SECTION 578-110-302

2. EQUIPMENT

2.01 · The following test equipment is

required for troubleshooting the inter-

face module:

(a) A Tektronix 422-type oscilloscope or

its equivalent

(b) A calibrated KS14510 volt-ohmmeter

or its equivalent.

2.02 It is suggested that the ·recommended

volt-ohmmeter be properly set for the

appropriate scale by the user before attempting to

make a measurement. The ohms scale may be

used for point.to-point checks of module wiring,

cabling, and interconnecting cords after circuit

cards are removed from the circuit wiring being

checked. ·

WARNING: NEVER USE A VOLT-

OHMMETER TO CHECK VOLTAGE OUT-

PUT OR CONTINUITY OF THE MICRO-

LOGIC ELEMENTS ON A CIRCUIT CARD.

ONLY AN OSCILLOSCOPE OR LOGIC

PEN SHOULD BE USED FOR MICRO-

LOGIC SIGNAL OR VOLTAGE CHECKS

OR PERMANENT DAMAGE MAY OCCUR

TO A MICROLOGIC DEVICE.

2.04 The CDIF810 module was designed for

use in a 2550 Cluster Controller Station

arrangement. It provides a means of data recovery

for the station standby magnetic tape set when a

system-down time occurs due to a central proc-

essor or line problem. During a system

malfunction, the cluster controller is operated in

standby which allows the peripheral equipment to

send to the MTT set.

2.05 When the system is restored to opera-

tion with the central processor, the

main editing send/receive device, either a CDT or

DATASPEED 40, locally retrieves the stored data

from the tape cartridge in the MTT set (Interrupt

Operation) makes deletions or additions, and then

sends the data to the central processor.

2.06 Operation testing of the module

requires that it be interconnected with

the associated station equipment. All devices

connected to the module should be in good

operating order before any checkout procedures

Page 2

are begun. Refer to the associated checkout

procedures for the interconnected equipment.

2.07 Interconnection diagrams to a CDT or

DATASPEED 40 Send/Receive device

are provided in Figures 2 and 3 respectively.

Cable wiring diagrams and other information are

provided in Installation Section 578-110-202.

'-..r

2.08 The spare parts listed in Table A are

necessary for troubleshooting and

repair of the module. Figure 1 provides a circuit

card location chart for verification of correct

circuit card installation. The view is from the

wired side of the module which also lists all

connector identifications.

2.09 Table B provides a listing of trouble-

shooting sections for the equipment

interconnected to the CDIF810.

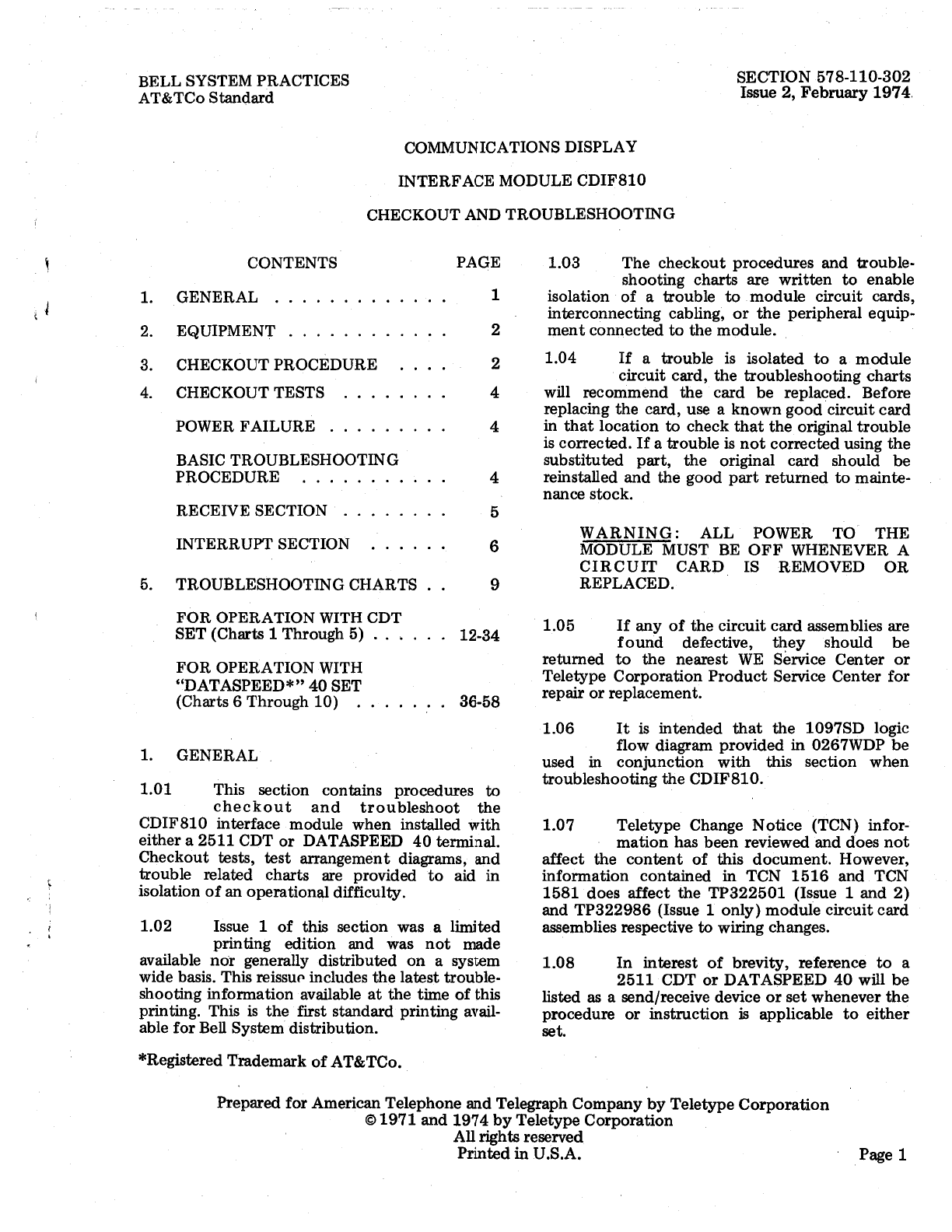

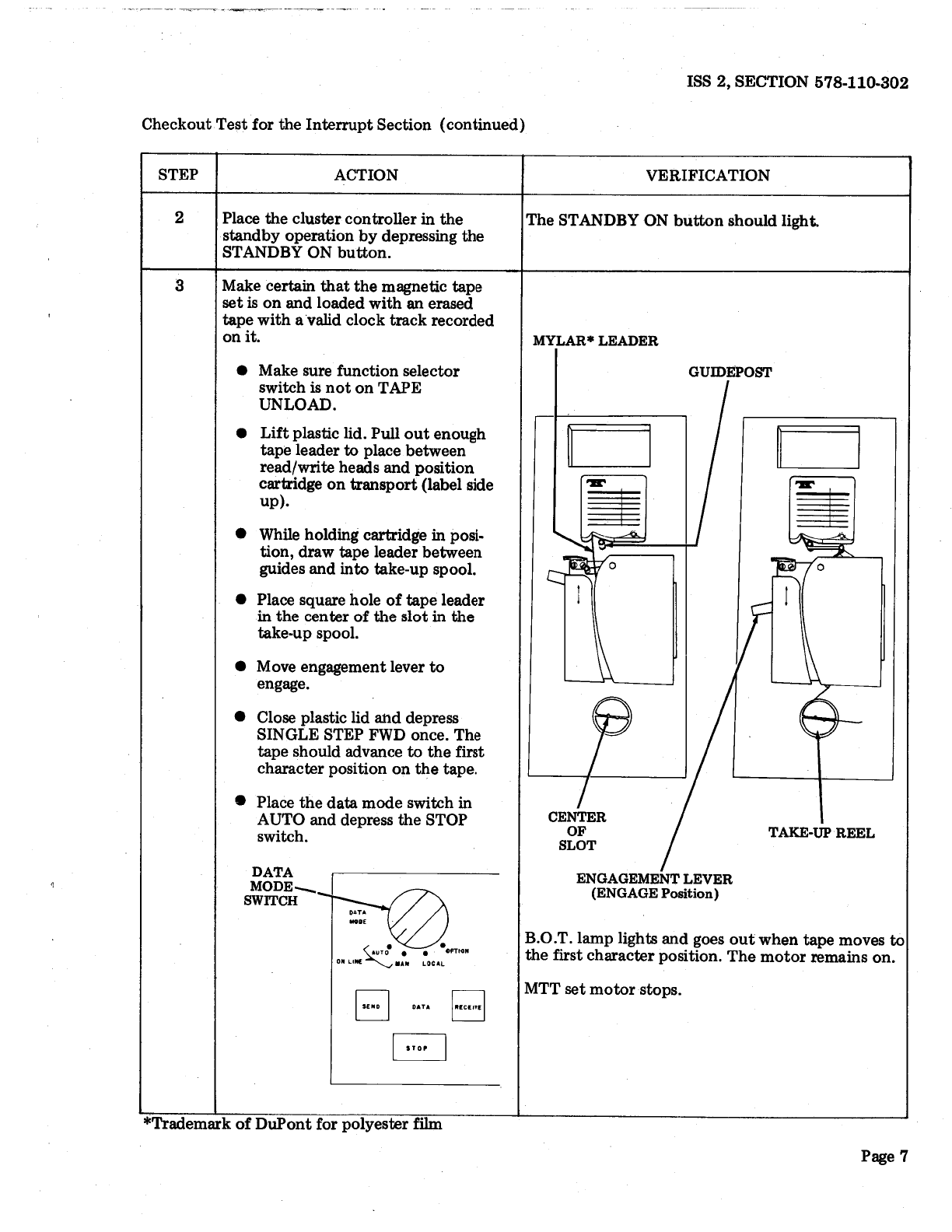

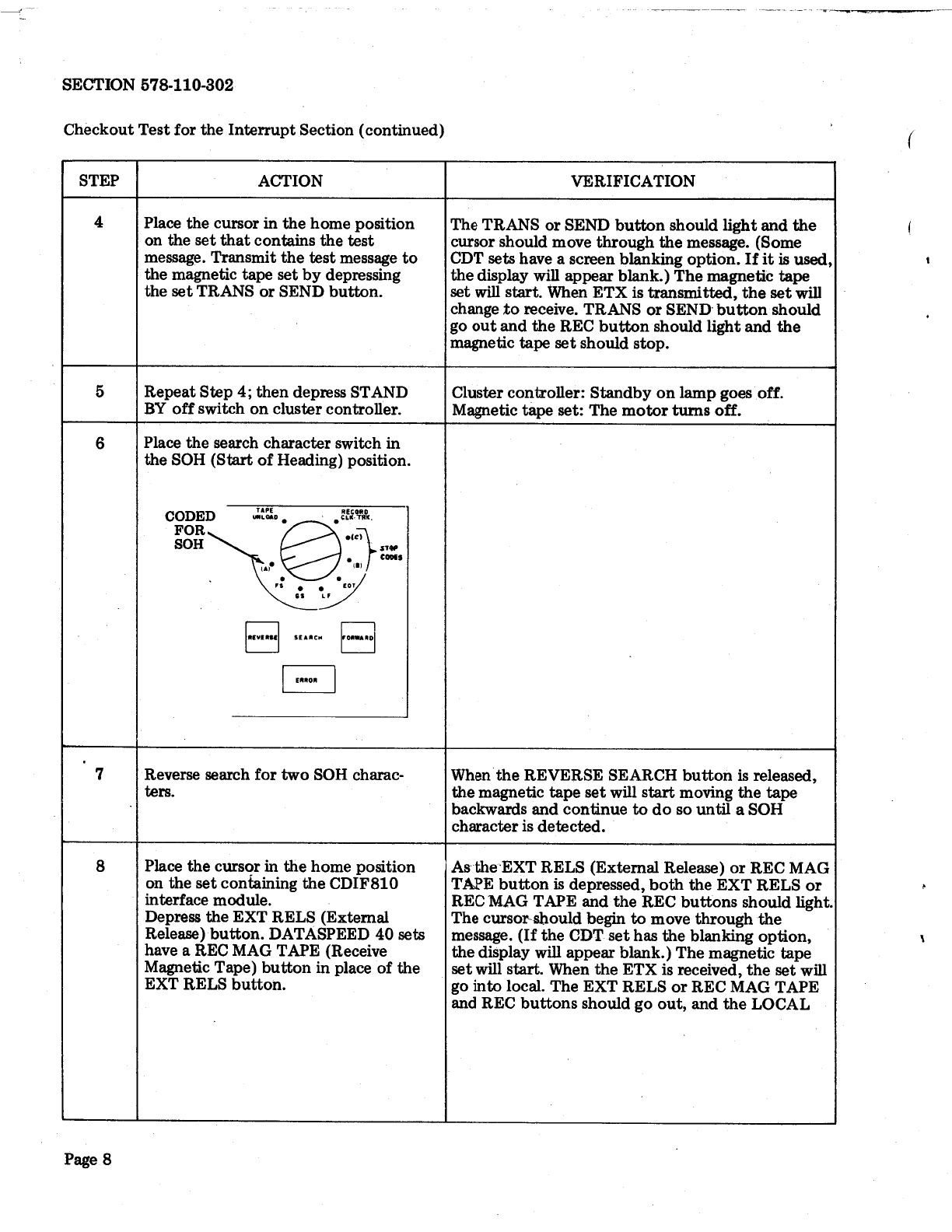

3. CHECKOUT PROCEDURE

3.01 Checkout tests are provided to assure

that the module or system

is

in proper

working order. The checkout tests are divided

into three columns: step, action, and verification.

The step column denotes the progression in

performing the test. The action column denotes

arrangements and test conditions. The verification

column denotes what should occur with respect

to the action column.

3.02 With the exception of the preliminary

de power input check, consider the

following before proceeding to checkout opera-

tion.

(a) All circuit cards must' be firmly seated

in their appropriate connectors.

(b) All cable connectors must

be

securely

connected. When a cable connection to

an external device

is

installed, make sure

that the interconnecting cable meets all

interface requirements listed in the cable

. diagrams in 578-110-202.

(c) All equipment connected to the inter-

face module should function in accord-

ance with the module operation

requirements ..