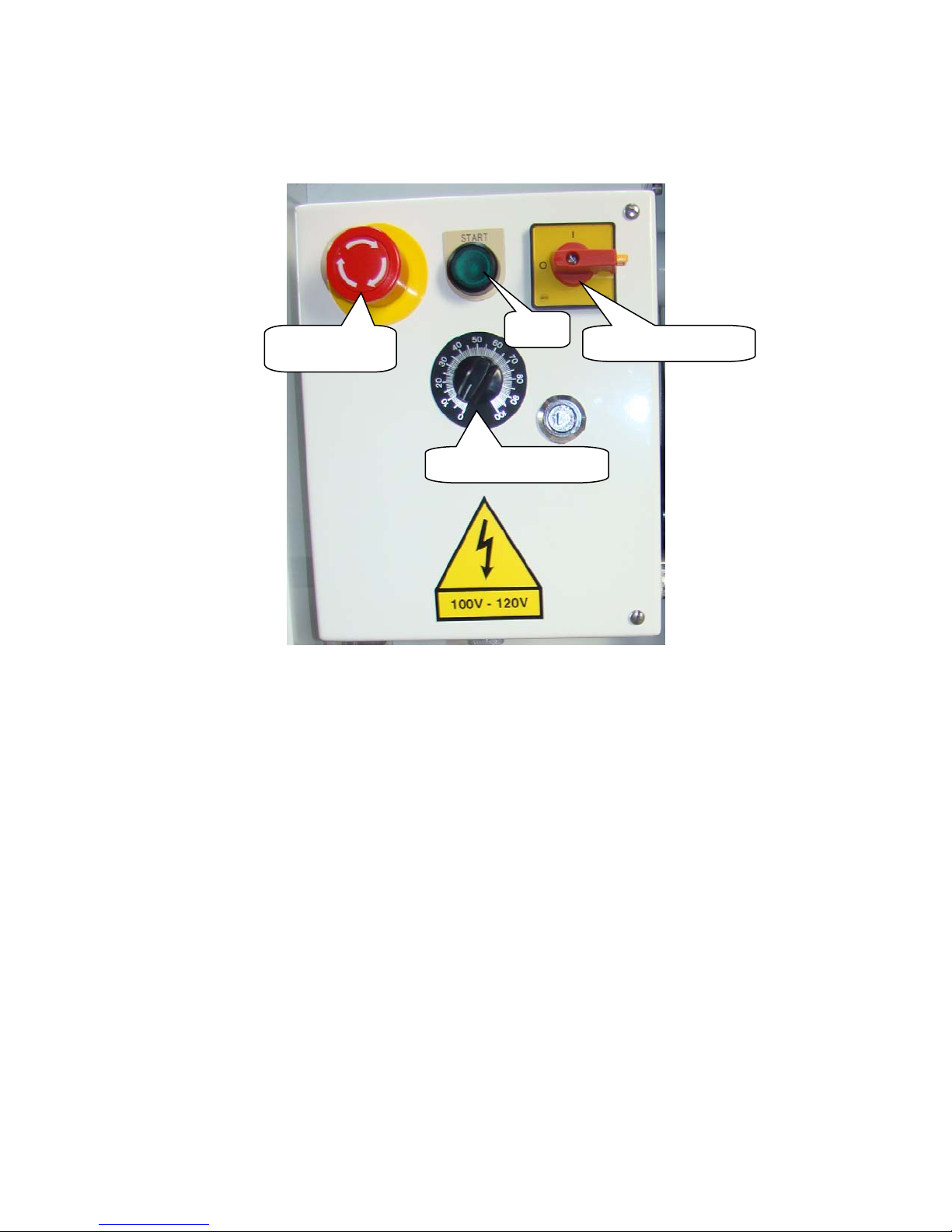

POWER/CONTROLOPTIONS

2‐134900‐560110VACpower

2‐134900‐570220VACpower

2‐134900‐610110VACpowerwithovertravelshutdownandmachinefeedback.Thisoptionwill

automaticallyshutdownthepre‐feederwhenthearmispulledallthewayforward.Thiscanhappen

whenthewireistangledandcannotbepulledoffthespool.Aconnectorisprovidedthatwillprovidea

drycontactthatopenswhenthepre‐feederisshutdown.Thisconnectorcanbewiredtoe‐stopthe

wirecuttingmachine.

2‐134900‐600220VACpowerwithovertravelshutdownandmachinefeedback.Thisoptionwill

automaticallyshutdownthepre‐feederwhenthearmispulledallthewayforward.Thiscanhappen

whenthewireistangledandcannotbepulledoffthespool.Aconnectorisprovidedthatwillprovidea

drycontactthatopenswhenthepre‐feederisshutdown.Thisconnectorcanbewiredtoe‐stopthe

wirecuttingmachine.

WIDEREELADAPTIONKITS

5‐144396‐xWidereeladaptionkit.Thisoptionaddsextensionarmstothebackofthepre‐feederso

thatitcanacceptwiderreels.

5‐144396‐1Baseparts.Orderoneoftheseandselectoneoftheitemsfromthelistbelow

Forthesizingbelowifyoudonotuseaconetocenterspoolontheshaft,themaximum

reelwidthis19.5(495mm),Thesizeoftheshaftis0.625(16mm)diameter.