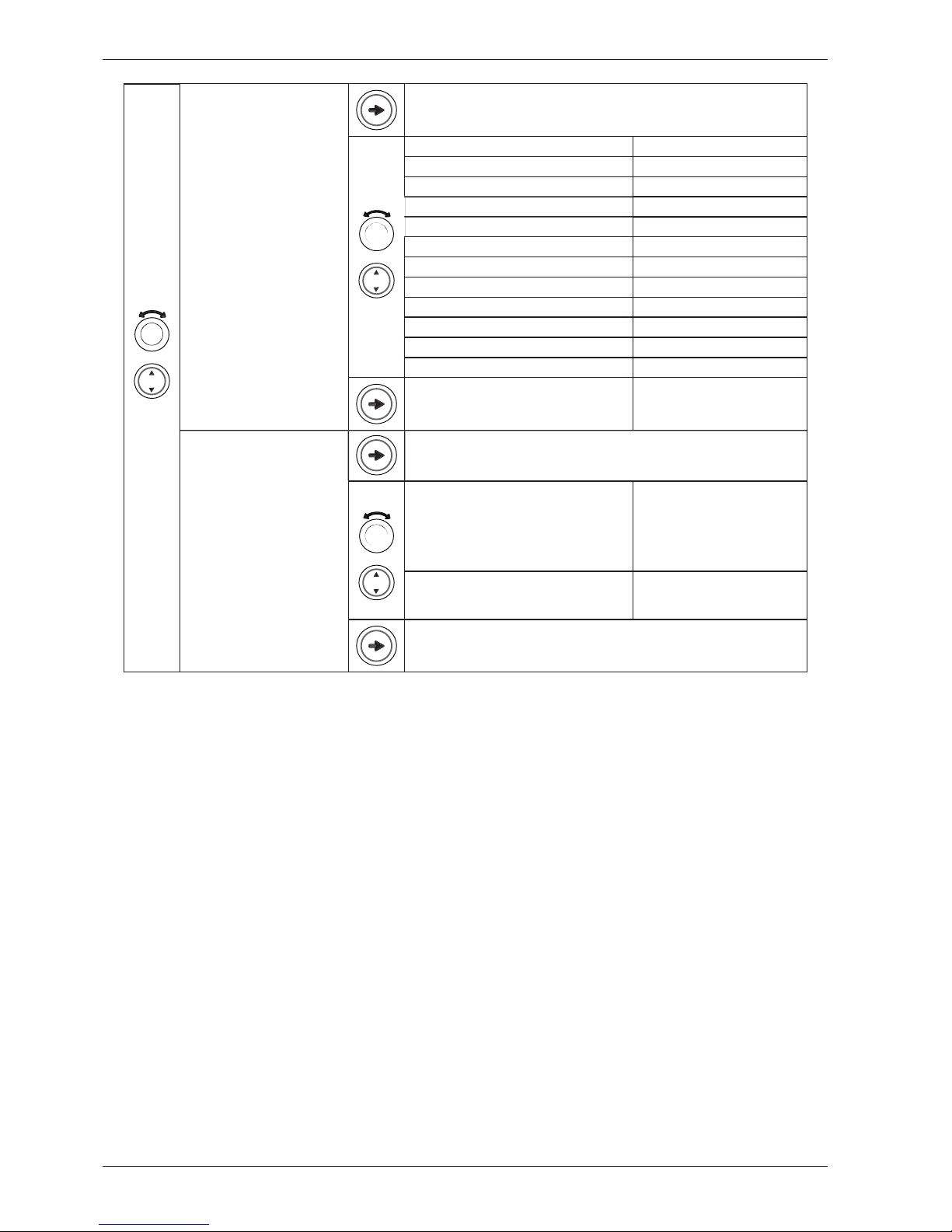

or items that are particularly di

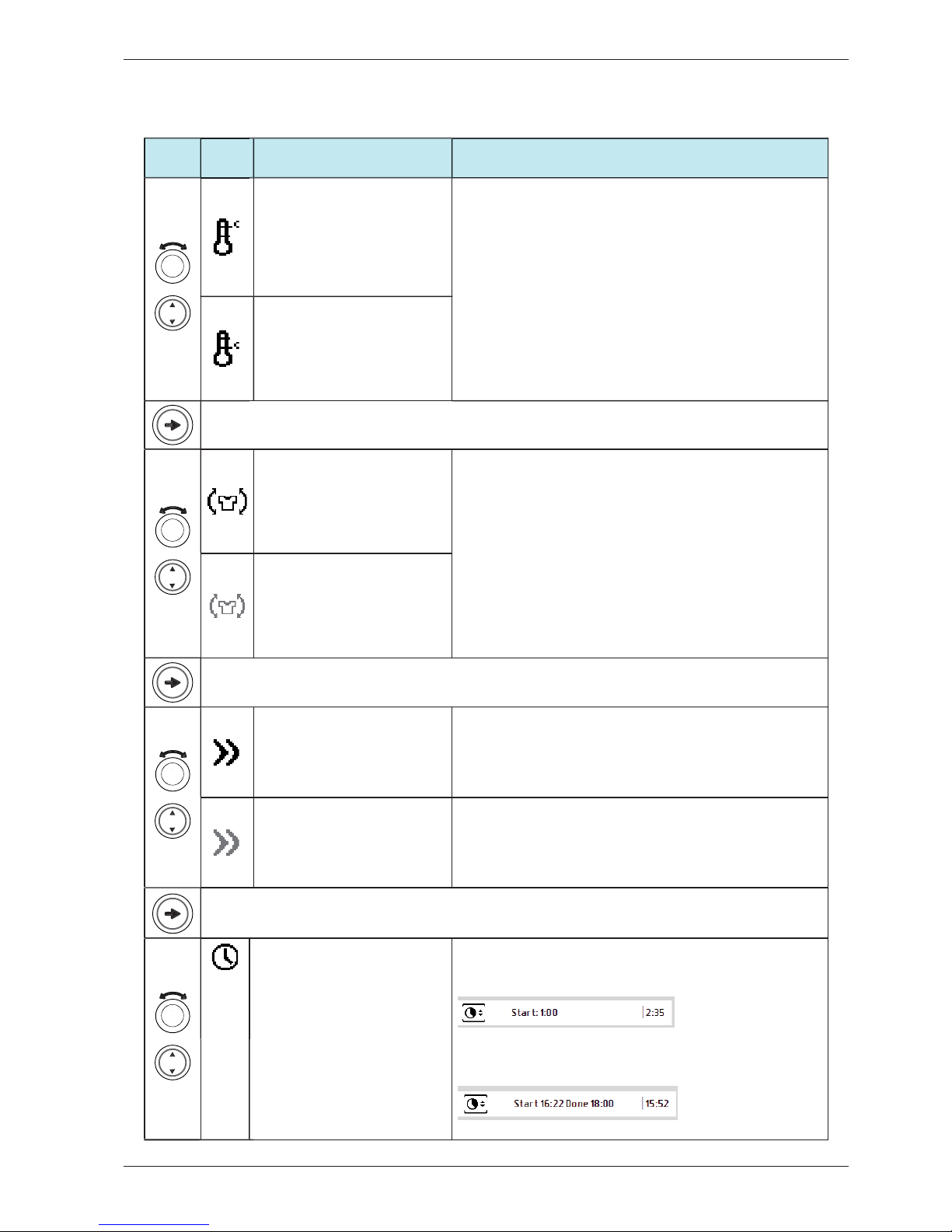

Dry, Normal, Auto dry, Auto sk

ptorrt,

Skabstørt, Auto tørt, Kaappikuiva, Sécha

ec. para armario auto, Hopмaльнaясyшкa,

the heat once the load is dry but be

ore

it is ”bone-dry”. The pro

ramme on position 2 shuts off the heat

s

ind out what works best. Use these pro

rammes when you want

items to be completely dry

, Delicate, Auto normal dr

uto nesten tørt,

Normaalikuiva, Sécha

roog, Asciutto norm. autom., Secado liviano

en

This programme shut off the heat once the load is dry but before

it is ”bone-dry”. The pro

ramme on position 3 shuts o

ram on position 4. Use trial and error to

find out what works best. Use these programmes when you want

Iron Dry, Iron Dry, Auto Iron dry, Auto stryktorrt,

Strygetørt, Auto stryketørt, Silityskuiva,

Repassa

, Asc. da stirare autom.,

Sec. para plancha auto, Сyшкa ”пoдyтюг”,

Bügeltrocke

ramme shuts off the heat once the load is just damp

enough

ijdprogramma, Progr. del tempo , Prog. de

secado,

The programme length you choose depends on what you intend

to do with the items a

them. Use trial and error to

ind

out what works best. When you use Timed dry to tumble-dry a

load o

the garments may remain damp.

Tumble-dry any damp

over-dry” if you have selected too lon

an cause the items to shrink or crease and become rough.

ynthetic materials can also become char

ed with static

electricity.

et the number of minutes incrementally. The selected time is

shown on the display. Try out different dryin

ir Fluff, Air Fluff , Revitalise, Luftnin

entilation, Ventileren, Arie

ивaниe, Lüften

Use the Revitalise pro

ramme when you just want to refresh, air

or soften up items Set the number of minutes incrementall

. The

selected time is shown on the display. Try out di

e,

Instellingen, Impostazioni, Ajustes, Haстpoйки,

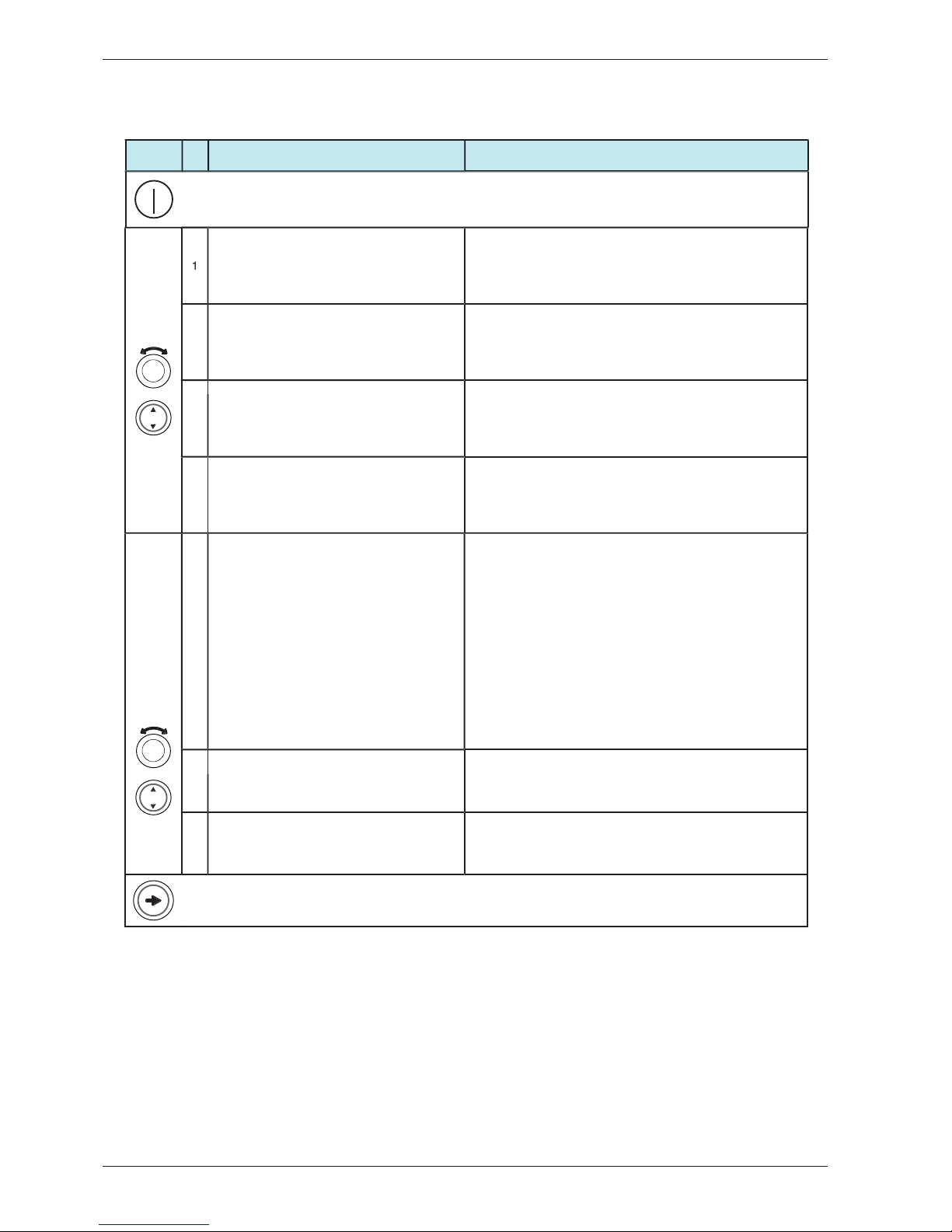

rogramme selection

The pro

rammes are displayed in the order they occur in L