10 Customer Care Center, 1-800-898-1879, www.askousa.com

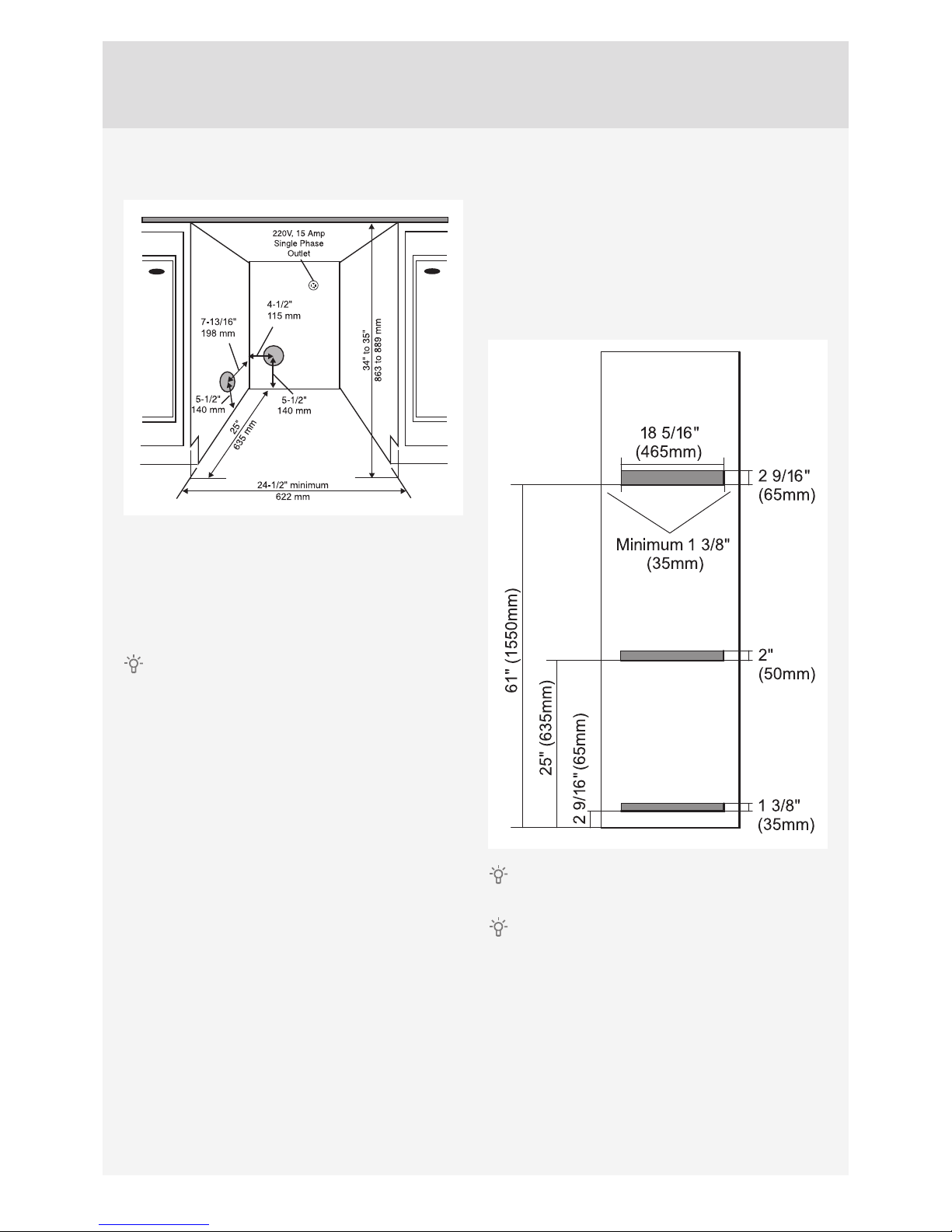

ELECTRICAL INSTALLATION

The receptacle on the rear of the machine is

designed to accommodate ASKO washers ONLY

(rated 208–240 V.) To use this receptacle, you must

use the ready-fitted plug supplied with the washing

machine or an equivalent.

ASKO washers rated 208–240 V have two internal

fuses of 15 A each.

The machine should only be connected to a

grounded wall socket.

This appliance must be properly grounded.

Refer to the “Important Safety Instructions” for

grounding instructions.

The power supply cord must be grounded. If the

machine is to be used in a wet area, the supply must

be protected by a residual current device.

Connection to a permanently wired supply point

must be made only by a qualified electrician. As

supplied: Single-phase, 208–240 V, 60 Hz, 3000W

heater rating 15 A circuit required.

Do not connect the machine to the mains

electricity supply by an extension lead.

Remove cover to access terminal box.

(Requires a 20-Torx screwdriver.)

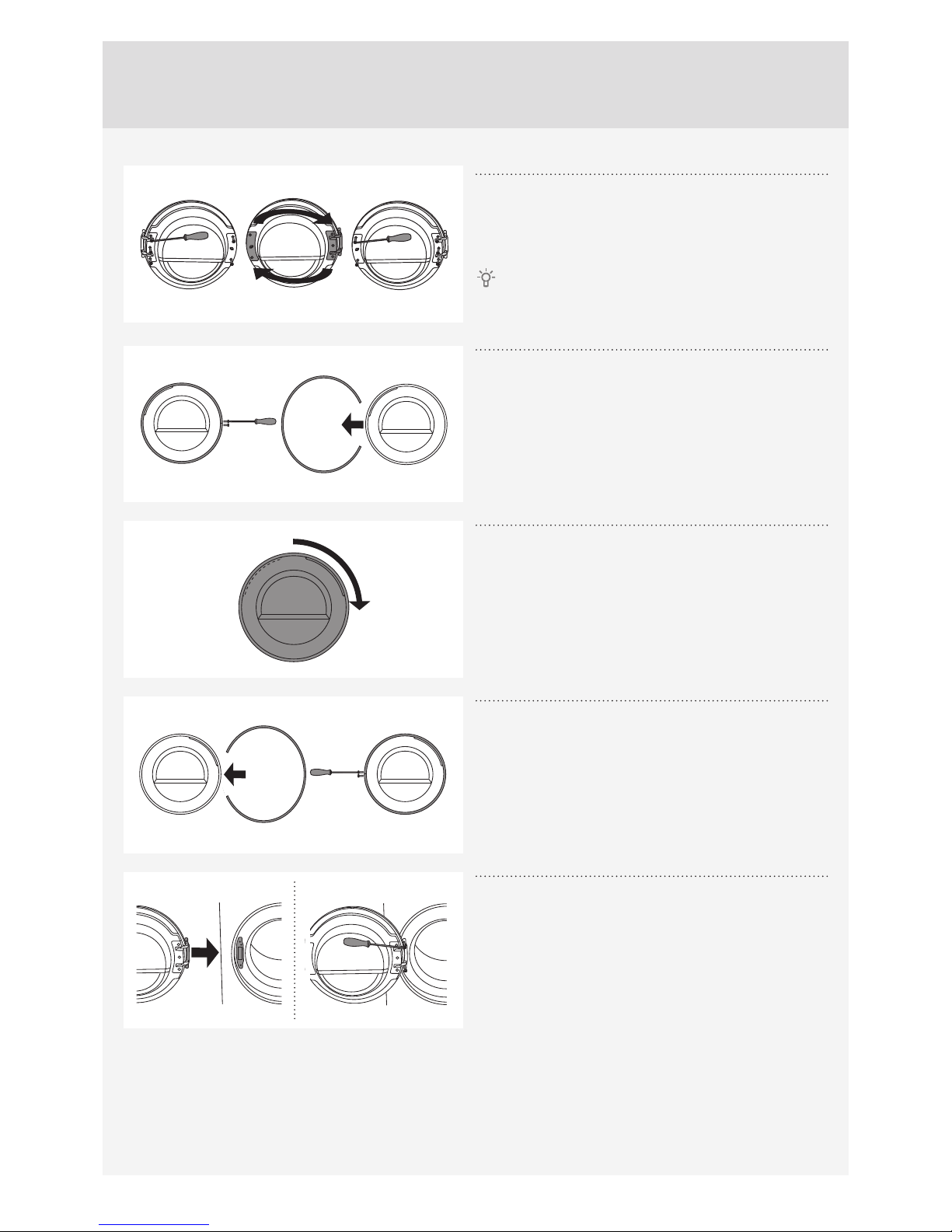

Electrical Connections

Read the Electrical requirements and grounding

instructions before connecting the tumble dryer.

Electric models of the dryer are manufactured for

a 3-wire connection system. The dryer frame is

grounded by a link to the neutral conductor on the

dryer terminal block. If local codes do not permit

grounding through the neutral, the grounding link

from the terminal block must be removed and a

separate ground wire must be used.

Only a 4-conductor cord shall be used when the

appliance is installed in a location where grounding

through the neutral conductor is prohibited.

Grounding through the neutral conductor is

prohibited for new branch-circuit installations,

mobile homes, recreational vehicles, and areas

where local codes prohibit grounding through the

neutral conductors. The grounding link on the dryer

must be removed for all 4-wire installations.

These Electrical Connection instructions provide for

installing the dryer in the following situations:

3-wire connection where local codes permit

grounding through the neutral. 3-wire connection

plus separate grounding connector where local

codes do not permit grounding through the neutral.

4-wire connection.

Each of the above connections can be made

with an approved power supply cord or by direct

wiring. Each connection instruction identifies

the appropriate Power Supply Cord and covers

requirements for direct wiring.

In Canada, the dryer is delivered ready-fitted

with a four-prong plug intended for connection to a

single-phase supply.

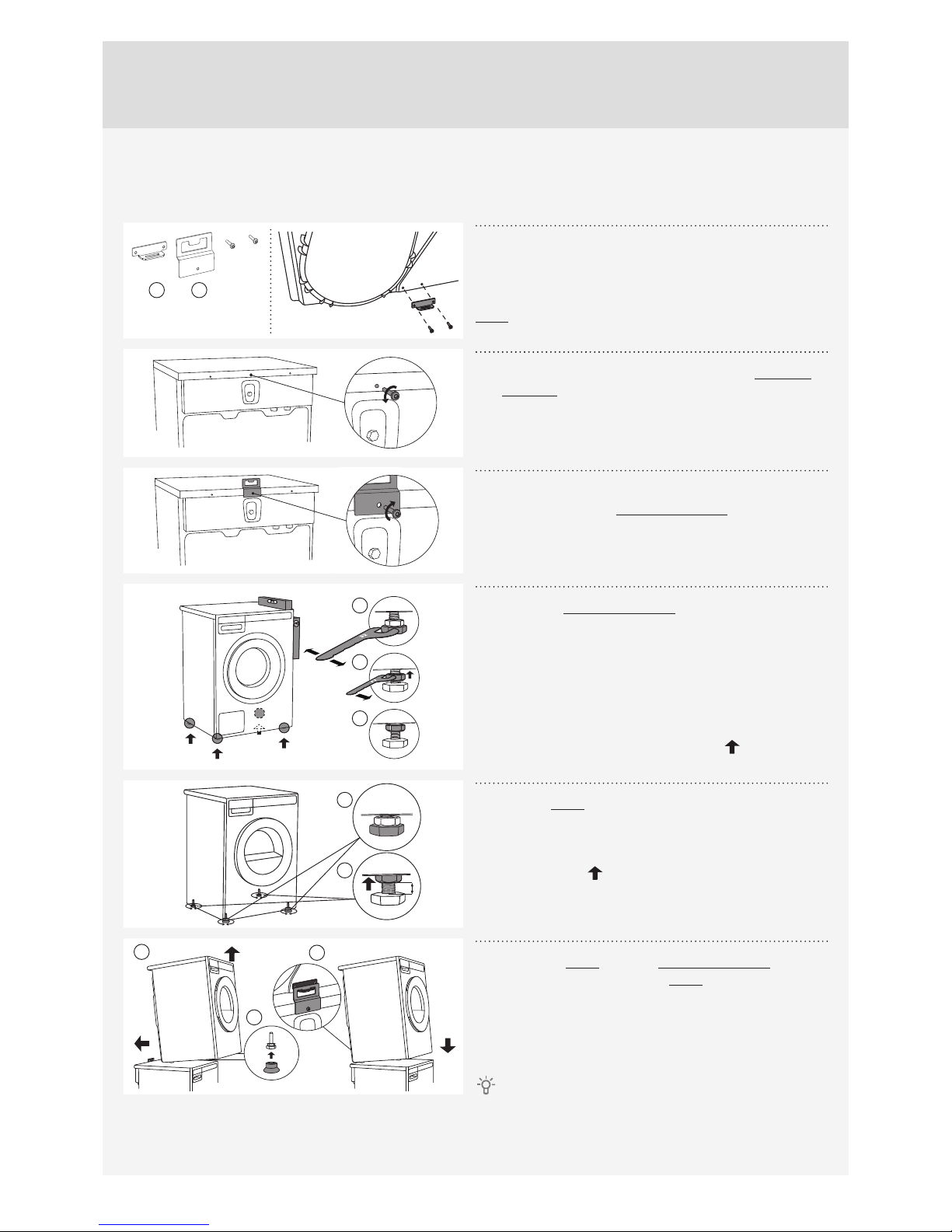

Connecting a 3-wire Power Cord

Before starting this procedure, be sure the

power is turned offat the breaker/fuse box.

Spade terminals

with upturned

ends

Ring

terminals

Ground

(center)

3/4" UL-listed

strain relief

Ground

This blade connects to

this conductor.

3-Wire Cord

Power Supply Cord

You will need a 3-wire power supply cord with

three No. 10 copper wires and a matching 3-wire

receptacle of NEMA Type 10-30R, as illustrated

below:

To connect a 3-wire power cord to the dryer, follow

the steps below.

The numbers in the illustration correlate to the

step numbers.

1. Turn the power offat the breaker or fuse box.

2. Remove terminal block cover.