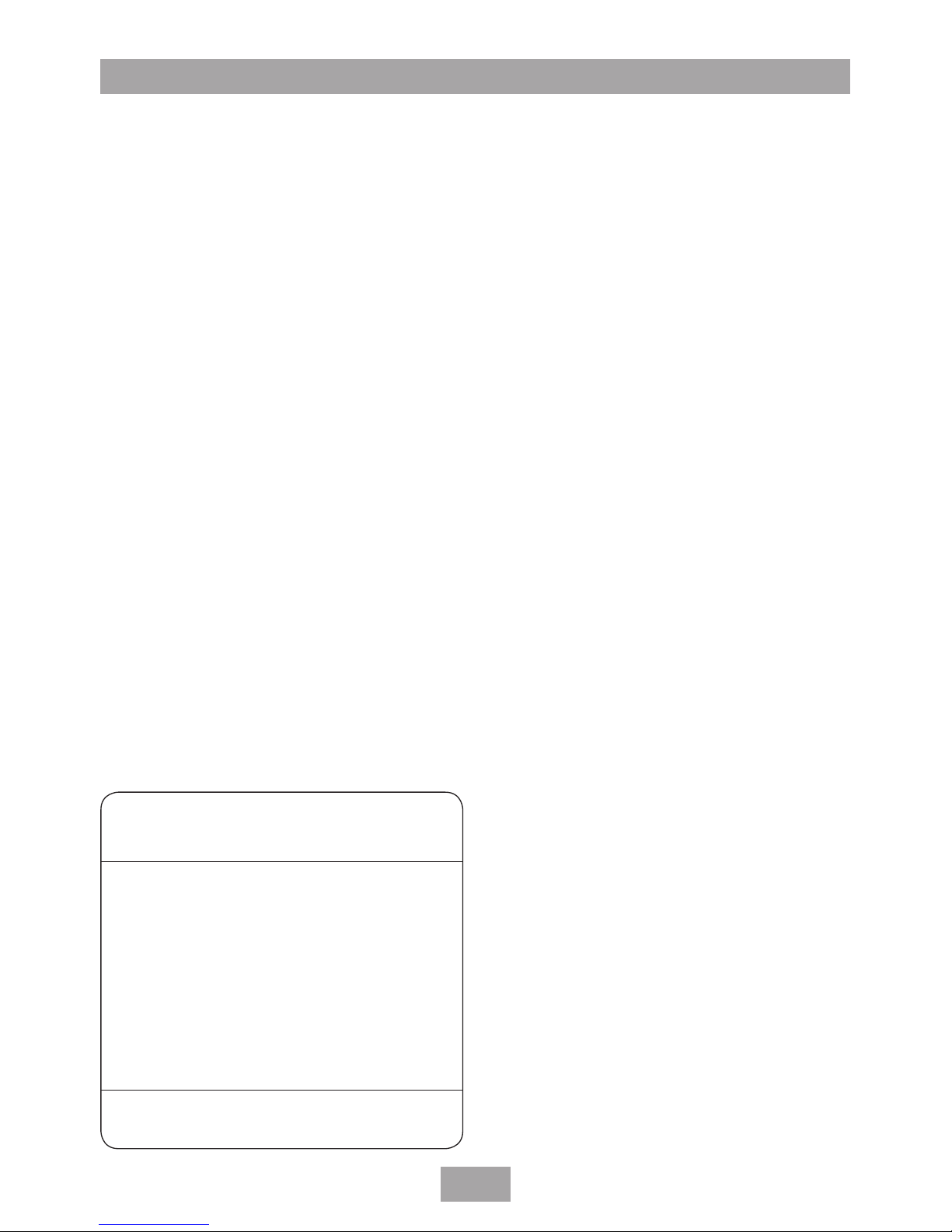

Note: Cable selection is dependent on

deratin

factors

Twin and earth PVC insulated cable

Current carrying capacity

In conduit

trunking

6 mm²

38A

10 mm²

52A

16 mm²

69A

Installed in an

insulated wall

6 mm²

32A

10 mm²

43A

16 mm²

57A

Clipped direct

or buried in a

non-insulated

wall

6 mm²

46A

10 mm²

63A

16 mm²

85A

The installation, supply cable and circuit

protection must conform with BS 7671 (IEE

wiring regulations) and be sufficient for the

amperage required.

The following notes are for guidance only:

1

1.1

2

3

3.1

4

4.1

4.2

5

5.1

6

6.1

7

7.1

7.2

8

9

9.1

9.2

10

10.1

10.2

10.3

E-002-A

The shower must only be connected to a

230-240V ac supply. If you are installing a

shower with a kilowatt rating above 9kW,

it is advisable to contact the local

electricity supply company.

The electrical rating of the shower is

shown on the rating label (Fig. ) within

the unit.

Before making any sort of electrical

connection within the installation make

sure that no terminal is live. If in any

doubt, switch off the whole installation at

the mains supply and remove the correct

fuse.

The shower must be connected to its own

independent electrical circuit. IT MUST

NOT be connected to a ring main, spur,

socket outlet, lighting circuit or cooker

circuit.

The electrical supply must be adequate for

the loading of the unit and existing

circuits.

Check your consumer unit (main fuse box)

has a main switch rating of 80A or above

and that it has a spare fuse way which will

take the fuse or Miniature Circuit Breaker

(MCB) necessary for the shower (Fig. ).

If your consumer unit has a rating below

80A or if there is no spare fuse way, then

the installation will not be straightforward

and may require a new consumer unit

serving the house or just the shower.

You will need to contact the local

electricity company. They will check the

supply and carry out what is necessary.

They will also check the main bonding.

The earth continuity conductor of the

electrical installation must be effectively

connected electrically to all exposed metal

parts of other appliances and services in

the room in which the shower is to be

installed, to conform to current IEE

regulations.

All exposed metallic parts in the bathroom

must be bonded together using a cable of

at least 4 mm² cross sectional area. These

parts include metal baths, radiators, water

pipes, taps and waste fittings.

For close circuit protection DO NOT use a

rewireable fuse. Instead use a suitably

rated Miniature Circuit Breaker (MCB) or

cartridge fuse (see Table A).

In the interest of electrical safety a 30mA

residual current device (RCD) should be

installed in all UK electric and pumped

shower circuits. This may be part of the

consumer unit or a separate unit.

A 45 amp double pole isolating switch

with a minimum contact gap of 3 mm in

both poles must be incorporated in the

circuit.

It must have a mechanical indicator

showing when the switch is in the OFF

position, and the wiring must be

connected to the switch without the use of

a plug or socket outlet.

The switch must be accessible and clearly

identifiable, but out of reach of a person

using a fixed bath or shower, except for

the cord of a cord operated switch, and

should be placed so that it is not possible

to touch the switch body while standing in

a bath or shower cubicle. It should be

readily accessible to switch off after using

the shower.

Where shower cubicles are located in any

rooms other than bathrooms, all socket

outlets in those rooms must be protected

by a 30mA RCD.

The current carrying capacity of the cable

must be at least that of the shower circuit

protection (see Table B).

To obtain full advantage of the power

provided by the shower, use the shortest

cable route possible from the consumer

unit to the shower.

It is also necessary to satisfy the

disconnection time and thermal

constraints which means that for any given

combination of current demand, voltage

drop and cable size, there is a maximum

permissible circuit length.

The shower circuit should be separated

from other circuits by at least twice the

diameter of the cable or conduit.

The current rating will be reduced if the

cabling is bunched with others,

surrounded by thermal loft or wall

insulation or placed in areas where the

ambient temperature is above 30°C. Under

these conditions, derating factors apply

and it is necessary to select a larger cable

size.

In the majority of installations, the cable

will unavoidably be placed in one or

more of the above conditions. This

being so, it is strongly recommended to

use a minimum of 10 mm cabling

throughout the shower installation.

In any event, it is essential that individual

site conditions are assessed by a

competent electrician in order to

determine the correct cable size and

permissible circuit length.

ELECTRICAL REQUIREMENTS

The installation, supply cable and circuit

protection must conform with BS 7671 (IEE

wiring regulations) and be sufficient for the

amperage required.

The following notes are for guidance only:

1

1.1

2

3

3.1

4

4.1

4.2

5

5.1

6

6.1

7

7.1

7.2

8

9

9.1

9.2

10

10.1

10.2

10.3

E-002-A

The shower must only be connected to a

230-240V ac supply. If you are installing a

shower with a kilowatt rating above 9kW,

it is advisable to contact the local

electricity supply company.

The electrical rating of the shower is

shown on the rating label (Fig. ) within

the unit.

Before making any sort of electrical

connection within the installation make

sure that no terminal is live. If in any

doubt, switch off the whole installation at

the mains supply and remove the correct

fuse.

The shower must be connected to its own

independent electrical circuit. IT MUST

NOT be connected to a ring main, spur,

socket outlet, lighting circuit or cooker

circuit.

The electrical supply must be adequate for

the loading of the unit and existing

circuits.

Check your consumer unit (main fuse box)

has a main switch rating of 80A or above

and that it has a spare fuse way which will

take the fuse or Miniature Circuit Breaker

(MCB) necessary for the shower (Fig. ).

If your consumer unit has a rating below

80A or if there is no spare fuse way, then

the installation will not be straightforward

and may require a new consumer unit

serving the house or just the shower.

You will need to contact the local

electricity company. They will check the

supply and carry out what is necessary.

They will also check the main bonding.

The earth continuity conductor of the

electrical installation must be effectively

connected electrically to all exposed metal

parts of other appliances and services in

the room in which the shower is to be

installed, to conform to current IEE

regulations.

All exposed metallic parts in the bathroom

must be bonded together using a cable of

at least 4 mm² cross sectional area. These

parts include metal baths, radiators, water

pipes, taps and waste fittings.

For close circuit protection DO NOT use a

rewireable fuse. Instead use a suitably

rated Miniature Circuit Breaker (MCB) or

cartridge fuse (see Table A).

In the interest of electrical safety a 30mA

residual current device (RCD) should be

installed in all UK electric and pumped

shower circuits. This may be part of the

consumer unit or a separate unit.

A 45 amp double pole isolating switch

with a minimum contact gap of 3 mm in

both poles must be incorporated in the

circuit.

It must have a mechanical indicator

showing when the switch is in the OFF

position, and the wiring must be

connected to the switch without the use of

a plug or socket outlet.

The switch must be accessible and clearly

identifiable, but out of reach of a person

using a fixed bath or shower, except for

the cord of a cord operated switch, and

should be placed so that it is not possible

to touch the switch body while standing in

a bath or shower cubicle. It should be

readily accessible to switch off after using

the shower.

Where shower cubicles are located in any

rooms other than bathrooms, all socket

outlets in those rooms must be protected

by a 30mA RCD.

The current carrying capacity of the cable

must be at least that of the shower circuit

protection (see Table B).

To obtain full advantage of the power

provided by the shower, use the shortest

cable route possible from the consumer

unit to the shower.

It is also necessary to satisfy the

disconnection time and thermal

constraints which means that for any given

combination of current demand, voltage

drop and cable size, there is a maximum

permissible circuit length.

The shower circuit should be separated

from other circuits by at least twice the

diameter of the cable or conduit.

The current rating will be reduced if the

cabling is bunched with others,

surrounded by thermal loft or wall

insulation or placed in areas where the

ambient temperature is above 30°C. Under

these conditions, derating factors apply

and it is necessary to select a larger cable

size.

In the majority of installations, the cable

will unavoidably be placed in one or

more of the above conditions. This

being so, it is strongly recommended to

use a minimum of 10mm cabling

throughout the shower installation.

NOTE: 10mm CABLE MUST BE USED ON

THE 10.5KW CHROME MODEL.

In any event, it is essential that individual

site conditions are assessed by a

competent electrician in order to

determine the correct cable size and

permissible circuit length.

ELECTRICAL REQUIREMENTS