ATD2030 - 2 - Rev. 10/02/03

11. Make sure the RPM rating of grinding wheels and

attachments do not exceed the rated speed of the

tool.

12. Protect yourself from noise. Noise

levels vary with work surface. Wear

ear protectors.

13. Wear gloves and protective clothing to avoid injuries

caused by chips or pieces, malfunctioning

accessories, or improperly clamped work.

14. When possible, secure work with clamps or vise so

both hands are free to operate tool.

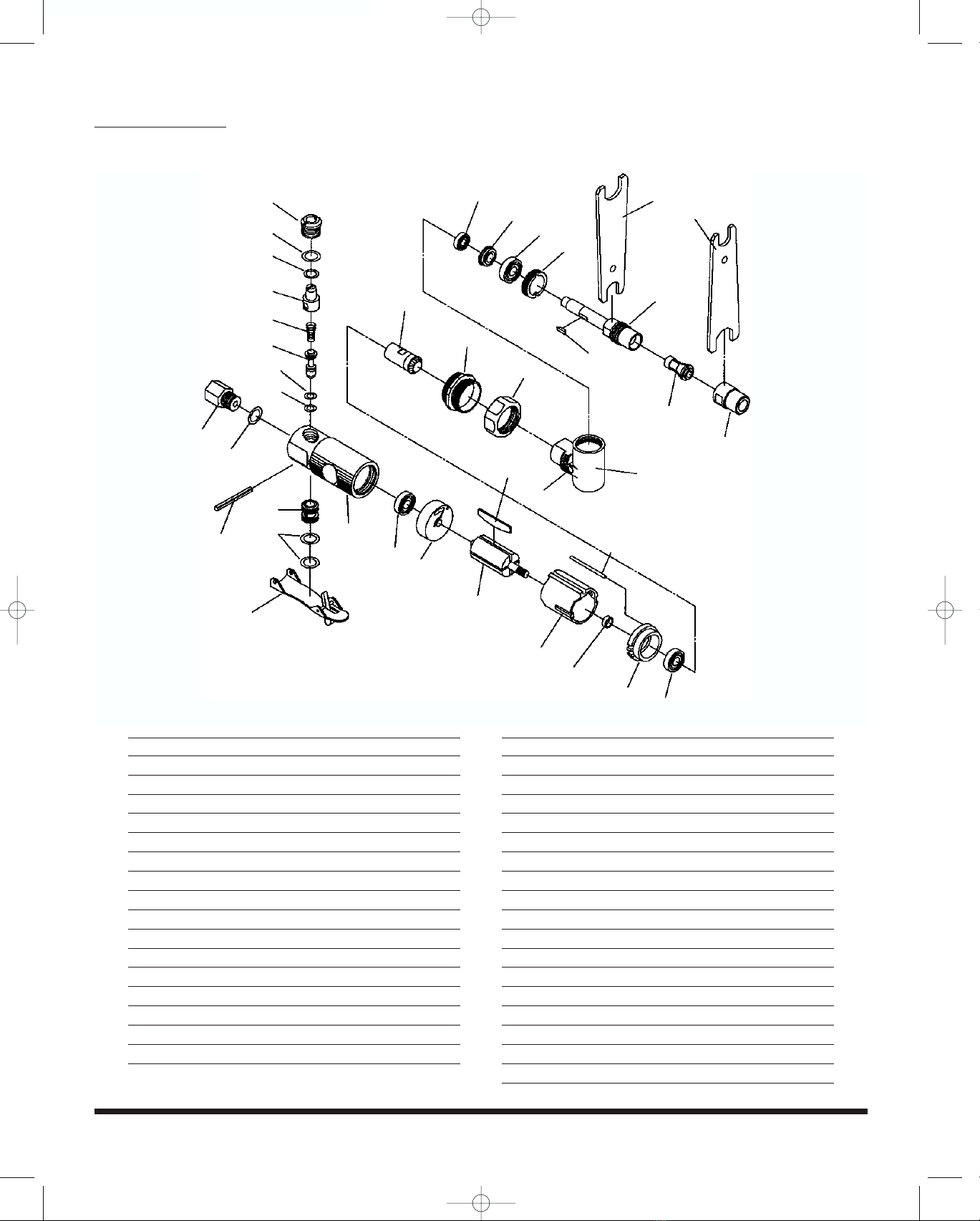

15. Correct grinding wheel mounting is necessary to

prevent injury from broken wheels. Do not use

chipped or cracked grinding wheels. Grinding wheels

should be a free fit on the spindle to prevent stress

at the hole. Use only wheel collars that come with

the grinder for mounting the grinding wheel. Flat

washers or other adapters may over stress the wheel.

Always use heavy paper blotter discs between the

wheel collars and the grinding wheel. Tighten the

wheel on the spindle to prevent spin off when the

air grinder is turned off.

1. Always wear approved eye protection.

Face or dust mask is recommended

when grinding operation creates dust

and grinding material.

2. Have throttle trigger in “OFF” position when

connecting to air supply.

3. Disconnect tool before performing service or when

not in use.

4. Always use tool a safe distance from other people in

work area.

5. Maintain tools with care. Keep tools clean and oiled

for best and safest performance. Follow instructions

for lubricating and changing accessories. Wiping or

cleaning rags and other flammable waste materials

must be placed in a tightly closed metal container

and disposed of later in the proper fashion.

6. Do not wear loose or ill-fitting clothing, remove

watches and rings.

7. Never use quick change couplings at tool. They add

weight and could fail due to vibration. Instead, add

a hose whip and connect coupling between air

supply, and hose whip, or between hose whip and

leader hose.

8. Don’t over reach. Keep proper footing and balance at

all times.

9. Don’t force tool. It will do the job better and safer at

the rate for which it was designed.

10. Don’t abuse hoses or connectors.

Never carry tool by the hose or yank

it to disconnect from power supply.

Keep hoses from heat, oil and sharp

edges. Check hoses for weak or worn

condition before each use, making certain that all

connections are secure.

▲

!

WARNING!

FAILURE TO OBSERVE THESE WARNINGS COULD RESULT IN INJURY.

• RPM of the accessory must exceed tool RPM.

• Read and understand instruction manual before

operating.

• Always wear safety goggles.

• Repetitive motions or extended exposure to

vibration may be harmful to your hands or arms.