Page iii XX69RT Series - Service & Parts Manual

November 2022

Hydraulic Module Installation � � � � � � � � � � � � � � � � � 53

Hydraulic Module Door Installation � � � � � � � � � � � � � � � 55

Hydraulic Module Assembly � � � � � � � � � � � � � � � � � 57

Drive Manifold Assembly � � � � � � � � � � � � � � � � � � 59

Function Manifold Assembly, XX69RT� � � � � � � � � � � � � � � 61

Ground Control Box Assembly � � � � � � � � � � � � � � � � 63

Hydraulic Tank Assembly � � � � � � � � � � � � � � � � � � 65

Fuel Tank Assembly � � � � � � � � � � � � � � � � � � � 67

Engine Module Installation� � � � � � � � � � � � � � � � � � 69

Engine Module Door Installation � � � � � � � � � � � � � � � � 71

Engine Module Assembly � � � � � � � � � � � � � � � � � � 73

Radiator Shroud Assembly � � � � � � � � � � � � � � � � � 75

Diesel Cooling System Installation � � � � � � � � � � � � � � � 77

Diesel and Dual Fuel Cooling System Assembly � � � � � � � � � � � � 79

Diesel Intake System and Exhaust System � � � � � � � � � � � � � 81

Diesel Engine Assembly � � � � � � � � � � � � � � � � � � 83

Diesel Fuel System Assembly � � � � � � � � � � � � � � � � � 87

Dual Fuel Engine Assembly � � � � � � � � � � � � � � � � � 89

Dual Fuel LPG Tank � � � � � � � � � � � � � � � � � � � 91

Outriggers and Ladder Installation� � � � � � � � � � � � � � � � 93

Outrigger Assembly � � � � � � � � � � � � � � � � � � � 95

Chassis Accessory Installation � � � � � � � � � � � � � � � � 97

Electrical Accessory Assembly � � � � � � � � � � � � � � � � 99

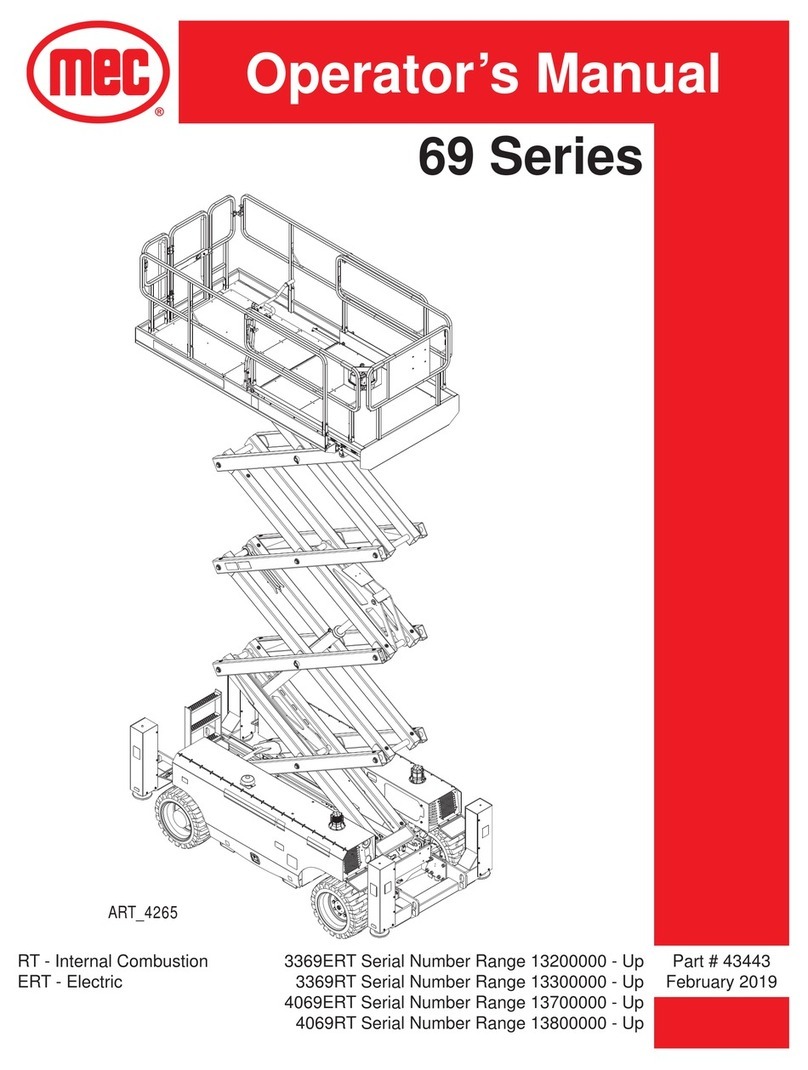

Section 9 - Scissor . . . . . . . . . . . . . . . . . 101

Scissor Assembly, 3369RT � � � � � � � � � � � � � � � � 101

Scissor Assembly, 4069RT � � � � � � � � � � � � � � � � 105

Slider Assembly � � � � � � � � � � � � � � � � � � � 109

Hose Clamp Assembly � � � � � � � � � � � � � � � � � �111

Hose Clamp Assembly, 4069RT � � � � � � � � � � � � � � � �113

Hose Clamp Assembly 2 � � � � � � � � � � � � � � � � � �115

Section 10 - Platform . . . . . . . . . . . . . . . . 117

Main Platform Assembly � � � � � � � � � � � � � � � � � �117

Support Roller Assembly � � � � � � � � � � � � � � � � � �119

Side Roller Assembly � � � � � � � � � � � � � � � � � � 121

Platform Extension Assembly � � � � � � � � � � � � � � � � 123

Platform Locking Device Assembly � � � � � � � � � � � � � � 127

Roller Assembly � � � � � � � � � � � � � � � � � � � 129

Platform Control and Sheet Material Tray � � � � � � � � � � � � � 131

Platform Control Box Assembly � � � � � � � � � � � � � � � 133

Section 11 - Hydraulic System . . . . . . . . . . . . . . 135

Lower Lift Cylinder Assembly � � � � � � � � � � � � � � � � 135

Upper Lift Cylinder Assembly, 4069RT � � � � � � � � � � � � � 137

Left Oscillate Cylinder Assembly � � � � � � � � � � � � � � � 139

Right Oscillate Cylinder Assembly� � � � � � � � � � � � � � � 141

Steer Cylinder Assembly � � � � � � � � � � � � � � � � � 143

Outrigger Cylinder Assembly, SUN � � � � � � � � � � � � � � 145

Outrigger Cylinder Assembly, HydraForce� � � � � � � � � � � � � 147