3

4. SAFETY INSTRUCTIONS

Make sure that this instruction booklet is read thoroughly and understood before attempting to install or

operate this hob.

The instructions are provided in the interest of your safety.

GAS SAFETY REGULATIONS AND USE OF YOUR HOB

1. It is a legal requirement that all gas appliances are installed by qualified personnel only in accordance

with current legislation. It is your responsibility to ensure compliance with the law.

2. Repairs or servicing of this product must only be carried out by an authorised service agent using

approved parts.

3. No attempt must be made to modify this appliance under any circumstances.

4. Cooking appliances can become very hot in use – please keep children and pets away from them.

5. Do not allow children to operate or play with any part of the appliance.

6. Do not use unstable pans and ensure that the handle is positioned away from the edge of the worktop.

7. In the interest of hygiene and safety, please ensure the hob is kept clean.

8. This appliance is designed for domestic cooking only. Commercial use will invalidate the warranty.

9. Do not cover the hob or place combustible materials on or near the surface even when the hob is not in

use.

10. Do not fill deep fat frying containers more than one third full of oil and NEVER leave unattended.

11. Before cleaning the hob, switch off at the mains.

12. When cooking is finished, switch off all controls and allow to cool.

13. These appliances are not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

14. If the supply cable is damaged, it must be replaced by the authorised service agent or qualified person

only.

15. Do not immerse the appliance or the power cable into water or any other liquid.

16. DO NOT SPRAY AEROSOLS IN THE VICINTY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

17. DO NOT USE OR STORE FLAMMABLE MATERIALS ON OR NEAR THIS APPLIANCE.

18. DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE.

19. DO NOT MODIFY THIS APPLIANCE.

5. INSTALLATION INSTRUCTIONS

TECHNICAL INFORMATION

The installation, adjustments, conversions and maintenance listed in this section must be carried out by

qualified personnel only.

The safety and automatic adjustment devices of the appliance may only be modified by an authorised service

agent.

The installation of this gas hob must comply with Australia and New Zealand standards.

This appliance must be fitted in compliance with the installation rules given above. Also, particular attention

must be given to the following requirements for ventilation.

INSTALLATION LOCATION

The appliance may be located in a kitchen, kitchen/diner or utility room, however, it cannot be in a room

containing a bath or shower.

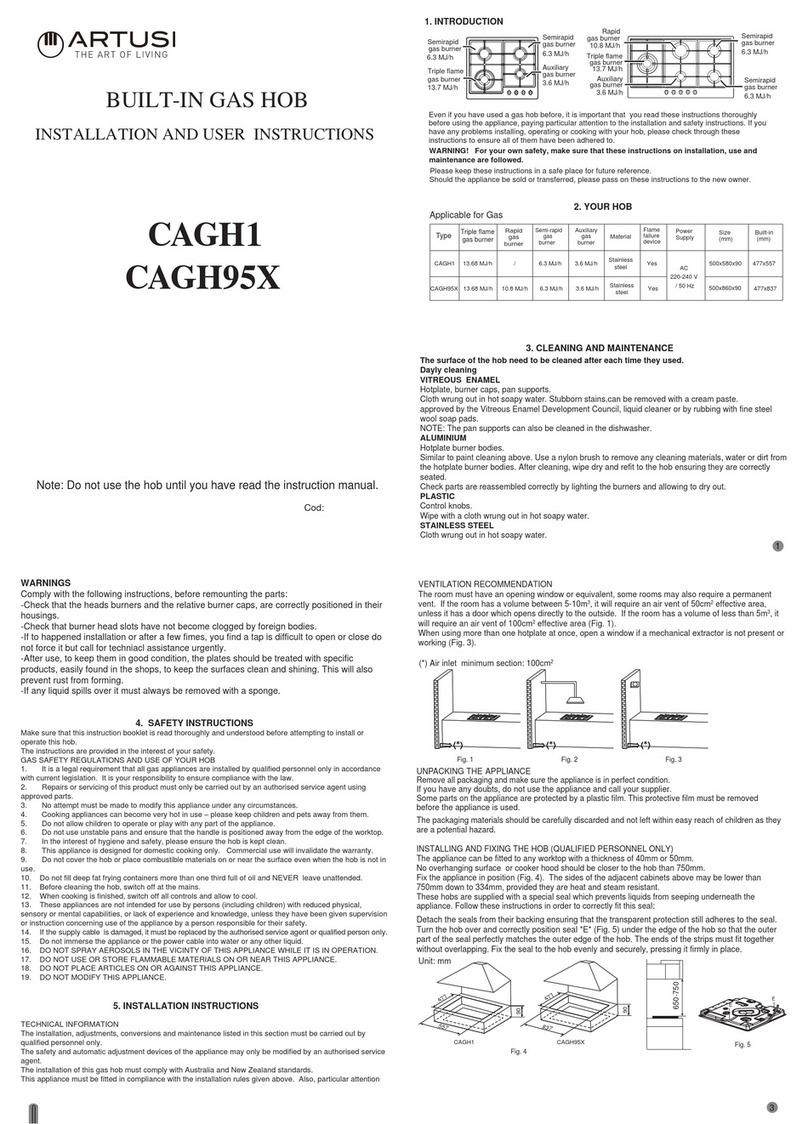

WARNINGS

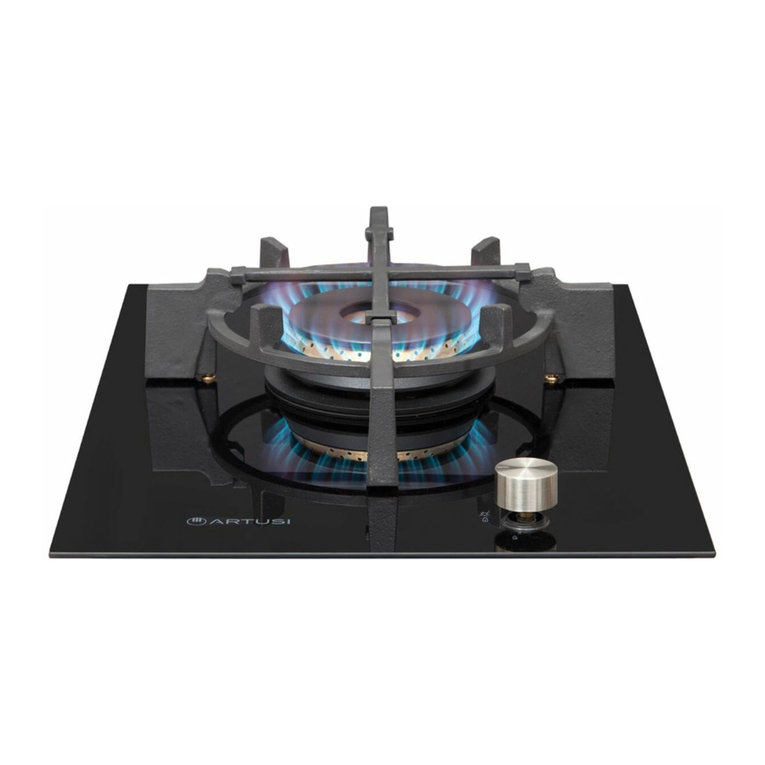

Comply with the following instructions, before remounting the parts:

-Check that the heads burners and the relative burner caps, are correctly positioned in their housings.

-Check that burner head slots have not become clogged by foreign bodies.

-If to happened installation or after a few fimes, you find a tap is difficult to open or close do not force it but

call for techniacl assistance urgently.

-After use, to keep them in good condition, the plates should be treated with specific products, easily found

in the shops, to keep the surfaces clean and shining. This will also prevent rust from forming.

-If any liquid spills over it must always be removed with a sponge.

PLASTIC

Control knobs.

Wipe with a cloth wrung out in hot soapy water.

STAINLESS STEEL

Cloth wrung out in hot soapy water

Never clean when the top and components are still warm.Do not use metal or abrasive pads,

abrasive powders or corrosive spray products.Never leave vinegar,coffee,milk,salty water,lemon or

tomato juice for any length of time on the surfaces.