Heatit HIP 24-12A User manual

SMART INSTANT HOT WATER

RECIRCULATING SYSTEM

HEATITCABLE.COM

HIP 24-12A

HEATITCABLE.COM 2

Table of Contents

HEATIT Smart Instant Hot Water Recirculating System help you to save gallons of water in waiting for water warm up

each year. Up to 10% of your water bill will be saved. You can get the instant hot water when you need it. No more

water wasted in waiting. HEATIT smart pumps bring you convenience and savings.

HEATIT HIP 24-12A smart pump was designed to be installed on the back water pipe to the water heater (see the

picture 1). If there is no back water pipe to water heater in your water loop, you may need HEATIT HIP 24-12B to be

installed under the faucet furthest from the water heater in each loop.

Product Overview

Hot water pipe

Backwater pipe

Cold water pipe

Product Features

• HEATIT HIP smart hot water recirculating pump adopts a plastic-sealed permanent magnet synchronous motor with

ultra-low safe voltage (24V). The shell is made of die-cast aluminum with high strength and anti-aging. The pump head

is made of lead free grade copper material, durable and rust-free, protecting the health of your whole family.

• Easy to install with the necessary accessories included. 10' power cord. Built in thermostat. Maintenance free. Can be

used with all types of pipe.

• Three modes can be chosen: energy-saving mode, smart mode and manual mode. When the water temperature in the

pump is lower than 33 ℃, the pump will push the cold water back to the water heater. As the temperature hits 38 ℃,

the pump will stop working.

• Advanced motor technology: Permanent magnet brush less motor DC motor makes the pump more powerful, more

quiet and more durable. (Max flow 6 GPM, Max head 39.3ft)

Package Contents

Package Contains the following:

• Smart Hot water recirculator pump with build-in thermostat

• Hook: 2x

• Self-tapping screws: 2x ST3.5x9.5

• Expansion screw: 2x M6×30

• Power adapter: 1x 24V/3A

• Installation and Operating Instructions

• Filter(optional)

picture 1

Inlet of pump

Outlet

of

pump

Product Overview …………………………… 2

Product Features ……………………………… 2

Product Contents ……………………………… 2

Important Safeguards and Warnings………… 3

General Installation Instructions……………………3

Commissioning …………………………………… 5

Troubleshooting ………………………………… 6

IMPORTANT SAFEGUARDS AND WARNINGS

HEATITCABLE.COM

3

Important safeguards and warnings

• Please read the Instruction Manual and keep it properly before installing and using the product.

• The electric pump must be reliably grounded before use, and leakage protection devices should be installed.

• It is forbidden to touch the electric pump during operation.

• Dry running of the electric pump is strictly prohibited.

• It is strictly prohibited for children, and persons with no capacity or limited capacity to use the product without supervision

of guardians (such as not being taught the safe use method of the product and understanding the risks involved).

• The pump system must be able to withstand the maximum pump pressure.

• The manufacturer shall not be held responsible for any consequences caused by the user modifying the electric pump

without authorization or operating the electric pump beyond the operating conditions.

Thank you very much for choosing our products. Please read the Instruction Manual carefully and keep it

properly before installation and use.

GENERAL INSTALLATION INSTRUCTIONS

The product is installed in the backwater pipeline of the water heater.

Conveying liquid

The conveying liquid is softened water and thin, clean, non-corrosive, non-explosive liquid without solid particles, fibers

and mineral oil, and the PH value of the medium is between 6.5 and 8.5.

The requirements for the operation system of the electric pump are shown in the following figure 2 :

Medium and ambient temperature

The system temperature (t1) must be always higher than the ambient temperature (t2) in order to avoid electrical short

circuit of junction box caused by condensation of pump body(see figure 3).

Maximum pressure borne by electric

pump 145 PSI

If the pressure difference between hot and

cold water pipes is greater than 1.45 PSI,

the backwater device may not return water

normally, thus affecting the use effect.

Min. liquid temperature·····35.6℉

Max. liquid temperature···158 ℉

System temperature (t1)

Ambient temperature (t2)

Min. ambient temperature····35.6℉

Max. ambient temperature····104℉

figure 2

figure 3

GENERAL INSTALLATION INSTRUCTIONS

1. Before installing the pump, check whether the pipeline system is connected reliably and ensure that impurities, welding

slag, dirt and the like in the pipeline have been removed. The output of the voltage adapter is low-voltage DC 24V.

During installation, a filtering screen can be installed at the inlet of the recirculating pump to filter large particles and

impurities in the water, and the filter screen shall be cleaned regularly. It depends on the pipe water situation. You can

choose to install or not. If the water in the pipe is always clean, you don’t need to install this screen.

2. The HIP24-12A pump must be installed or maintained by a professional plumber . Install the pump according to the

installation diagram of the HIP24-12A pump. Pay attention to the water pipe connection between the water inlet and

the water outlet. After installation, check the HIP24-12A pump and all water pipe fittings for water leakage.The

HIP24-12A pump shall be prevented from being splashed by water to avoid electric shock.

3. After connecting the power adapter, conduct a test run of the recirculating pump to check whether the startup is normal,

but the nonwater running time should not exceed 5 seconds to prevent the operation from reducing the bearing life.

4. When the HIP24-12A pump works, if you want to adjust the position of or touch the recirculating pump,the power supply

must be the first cut off to prevent accidents.

5. Carry out regular inspection and make replacement in time when damage occurs.

6. If the HIP24-12A pump is not used for a long time or no one is at home, please close the water pipe valve at the inlet

and outlet end and cut off the power supply of the recirculating pump.

7. Cable or power adapter, when damaged, must be replaced.

8. In winter, when the ambient temperature is lower than 0°C, if the electric pump stops running, the water in the pipeline

system must be drained to prevent the pump from freezing and cracking.

Installation tips

Installation steps

1. For Electric Water Heater : Turn off Power to your Water Heater. ( turn off power at breaker box ). For Gas Water

Heater : Turn off the gas to your water heater and ensure that the pilot light is not burning. Shut off the supply water

valve to the water heater. In most cases, the supply water valve located above the hot water heater on the cold water

inlet to the hot water heater.

2. Drain the water from the backwater pipe by opening a cold water faucet in the house. Let the water run until it stops

flowing. Then drain remaining water from hot water heater spigot. Leave the faucet open until the pump installation is

complete. If water does not stop flowing, check to make sure the water to the hot water heater has been completely

shut off.

3. Disconnect the backwater pipe with the water heater.

3.2 (optional)Find a suitable installation position (on the back water pipe near the water heater end). When installing

the water pump support plate in advance, the support plate can be placed in the pre-installation position and marked

with a marker at the installation hole. The drilling size is φ6.

HEATITCABLE.COM 4

3.3 Insert the plastic expansion screw into the hole drilled in the wall.

3.4 Fix the support plate on the wall with self-tapping screws.

3.5 Clip the pump onto the hook of the support plate indicated by the arrow.

GENERAL INSTALLATION INSTRUCTIONS

HEATITCABLE.COM

5

4. Install pump onto the backwater pipe, using the 3/4” female fitting and gasket ensuring

that the pump shaft is horizontal. The pump should be installed so that the pump is

pumping away from the hot water heater, towards the house. Confirm the direction

of pumping by observing the flow arrow on the side of the pump housing. Be sure that

the pump is not touching the exhaust vent piping (chimney) of a gas or oil-fired hot

water heater. (See Picture #2)

5. Connect the backwater line to the 3/4” NPT inlet of the pump. Use pipe dope or Teflon

tape to seal threads when connecting to a 3/4 female NPT connection. If a gasket

flexible copper water heater connector is used pipe dope or Teflon tape is not required.

6. Reopen the supply valve to the hot water heater and allow the water to run until all the

air has been purged from the piping.

7. Close faucet inside the house. page 2 Picture 1 Disconnect Direction of water

8. Plug the line cord of the pump into a 115V outlet. Be sure to route the power cord so

that it does not touch the exhaust vent piping of a gas or oil-fired hot water heater.

Key points of installation: remember to open the valve of cold

water pipe/hot water pipe/return pipe after installation.

DO NOT Mount Motor Shaft in Vertical Position

Commissioning

Panel description

Function description

Mold name Mold description

Smart constant

temperature mode

Energy-saving constant

temperature mode

Manual mode

When turned on, the icon lights orange, and the pump operates at constant

temperature throughout a day.

When turned on, the icon lights green, and the pump operates at an energy-saving

constant temperature state throughout a day.HEATIT Smart pump can decrease the

temperature setting point automatically if you didn’t use the hot water for some time.

When pressing the icon briefly in any state, the pump will stop after reaching the set

time or target temperature.

Function name Function description

Mode switch

Pump speed switch

Antifreeze protection

Smart constant temperature mode (orange light), energy-saving constant temperature

mode (green light), Manual mode (no light).

The product is divided into three gears. When running, the gear is indicated by the

rotating speed of the light bar. The faster the rotating speed is, the higher the gear is.

When the water temperature of the pipeline is lower than 5℃for 30s, the electric pump

will operate until the water temperature meets 10C. If the water temperature can’t meet

10C, a buzzer will sound to give an alarm.

Speed

Mode Set

Picture 2

Commissioning

HEATITCABLE.COM 6

Commissioning method

• Mode switch: press and hold the icon 2 second or above for mode switch

• Speed switch: press the icon briefly for speed switching.

Product installation dimension drawing:

Troubleshooting

Fault Main cause Troubleshooting

Power failure Check power adapter and circuit connection

Enter protection logic

Temperature sensor failure

Check valve is blocked or inlet

and outlet installed reversely

No loop is formed in the

circulation pipeline

There are sundries in the flow

passage of the electric

Electric pump flow setting is too

large

There is a lot of air at the electric

pump

Power on again after cutting off the power for

10 seconds

If the red light blinks, remove the circulation pump and

sent it back to the manufacturer for repair.

Check whether the check valve is blocked or installed

Check whether there are any valves that are not open

Remove the pump body and remove sundries

Switch to low gear operation or turn down the outlet

valve appropriately

Drain some hot water and tighten the water inlet pipe

Open the inlet valve

The inlet valve is not open

Abnormal noise appears

The electric pump stops

before the target temperature

The recirculating pump does

not operate

Main Technical Parameters

Model Rated

voltage

Max.

current

Max. lift

(foot)

Input

power /w

Max. flow

(GPM)

Pipe size

(inch)

Lift range

(foot)

DC-24 2.5A 39.3 55 6.6 3/4 NPT 0-39.3HIP24-12A

Table of contents

Other Heatit Heating System manuals

Popular Heating System manuals by other brands

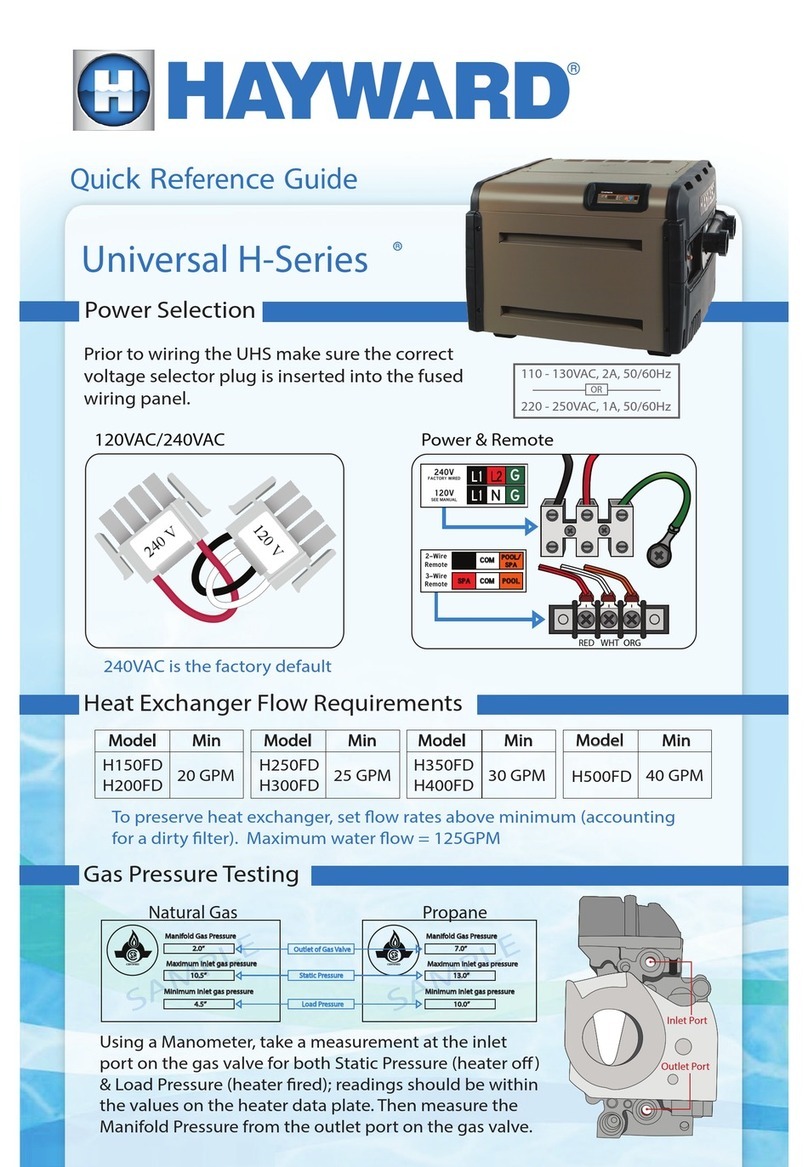

Hayward

Hayward H150FD Quick reference guide

Ferroli

Ferroli UT REC Installation and operation manual

KWB

KWB Multifire USV 15/25 D/ZI Installation and maintenance manual

Toyostove

Toyostove Laser 73AT Assembly, installation and operation instructions

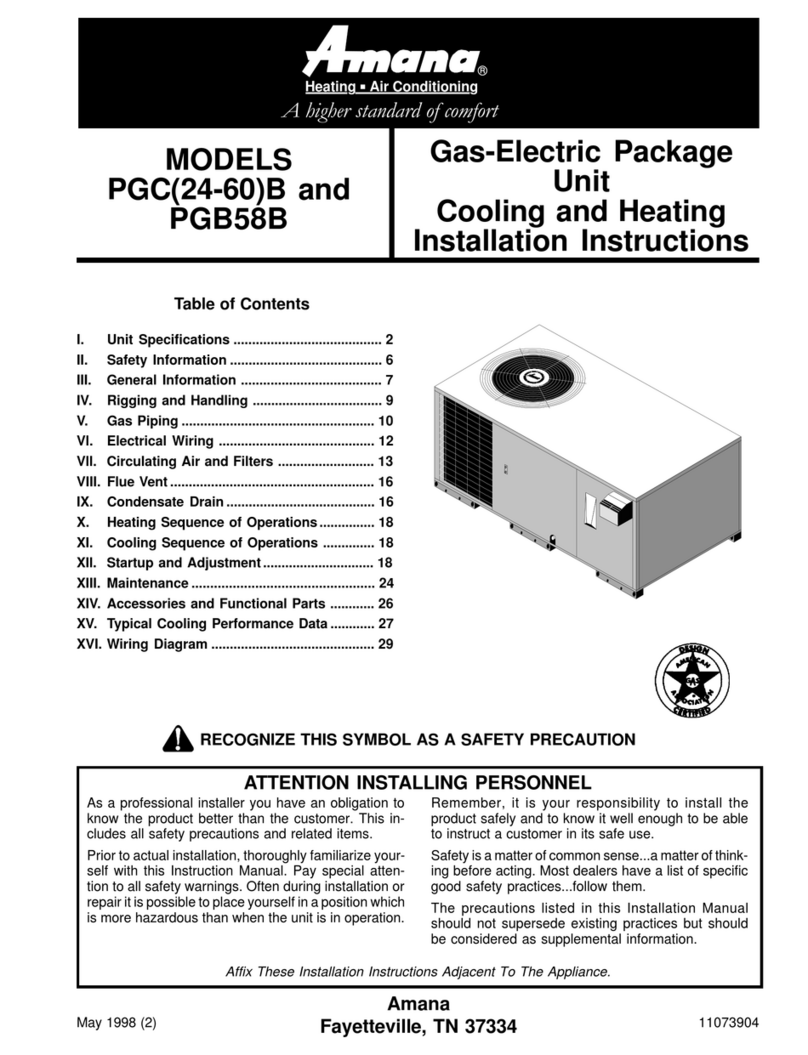

Amana

Amana PGB58B installation instructions

TPI Corporation

TPI Corporation HotPod EHP6-10002CT Installation and operation instructions

Immergas

Immergas HYDRO Instructions and warnings

Airxcel

Airxcel Aqua-Hot AHM-125D Series Service manual

CALEFFI

CALEFFI 5026 series installation guide

TANGRA

TANGRA EVB - HiE Installation and service manual

Aqua-Hot

Aqua-Hot AHE-100-04S-12 VDC installation manual

Hotstart

Hotstart OLA Installation & operation manual