8 / 31

Electrical Considerations

This section is designed to provide you with a very basic understanding of electrical noise and how to

keep it away from CPUs. Industrial plants have a number of generators of electrical noise that are

sometimes also referred to as Radio Frequency Interference (RFI). Anytime an inductive load like a

motor, motor starter, or solenoid is turned off, it generates a burst of excess energy that has to flow

back to ground, just like electrical energy from a lightning storm has to flow back to Earth. RFI is short

bursts of electrical energy at very high frequencies. Other sources include RF Welders or Radio

Transmitters.

Effect of RFI on Electronic Automation Equipment

Electronic controls use faster and faster CPUs today. These CPUs are also operating at 2.5V to 5VDC

logic level power supply. RFI, if allowed to enter the CPU inside, is a killer of logic. A CPU under this

environment loses its brain and behaves erratically. A smart industrial-grade CPU like the EZ7 Series

HMI Card Engine, when faced with RFI, halts its operation instead of giving false outputs.

Types of RFI

RFI enters electronic controls in two ways: radiated RFI or conducted RFI. For most practical purposes,

electronic devices, unless sitting right next to a powerful RFI transmitter, will not be affected by noise

because air space severely attenuates such interference. On the other hand, conducted RFI travels

over conductive surfaces such as power supply wires, electrical wiring of field devices, and worst of

all; improper ground planes.

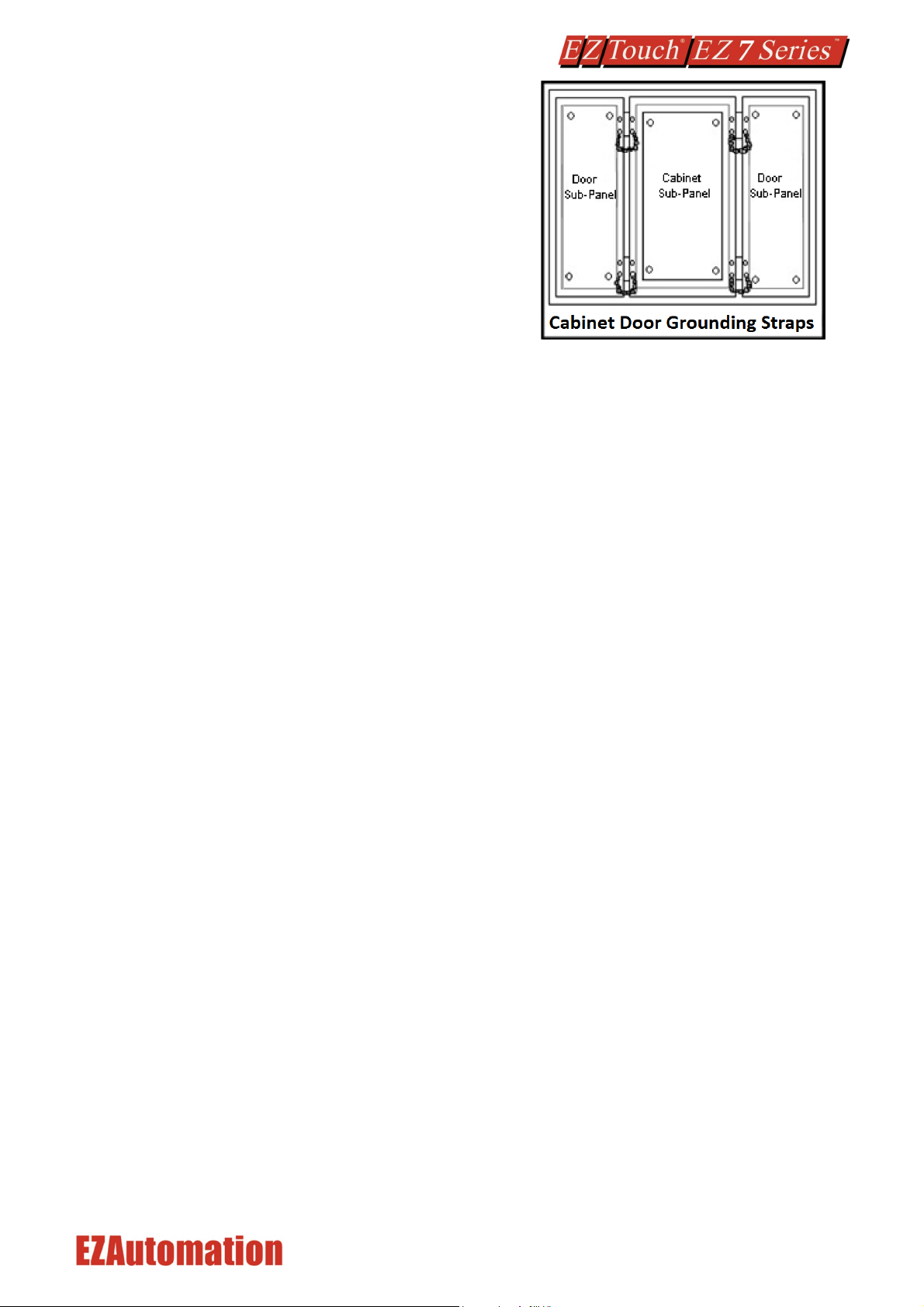

Equipment cabinets usually incorporate one or two doors and/or hinged cabinet panels. Relying on

door hinges and swinging panels for a good metallic bond between hinged parts and the main body of

the cabinet does not insure adequate grounding. Instead, the use of ground straps is

recommended. It is vital for the reliable operation of any electronic device to have any of its metallic

surfaces well ground to Earth. This not only provides for safe operation, it will also drain out any

conducted RFI to Earth, away from the CPU's signal ground.

Shielding from RFI

Shielded Cables

Power cables, I/O cables or wiring, and communication cables should all be separate so that they do

not couple the conducted RFI on any of these wires/cables. Another path for RFI into the PLC is

through its RS232 port. Hence, the cables to this port must be shielded properly.

Equipment Cabinets

As mentioned, equipment cabinets typically incorporate one or two doors and/or hinged cabinet

panels. In addition, sub-panels may be utilized on those electronic controls and electromechanical

items that are mounted. The goal is to create a medium for mounting the equipment and ensure

grounding of the control’s chassis to it. However, the door hinges and swinging panels by themselves

are not enough to ensure adequate grounding.