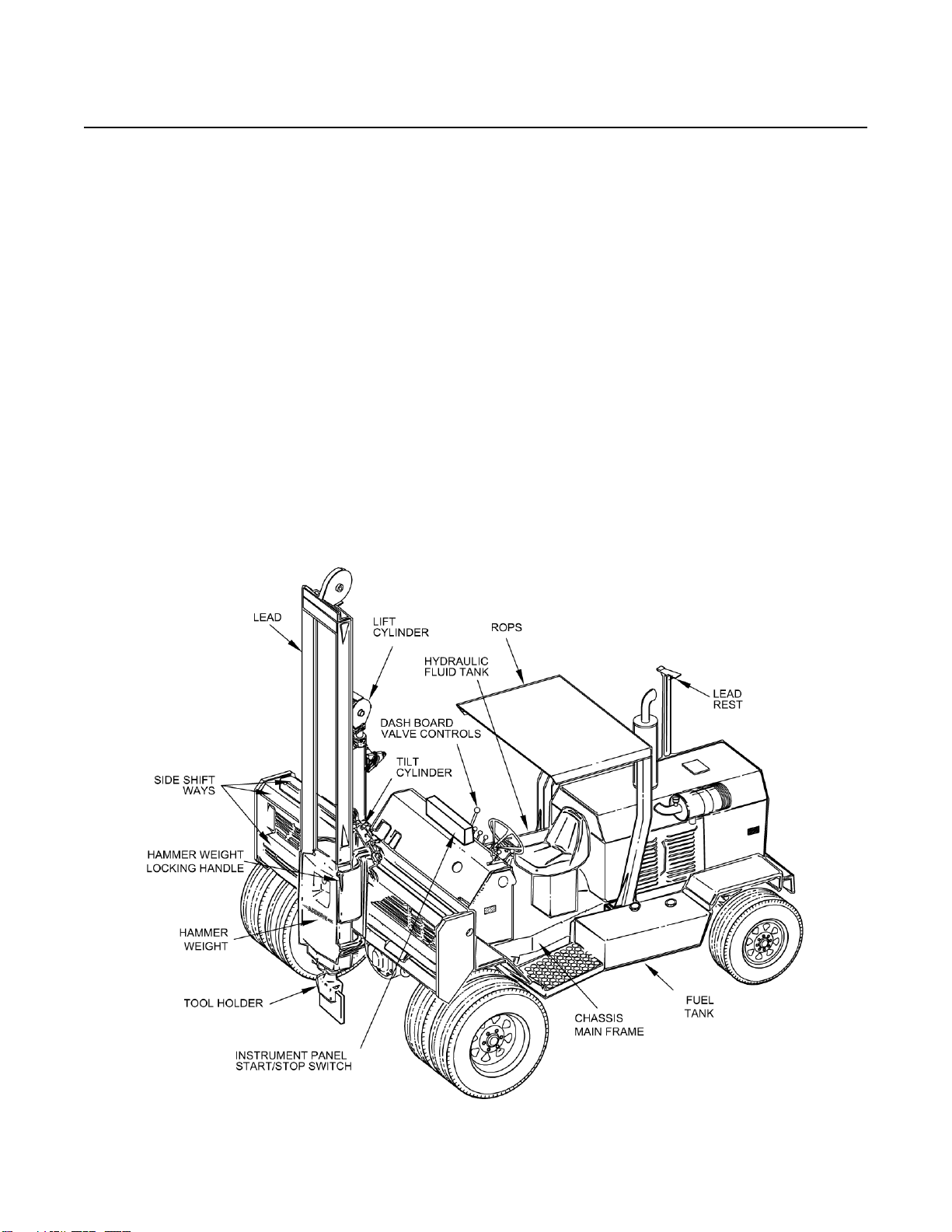

Page 1-2 - Description

5000053 01/12

Intended Application

The Arrow Hammer is designed for breaking/demolition, cutting/sectioning, compaction, and driving and impacting using

specifically designed attachments. Any other applications are considered unintended application, and are not the responsibility

of the manufacturer. Any damages resulting from such unintended application are at the sole risk of the operating contractor.

Intended application also involves strict adherence to the manufacturer's operating instructions, service instructions, and

maintenance instructions. The Arrow Hammer should only be operated, serviced, and maintained by experienced personnel who

have been instructed about any possible dangers. While working, the machine is to be operated by the driver only. The presently

valid accident prevention regulations, as well as the generally accepted safety, working medicine and road traffic regulations are

to be followed.

Any alterations to the machine which are not approved by the manufacturer, and any damages resulting therefrom, are at the sole

risk of the operating contractor. The manufacturer's operating instructions, service instructions, and maintenance instructions are

to be strictly adhered to.

Tools and Attachments

The list below contains the tools and attachments approved for use with the Arrow-Hammer. These tools and attachments are

available from the manufacturer and shall only be used as outlined.

!Tamper (36" - 914 mm) Compaction of soil, sand, and granular fill.

!Tamper (72" - 1829 mm) Compaction of soil, sand, and granular fill in deeper trenches.

!Frost Chisel Cutting frozen ground.

!Breaker Head General concrete breaking., Crack and Seat (Detensioning)

(8" - 203mm Round)

!Concrete Breaker General concrete breaking.

(4-1/2" - 114 mm Round)

!Heavy-Duty Breaker Controlled and general concrete breaking.

(2" x 8" - 51 x 203 mm)

!Concrete Wedge Breaking concrete with asphalt overlay.

!Tapered Asphalt Cutter Cutting asphalt.

!Blunt Asphalt Cutter Scoring asphalt.

!Tapered Scoring Tool Cutting concrete .

!Blunt Scoring Tool Scoring concrete.

!Post Driver Setting posts in soil.

!Rock Breaker Breaking natural rock.

!Post Hole Punch Punching round holes in soil, concrete, and asphalt.

!Trencher Making small trenches in soil.

!Star Tool Cutting round post holes in soft rock

!Post Extractor Extracting posts from soil.

Unintended Application

The Arrow Hammer should not be used:

To carry passengers who are not operating personnel of the machine.

To tow or push other machines or vehicles.

To lift or carry any materials or loads.

With any attachments or tools not specifically designed for the machine by the manufacturer.

This machine could be dangerous if it is operated by non-trained personnel, incorrectly operated by trained personnel, or misused

for unintended applications. The machine must not be operated with any guards or shields missing.