DAC-3 Functions :

A - Source Selector Tactile Button

This button will activate a manual or automatic

advancement to the next digital source input.(See page

25 for setup.)

B - Source Selector LED's

These LED's indicate which digital source input is

currently selected - either the I2S,ST-Optical,TOSLINK-

Optical, AES/EBU, Coaxial-BNC, or Coaxial-RCA.

C - Phase Tactile Button

Reverses the absolute polarity of the Analog Output

Signals.

NOTE ON PHASE SELECTION:

The phase inverts the absolute polarity of the analog

output (A positive signal becomes a negative signal).

This can be used to compensate for recordings with

inverted polarity. The correct phase for a recording can

be found by playing a CD in both phase positions.When

absolute polarity is correct the music will be more

precise, with a wider, deeper soundstage.

D - Phase LED

This LED will indicate the currently selected phase

polarity. When lit, the absolute phase is inverted 180

degrees.

E - Power LED

This coool blue LED will light when the DAC-3 is

plugged in and switched on while receiving AC power.

F - Mute LED

Muted conditions of all the audio O/P's are indicated by

this LED.While lit this indicates that the audio O/P's are

muted. This Mute LED comes on during digital I/P

scanning, or when no active digital source is connected

and received by the DAC-3, (In both cases, no Lock

condition also applies.)

G - Mute Tactile Button

Depressing this button will active the muting relays for

each audio channel and signal phases, allowing no

audio from any of the audio O/P's as indicated by the

Mute LED above.

H - De-emphasis LED

This LED lights when a digital source is recorded with

the standard CD pre-emphasis of 50/15 microseconds.

(This LED rarely comes on.)

I - Lock LED

This LED indicates when a signal from a digital source,

with a sampling rate of 32kHz to 96kHz, is being

properly received.

G - HDCD®LED

Lights when an HDCD®encoded Disc is played into the

DAC-3.

H - Power Switch Button

The switch is a push-on push-off type button.The power

to the DAC-3 is completely turned off while the switch is

in the out position.

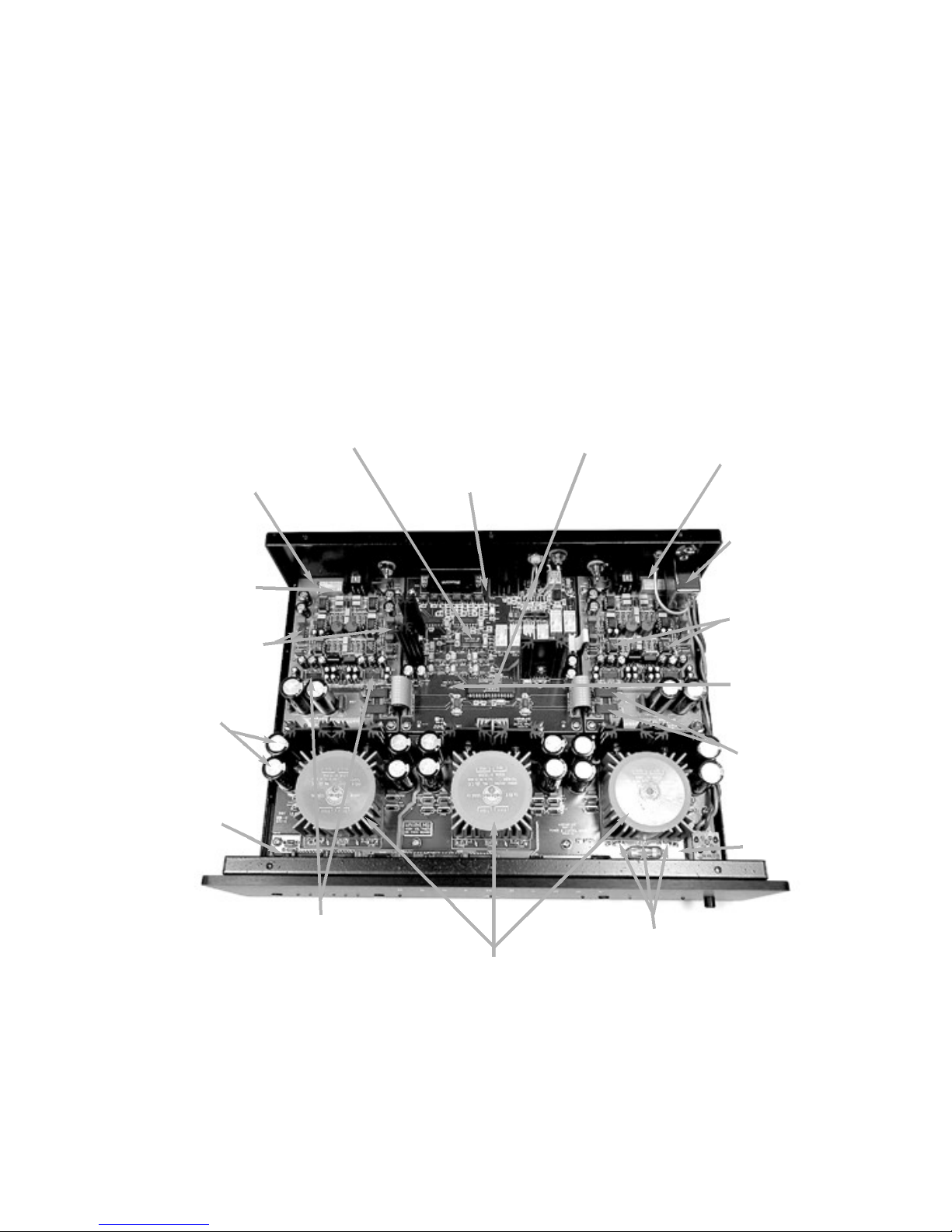

BA C HGIHGFED

9