ASURITY FP-22 User manual

Installation Instructions

Models: FP-22, FP-22-230

Acidic & High

Temperature Applications

Condensate

Pump Specialty

ASURITYTM

CONDENSATE MANAGEMENT PAGE 2

INTRODUCTION

SAFETY INFORMATION

Please read, understand, and follow all safety instructions. Failure to follow

instructions may result in property damage, serious injury, or death.

DANGER

ALWAYS disconnect power prior to moving, adjusting, or servicing

pump or attached systems. DO NOT use this pump in the presence of

spraying or standing water. Failure to do so could result in a fatal electric

shock.

WARNING: FIRE AND EXPLOSION HAZARD

DO NOT use this pump to move ammable or explosive liquids. DO

NOT use this pump in explosive or ammable environments.

Carbon monoxide hazard. Ensure that pump is mounted away from heat

exchanger or wiring. If you are unsure of any items in this manual, please

consult a professional and DO NOT attempt to install this product.

CALIFORNIA PROPOSITION 65

This product may contain chemicals known to the state of California to

cause cancer, birth defects, or other reproductive harm. Wash hands

after handling this product.

CAUTION: FLOOD RISK

Personal injury or property damage can result from an inoperative

pump. If a ood has occurred, DO NOT walk in wet area until all power

has been turned o. Check with local electric company or a qualied

electrician before disconnecting any electrical service prior to pump

removal.

WARNING

Pump must be properly wired to condensate producing appliance control

board in order to shut o appliance in alarm (high water) conditions.

Supply voltage and frequency must match what is shown on pump

nameplate. Source voltages lower than the rated supply can reduce

performance and cause pump to overheat.

Pump must be level or should be placed on a solid surface or oor.

DO NOT cover pump air vents. Pump is air cooled. DO NOT cover vent

holes located on top or sides of the pump housing. Pump may be

operated continuously as long as air vents are not covered.

Pump should be stored indoors. The chosen location should be clean

and dry.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

www.diversitech.com | 800.995.2222 PAGE 3

experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play

with the appliance.

If the supply cord is damaged, it must be replaced by the manufacturer, its

service agent or similarly qualied persons in order to avoid a hazard.

TEMPERATURE RATING

• Continuous duty 170˚F

• Max inlet temperature 190˚F

• Not suitable for contact with steam or gases that exceed 190˚F.

GENERAL INFORMATION

This pump is designed to automatically remove the condensate water that

collects from appliances such as air conditioners, high-eciency furnaces,

and de-humidiers. The pump has a built-in tank that collects water from

the appliance. When water collected reaches sucient level inside pump

tank, pump switches on and pumps water to a remote location for disposal.

When tank is suciently empty, pump automatically switches o. Pump is

capable of lifting water up to 22 ft. and is equipped with a check valve that

prevents water from owing back into tank when pump shuts o.

The pump utilizes LED lights that show the status of Power Available, Motor

Running, and High Water (Alarm) Conditions. Pump is also equipped with a

switch that activates when water in tank reaches an overow condition. The

overow safety switch may be connected to turn o the appliance if high

water condition occurs.

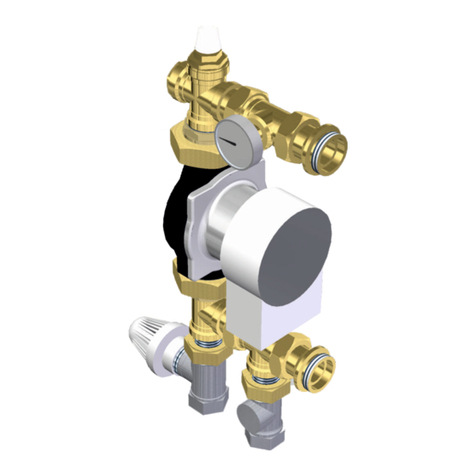

FEATURES

POWER

Metal Hang Tabs

Lengüetas colgantes

de metal

LED Indicator Lights

Luces indicadoras con

bombilla LED

Inlet Hole

Orificio de entrada

Inlet Hole Cover

Cubierta

Overflow Safety Switch

Interruptor de seguridad

de rebose

Check valve - 1/4 Turn

Removable

Válvula de retención -

Removible con ¼ de giro

Integrated P-Traps in

Corners

Siphons en “P” intégrés

dans les coins

Chemical + Temperature Resistant Tank

Tanque resistente a la temperatura y a los químicos

ASURITYTM

CONDENSATE MANAGEMENT PAGE 4

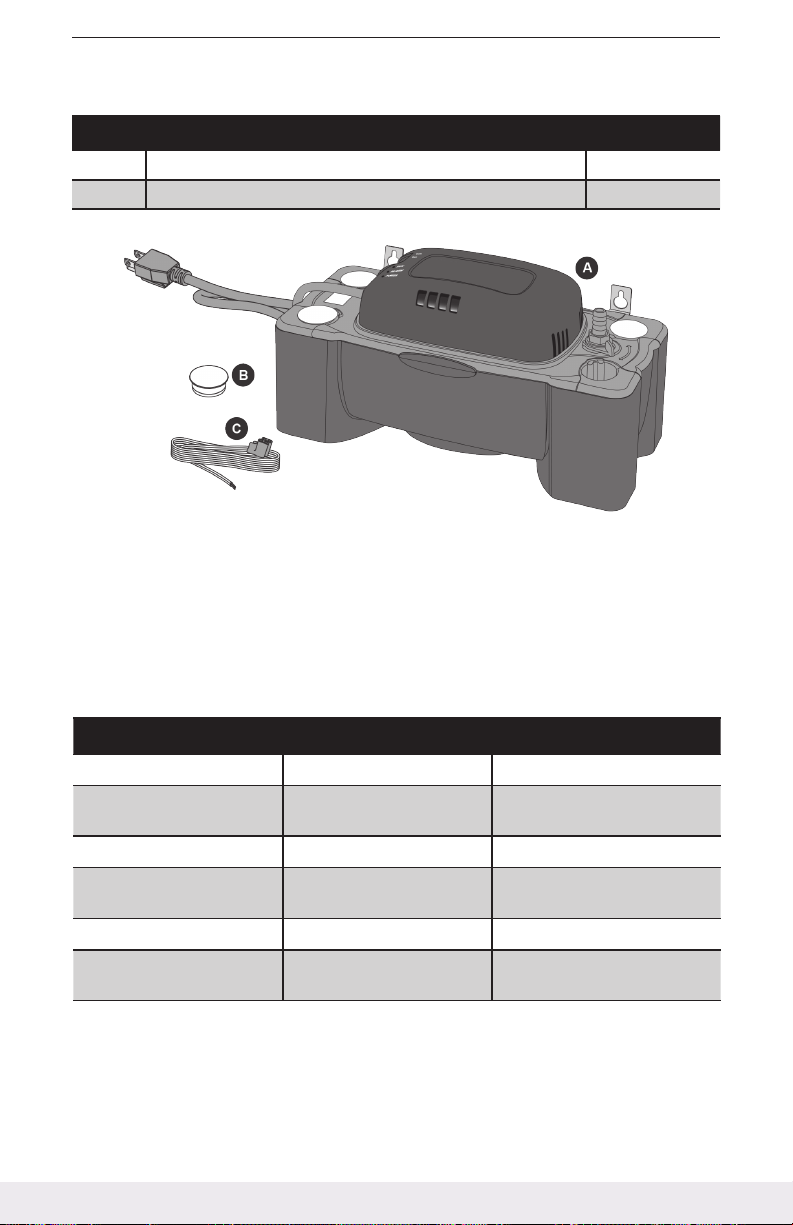

PACKAGE CONTENTS

SPECIFICATIONS

PART DESCRIPTION QUANTITY

A Condensate Pump 1

B Inlet Hole Covers 3

C Wires with Pre-crimped connectors 1

FP-22 FP-22-230

Rated Voltage 120 Volts/60Hz 220 Volts/60 Hz

Rated Current Draw 1.9 Amps 1.0 Amps

Head Height 22 ft. maximum 22 ft. maximum

Flow Rate at Zero

Head

1.6 GPM 1.0 GPM

Product Weight 4.8 lbs. 5.2 lbs.

Inlet Height from Base 4.3" 4.3"

www.diversitech.com | 800.995.2222 PAGE 5

INSTALLATION

MOUNTING OPTIONS

1A. PLACE ON FLOOR

Determine condensate pump location.

1B. ATTACH TO WALL

Attach condensate pump with screws (8” between mounting tabs).

OPTION: REVERSE TOP IF

NECESSARY

Pump top may be rotated 180˚

to allow access to pump outlet

or power connection.

ASURITYTM

CONDENSATE MANAGEMENT PAGE 6

INSTALLATION (continued)

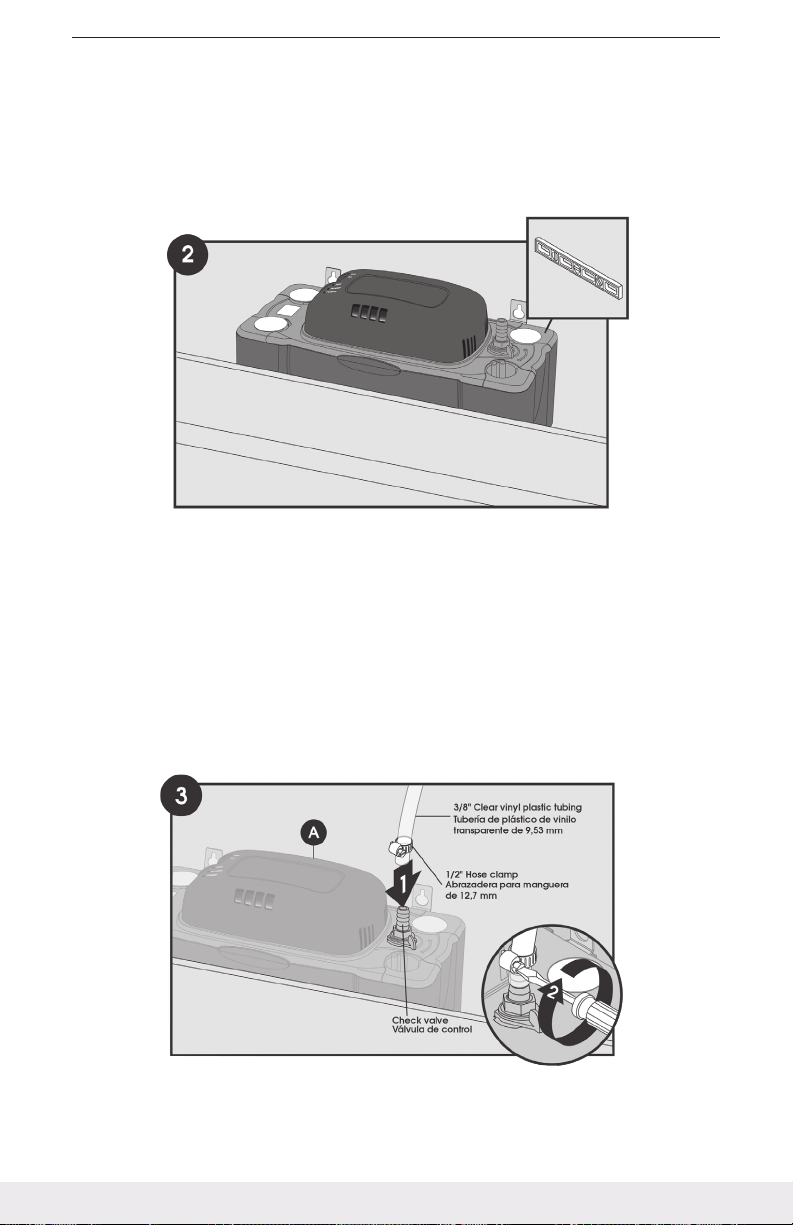

2. LEVEL UNIT

Ensure that condensate pump is level.

OUTLET CONNECTIONS

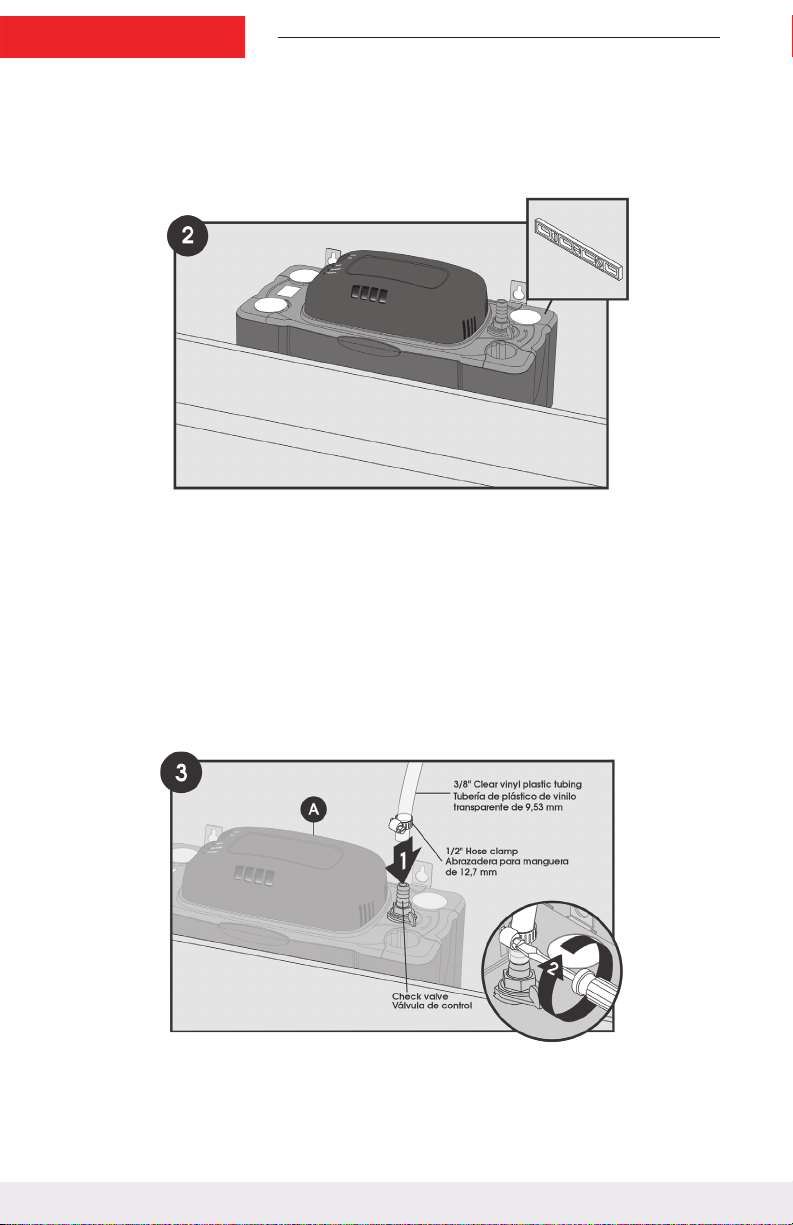

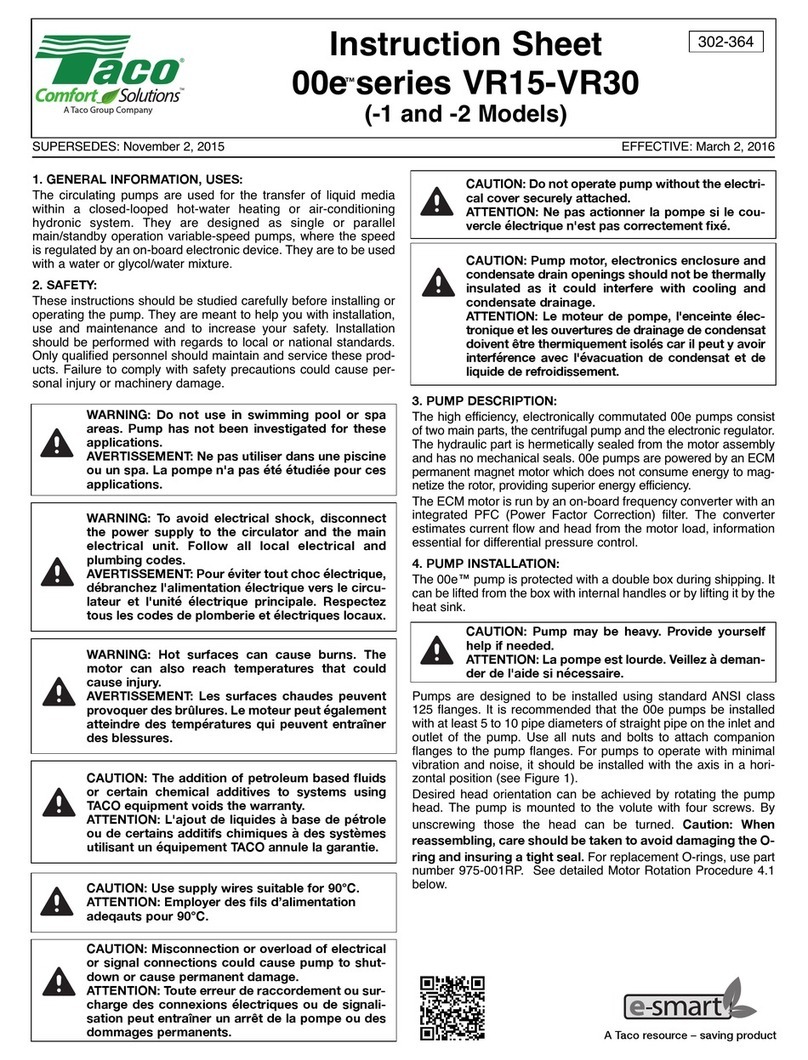

3. INSTALL OUTLET TUBE CONNECTION

Attach plastic tubing to check valve and secure with hose clamp. Route

tubing up and away from condensate pump (avoid compressing or

kinking tubing).

www.diversitech.com | 800.995.2222 PAGE 7

INSTALLATION (continued)

INLET CONNECTIONS

4. INSTALL INLET TUBE CONNECTIONS

Install condensate drain tubing into one of the four inlet holes, making

sure tubing is straight.

If installing to a humidier, a

“P” trap should be used.

INLET COVERS

5. INSTALL INLET COVERS

Insert inlet covers in remaining condensate pump inlet holes.

ASURITYTM

CONDENSATE MANAGEMENT PAGE 8

INSTALLATION (continued)

6. SAFETY SWITCH CONNECTION

Connect overow safety switch terminals as shown in wiring diagram.

WARNING: RISK OF ELECTRIC SHOCK

Ensure that power to appliance and pump is shut o before

attempting this step! Failure to follow these warnings will void the

warranty and could result in a fatal electric shock.

Com

Run

RUN

Shut-Down Circuit*

Shut-Down Circuit*

*Overflow Switch is normally

closed and opens when a

high water level is detected.

Connect this circuit in series

with the appropriate 24V

shut-down circuit for the

appliance.

www.diversitech.com | 800.995.2222 PAGE 9

INSTALLATION (continued)

ELECTRICAL CONNECTION

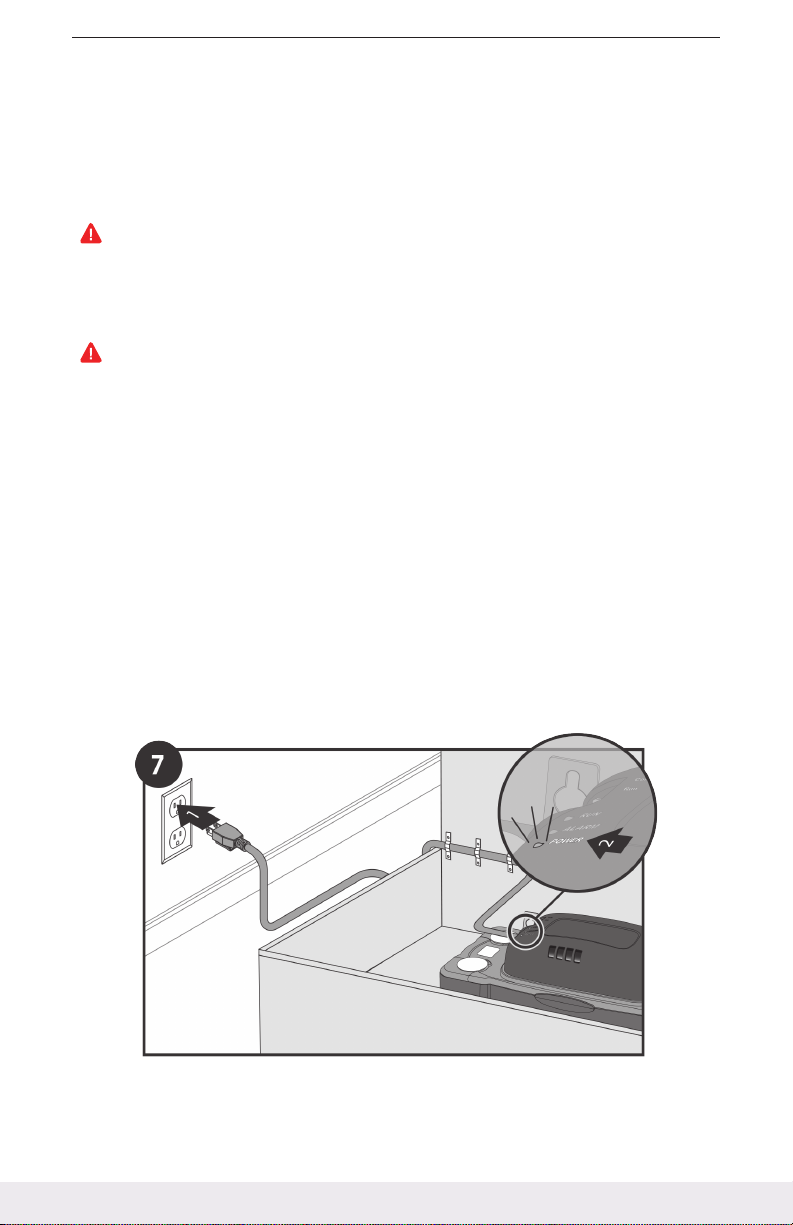

7. ELECTRICAL CONNECTION

WARNING: RISK OF ELECTRIC SHOCK

This pump must be properly connected to power following the

National Electric Code (NEC). Failure to follow these warnings will void

warranty and could result in a fatal electric shock. A green LED will

indicate if power is available.

This pump is supplied with a grounding conductor and grounding

type attachment plug. To reduce the risk of electric shock, be certain

that it is connected only to a properly grounded, grounding-type

receptacle.

PLUG NOTE: REMOVAL OF THE WALL SIDE ELECTRICAL PLUG MAY

BE PERMISSIBLE IF:

1. The power leads, after plug removal, are connected directly within an

approved junction or conduit box, as judged by the local authority having

jurisdiction.

2. The modication is performed by a qualied technician.

3. The modication meets code compliant requirements according to the

local authority. This modication does not void the factory warranty. Final

installations should always be inspected and approved by the local

authority according to the requirements set forth by the same local

authority.

ASURITYTM

CONDENSATE MANAGEMENT PAGE 10

OPERATION

1. TESTING FLOAT

Manually ll the tank with water. An amber LED will indicate pump is

operating.

2. TESTING OVERFLOW SWITCH (IF CONNECTED)

Manually overll tank with water. If overow safety switch is wired

correctly, appliance will shut down, condensate pump will pump out

water, and a red LED will illuminate.

2

www.diversitech.com | 800.995.2222 PAGE 11

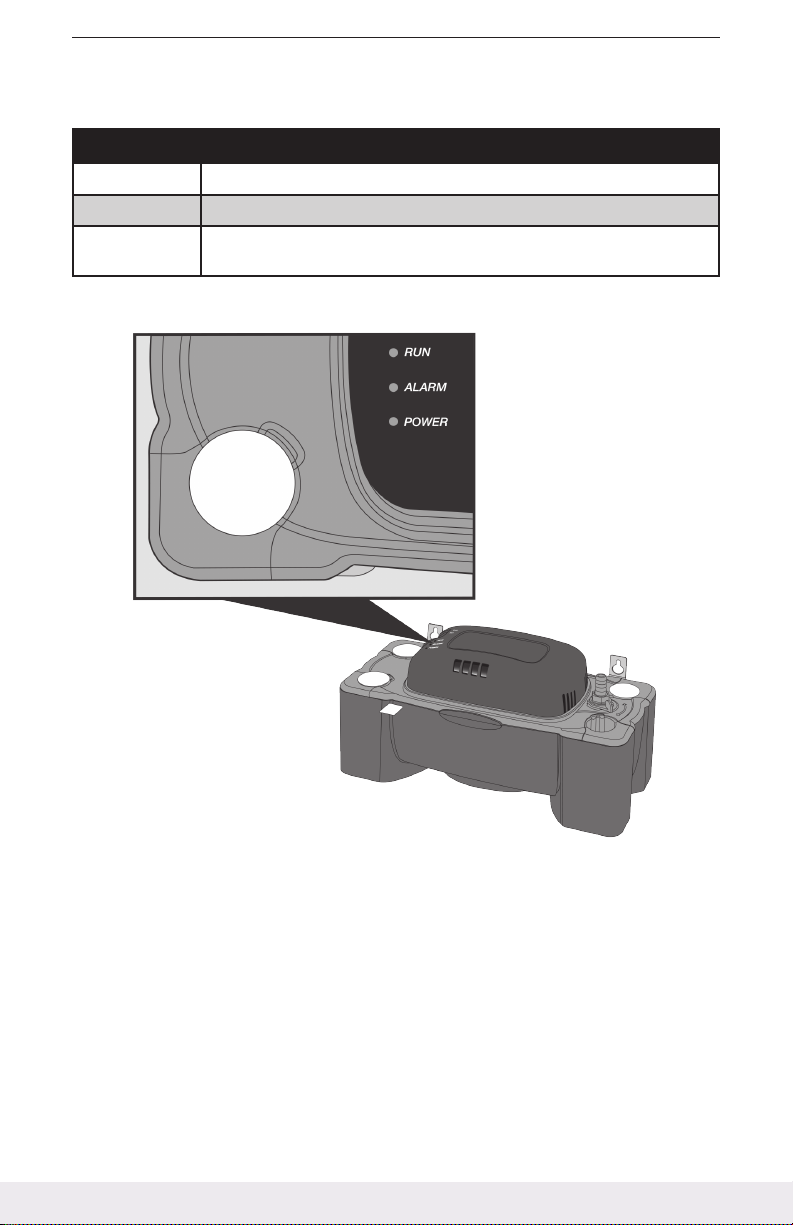

LED INDICATOR STATUS

LED STATUS

Green LED Indicates pump has power and is ready

Amber LED Indicates pump is running and removing condensate from tank

Red LED Indicates pump is in alarm mode and that the system is shuto/

disabled (if connected)

ASURITYTM

CONDENSATE MANAGEMENT PAGE 12

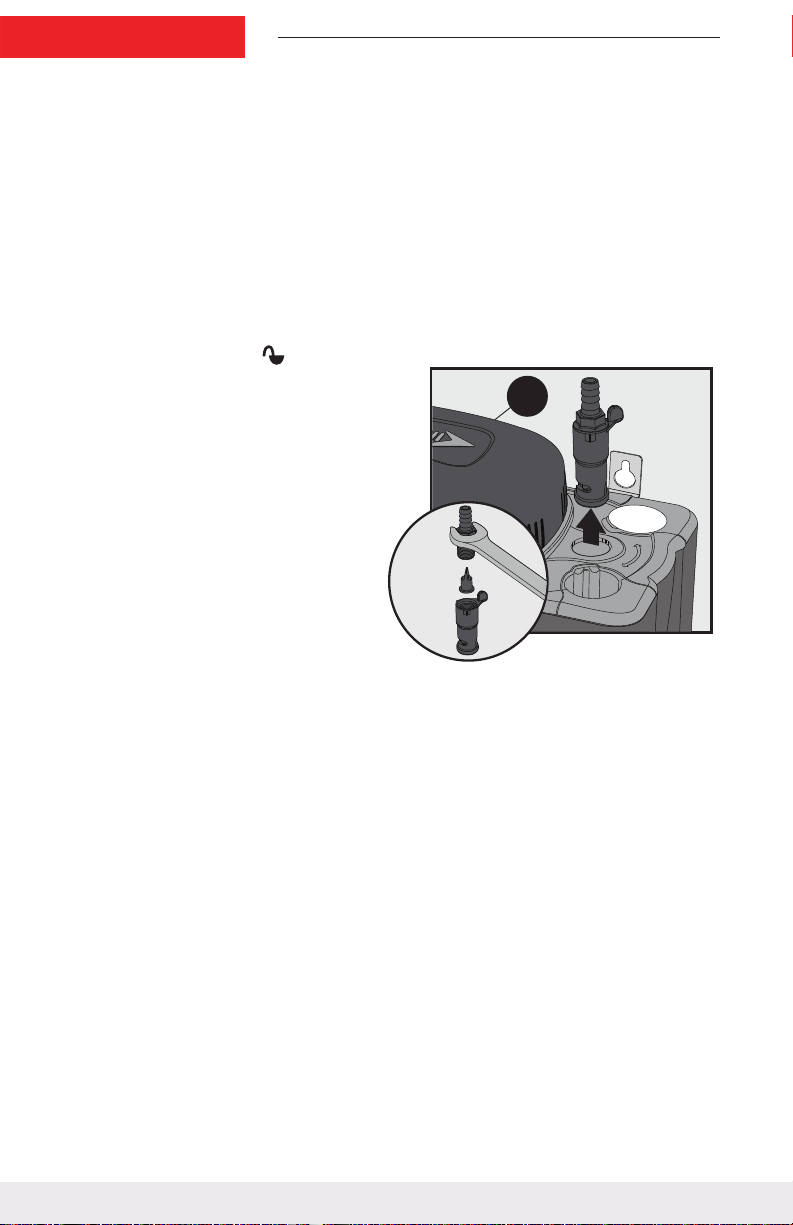

MAINTENANCE AND DISASSEMBLY

ALWAYS disconnect power before performing maintenance. Pump and

deck may be removed from tank by pushing tabs located on tank sides

away from deck while lifting on pump cover.

Periodically inspect the condensate pump tank to ensure it is free of accu-

mulated dirt or sludge. DO NOT use solvent cleaners. Clean tank with soap

and warm water only. For pump service/

replacement, entire check valve/shuttle assembly can be removed via 1/4-

turn engagement.

Rotate tab 1/4-turn to and pull

up. This will prevent all water still

remaining in tubing from draining

out. However, the check valve may

be removed for cleaning or

replacement by rst unlocking and

removing the check valve shuttle

assembly and then unscrewing the

barbed tting with a 5/8” wrench.

This is required to remove the check

valve from the shuttle body

(for service/replacement).

Clean inlet and outlet piping. Re-

assemble system and check for

correct operation.

A

2

www.diversitech.com | 800.995.2222 PAGE 13

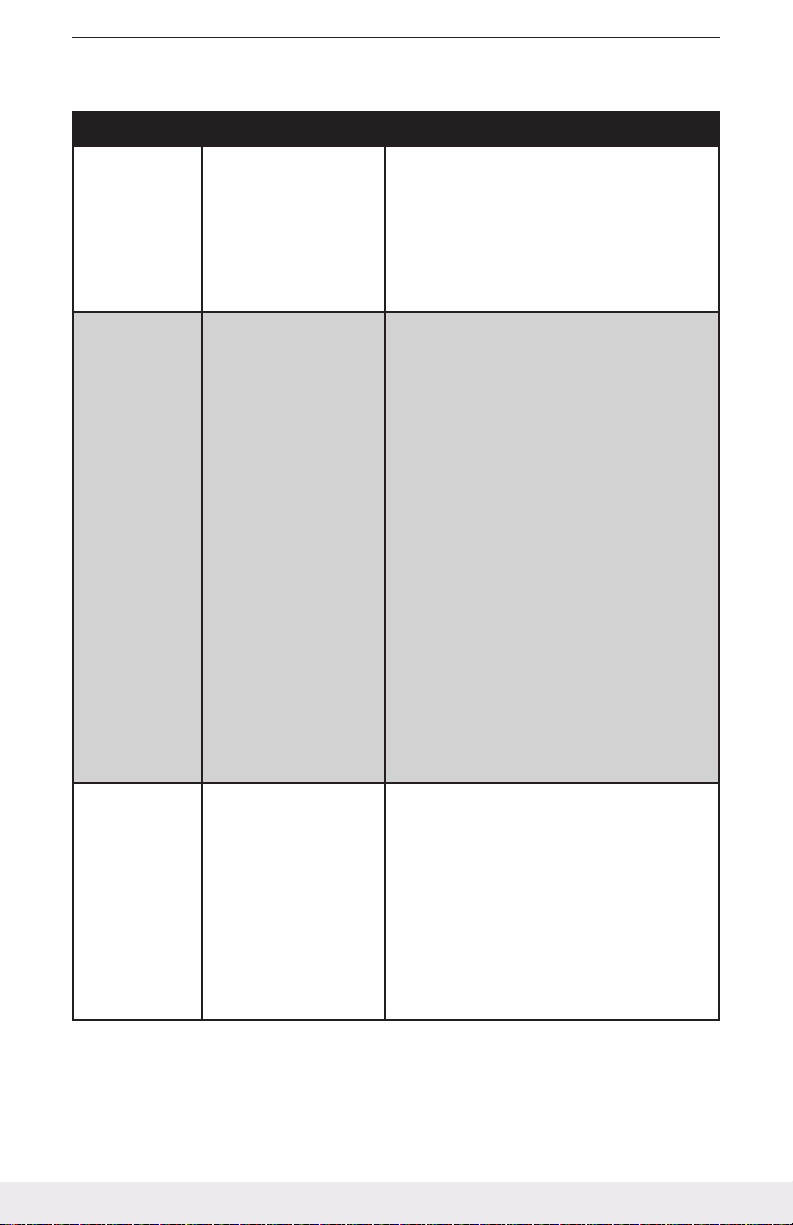

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Unit does not

start when

full of

condensate

1. Power is not

supplied to pump.

2. Pump impeller is

not turning.

1. Ensure that power is supplied to pump. A

green LED indicator on top of pump cover

will show that power is supplied and that

pump is ready.

2. Clear any blockage in impeller housing. If

problem persists, motor is stuck. Return

pump to place of purchase if under

warranty.

Condensate is

overowing

from unit

1. Power is not

supplied to pump.

2. Pump is in overow

condition.

3. Pump is not level.

4. Outlet ow is

blocked.

5. Pump impeller is not

turning.

1. Ensure that power is supplied to pump. A

green LED indicator on top of pump cover

will show that power is supplied.

2. The inlet ow to condensate pump is

exceeding outlet ow. Check to ensure

that pump safety switch (alarm circuit)

is connected to appliance. The safety

switch connection will shut o appliance

in this condition.

3. Check to ensure that pump is level. If

pump is not level, it may not activate,

causing water to overow from tank.

Place unit on a at and level surface.

4. Check outlet tubing to ensure that it is not

kinked or blocked. Clear blocked tubing

of slime and debris. Clean inlet and outlet

piping.

5. Clear any blockage in impeller housing. If

problem persists, motor is stuck. Return

pump to place of purchase if under

warranty.

Pump will not

shut o

1. The pump is in

overow condition.

2. Outlet ow is

blocked.

1. The inlet ow to condensate pump is

exceeding outlet ow. Check to ensure

that pump safety switch (alarm circuit)

is connected to A/C / furnace unit. The

safety switch connection will shut o A/C

/ furnace in this condition.

2. Check outlet tubing to ensure that it is not

kinked or blocked. Clear blocked tubing

of slime and debris. Clean inlet and outlet

piping.

ASURITYTM

CONDENSATE MANAGEMENT PAGE 14

WARRANTY

All pumps manufactured by or for DiversiTech Corporation (the Company)

and sold by the Company under the Asurity or Diversitech brand are

warranted to be free of defects in workmanship and materials for a period

of 36 months from date of sale from the distributor to the contractor. The

Company will credit, repair or replace, at its option, any Pump if deemed

defective within this time period. All products returned to the Company

must include a return authorization issued by the Company. The returned

product should be suitably packaged and shipped prepaid from the point of

shipment to the point designated in the Company’s return authorization.

This warranty is a limited warranty and shall be in lieu of any other

warranties, expressed or implied, including, but not limited to, any implied

warranty of merchantability or tness for a particular purpose. There are

no other warranties that extend beyond the description of the face hereof.

The liability of the Company arising out of its supply of said products, or

their use shall not in any case exceed the cost of correcting defects in the

products as set forth above. The Company shall not be liable for any costs

or damage incurred by its customers in the removal or replacement of

defective products from units in which the products have been assembled.

In no event shall the company be liable for loss of prots, indirect,

consequential, or incidental damages.

www.diversitech.com | 800.995.2222 PAGE 15

INFORMACIÓN DE SEGURIDAD

Lea, comprenda y siga todas las instrucciones de seguridad. Si no respeta

las instrucciones, se pueden producir daños a la propiedad, lesiones graves

o la muerte.

PELIGRO

SIEMPRE desconecte la alimentación antes de mover, ajustar o realizar

mantenimiento a la bomba o a los sistemas conectados. NO use esta

bomba con agua estancada o agua que se rocíe. El incumplimiento de

esta medida podría provocar una descarga eléctrica fatal.

ADVERTENCIA: PELIGRO DE INCENDIO Y EXPLOSIÓN

NO use esta bomba para mover líquidos inamables o explosivos. NO

use esta bomba en ambientes inamables o explosivos.

Peligro de monóxido de carbono. Asegúrese de montar la bomba lejos

del intercambiador de calor y el cableado. Si NO comprende algún

ítem de este manual, consulte a un profesional y no intente instalar este

producto.

PROPUESTA 65 DE CALIFORNIA

Este producto puede contener sustancias químicas reconocidas por el

estado de California como causantes de cáncer, defectos congénitos u

otros daños en el aparato reproductivo. Lávese las manos después de

manipular este producto.

PRECAUCIÓN: RIESGO DE INUNDACIÓN

Una bomba que no funcione puede producir lesiones personales o

daños a la propiedad. Si se produce una inundación, NO camine en

el área mojada hasta que desconecte la alimentación. Consulte a la

compañía de electricidad local o un electricista calicado antes de

desconectar el servicio eléctrico para retirar la bomba.

ADVERTENCIA

La bomba debe estar conectada correctamente para condensar y

ocasionar el control del tablero de control del electrodoméstico para

cerrar la bomba en condiciones de alarma (agua alta).

El voltaje y la frecuencia del suministro deben coincidir con los que se

muestran en la placa de datos de la bomba. Si los voltajes de la fuente

son inferiores al del suministro calicado, el rendimiento de la bomba

podría reducirse y esta podría sobrecalentarse.

Bomba debe estar nivelada y se debe colocar sobre una supercie o

piso sólido.

NO cubra los respiraderos de la bomba. La bomba se refrigera por aire.

NO cubra los oricios de ventilación ubicados en la parte superior o en

los costados de la carcasa de la bomba. La bomba puede funcionar de

manera continua siempre y cuando no se cubran los respiraderos.

Esta bomba se debe almacenar en interiores. La ubicación elegida debe

estar limpia y seca.

ASURITYTM

CONDENSATE MANAGEMENT PAGE 16

ÍNDICE DE TEMPERATURA (NON TESTÉE POUR L’EAU CHAUDE)

• Funcionamiento continuo a 60 ˚C

• Temperatura máxima de entrada de 71,1 ˚C

• No es adecuado para contactarse con vapor o con gases que superan los

71,1 ˚C

INFORMACIÓN GENERAL

Esta bomba de condensación está diseñada para eliminar automáticamente

el agua condensada que recolecta de electrodomésticos tales como

acondicionadores de aire y deshumidicadores de alta eciencia. La bomba

tiene un tanque integrado que recolecta el agua de los electrodomésticos.

Cuando el agua recolectada alcanza un nivel suciente dentro del tanque de

la bomba, la bomba se enciende y bombea el agua a una ubicación remota

para su eliminación.

Cuando el tanque está lo sucientemente vacío, la bomba se apaga

automáticamente. La bomba tiene capacidad para elevar el agua hasta

6,10 m y está equipada con una válvula de control que evita que el agua se

devuelva al tanque cuando la bomba se apaga.

La bomba cuenta con luces en su exterior que muestran el estado de la

alimentación disponible, el funcionamiento del motor y condiciones en

las que hay una alta cantidad de agua (alarma). Esta bomba también está

equipada con un interruptor que se activa cuando el agua en el tanque

alcanza una condición de desborde. El interruptor de seguridad para

desbordes se puede conectar para apagar el electrodoméstico cuando

ocurra una condición de una alta cantidad de agua.

CARACTERÍSTICAS

www.diversitech.com | 800.995.2222 PAGE 17

CONTENIDO DEL PAQUETE

ESPECIFICACIONES

PIEZA DESCRIPCIÓN CANTIDAD

A Bomba de Condensacion 1

B Cubierta 3

FP-22

FP-22-230

Voltaje calicado 120 voltios/60 Hz 220 voltios/60 Hz

Consumo calicado de

corriente

1,9 amperios 1,0 amperios

Alto de cabezales Máximo de 6,71 m Máximo de 6,71 m

Índice de ujo con cabezal

cero

6,01 LPM 3,79 LPM

Peso de producto 2,18 kg 2,27 kg

Alto de entrada a partir de

la base

11,18 cm 11,18 cm

ASURITYTM

CONDENSATE MANAGEMENT PAGE 18

INSTALACIÓN

OPCIONES DE MONTAJE

1A. COLOQUE EN EL PISO

Determine la ubicación de la bomba de condensación

1B. FIJE A LA PARED

Fije la bomba de condensación con los tornillos (20,32 cm entre las

lengüetas de montaje).

OPCIÓN: 2 INVIERTA LA PARTE

SUPERIOR SI FUERA NECESARIO

La parte superior de la bomba puede

girar 180˚ para permitir un fácil acceso

a la salida de la bomba o para

conectar la alimentación.

www.diversitech.com | 800.995.2222 PAGE 19

INSTALACIÓN (continuado)

2. UNIDAD DE NIVEL

Asegúrese de que la bomba de condensación esté nivelada.

CONEXIONES DE SALIDA

3. INSTALE LA CONEXIÓN DEL TUBO DE SALIDA

Fije el tubo de plástico para vericar la válvula y asegurarlo con la

abrazadera para manguera. Guíe la tubería hacia arriba y lejos de la

bomba de condensación (Evite comprimir o retorcer la tubería)

ASURITYTM

CONDENSATE MANAGEMENT PAGE 20

INSTALACIÓN (continuado)

CONEXIÓN DE ENTRADA

4. INSTALE LAS CONEXIONES DEL TUBO DE ENTRADA

Instale la tubería de drenaje de condensación en uno de los cuatro

oricios de entrada, asegurándose de que la tubería esté recta.

Si instala la bomba a un

humidicador de

condensación, deberá usar

una trampa plástica.

CUBIERTA

5. INSTALE LAS CUBIERTAS DE ENTRADA

Coloque las cubiertas de entrada en los oricios de entrada restantes

de la bomba de condensación.

This manual suits for next models

1

Table of contents

Languages:

Other ASURITY Water Pump manuals

Popular Water Pump manuals by other brands

Taco Comfort Solutions

Taco Comfort Solutions VR15 instruction sheet

Emil Lux

Emil Lux STP-850 Original instructions

Mega

Mega B-4Z Product information bulletin

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS T4A61S-B Installation, operation, and maintenance manual with parts list

Cobalt Aquatics

Cobalt Aquatics E-X-T 800 Instructions and warranty

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 02D3-X2 3P Installation, operation, and maintenance manual with parts list