ENGLISH

1 Número de revisión Rev 001-2013-08-06

SOMMAIRE –CONTENTS –SUMARIO –SOMMARIO

SUMARIO –INHALTSVERZEICHNIS

TECHNICAL SPECIFICATIONS AND GENERAL INFORMATION .................................................................. 2

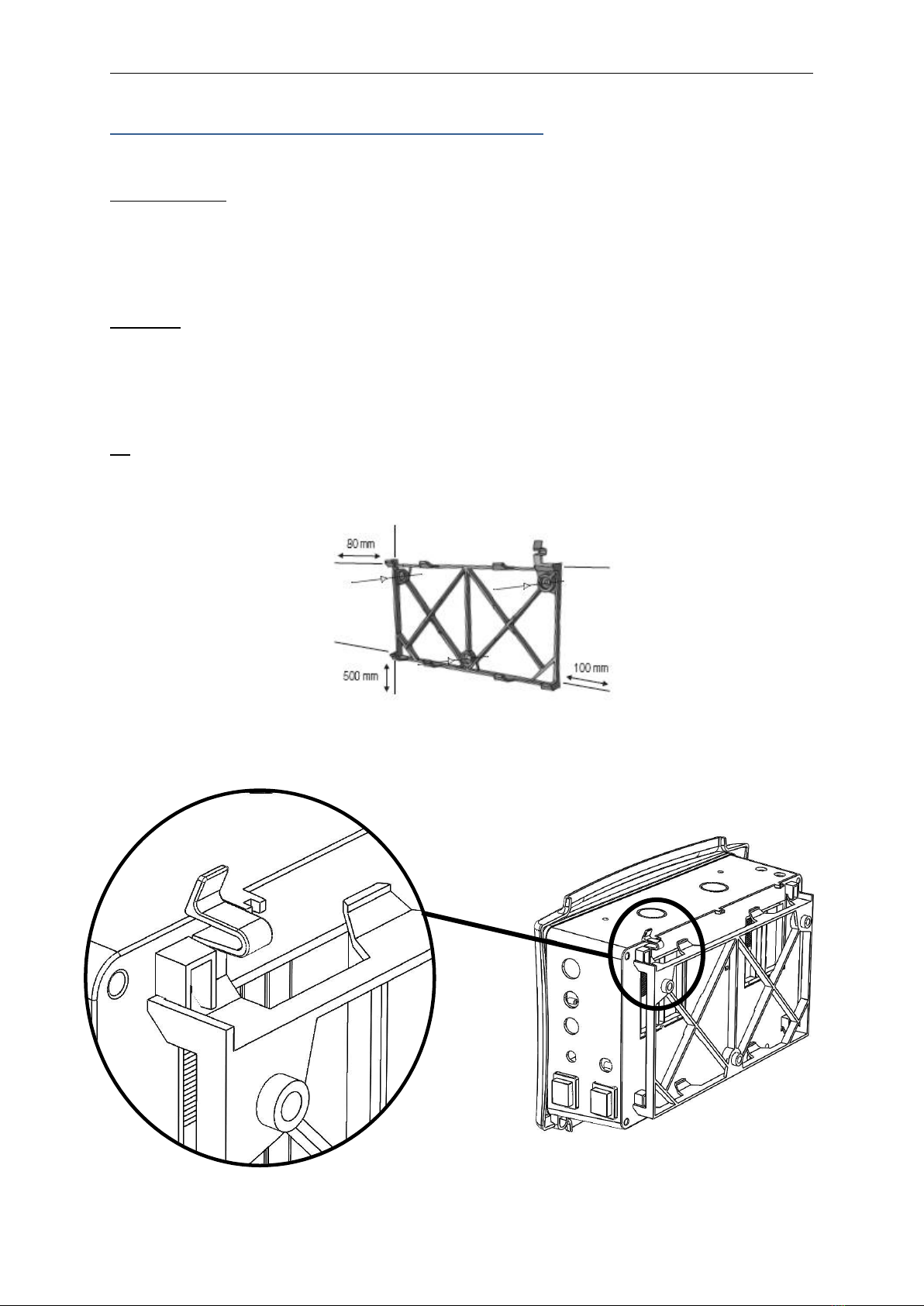

INSTALLATION IN THE TECHNICAL AREA................................................................................................. 3

INSTALLATION OF THE CHAMBER: .......................................................................................................... 4

PROBE:..................................................................................................................................................... 5

FLOW SWITCH: ........................................................................................................................................ 5

INSTALLATION OF THE EARTH ELECTRODE: ............................................................................................ 6

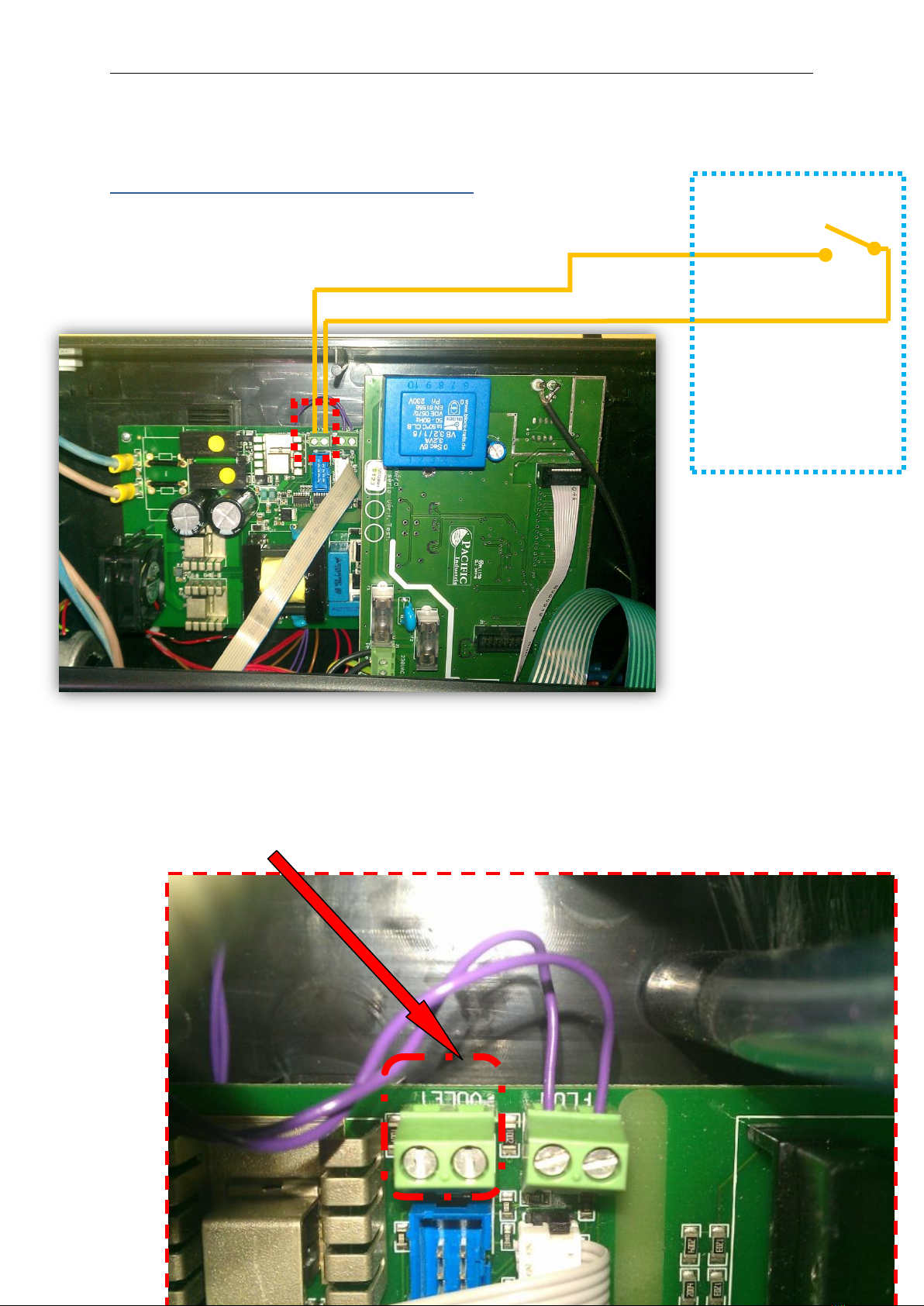

ELECTRICAL CONNECTIONS: .................................................................................................................... 7

SERVO-CONTROLLED BY THE COVER....................................................................................................... 8

OPERATING THE ELECTROLYSER.............................................................................................................. 9

RECOMMENDATIONS............................................................................................................................ 10

SWITCHING ON THE ELECTROLYSER...................................................................................................... 10

ADJUSTING CHLORINE PRODUCTION.................................................................................................... 11

CHLORINE ANALYSIS METHOD .............................................................................................................. 11

INDOOR POOL OR POOLS WITH COVERS .............................................................................................. 11

ADJUSTING THE DURATION OF THE POLARITY INVERSION .................................................................. 12

CHECKS AND MAINTENANCE ................................................................................................................ 12

NON-MODIFIABLE PARAMETERS: ......................................................................................................... 13

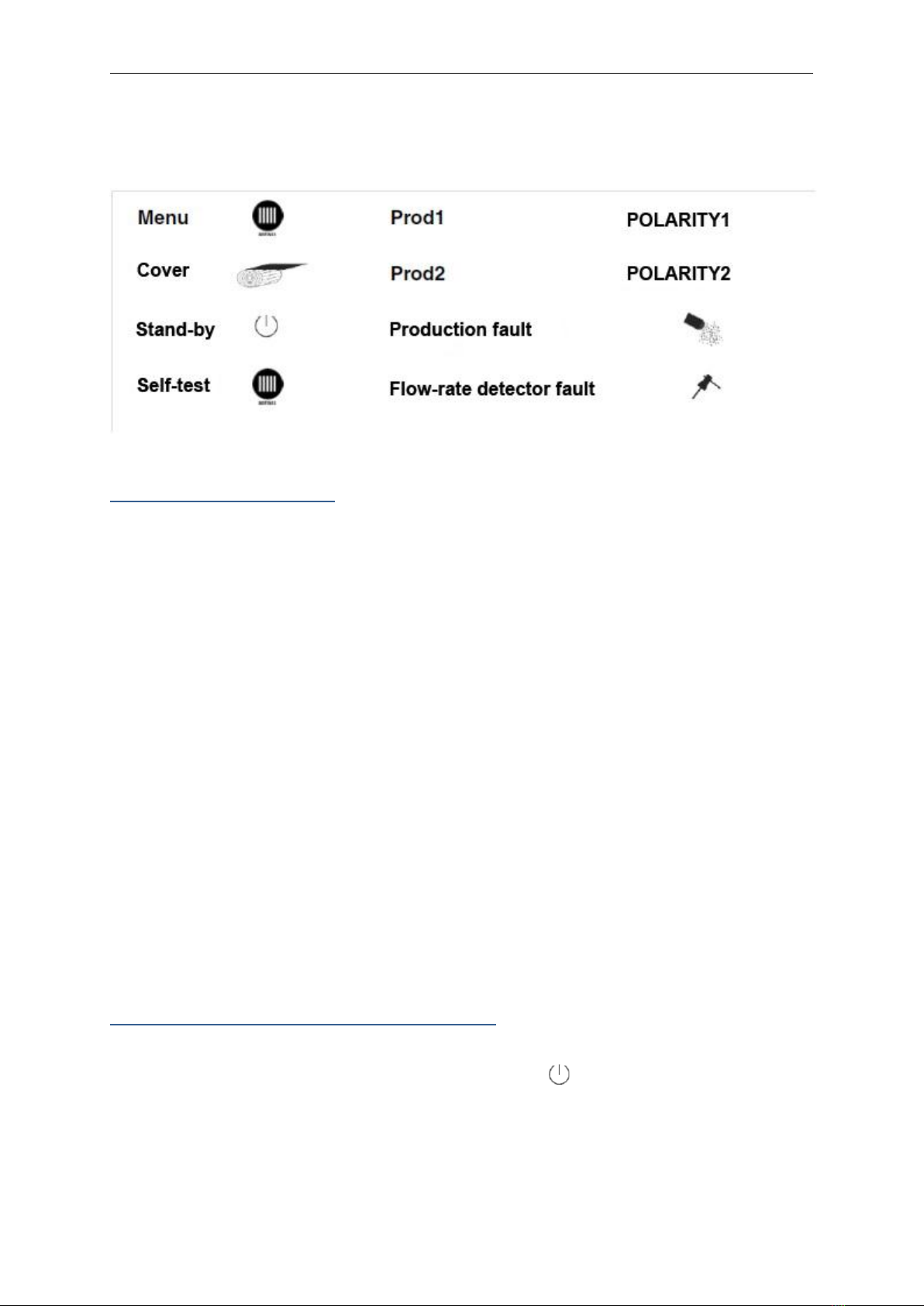

INDICATORS........................................................................................................................................... 15

pH REGULATION .................................................................................................................................... 16

SWITCHING ON FOR THE FIRST TIME.................................................................................................... 17

TIPS FOR THE CORRECT USE OF THE pH REGULATOR........................................................................... 18

TAYLOR SCALE ....................................................................................................................................... 19

WARRANTY............................................................................................................................................ 19