Installation & Servicing Instructions ATAG Q-Solar

3

Content

1 Introduction ...........................................................................................................................................................................4

2 Rules ................................................................................................................................................................................5

3 Scope of the supply ..............................................................................................................................................................7

4 Description of the boiler ........................................................................................................................................................7

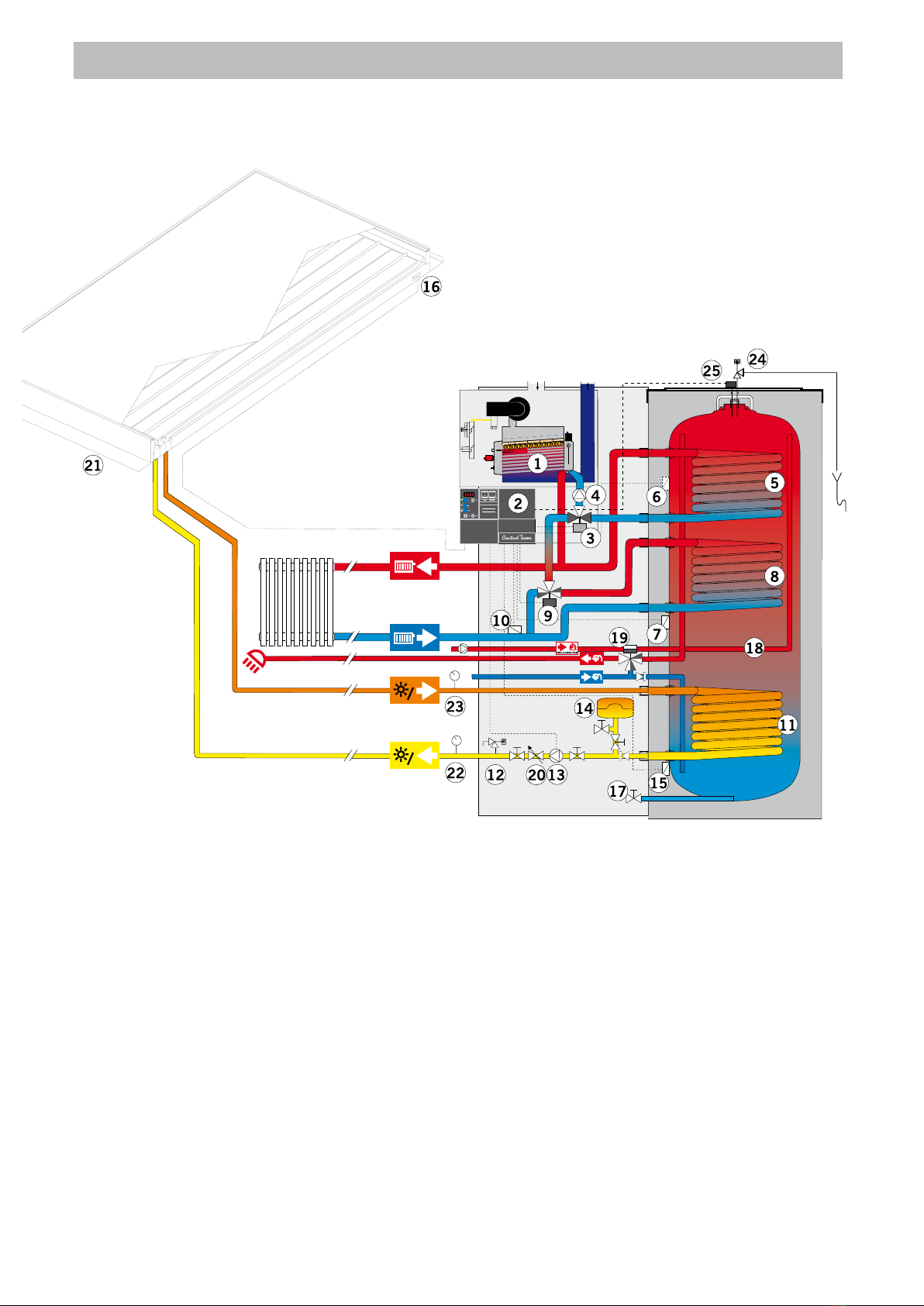

4.1 Schematic lay out of the Q-Solar ............................................................................................................................9

5 Mounting the boiler .............................................................................................................................................................10

5.1 Dimensions ........................................................................................................................................................... 11

6 Connecting the boiler .......................................................................................................................................................... 12

6.1 Central Heating system ........................................................................................................................................13

6.2 Expansion vessel .................................................................................................................................................. 14

6.3 Underoor heating system (plastic pipes) ............................................................................................................15

6.4 Gas connection ..................................................................................................................................................... 15

6.5 Hot water supply ...................................................................................................................................................16

6.5.1 Secondary DHW Circulation. ................................................................................................................................17

6.6 Condensation drain pipe ....................................................................................................................................... 18

6.6.1 Condensate discharge .......................................................................................................................................... 18

6.7 Flue gas exhaust system and air supply system ..................................................................................................20

6.7.1 Flue system dimensions .......................................................................................................................................23

7 Solar circuit .........................................................................................................................................................................24

7.1 Expansion vessel solar circuit ..............................................................................................................................24

7.2 Filling and de-aerating the solar cicuit ..................................................................................................................24

7.3 Solar pump ...........................................................................................................................................................24

8 Electrical connection ........................................................................................................................................................... 25

8.1 Electrical connections between cylinder and boiler ..............................................................................................26

8.2 Outside sensor (optional) .....................................................................................................................................28

8.3 Solar absorber sensor ..........................................................................................................................................28

8.4 Calibrating the sensors .........................................................................................................................................28

9 Boiler controls .....................................................................................................................................................................29

9.1 Explanation of the function keys ...........................................................................................................................30

9.2 Solar module ........................................................................................................................................................31

9.3 Functioning of the Solar module ...........................................................................................................................31

10 Filling and venting the installation ....................................................................................................................................... 32

10.1 Filling the cylinder (secundary DHW circuit) .........................................................................................................32

10.2 Central heating system (primary circuit) ...............................................................................................................33

11 Commissioning the boiler ..................................................................................................................................................34

11.1 Central Heating system ........................................................................................................................................34

11.2 Hot water supply ...................................................................................................................................................34

11.3 Solar circuit ...........................................................................................................................................................34

11.4 Adjustments ..........................................................................................................................................................35

11.5 Activating factory settings (green key function) ...................................................................................................37

12 Isolating the boiler .............................................................................................................................................................38

13 Commissioning ...................................................................................................................................................................38

13.1 Checking for contamination ..................................................................................................................................39

13.2 Checking the CO2/O2 ..........................................................................................................................................40

13.3 Maintenance activities ..........................................................................................................................................41

13.4 Draining the installation ........................................................................................................................................43

13.5 User's instructions ................................................................................................................................................44

13.6 Maintenance frequency ........................................................................................................................................44

13.7 Warranty ...............................................................................................................................................................44

14 Technical specications ......................................................................................................................................................45

15 Parts of the boiler ...............................................................................................................................................................46

16 Error indication ...................................................................................................................................................................48

17 CE Declaration of conformity ..............................................................................................................................................49

Benchmark Checklist ..........................................................................................................................................................50

Service Record ...................................................................................................................................................................51

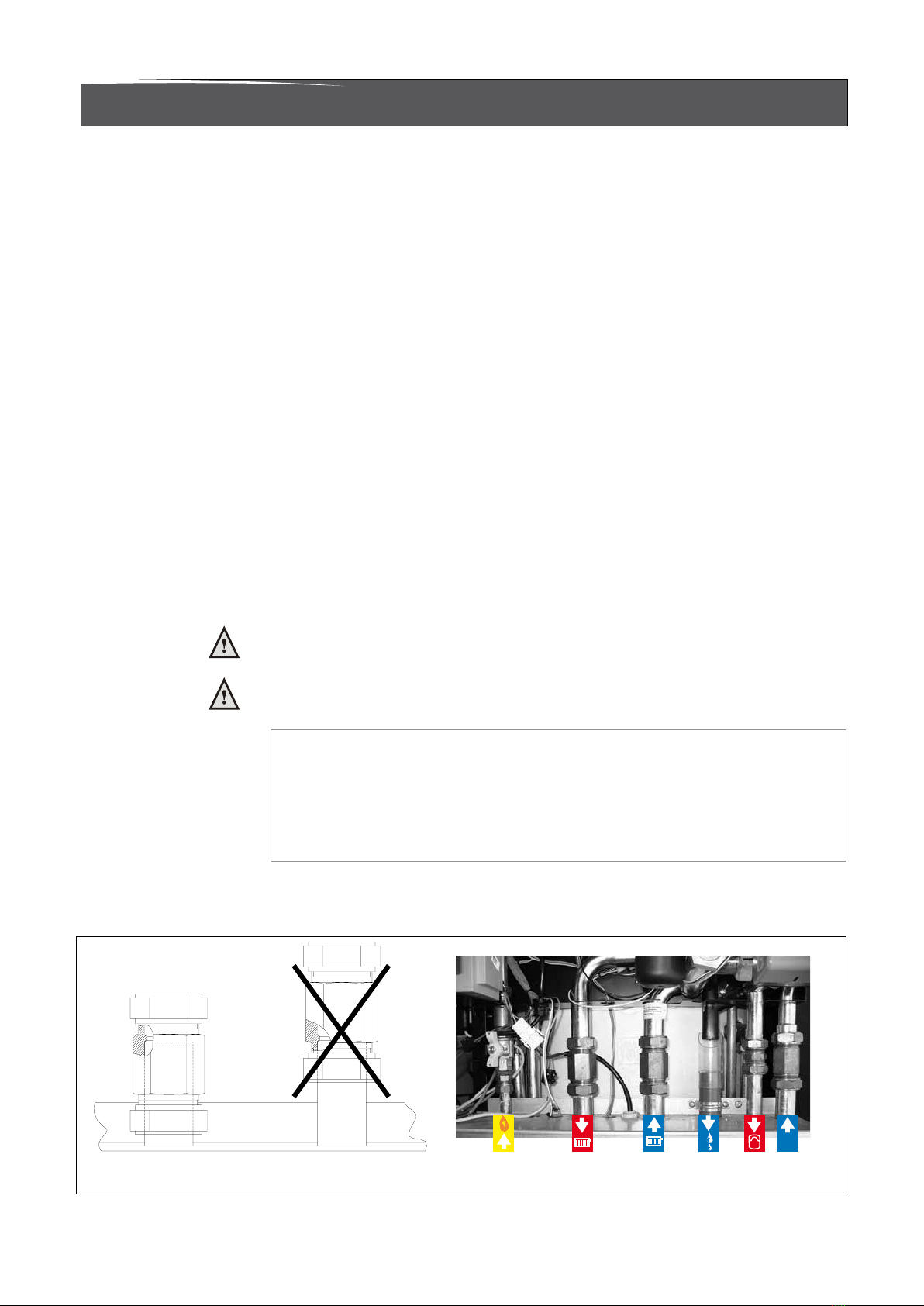

Note:

Handling and storage packages:

- Handle with care. Note the instructions/symbols on the packages

Installation:

- Always read the installation manual before installing the system and putting the system into operation

Technical details:

- See page 11 for dimensions and page 45 for Technical specications.

Work on the installation should only be carried out by qualied personnel

with calibrated equipment.