Installation/Operating Instructions AQUA 8

ATB WATER GmbH, üdstraße 2, 32457 Porta Westfalica, Germany, www.atbwater.com

Version: 14.01.2022 / Page 5 of 19

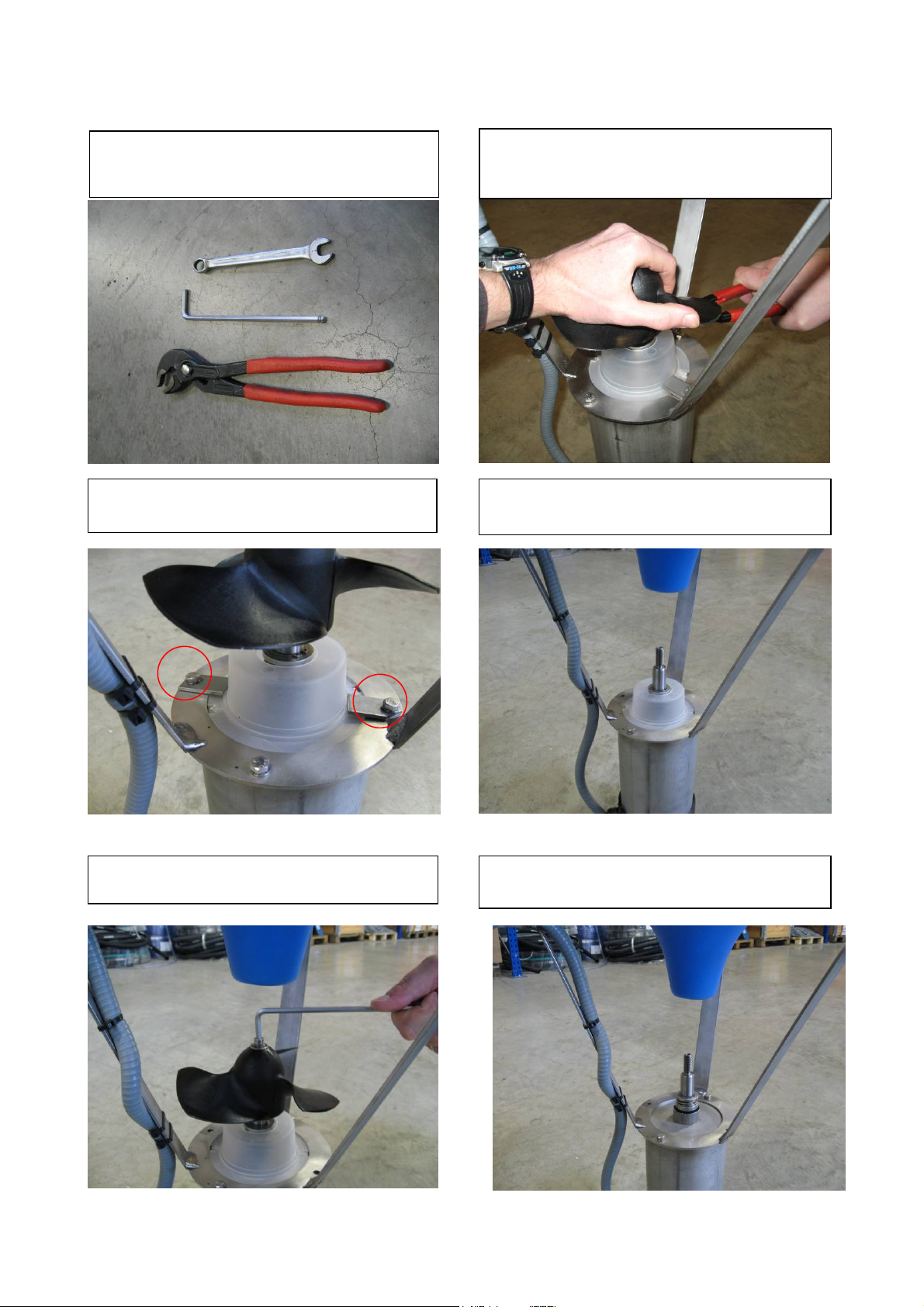

2 Installation and Commissioning

2.1 Installation instructions

The aeration unit AQUA 8 consists of a

separable float with suction pipe (1) and the

motor unit with propeller and distributor (2). All

materials are made of V2A stainless steel or

plastic and are thus suitable for use in

wastewater.

For tank openings (3) smaller than 800mm, the

two-part float can be opened on one side and

inserted into the tank. It must then be screwed

back into the tank. The clear diameter of the tank

opening should be at least 600mm. When

delivered, both halves of the float are usually

only screwed together hand tight.

The intake pipe is to be screwed together with

the float to form a unit. To do this, turn the

pontoon upside down and screw the stainless-

steel pipe to the float using the retaining

brackets. To do this, use the corresponding

threaded inserts on the pontoon and the drill

holes in the stainless-steel pipe.

The float with suction pipe is then positioned on

the tank bottom centrally under the maintenance

opening.

Then the positions for the heavy-duty anchors of

the guide chains are measured in the area of the

tank opening so that the chains can run vertically

at a distance of approx. 75 cm through the guide

elements on the float and can hang down to the

tank bottom.

For the assembly of the guide chains, the

turnbuckles are turned up to maximum length

and fastened to the heavy-duty anchors with ring

nuts and shackles. The vertically hanging guide

chains determine the lower fixing points. The

lower heavy-duty anchors are now mounted here

and connected to the lower chain ends. The

chain must be shortened to the required length.

Attention Free chain ends can be sucked in by

the aerator and cause damage.

The guide chains are then tensioned over the

turnbuckles and fixed with the lock nut.