DFS-*-O/W

3

3. Installation tips

(1) Before installing the sensor, flush all piping passages clean.

(2) For accuracy, provide straight piping of more than 10 times the inner diameter of the pipe

on the upstream side, and more than 4 times on the downstream side. Do not install curved,

confluence, or branch piping (, that is, elbow, tee, throttle valve ), near the outlet.

(3) The sensor does not have a dedicated “in port”and “out port”. Therefore, you can use either

port for connecting the in-flow and out-flow pipes.

(4) When connecting pipes, avoid torqueing, bending, or applying any unnecessary load to any

portion of the sensor except for the hexagonal part on either end.

Ensure that the piping is properly supported. Do not remove the amplifier box from the

body.

(5) Avoid operating the sensor near areas containing a strong magnetic field or static electricity.

Doing so may cause the sensor to malfunction.

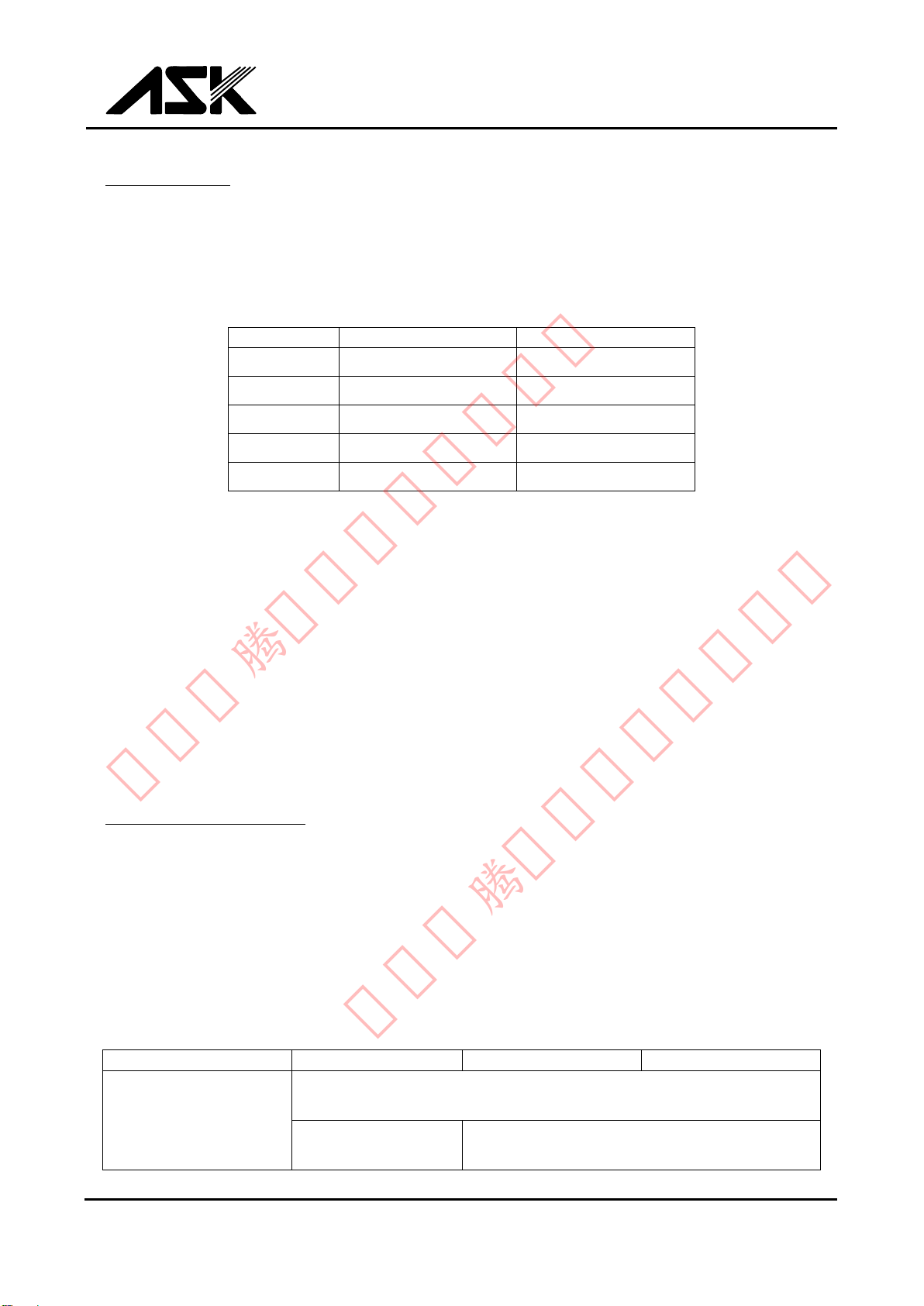

4. Necessary considerations

(1) Be sure to use the sensor within the maximum flow rate for your model. Exceeding the

flow rate may shorten the life of this sensor or cause damage.

(2) Be sure that the fluid flowing through the sensor is clean, or install a “filter”to prevent

clogging.

(3) Avoid using the sensor with fluids that contain magnetic materials; the sensor contains a

permanent magnet, and magnetic materials in the fluid may cause the sensor to

malfunction.

Recommended Filtration Element and Available Fluid

Available Fluid

(Filter Element)

Hydraulic oil, Lubricating oil

(5~20 μm)

Water, Water-soluble cutting oil

(20~50 μm)

昆山瑞腾精密自动化有限司

昆山瑞腾精密自动化有限司