DPM 8016

DPM 8016 - 5

fering with the installation of the system. The PC only

needs to be connected to the system to load or to change

the configuration. During operation, it is not required. In

many cases, however, a permanently connected PC is very

helpful, e.g. for detailed status indication and protocol

printing, volume level and sound control in real-time, or for

remote diagnosis and remote maintenance via the net-

work. The user interface can be individually designed and

provided with up to 32 password levels.

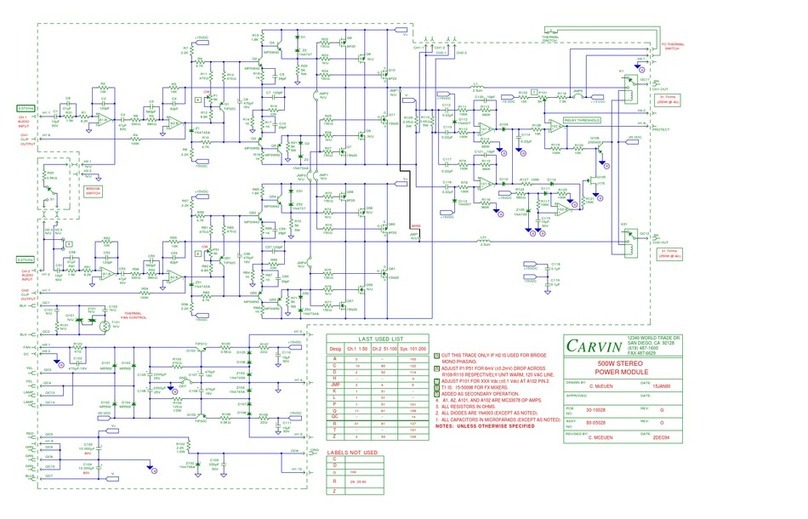

AUDIO ROUTING

The DPM 8016 integrates a digital 32 x 16 audio matrix

that offers both switching functions and mixing functions

in arbitrary combination. Up to 16 local audio inputs plus

16 optional CobraNet network inputs are available. It is

possible to use the 16 matrix outputs locally as audio out-

puts or to optionally make them available via CobraNet.

This allows the parallel use of 16 audio channels in a sys-

tem that can be connected to amplifiers. Each loudspeaker

group can be connected to amplifier outputs using a relay

matrix, which allows the realization of 500 A/B loudspeak-

er zones (1,000 loudspeaker circuits) while the DPM 8016

takes over the management and priority-dependent distri-

bution of the audio signals. Next to connecting paging sta-

tions to the audio inputs, it is also possible to connect

other audio signal sources, like for example microphones,

mixers, CD Players, MP3 Players, tuners, etc. Different

connectors are available for optimal adaptation.

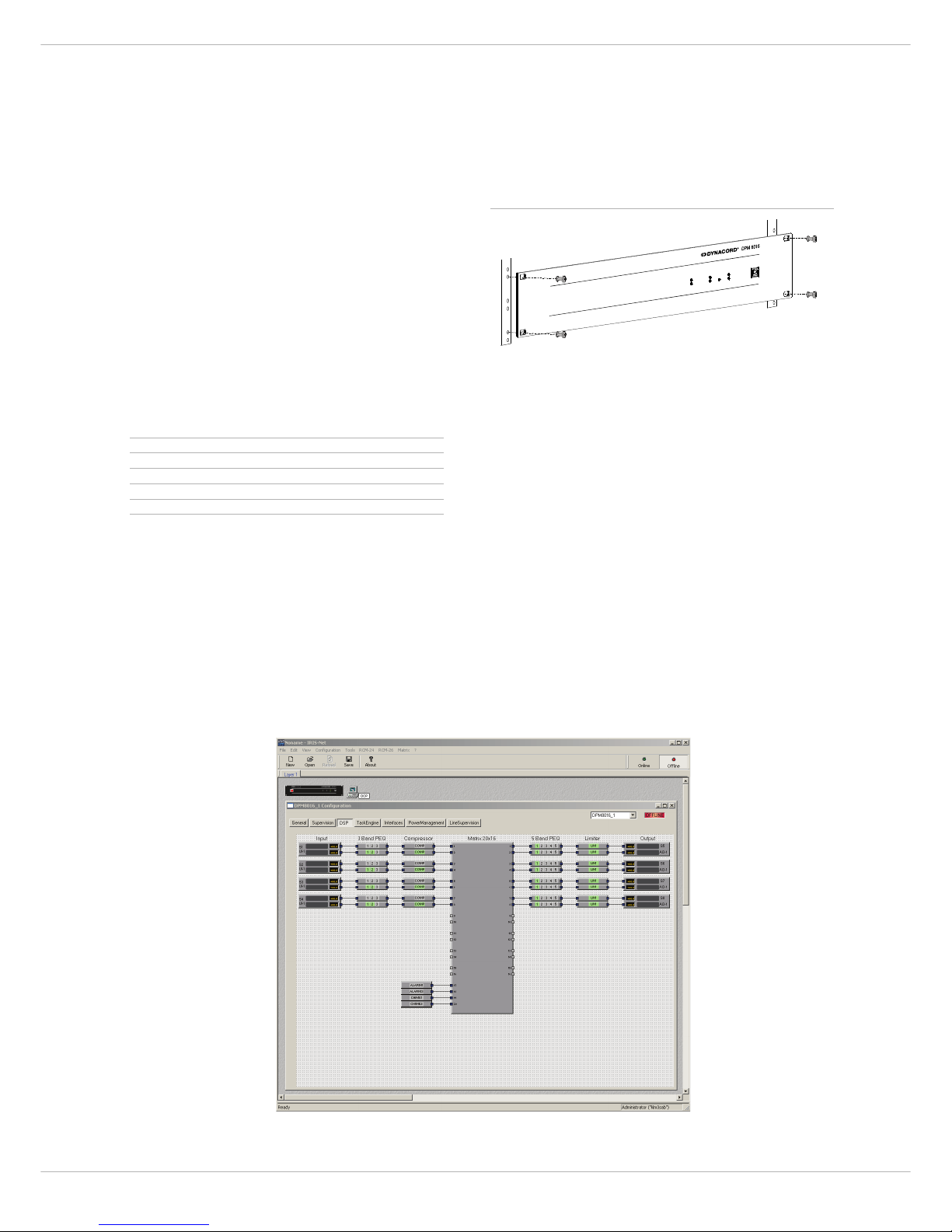

AUDIO PROCESSING

The DPM 8016 provides a separate volume control with

mute function for each audio input and audio output. Each

audio input has a 3-band equalizer and a compressor for

optimal sound adjustment of the audio sources. All out-

puts have a 5-band equalizer and a limiter. It is possible to

chose between six different filter types for each band filter

of the equalizers (peak, low shelving, high shelving, high

pass, low pass, all pass). Level settings, filter parameters,

etc. are set during the configuration on the PC. However,

they can be modified in real-time during operation using

the graphical user interface, the special keys of the paging

stations or external controls.

SIGNAL GENERATORS

The DPM 8016 provides four signal generators: two inde-

pendent signal generators for the generation of alarm sig-

nals and two independent signal generators for the

generation of chime signals. The user can select from 24

factory pre-set alarms and six gong signals.

PAGING STATIONS

The DPC 8000 Series paging stations are used mainly for

announcements but also for manual control of the

PROMATRIX 8000 system. Possible paging station func-

tions are group / zone selection, announcements, program

assignment, triggering of gong and alarm signals as well as

voice memory playback. Moreover, the paging stations can

also be used for special commands, like volume control,

monitor selection, preset switching, lighting control, indi-

cation of functions and many others. The paging stations

can hence be configured to function as control panels for

general control purposes. If an announcement is made

from a paging station into loudspeaker groups that are al-

ready busy reproducing another signal, you will get a

"busy" message, i.e. the BUSY LED indicator blinks. If the

own station has a higher priority setting, it can interrupt

the call from the station or any other signal with a lower

priority. Of course, this does not happen uncontrolled,

since the system configuration is already displayed by the

flashing BUSY LED indicator during group selection, i.e.

before an interruption takes place. The user now has the

opportunity to decide whether he wants to interrupt the

currently active message or wait until it ends. Each zone

selection key provides two LED indicators: a green LED in-

dicates the current selection and a yellow LED indicates

the current state of the loudspeaker zone (busy, free,

alarm active). The illuminated graphical display of the pag-

ing station shows system status information or error mes-

sages.

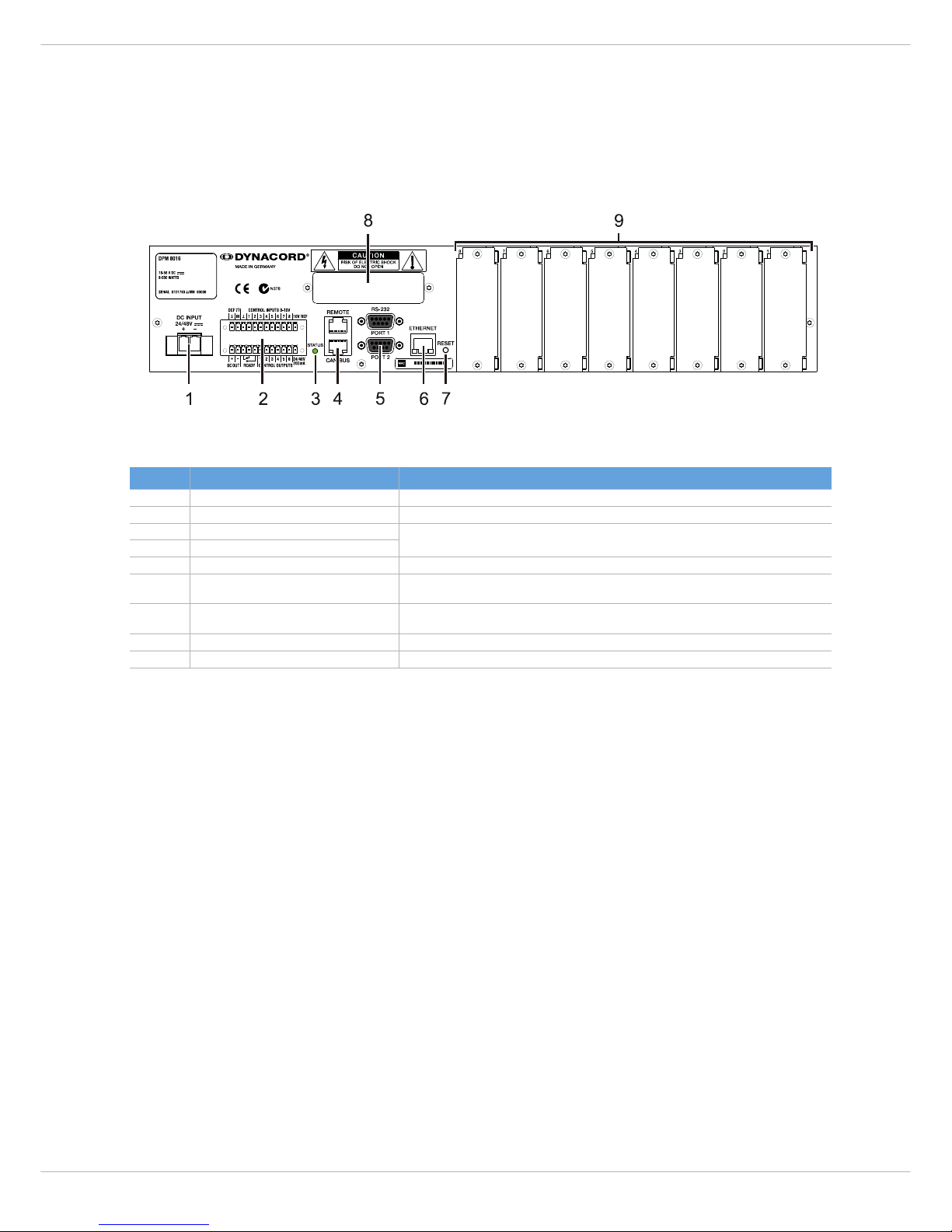

CONTROL INPUTS AND CONTROL OUTPUTS

The PROMATRIX 8000 system provides analog as well as

digital control inputs and control outputs. Using the con-

trol inputs allows establishing a connection to fire alarm

systems, intrusion systems or to a control room. However,

the connection of external switches, pushbuttons, con-

trols or rotary encoders is likewise possible. It is also pos-

sible to query the control outputs of external devices

(power supply unit, power amplifier, etc.). The control out-

puts are used to switch on / off external devices, trigger

signals or events, remotely control doors, gates or blinds,

create analog signal levels for media control systems, and

much more.

AUTOMATED CONTROL

The DPM 8016 has a real time clock that can be switched

to DCF77 radio controlled clock operation using an option-

ally available receiving aerial (radio receiver NRS 90193).

The system clock automatically recognizes leap years. In

DCF77 operation, the system clock also automatically

switches between daylight saving time and standard time.

The system clock can control up to 40 external slave

clocks. For this purpose, the DPM 8016 provides a special

short-circuit-proof output for polarity reversal pulses.

Slave clocks are automatically adjusted when a time differ-

ence to the system clock is being detected, e.g. after a

power outage or after manually entering a time value. The

system clock can be used in conjunction with the calendar

function to trigger functions, such as recess gong, music

reproduction, door or gate control, lighting control, etc. at

certain times. These functions can be programmed for spe-

cific days, but they can also be executed on an hourly, dai-

ly, weekly, monthly and yearly basis. It is possible to

program up to 500 time-triggered events. Functions and

parameters can be combined in an internal sequential

process. The TaskEngine of the DPM 8016 provides a pos-

sibility to arrange individual processes graphically. An ex-

ample would be a gong signal, which is to be transmitted

in certain zones with a certain volume level and priority,

while simultaneously triggering a control output. In this

case, the process consists of the function-blocks "Gong"

and "Analog Output" with the parameters gong type, vol-

ume level, priority number setting, zone numbers and type

and number of the control output. The processes can be

triggered by special function keys on the paging stations or

by control inputs, but also be linked to clock times or cal-

endar dates.