Page: 10 Version 2 : 11-04-2016

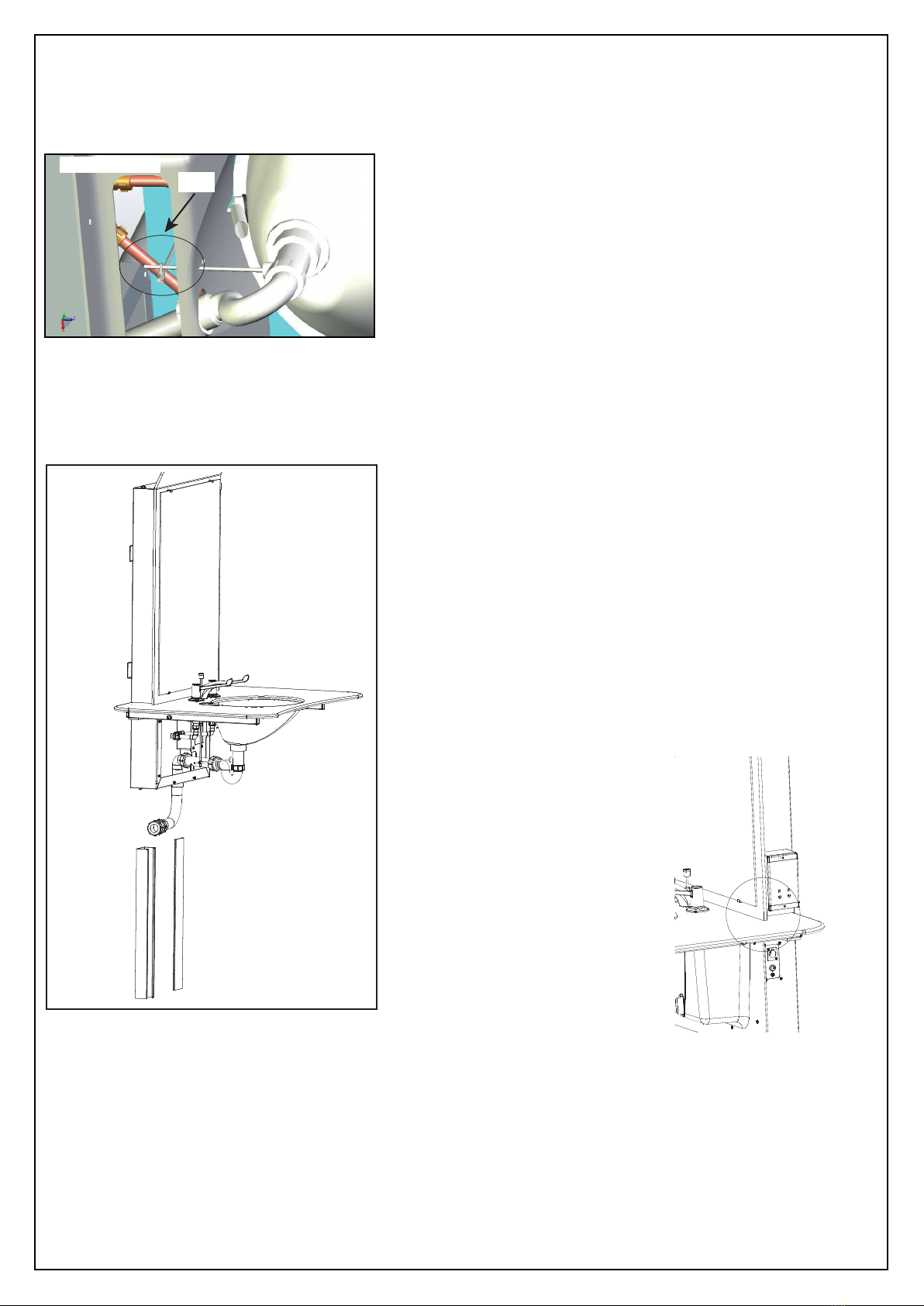

Working through the aperture in the base of the cover, support the waste assembly, fit the nut

and seals from the P trap through the front hole in the cover and then connect to the P trap

Connect the P Trap to the underside of the basin.

Fit the free end of the flexible hose to the waste pipe fitted to the site as part of the pre

installation preparations and secure with a cable tie as shown in the picture on page 5.

Rod

Adjuster

Basin viewed from below

Rod

Adjuster

Basin viewed from below

Adjustments to the screw on the pop-up waste plug

base and clamp for the rods may be necessary to ensure maximum lift of the waste plug. Access

to the clamp may be gained through the large hole in the base of the white plastic lower cover

Fit the Trunking:

The hot and cold supply hoses need to be enclosed

within the white self adhesive trunking supplied.

Using the handset, raise the assembly to its highest

position

Remove the capping from the front of the trunking.

Remove the protective film from the self adhesive tape

fitted to the rear of the trunking.

Pass the trunking behind the hot and cold supply hoses

taking care to ensure that the self adhesive tape is kept

away from the wall at this time. The top of the trunking

needs to be aligned with the recess in the bottom left

hand side of the rise and fall unit; through which were

passed the supply hoses earlier.

Using a level, ensure the

trunking is vertical. Once

aligned, press the self adhesive

tape against the wall to secure

the top of the trunking. Then

press the entire length of the

trunking into position.

Fit the capping.

Fit the mirror:

Remove the two white plastic

caps from above the top mirror

clips and remove the screws.

Place the bottom edge of the mirror into the lower catches and hold

in a vertical position. Ensure the mirror is fitted centrally. Gently push the uppermost catches

downwards into position such that they retain the mirror in its correct position. Fit the 2

security scews .

Test the unit:

Operate the handset to raise and lower the basin over the full range of travel to ensure there

is clearance between all moving surfaces. Examine for evidence of leaks correct as necessary,

examine and clean the assembly. Complete the warranty documentation and pass the completed

warranty document to the client.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•