[AK8975/C]

3. Table of Contents

1. Features....................................................................................................................................1

2. Overview ...................................................................................................................................2

3. Table of Contents ......................................................................................................................3

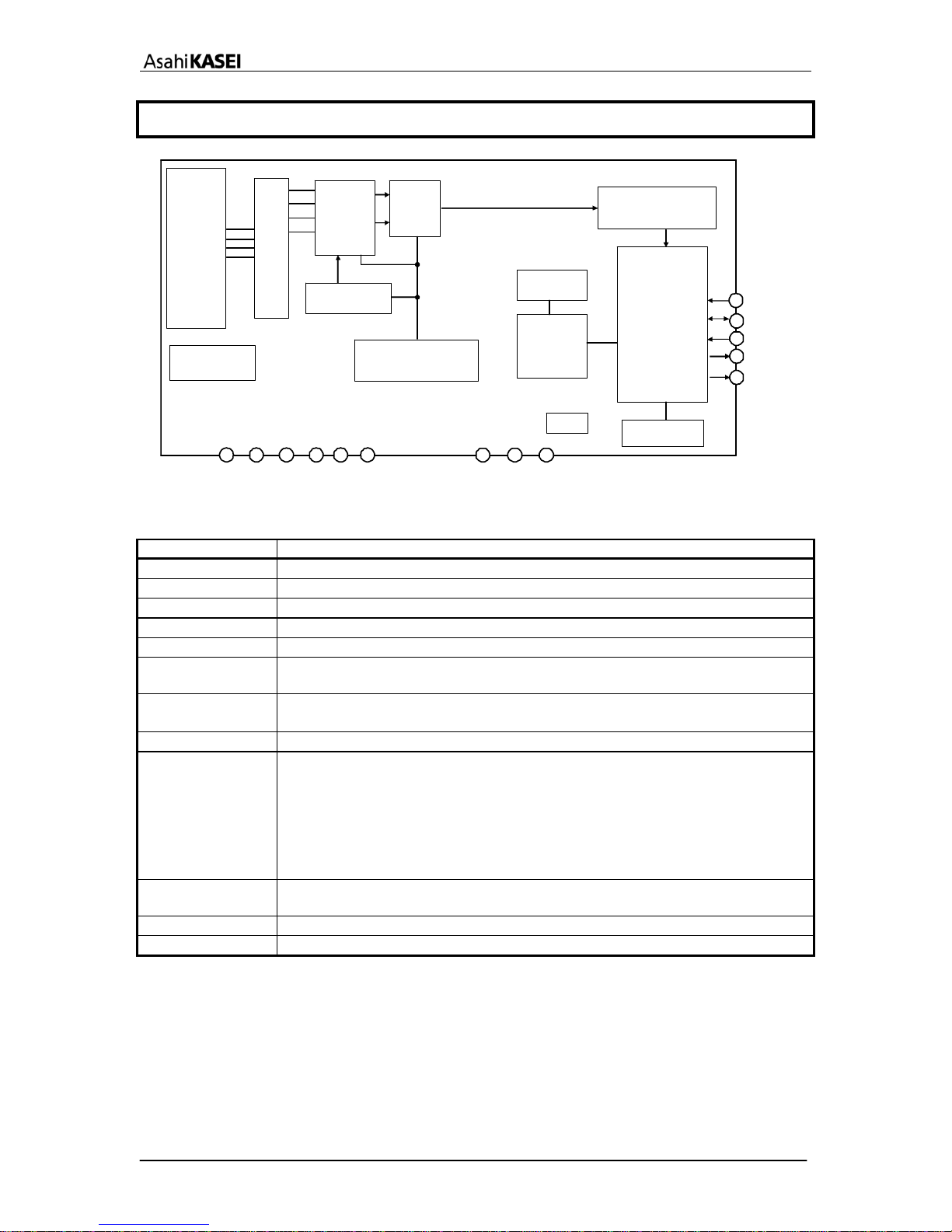

4. Circuit Configuration..................................................................................................................5

4.1. Block Diagram....................................................................................................................5

4.2. Block Function....................................................................................................................5

4.3. Pin Function.......................................................................................................................6

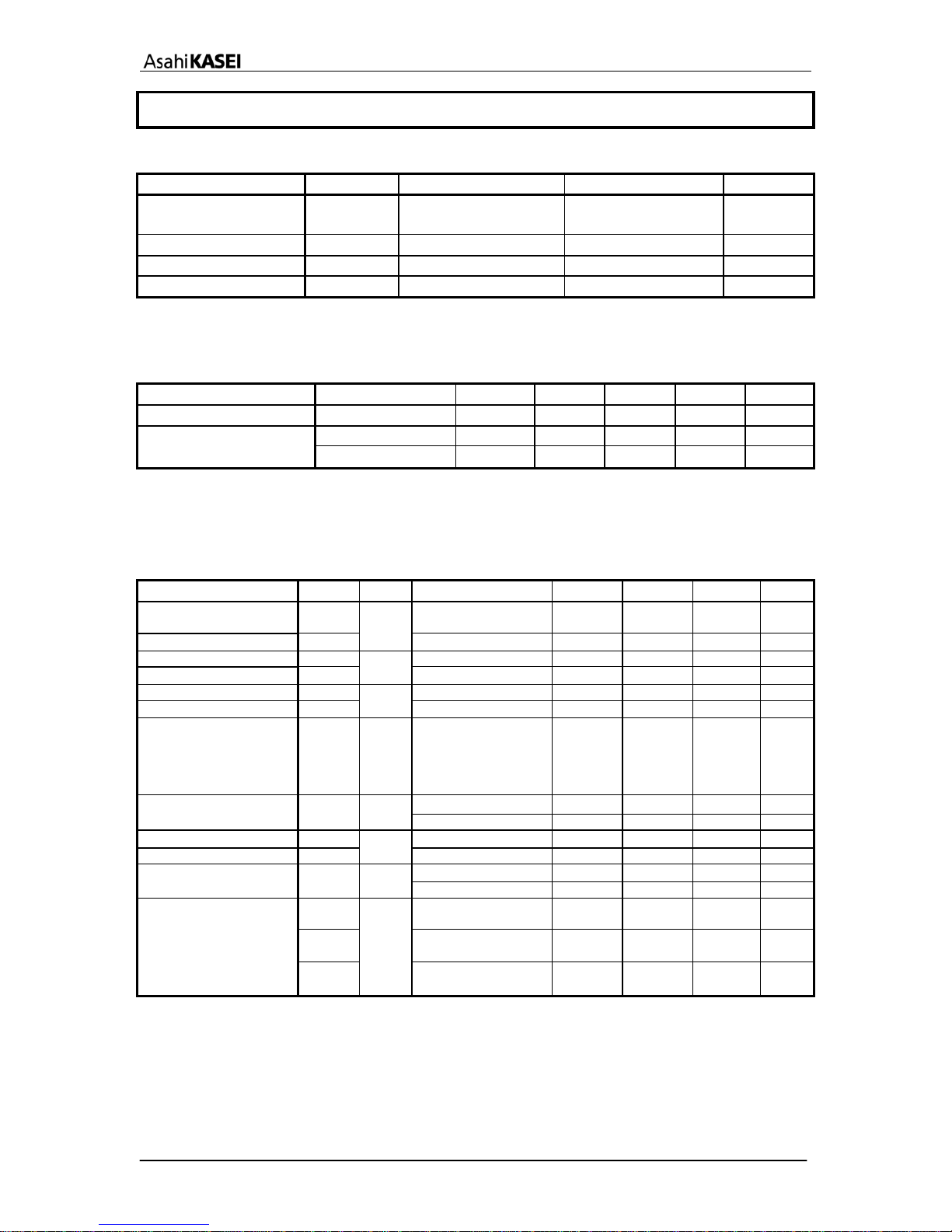

5. Overall Characteristics ..............................................................................................................7

5.1. Absolute Maximum Ratings................................................................................................7

5.2. Recommended Operating Conditions ................................................................................7

5.3. Electrical Characteristics....................................................................................................7

5.3.1. DC Characteristics......................................................................................................7

5.3.2. AC Characteristics ......................................................................................................8

5.3.3. Analog Circuit Characteristics.....................................................................................8

5.3.4. 4-wire SPI ...................................................................................................................9

5.3.5. I2C Bus Interface.......................................................................................................10

6. Functional Explanation............................................................................................................11

6.1. Power States....................................................................................................................11

6.2. Reset Functions ...............................................................................................................11

6.3. Operation Modes..............................................................................................................12

6.4. Description of Each Operation Mode................................................................................13

6.4.1. Power-down Mode....................................................................................................13

6.4.2. Single Measurement Mode .......................................................................................13

6.4.2.1. Data Ready........................................................................................................13

6.4.2.2. Data Error ..........................................................................................................14

6.4.2.3. Magnetic Sensor Overflow.................................................................................14

6.4.3. Self-test Mode...........................................................................................................15

6.4.4. Fuse ROM Access Mode ..........................................................................................15

7. Serial Interface........................................................................................................................16

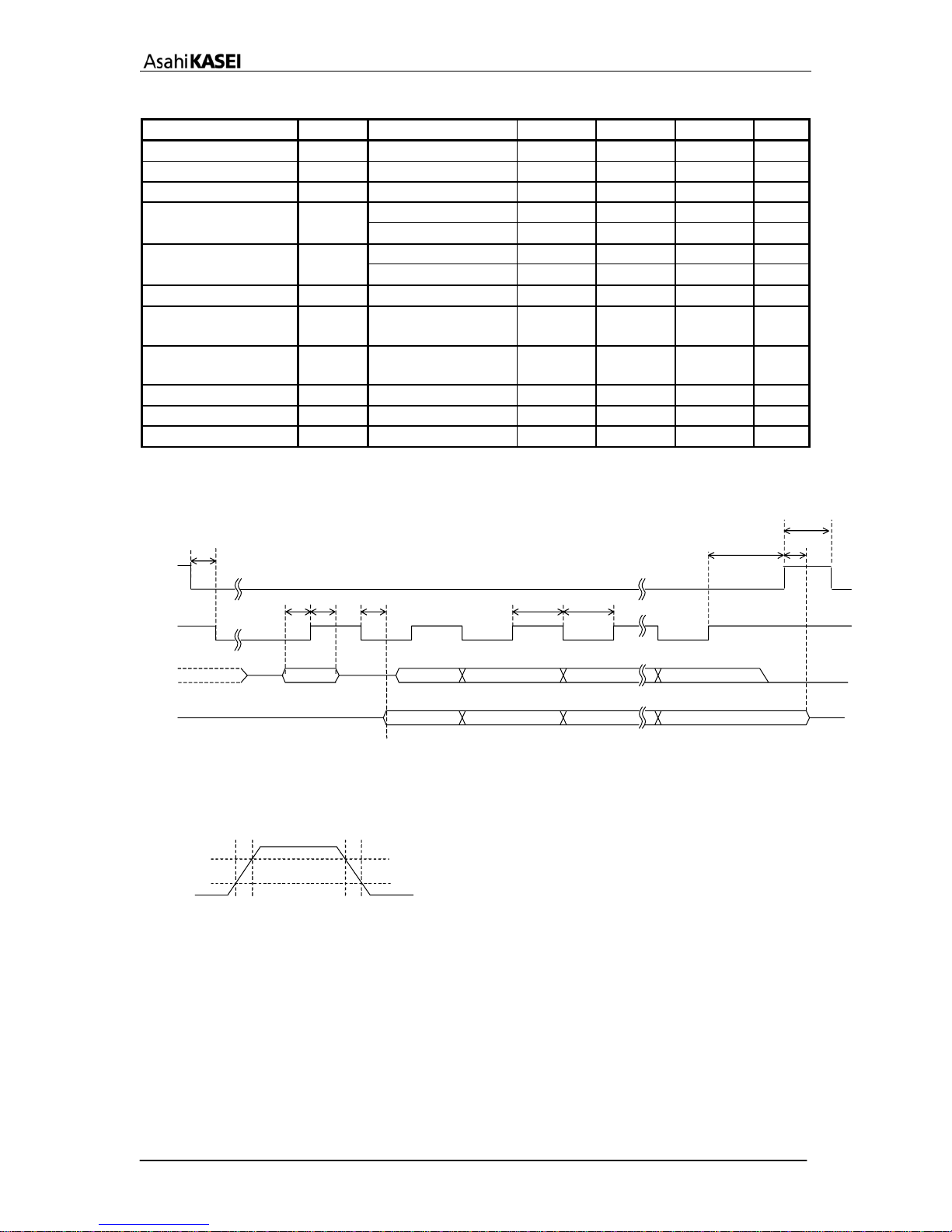

7.1. 4-wire SPI.........................................................................................................................16

7.1.1. Writing Data ..............................................................................................................16

7.1.2. Reading Data............................................................................................................17

7.2. I2C Bus Interface..............................................................................................................18

7.2.1. Data Transfer ............................................................................................................18

7.2.1.1. Change of Data..................................................................................................18

7.2.1.2. Start/Stop Condition ...........................................................................................18

7.2.1.3. Acknowledge......................................................................................................19

7.2.1.4. Slave Address....................................................................................................19

7.2.2. WRITE Instruction.....................................................................................................20

7.2.3. READ Instruction.......................................................................................................21

7.2.3.1. One Byte READ.................................................................................................21

7.2.3.2. Multiple Byte READ ...........................................................................................21

8. Registers.................................................................................................................................22

8.1. Description of Registers...................................................................................................22

8.2. Register Map....................................................................................................................23

8.3. Detailed Description of Registers.....................................................................................24

8.3.1. WIA: Device ID..........................................................................................................24

8.3.2. INFO: Information......................................................................................................24

8.3.3. ST1: Status 1.............................................................................................................24

8.3.4. HXL to HZH: Measurement Data...............................................................................25

8.3.5. ST2: Status 2.............................................................................................................26

8.3.6. CNTL: Control...........................................................................................................26

8.3.7. RSV: Reserved .........................................................................................................27

8.3.8. ASTC: Self Test Control ............................................................................................27

8.3.9. TS1, TS2: Test 1, 2 ...................................................................................................27

8.3.10. I2CDIS: I2C Disable...................................................................................................27

8.3.11. ASAX, ASAY, ASAZ: Sensitivity Adjustment values...................................................28

MS1187-E-02 - 3 - 2010/05