Atco LPX-1000 User manual

Copyright © 2008-2012 ATCO. All Rights Reserved.

Revision A.0

LPX-1000 Scanner User Manual

Table of Contents

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 1 Revision A.0

System Introduction

System Components

Scanner ............................................................................ 2

XAxis ...................................................................... 2

YAxis ...................................................................... 2

ControlCableConnectors ....................................................... 2

MCU-P500 Motor Control Unit .......................................................... 3

ClampingChain ...................................................................... 3

Scanner Field Use and Operation

SafetyConsiderations ................................................................. 4

HandlingtheScanner.................................................................. 4

YAxisAdjustment ................................................................... 4

TighteningtheAdjustmentScrews ................................................ 4

AttachingtheScanner ................................................................. 5

AdjustingtheY-Axis .................................................................. 6

Maintenance and Storage

YAxisMaintenance .................................................................. 7

ChangingtheYAxisDriveBelt .................................................. 7

YAxisDriveBeltTension ..................................................... 10

GeneralMaintenanceoftheYAxis...................................................... 10

YAxisDriveBeltTension ..................................................... 10

XAxisMaintenance ................................................................. 10

GeneralStorageandShipping .......................................................... 10

Scanner ........................................................................... 10

DriveTrain ................................................................. 10

ControlCabling(Tether) ....................................................... 11

Couplant Pump .............................................................. 11

Recommended Spare Equipment

RecommendedFieldRepairTools....................................................... 11

RecommendedSpareParts............................................................. 11

LPX-1000 Scanner System User Manual

Section 1

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 1 Revision A.0

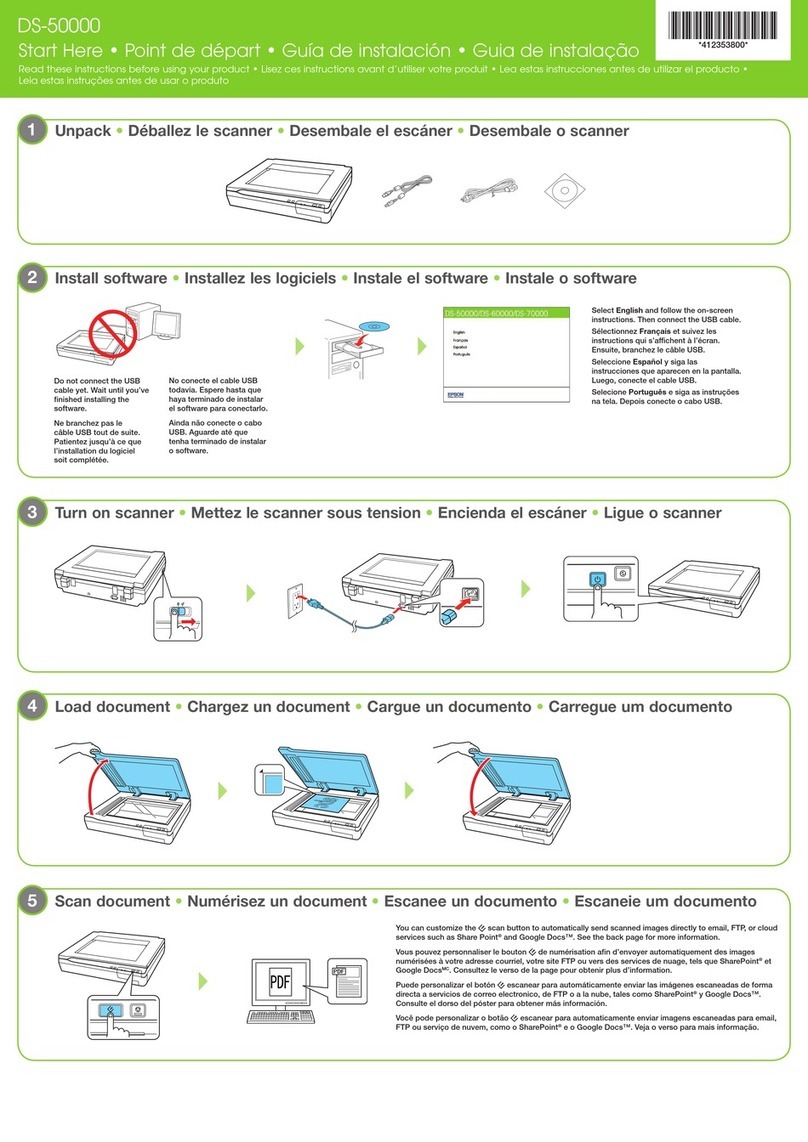

System Introduction

This manual outlines basic field usage and maintenance information. The sections are listed below with

descriptions of their contents. It is recommended that each section of this document be read before

deploying the LPX-1000 scanner system for field use.

Section 1 Introduction

Section 2 Scanner Components

This section describes some of the components of the LPX-1000 system. It is recommended that

you read this section and familiarize yourself with the system.

Section 3 Scanner Field Use and Operation

This section describes important information about the field use of the system and should be read

prior to use in the field.

Appendix A Control Cabling Pinouts and Connectors

Appendix B Transducer Mounting Plate Bolt Hole Dimensions

Appendix C Link Selection Table

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 2 Revision A.0

System Components

This section describes the components that make up the LPX-1000 System. Reading this section will help you to

become familiar with the parts of the system.

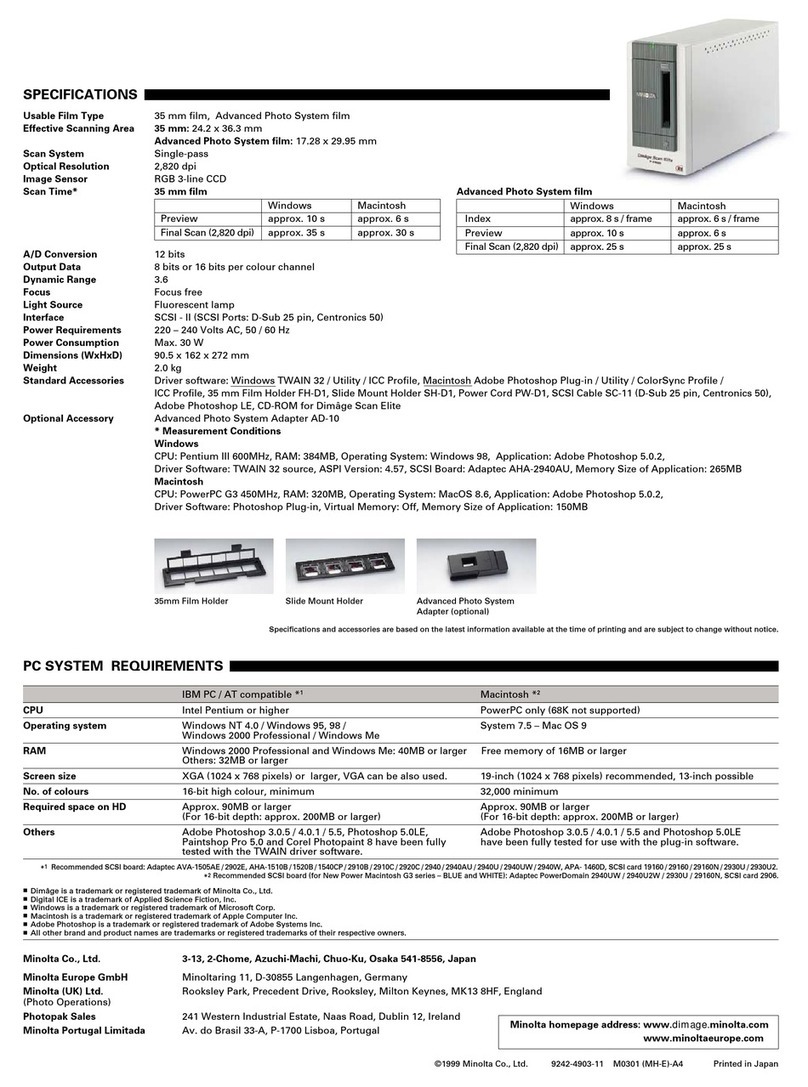

Scanner

The LPX-1000 scanner system features a dual axis scanning configuration. The scanner can be controlled in both

forward and reverse with the Y Axis arm (5.6 inches wide standard) running perpendicular to the scanner motion.

This provides the ability to perform raster scans on equipment.

X Axis

The X Axis is the vehicle that drives the scanner around the surface. Magnetic or rubber wheels can be

used depending upon your application. The magnets provide considerable holding force. Even though the

magnets provide a strong bond to a metal surface, precautions must be taken to reduce the possibility of loss

of adhesion and subsequent un-attachment of the scanner. Refer to Section 3 Scanner Field Use and

Operation for more information. When using rubber wheels the chain mechanism is used to attach the X-

Axis to the surface of the piping. Later in this section the chain mechanism will be discussed in more

detail.

Y Axis

The Y Axis Arm allows travel of up to 5.6 inches. The articulation of the arm makes the scanner highly

flexible and allows it to conform to a wide variety of surface geometries. There are three pivot adjustments

that are easily rotated to make changing the configuration quick and simple.

Control Cable Connectors

The control cable from the motor control unit connects to the X and Y Axis’ on the side of the scanner body

and on the motor housing of the Y Axis. Refer to Section 5 Maintenance and Storage for maintenance

instructions. ALWAYS keep this receptacle dry and free of debris.

MCU-P500 Motor Control Unit

YAxis

Arm 5.6 in.

Travel

Fixture Mounting

Plate Magnetic or

Rubber Wheels

Y Axis Pivot

Adjustment

X Axis

Cable Connector

Y Axis Cable

Connector

Figure 1 Parts of the Scanner

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 3 Revision A.0

The MCU-P500 motor control unit is battery operated. A 110VAC power supply / charger is provided which can be

used to power the unit. Refer to the MCU-500P Manual for more details.

Clamping Chain

The Clamping Chain can be used to hold the scanner

in place for piping or similar applications that require

it. The chain assembly is made up of a series of links

and a latch hook. Adjust the number of links

according to the diameter of the pipe being scanned.

Combinations of links will accommodate virtually any

diameter of pipe.

Use the table in Appendix C to determine the

combination of links required for the diameter piping

you are working with.

CHARGE

X-SPEED

Y-SPEED

Y- A XI SX-AXISREMOTE

+

+

MCU-P500

1 2 3

4 5 6

7 8 9

0

ESC

SPC

BSPC

ENT

Scanner Control

Cable

Recepticles

Remote Contro

Recepticle

Keypad

Charger

Recepticle

Power

Switch

X & Y Speed

Controls

Emergency

Stop

Display

Battery Cover

Scanner

Latching Link

Links

Rubber Tires

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 4 Revision A.0

Scanner Field Use and Operation

This section describes some essential considerations and guidelines for using the LPX-1000 Scanner System in the

field. It is recommended that you read this section thoroughly prior to using the scanner in the field.

Safety Considerations

A safety line should be used when the scanner is used at any elevated position. This will minimize any damage to

the scanner and more importantly reduce the possibility of injury to anyone on the ground.

Never allow work or activity underneath the scanner while in use.

Handling the Scanner

Care must be exercised when handling the LPX-1000. The Y Axis or

Y Axis motor housing (shown right) should never be used when

manipulating the position of the scanner or removing the scanner from

the surface.

Y Axis Adjustment

The Y Axis can be adjusted to conform to a wide variety of scanning

arrangements. The figure to the right shows the screws used to adjust

each pivot point of the arm. Figure 6 shows some of the adjustments that

can be made to the Y Axis.

Tightening the Adjustment Screws

When adjusting the Y Axis positions, the screws require only minimal torque. Tighten the screws only to the point

where there is no movement in the arm. Never over-tighten them.

Attaching the Scanner

DO NOT use this Y Axis or Y

Axis Motor Housing as a handle

for removing the scanner.

Y-Axis

Adjustment

Screws

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 5 Revision A.0

When using the chains to attach the scanner you must first

determine the number of links required based upon diameter

of the pipe. Using the table in Appendix C, determine the

number of long and/or short links required as a starting point.

The number of links specified in the table do not include the

short links that are attached to each side of the LPX-1000

(shown right).

Once the number of long and/or short links has been

determined, connect them all by hooking the ends of the

links together (shown right).

Once all links have been attached together, hook the last

link with the latching link hook as shown to the right.

With the Latching Lever in the position shown, adjust the

travel (blue arrow) of the hook until it catches the hook on

the last link.

Short Links

Permanently attached

Adjustment

Latching Lever

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 6 Revision A.0

Latch the link by rotating the Latching Lever back as shown

right. The scanner requires a minimal amount of force to

sufficiently hold the scanner in place.

CAUTION: It should only take a few pounds of force exerted

on the Latching Lever. Be careful not to use too much force

when clamping the scanner chain. Excessive force can damage

the components of the system.

Adjusting the Y-Axis

The Y-Axis can be adjusted to support

various configurations. The height of the

Y-Axis can be changed by rotating the arm

as shown right. Using a 3/16" allen

wrench, loosen the two fasteners on the

mounting arm (shown right) to adjust the

arm.

The fasteners used are listed below in case

replacements are needed. They are listed

by number according to the callout in the

figure to the right.

1) 1/4-28 x 1 ½" Socket Hd Screws

2) 6-32 x ½” Socket Hd Screws

3) 6-32 x 3/8" Socket Hd Screws

CAUTION

Use Minimal Force

to Latch

1

2

3

Loosen to Raise/Lower Axis (2)

Use 3/16" Allen Wrench

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 7 Revision A.0

Scanner Movement

The scanner can be moved using the arrow keys on the MCU-P500 by using the A-JOG menu option. The

orientation and movement direction for each arrow key is shown below.

+Y

-Y

0

-X +X

0

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 8 Revision A.0

Remove (2)

Screws on Back

of YArm

Figure 13

Slide

Sprocket

Back

Slide

Block

Belt

Mounting

Clip

Figure 14

Maintenance and Storage

This section covers some basic maintenance and storage tips.

NOTE: No internal components should need to be accessed; therefore disassembly of the scanner

should not be required and is not recommended.

Y Axis Maintenance

Changing the Y Axis Drive Belt

Occasionally the Y Axis drive belt needs replacement. Follow the steps show below to ensure proper installation.

Step 1

The first step in is to remove the existing belt. To do this, remove the two screws on the back side of the arm that

hold the sprocket mounting plate (Figure 12).

Step 2

The sprocket must be pulled back to allow the slide block to

move past the sprocket (Figure 14). Without moving the

sprocket, the belt mounting clip cannot move past it.

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 9 Revision A.0

Figure 16 Remove Belt Clip Screw

Pull Slide From

the Y Axis Remove (2)

Screws

Figure 15 Removing the Slide Block

Fasten the Belt Clip

Belt Clip

Mounting Point Screw

Spacing for Screw

Figure 17 Fastening the Belt Clip

Step 3

Remove the slide block (Figure 14).

Step 4

Remove the screw that holds the belt to the clip, and remove

the old belt. (Figure 15). Place the clip on the new belt and

secure the screw.

Step 5

Fasten the belt clip on to the new belt. Be sure to fasten

the clip to the appropriate location on the belt. There is

a belt clip mounting point with the appropriate spacing

for the screw (Figure 16).

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 10 Revision A.0

Place the Slide

Block back on the

Y Arm

Refasten the Clip to

the Slide Block with

the (2) Screws

Figure 18 Attaching the Slide Block to the Y Axis

Refasten the (2) Screws to the

Back of the Sprocket Bracket

but only finger tight

Figure 19 Fastening the

Sprocket Bracket

Tension the Belt and Secure the Screws

on the Sprocket Plate

DO NOT OVERTENSION THE BELT!

Figure 20 Tensioning the Belt

Step 6

Refasten the belt clip to the

slide block and place the slide

back on the Y Axis. (Figure

17) Be sure, once again, to

move the sprocket back so the

belt clip will clear it.

Step 7

Align the belt and place it on the two sprockets. Refasten the screws on the back

side of the sprocket bracket. Do not tighten them at this point (Figure 18 ).

Final Step

Tension the belt by pulling the sprocket outward. (Figure 19). Be careful not to overtension the belt. Secure the

screws on the back side of the sprocket

bracket.

LPX-1000 Scanner System User Manual

Section 2

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 11 Revision A.0

Keep Clear of

Debris and Dirt

Y Axis Top View Y Axis End View

Figure 21 Y Axis

Keep Clear of

Debris and Dirt

Y Axis Top View Y Axis End View

Figure 22 Y Axis

General Maintenance of the Y Axis

The Y Axis should be inspected

prior to use. Inspect the rail where

the slide bearings make contact

with the arm (shown right) to

remove any loose debris or dirt.

Y Axis Drive Belt Tension

The Y Axis drive belt must be secure, but not overtightened. There should be minimal play in the transducer slide

block.

General Maintenance of the Y Axis

The Y Axis should be inspected prior to use. Inspect the rail where the slide bearings make contact with the arm

(shown right) to remove any loose debris or dirt.

Y Axis Drive Belt Tension

The Y Axis drive belt must be secure, but not over-tightened. There should be minimal play in the transducer slide

block.

X Axis Maintenance

The X Axis should be inspected prior to use.

LPS-1000 Scanner System User Manual

Appendix A Control Cabling Pinouts and Connectors

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 1 Revision A.0

X-Axis

(DB9M)

PIN # Description

1MTR+

2MTR-

3 ENC A -

4 ENC A +

5 ENC B -

6 ENC B +

7+5V

8GND

9NC

Y-Axis

(DB9M)

PIN # Description

1MTR-

2MTR+

3 ENC A -

4 ENC A +

5 ENC B -

6 ENC B +

7+5V

8GND

9NC

LPS-1000 Scanner System User Manual

Appendix B Transducer Mounting Plate Bolt Hole Dimensions

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 1 Revision A.0

6-32 (8 PLCS)

2.500

0

0.500

0.813

1.688

2.000

0

0.500

0.688

1.563

1.750

2.250

LPS-1000 Scanner System User Manual

Appendix C Link Selection Table

Copyright © 2008-2012 ATCO. All Rights Reserved.

850-004134 Page 1 Revision A.0

Select the Diameter of the pipe in the column heading and use the number of long and/or short links required. The

diameters start at 4 inches. The first column is 4" to 4.25" and column to the right of it, is for piping greater than

4.25" up to 5" and so on down the table.

Links 4 to 4.25 5 5.75 6.75 7.5 8.25 9

Short 1 234567

Long 0 000000

9.75 10.75 11.375 12.25 13 13.75 14.5

Short 8 901201

Long 0 033344

415.25 16.13 17 17.625 18.5 19.25 20

Short 2 012012

Long 4 555666

420.875 21.625 22.375 23.25 24 24.75 25.5

Short 0 120120

Long 7 778889

426.375 27.25 28 28.75 29.5 30.375 31.125

Short 1 201201

Long 9 9 10 10 10 11 11

432 32.75 33.5 34.25

Short 2 0 1 2

Long 11 12 12 12

Table of contents