1

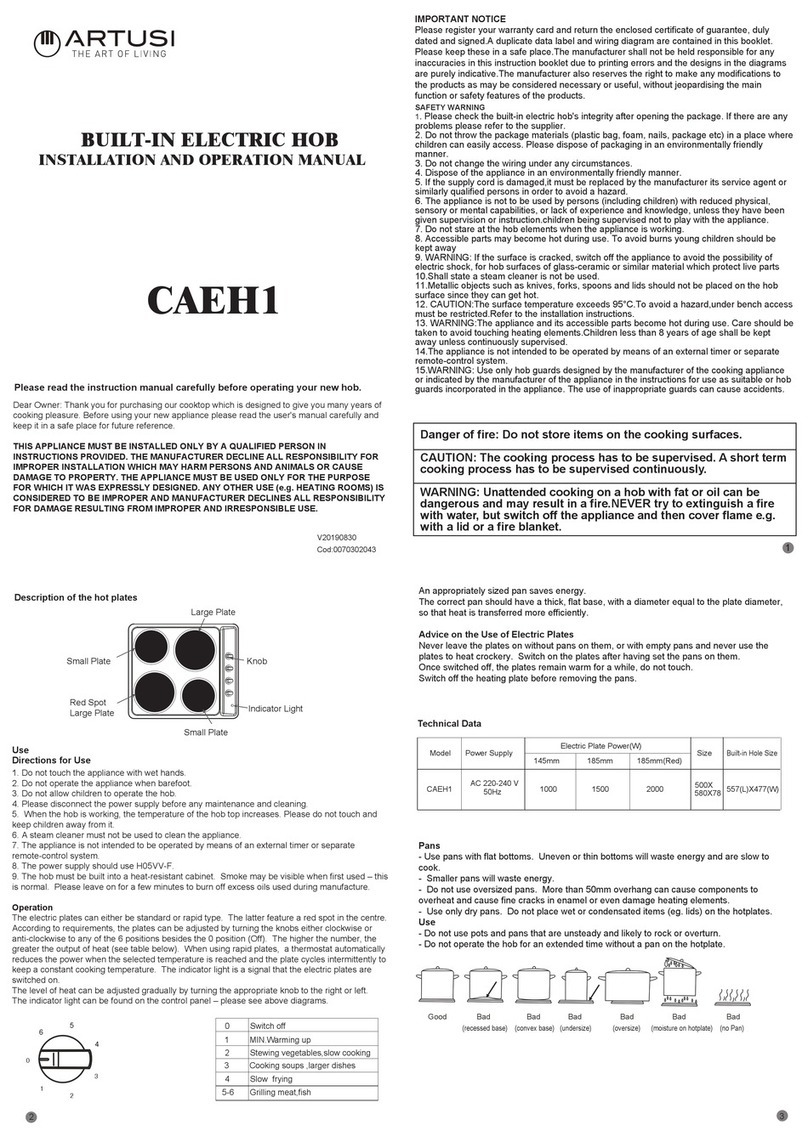

This manual explains the proper installation and use of your appliance, please read it

carefully before using even if you are familiar with the product. The manual should be kept

in a safe place for future reference. In case of failure, only the Authorized Technical

Service may repair this hob. Otherwise the guarantee will be null and void.

Warning

General Safety

The appliance may only be installed and connected by licensed gasfitters / authorized

persons.

Built-in appliances may only be used after they have been built in to suitable cabinets and

work surfaces that meet local authority standards.

Repairs to the appliance must only be carried out by trained registered authorized service

persons / engineers.

Consult the reference data label before making the electrical connections. It is located on

the underside of the appliance.

The electrical connections must be made by specialist installers to the local legal and

regulatory requirements.

If the cable is damaged in any way it must be replaced by the manufacturer or after sale

service or by authorized technical staff.

NEVER USE OR STORE FLAMMABLE MATERIALS IN THE APPLIANCE STORAGE

DRAWER OR NEAR THIS APPLIANCE.

NEVER SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN

OPERATION.

ALTERATION OR MODIFICATION OF THIS APPLIANCE IS FORBIDDEN.

USE OF THIS APPLIANCE AS A SPACE HEATER IS VERY DANGEROUS AND MAY

RESULT IN INJURY OR DEATH.

Correct Use

People including children, who, because of their physical, sensory or mental capabilities

or their inexperience or ignorance are not able to use the device safely, should not use

this device without supervision or instruction by a responsible person.

Only use this appliance for normal domestic cooking and frying of food. It is not for

commercial use.

The appliance must not be used as a work surface or as a storage surface.

Additions or modifications to the appliance are not permitted.

Do not place or store flammable liquids, highly inflammable materials or fusible objects