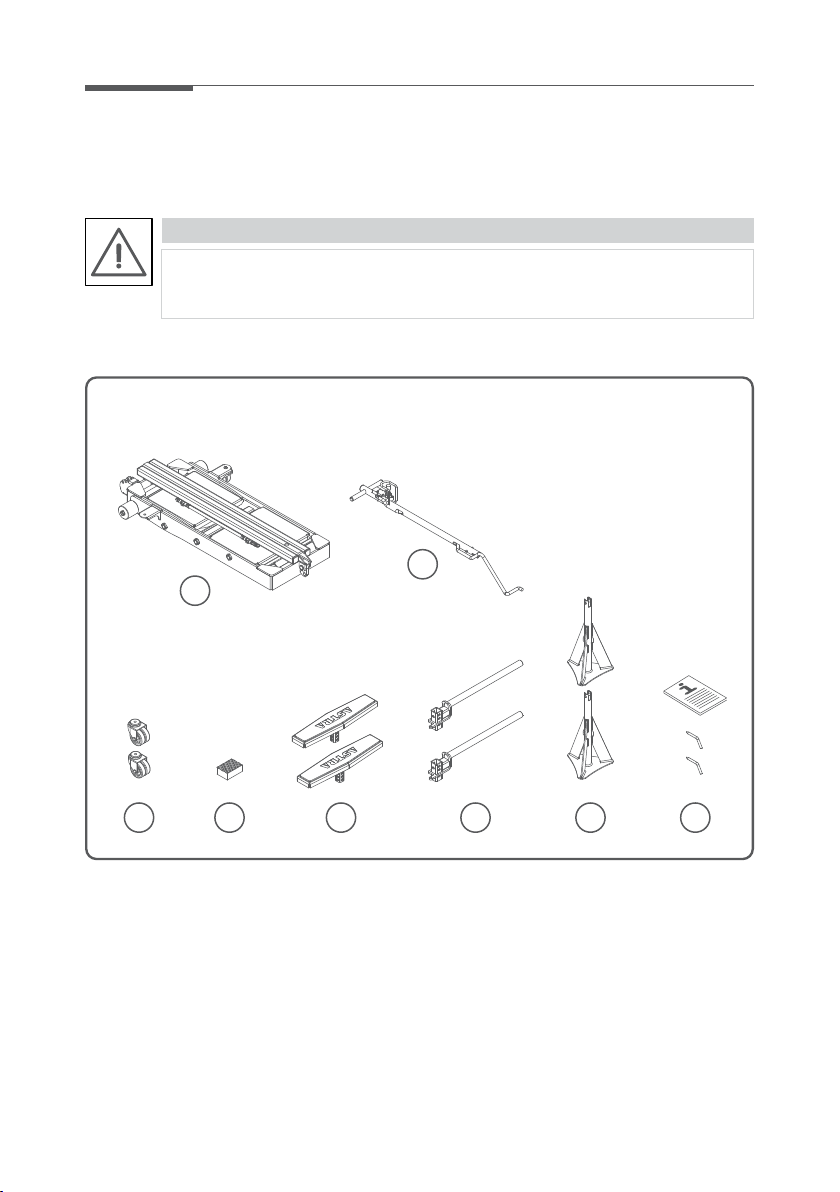

For your safety, read this manual carefully before installing or using this product.

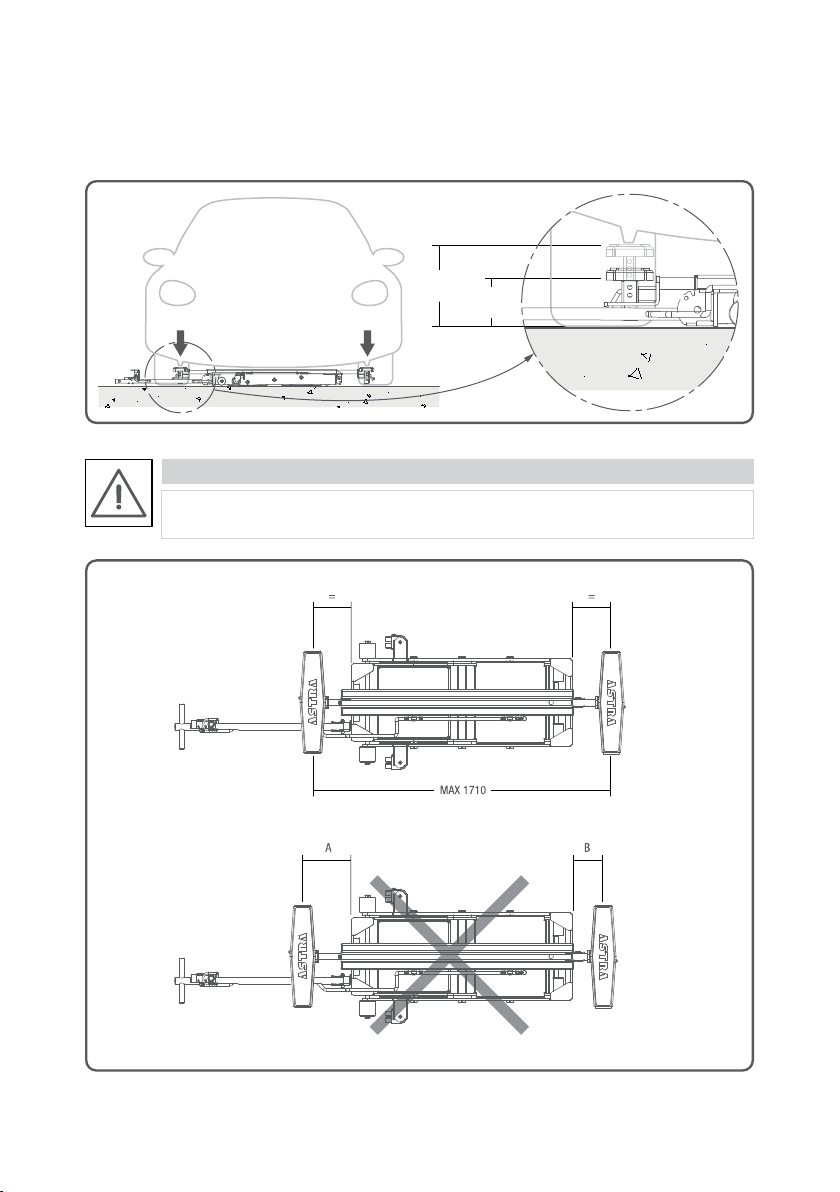

The miniLIFT is a scissor lift with two pneumatic actuators and small size designed for those workshops

where is able to lift half of the vehicle up to 2.500kg.This lift is able to carry out three different movements:

·Front side elevation

·Rear side elevation

·Special side elevation

It means that, when you lift the car, front or rear wheels will be always raised.

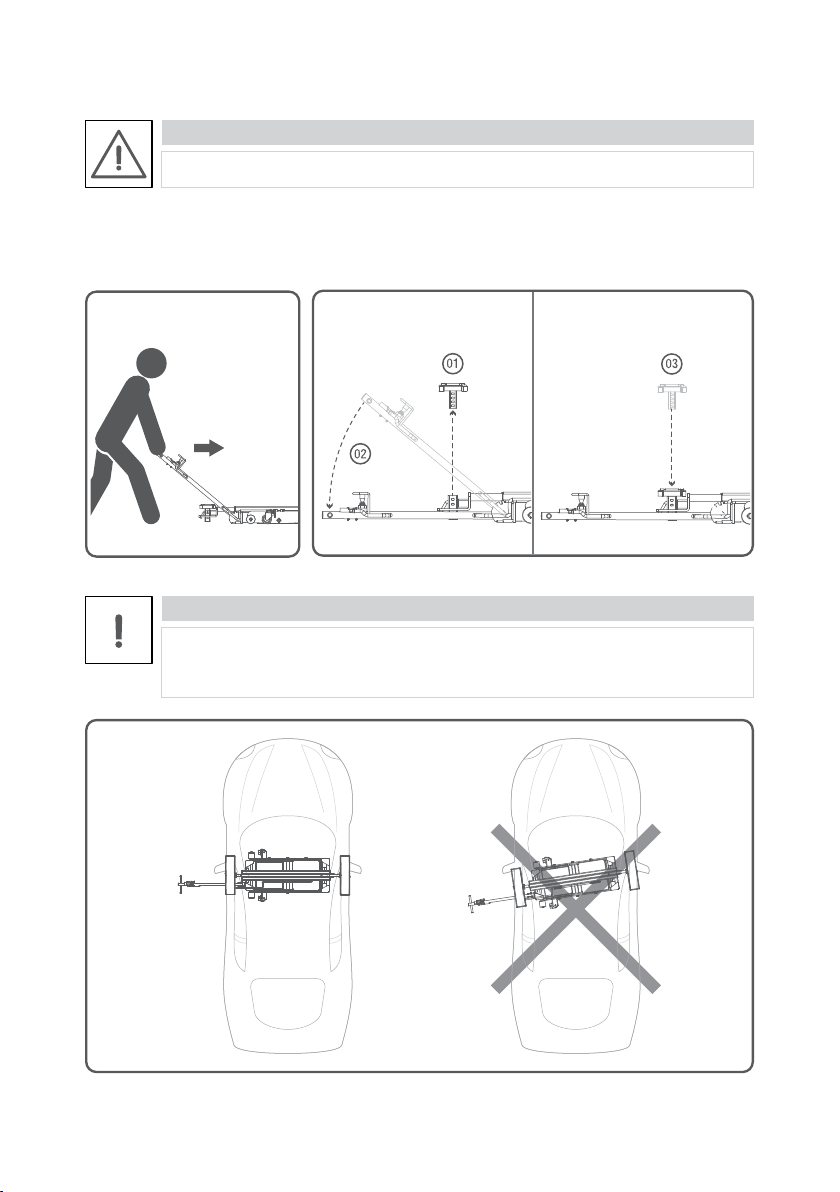

The miniLIFT is an easy to use and versatile product. Thanks to its handle you can move the lift without

making effort to any place of the garage and, in addition, to control the elevation of the lift.

The pneumatic system is easy to connect (you only need an air intake).

1 Information about this manual

2 Intended use

1.1 Symbols of the manual

DANGER

CAUTION

NOTE

Possible risk of death, serious injury and / or material damage.

Possible risk of injury and / or material damage.

Recommendations for the correct use.

4USER MANUAL · AE1001 MINILIFT